Table of Contents

Assay furnaces are made to use three kinds of fuel—gaseous, liquid and solid. Those using gas are very little employed, usually only in city laboratories where but a few assays are made. They are, of course, very convenient when occasional assays are made,

as in the laboratory of a consulting chemist, who is sometimes called upon to determine the value of a gold or silver ore.

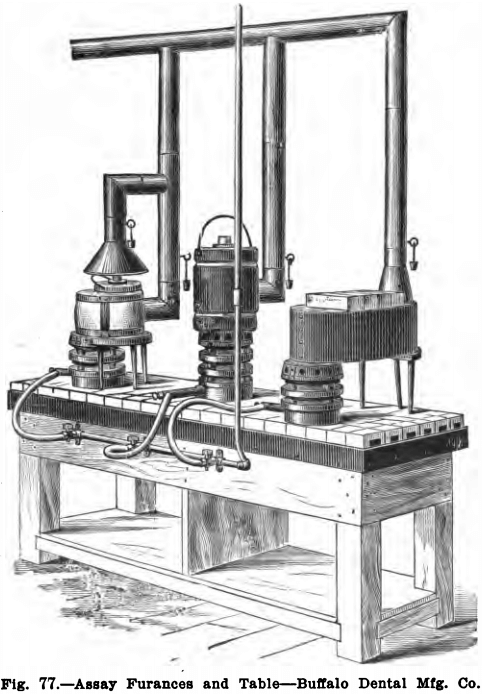

Perhaps the best of these gas heated furnaces are those manufactured by the Buffalo Dental Manufacturing Co., Buffalo, N. Y. For assaying, three of these furnaces will be needed (see Fig. 77).

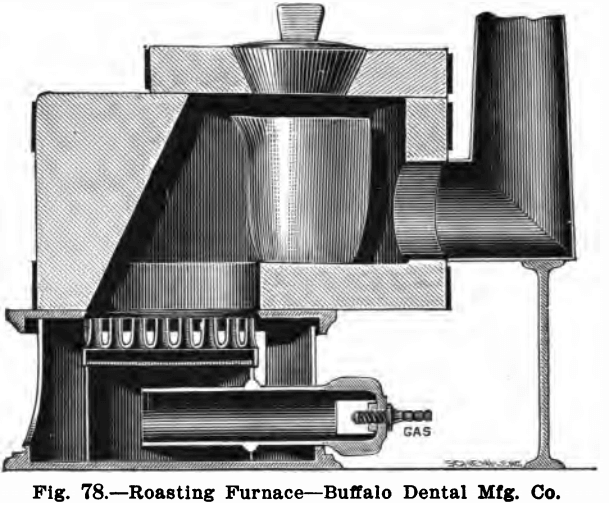

One for roasting sulphide ores, one for crucible fusions and one for cupellation. Figure 78 shows the roasting furnace, which is known as “No. 63, Direct Draft Crucible Furnace.” It consists of a fire clay body strapped with sheet-iron bands, and provided with a Fletcher burner. The opening at the top, which is protected when not in use by a cover, is to allow the heat to have full play upon the roasting dish placed upon it. The hot flame passes through the furnace and up the chimney. When set up this furnace should have a hood or funnel placed over it as shown in Fig. 77. This carries off the odors and gases given off by the ores. The pipe and hood should be provided with dampers. This furnace is listed at $12.00.

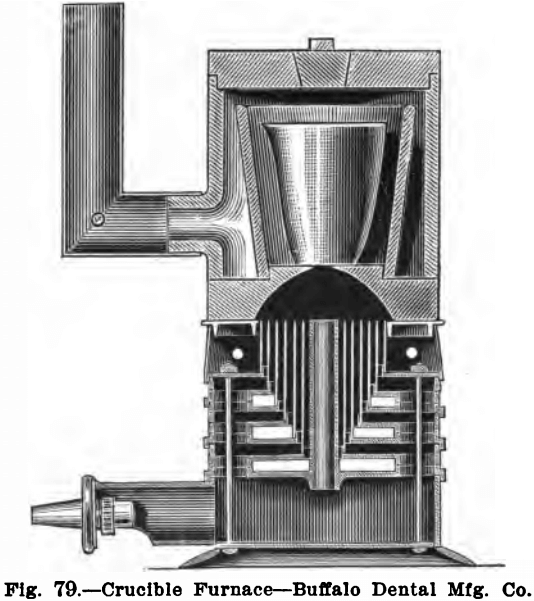

The crucible furnace is shown in Fig. 79. The furnace is heated by a No. 15 Fletcher burner and is made in five parts—an outer cylinder of fine clay, which is covered by a removable fire clay top with handle attached, and rests upon a bed plate, also made of fire clay, which has a hole in it through which the flame passes, a graphite inner cylinder and a combustion chamber below. This furnace is listed as “No. 15 Crucible Furnace” and priced at $16.00.

