HMS and DMS are acronyms for Heavy (Dense) Medium Separation and is applied to the process of pre-concentration of minerals – mainly the production of a high weight, low assay product, which may be rejected as waste.

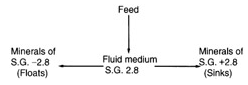

In principle it is the simplest of all gravity processes and is a standard laboratory method for separating minerals of different specific gravity. Fluids of suitable density are used so that the minerals lighter than the fluid float and those denser sink.

Heavy liquids are used in laboratories on small samples (50g to 10 kg) at specific gravities ranging from 0.80 to 4.00

The low SG range of liquids are used for coal/ash samples, while most mineral samples are separated in the range 2.50 to 4.0.

[Suspensions of ground material (known as media – usually magnetite, S.G. 5.1, and/or ferrosilicon, S.G. 6.8) are used on larger scale laboratory samples and in industrial applications.]

Closely sized samples are required for optimum separation. The ore sample to be tested is crushed to the required top-size and screened at at appropriate sizes (we and dry screening is carried out at 38-75 microns if these sizes are to be examined). A typical size distribution on crushed drill core would be 2440, 850, 300, 106 and 38 microns from a top-size of 3350 microns.

Dense medium separation (or heavy medium separation (HMS), or the sink-and-float process) is applied to the pre-concentration of minerals, i.e. the rejection of gangue prior to grinding for final liberation. It is also used in coal preparation to produce a commercially graded end-product, clean coal being separated from the heavier shale or high-ash coal.

In principle, it is the simplest of all gravity processes and has long been a standard laboratory method for separating minerals of different specific gravity. Heavy liquids of suitable density are used, so that those minerals lighter than the liquid float, while those denser than it sink (Figure 11.1).

Since most of the liquids used in the laboratory are expensive or toxic, the dense medium used in industrial separations is a thick suspension, or pulp, of some heavy solid in water, which behaves as a heavy liquid.

The process offers some advantages over other gravity processes. It has the ability to make sharp separations at any required density, with a high degree of efficiency even in the presence of high percentages of near-density material. The density of separation can be closely controlled, within a relative density of 0.005 kg l -1 and can be maintained, under normal conditions, for indefinite periods. The separating density can, however, be changed at will and fairly quickly, to meet varying requirements. The process is, however, rather expensive, mainly due to the ancillary equipment needed to clean the medium and the cost.

Warning

ORGANIC HEAVY LIQUIDS ARE TOXIC. INHALATION OF FUMES IS EXTREMELY DANGEROUS AND A THE FUME CUPBOARD WITH DOWNDRAFT VENTILATION MUST ALWAYS BE USED. SKIN CONTACT MUST ALSO BE AVOIDED (USE RUBBER GLOVES). HOWEVER, IF THE SAFETY PRECAUTIONS ARE STRICTLY ADHERED TO, THE OPERATION IS QUITE SAFE.

Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, Seventh Edition