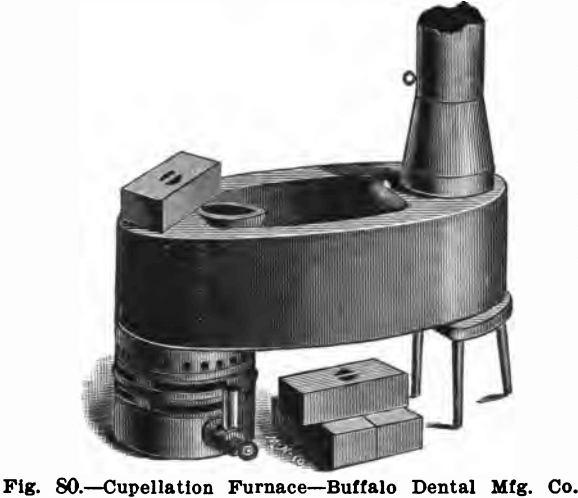

The cupellation and scorification furnace is shown in Fig. 80. This furnace was designed by Mr. Walter Lee Browne, and is described by him in his “Manual of Assaying.” In form it is almost that of the reverberatory furnace, the movable bricks when in place being the roof. In the interior, upon the bottom, are four little wedge-shaped bridges of fire clay, which are movable, and upon them rests a false bottom or floor, also movable. The latter corresponds to the muffle bottom of an ordinary furnace and upon it is done all the work. The furnace is heated by a No. 16 burner, and is made by the Buffalo Dental Manufacturing Co. It is called by them “No. 630 Monitor Furnace” and is listed at $18.00.

The table is of pine and is covered with fire clay tile. The whole outfit, table and furnace, is listed at $75.00.

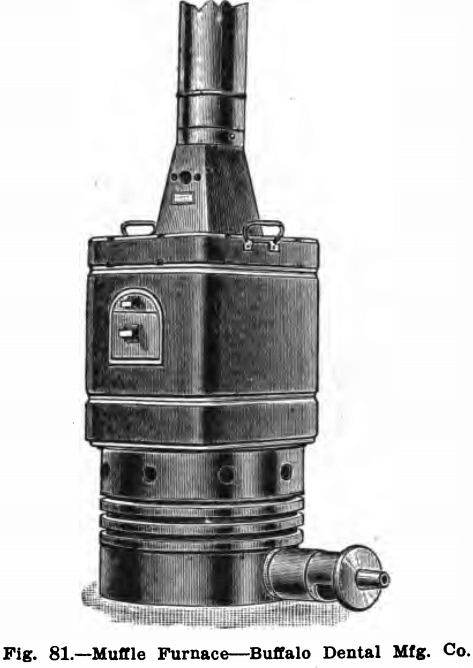

Another small gas-fired assay furnace, also manufactured by the Buffalo Dental Manufacturing Co., is shown in Fig. 81. It is made in four sizes, the smallest priced at $17.00, and having an inside muffle space 3 x 4 x 2 3/8, and the largest costing $45.00 and having a muffle space of 6 x 8½ x 4 7/8. A simple outfit for assaying would consist of the No. 4 size of this, having a muffle space 3 7/8 x 5 7/8 and priced at $20.00, for the cupelling and the crucible furnace referred to before, which could be made to do the roasting also if set up with a hood over it. Some assayers, however, do not roast their ores.

Liquid Fuel (diesel = gasoline) Assay Furnaces

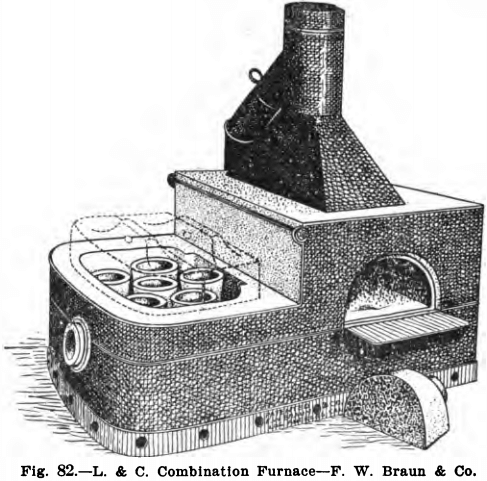

A large number of very convenient assay furnaces designed for the use of gasoline are now on the market, and where much assaying is done, and the assayer is not permanently located and gasoline can be obtained, nothing quite takes their place. They are small and can be quickly heated. They can also be easily transported from place to place.  They are designed for either crucible fusions or for cupellations or for both. The latter, so called “combination furnaces,” are the most convenient and economical. In them the fusion is carried on in one part of the furnace while the cupellation is being done in the muffle.

They are designed for either crucible fusions or for cupellations or for both. The latter, so called “combination furnaces,” are the most convenient and economical. In them the fusion is carried on in one part of the furnace while the cupellation is being done in the muffle.

Fig. 82 shows the L. & C. combination furnace, manufactured by the F. W. Braun Co., Los Angeles, Cal. This furnace consists of a compartment for crucibles at one end and the muffle at the other. It has a burner hole at either end and is mounted on a swivel which allows the furnace to be revolved so that the burner may be inserted in either one. Usually the burner is first inserted in the crucible end long enough to make one melt; the furnace is then revolved and the burner inserted in the muffle end. From this time on the melting and cupellation may be carried on at the same time without revolving the furnace. A dividing brick is furnished, to be placed between the melting and muffle departments, if only one is to be heated. A small trap-door is placed in the bottom of the crucible compartment, and if a spill occurs this may be opened, the bottom punched out and a new one of fire clay and sawdust put in. Oxidation in the muffle is secured by means of a fire brick flue connecting the muffle, through a hole in the latter, with the main flue by means of a pipe at the back of the furnace, as shown. The pipe is provided with a damper to regulate the draft when the buttons in the cupel are opening.

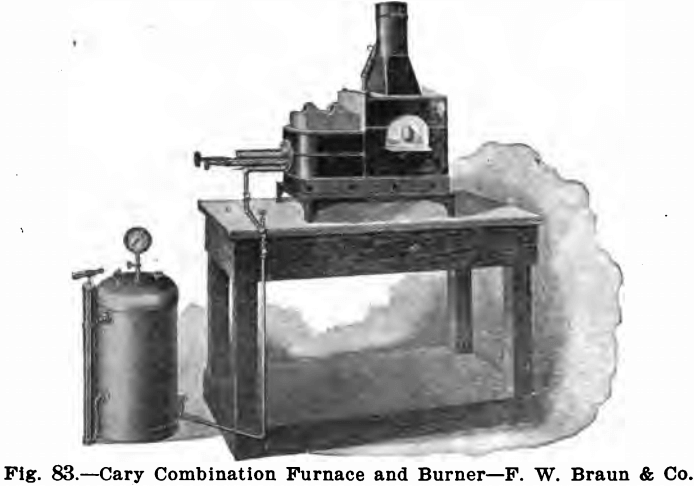

These furnaces are intended to be heated by the “Sunset” burner, made by the same firm. The arrangement of furnace and burner is illustrated in Fig. 83. The furnace itself should be raised slightly from the table, as shown, and the latter should be covered with asbestos, or better still, with fire tiles. The concrete table top mentioned in Chapter II. is suited to this, particularly if coarse calcined magnesia or asbestos fibre is used in place of sand, in the proportions of about three parts to one of cement.

This furnace is made in a number of sizes ranging from a 4¾ x 8 x 3-inch muffle, holding two No. G crucibles to one having a muffle 6 x 9 x 4 inch and taking four No. G crucibles. The price of the latter size together with burner, gasoline tank, pump, etc., is $44.50. A furnace made similar to the one described above called the “Cary Combination Furnace,” is to be heated by the “Cary” burner, a more efficient burner than the “Sunset.” The price of the complete Cary outfit as shown in Fig. 83 is $55.00, exclusive of the table.

Combination Furnace

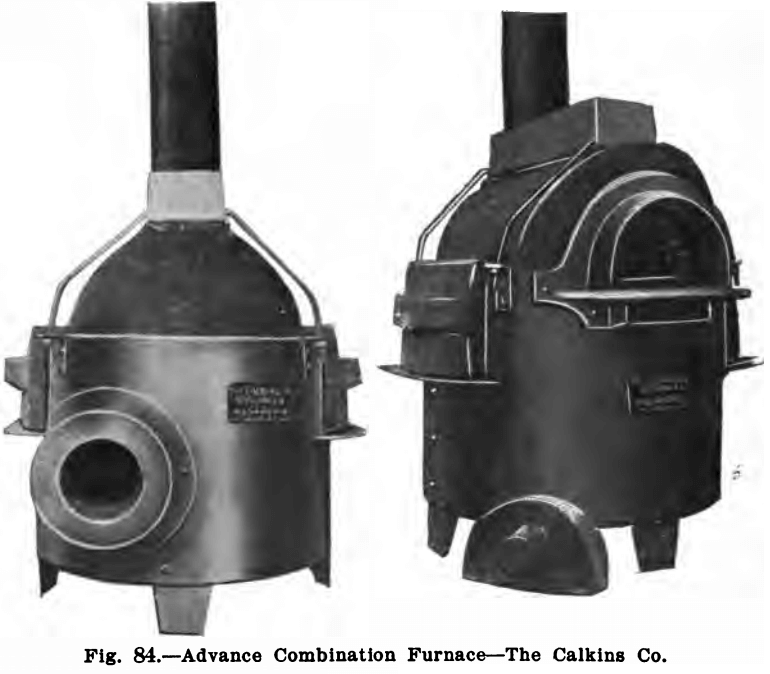

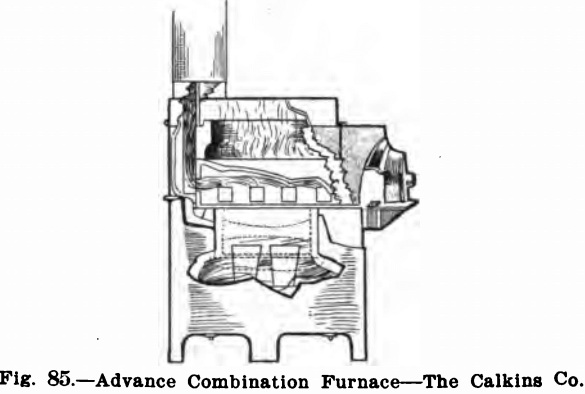

The “Advance Combination Melting and Muffle Furnace No. 10,” manufactured by The Calkins Company, is shown in Figs. 84 and 85. This furnace consists of a circular crucible chamber above which is the muffle, Fig. 84. Access to the crucible chamber is had from either side of the furnace through covered apertures. The flame is shot into the crucible chamber at a tangent to the inner wall of the furnace, Fig. 85, and swirls around the crucibles. It is claimed that by not impinging the flame on the crucibles the life of the latter is thereby greatly increased and that the products of combustion rising unobstructed around the muffle, the latter is uniformly heated. The muffle is ventilated, as shown in Fig. 84. The furnace itself is encased in an iron jacket and is provided with a removable bottom to allow replacement of the floor of the crucible chamber. The furnace is 16 inches in diameter and 21 inches high and weighs 180 pounds. The muffle is 4 x 6 x 12 inches and the crucible chamber is 12

inches inside diameter and 8 inches high. Starting with a cold furnace, a good working heat can be obtained in 20 minutes and the muffle will be ready for cupelling before the melt is completed. The furnace is heated by an “Advance” hydrocarbon burner. The price of the furnace above is $25.00 or of furnace, burner, 7½- gallon gasoline tank and pump, is $48.00. The “Advance” fur-

nace is made in two smaller sizes, one of which costs $20.00 and the other $16.00.

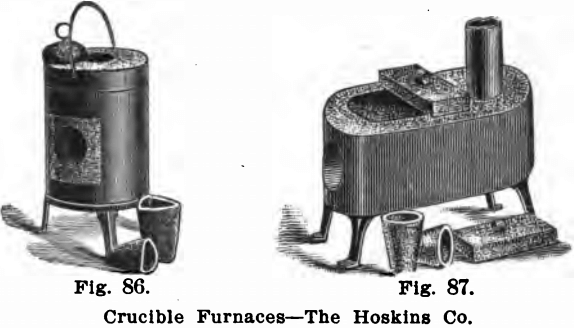

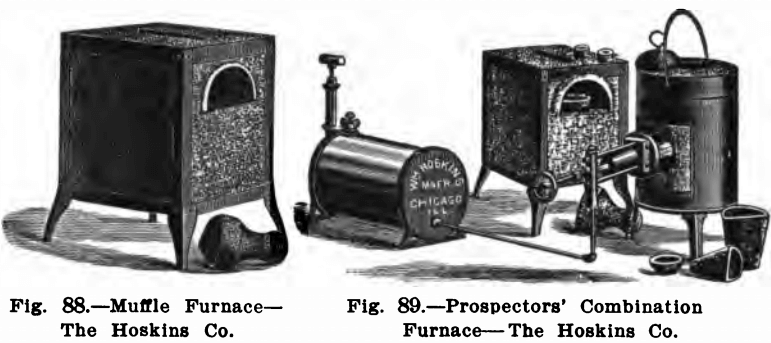

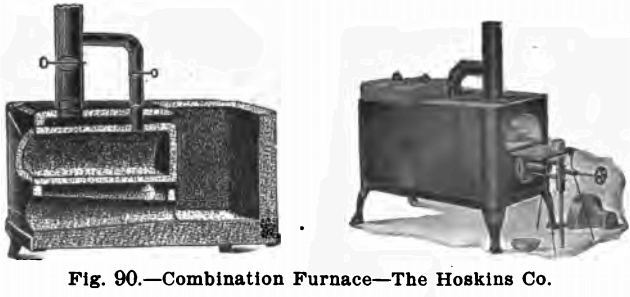

The Hoskins Company, 93 Erie St., Chicago, III., make several forms of gasoline-heated assay furnaces. Figures 86 and 87 illustrate crucible furnaces of which the first is intended for only one crucible, the second is made in two sizes taking respectively two and four crucibles. Fig. 88 shows the muffle furnace. The price of the crucible furnace for one crucible, muffle furnace, and one gallon blow pipe outfit, complete, is $40.00. Their combination furnaces are shown in Fig. 89 and Fig. 90. The first furnace shown is very light and portable and is intended for prospectors. It is also of use when only an occasional assay is made. On the right of Fig. 89 the furnace is shown prepared for crucible

work. By lifting off the cover and substituting the part with the muffle opening, and sliding into this the muffle, the furnace is prepared for cupelling or scorification. The muffle is 6 x 3½ x 2½ and the crucible furnace is 4 inches in diameter and 5½ inches deep. Its price with ½-gallon blow pipe outfit is $30.00. The combination furnace, shown in Fig. 90, is made in two sizes, the

smaller of which has a muffle 6 x 3½ x 2½ inches and a crucible compartment large enough for one fusion. The larger size is intended for four No. F crucibles and has a muffle 10 x 6 x 4 inches. The price of the smaller furnace is, with ½-gallon blow pipe outfit, $33.00, and of the larger one with a gallon blow pipe outfit, is $46.00.

Portable Assay Furnaces

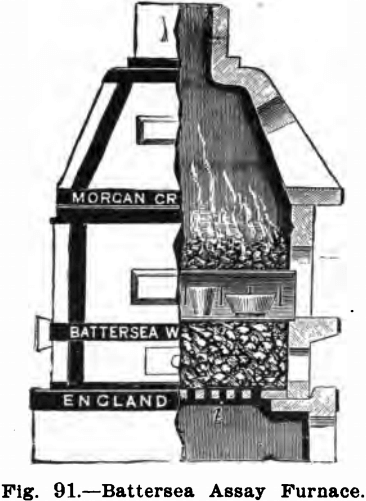

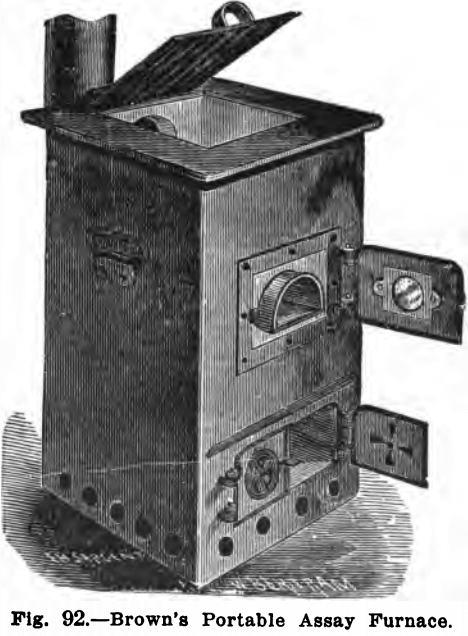

Of the portable coal-fired furnaces, Bosworth’s, the Battersea and Brown’s forms are all extensively used in this country. The Battersea and Bosworth’s furnaces are very similar and are made of fire clay, in sections, bound together with iron bands. They are mufflle furnaces exclusively, but they are made in large sizes and in these latter crucible melts can be made in the muffle. These two furnaces cost about the same, the price ranging between $30.00 and $40.00 for the various sizes. The Battersea is shown in Fig. 91. Brown’s Portable Assay Furnace is illustrated in Fig. 92. It consists of a nearly square sheet iron frame, 28 inches high, 16 inches wide, and 14 inches deep, lined with fire brick. The cover is cast iron, as are also the doors to the muffle and ash pit. In the muffle door is a window filled with mica so that the operations going on inside the muffle may be observed when the door is closed. The ash pit doors are provided with wheel openings to further regulate the draft. The grate is formed of cast-iron bars resting upon a cast-iron frame. It is made for a muffle 12 inches long, 6 inches wide and 4 inches high, and weighs 155 lbs. It costs $20.00 boxed for transportation. This furnace is also made in a larger size, taking a muffle 15 x 9 x 6 inches, weighing 300 pounds and costing $35.00.

A small furnace called the “Jackass” is made by the Denver Fire Clay Co. This furnace is somewhat similar to Brown’s furnace. It is much lighter, however, weighing 100 lbs. It takes the same size muffle and costs about the same.

Coal Fired Furnaces

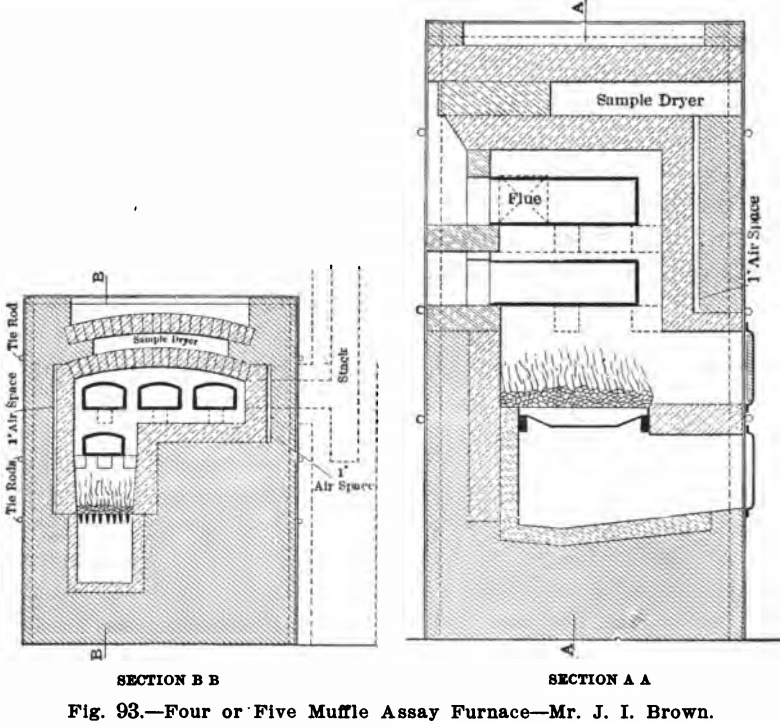

In the laboratories of mines and smelters, where many assays are a part of every day’s work, the proper furnaces are those built of brick. One of the best of these is that described by H. W. Parmelee and used in the assay office of Mr. J. I. Brown, Cripple Creek, Colo., by whom it was designed. The construction of the furnace is evident from Fig. 93, and its good points are thus summed up by Mr. Parmelee:

First, it has larger capacity than the ordinary furnace, being capable of being built for either four or five muffles. This enables the operator to conduct several different operations in the furnace at the same time, thus greatly hastening the completion of the day’s work. Fusion, scorification and cupellation can be carried on at the same time, and by constantly advancing the assay through the necessary stages, it is possible to run through a large number of samples. Fusions are made in the lower and upper muffles directly over the fire box; scorifications in the next right-hand muffle and cupellations in the last. The theoretical capacity of this four-muffle furnace is 90 assays per hour. Practically, Mr. Brown has repeatedly handled 400 assays per day of 10 hours, and states that the furnace could easily be made to turn out between 500 and 600 assays per day of 10 hours.

Second, it has a sufficiently large combustion chamber to permit of almost complete combustion of the gases before they escape into the flue. This means that the full effect of the heat is received, with the result stated in the preceding paragraph. Five tons of coal per month are required to operate this furnace to its full capacity, running ten hours per day.

Third, it is provided with a sample dryer, which is a valuable adjunct when large numbers of mine samples are to be assayed.

This sample dryer makes use of the heat above the muffles, and has greater capacity than a hot plate or similar contrivance, at the same time being absolutely inexpensive.

Fourth, the fire-clay linings are conveniently replaced when burned out. The front of the furnace surrounding the muffles is made of the ordinary moulded blocks found on the market especially for this purpose. These can be removed and the inside of the furnace is then open for the purpose of replacing the burned-out interior layer of fire brick. It will be noticed in this connection that between the pressed-brick body of the furnace and the fire-brick interior there is a 1-inch air space. This permits of the successive expansion and contraction of the fire brick without placing the stress on the outside walls and tie-rods.

Fifth, it is a forced-draft furnace, the blast being supplied by an electrically-operated blower. To prevent the burning out of the grate bars, which would ensue under the great heat generated, the ash-pit is provided with a cement water pit which is kept full with water up to the level of the ash-pit door.

The materials used in the construction of the furnace are those commonly used everywhere. The outside walls are of red-pressed brick. The inner linings are of fire brick, and the lining of the ash pit is of cement.”

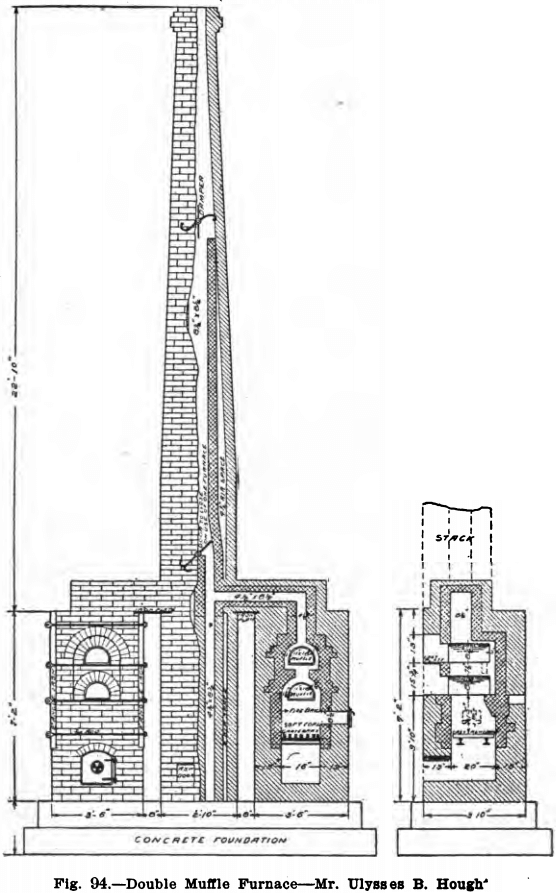

Fig. 94 shows a superimposed double-muffle assay furnace used by some of the lead-silver mining companies of Washington and Idaho. Two furnaces are built, one on either side of the stack, only one being used at a time, each being large enough to do the entire work of a large mine. The furnace, when once started, is used from day to day until burned out, lasting from 19 to 22 months. The second furnace is then started while the first is being repaired. By building double, one furnace can always be ready. The repairing of a furnace requires the labor of a mason and helper from two to two and a half days. The stack will not require repairing.

The fuel used is soft coal. The consumption ranges from 175 to 250 lbs. per day, and the assays made will range from 75 to 150 of lead and silver. This furnace can be brought to a proper heat for work in 45 min., but two hours are usually taken. The drawing plainly shows all dimensions.

The grate-bars are of cast iron, as well as all doors, which are lined with cast plates perforated by ½-inch holes. The lining only is replaced from time to time. The outside should be securely stayed, as shown. The rods are to be made with a nut in one end and an eye in the other. In this furnace both muffles heat alike, work being done in one as well as in the other.