Table of Contents

As part of its mission to advance minerals technology, the Federal Bureau of Mines has conducted investigations to determine the feasibility of producing subsieve-size material by an attrition grinding method. The Bureau-patented technique involves the intense agitation of a slurry composed of the material to be ground, a granular grinding medium, and a suspending fluid. Investigations were made to determine the efficiency of the method in grinding numerous industrial minerals, metals, and ceramic materials. The research has demonstrated the feasibility of the process for comminuting a variety of materials to extremely fine particle sizes. Transfer of this technology to industry has been achieved, and commercial-scale units currently are being used in the paper-coating clay and titania pigment industries.

In recent years, the demand for finely ground industrial minerals, ceramic materials, and related products for such uses as fillers and chemically reactive components has increased markedly. The particle size specifications for these materials vary greatly and depend on the particular end purpose as well as the physical properties of the material itself. Size reduction of most mineral materials usually is achieved by conventional crushing and grinding methods. Some specialized milling techniques, however, have been developed for reducing various materials to extremely fine particle sizes. As part of its research program to advance minerals technology, the Federal Bureau of Mines has investigated an attrition grinding method to produce ultrafine, subsieve-size particles. The Bureau-patented process involves the intense agitation of a slurry composed of the material to be ground, a relatively fine granular grinding medium (generally Ottawa sand), and a suspending fluid. Initial Bureau research focused on the comminution of coarse kaolin on both a batch and a continuous basis. Studies also were made to determine the efficiency of the process in grinding a variety of industrial minerals, pigments, metals, and ceramics. As a result of this work, the process was adopted by industry to produce paper-filler-grade kaolin and ultrafine titania pigment on a commercial scale. This report summarizes the results of the Bureau’s research studies and includes a brief description of the commercial applications.

Grinding of Kaolin

The primary objective of every research activity carried on by the Bureau of Mines is wise and efficient use of our Nation’s mineral wealth. In 1959, Bureau analysts noted a 75-fold increase in the production of paper-coating-grade clay from 1925 to 1959, whereas production of paper-filler grade clay increased only fivefold over the same period. In commercial practice, recovery by washing of paper-coating-grade clays from southeastern U.S. crude kaolins leaves a high percentage of relatively coarse, paper-filler-grade material, which has only a limited market and often is rejected as waste. With the intent of extending the useful life of the Nation’s paper clay resources, the Bureau initiated research to develop a method for grinding filler-grade clays to paper-coating-grade material.

Batch Grinding Studies

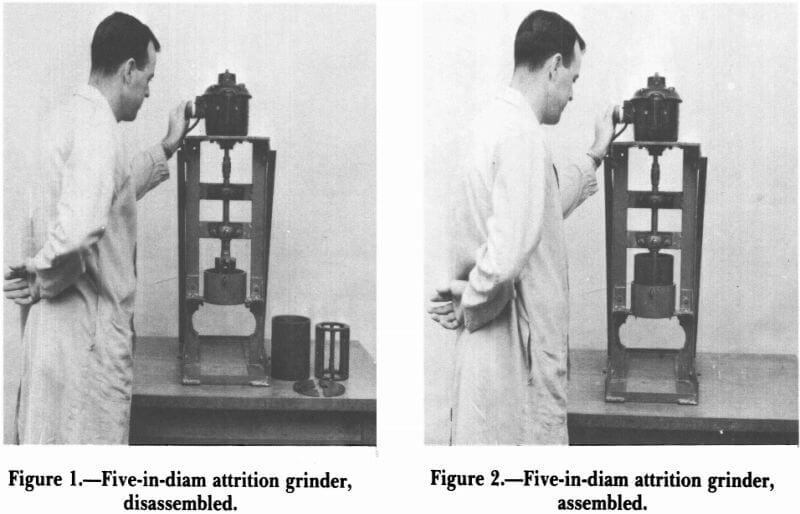

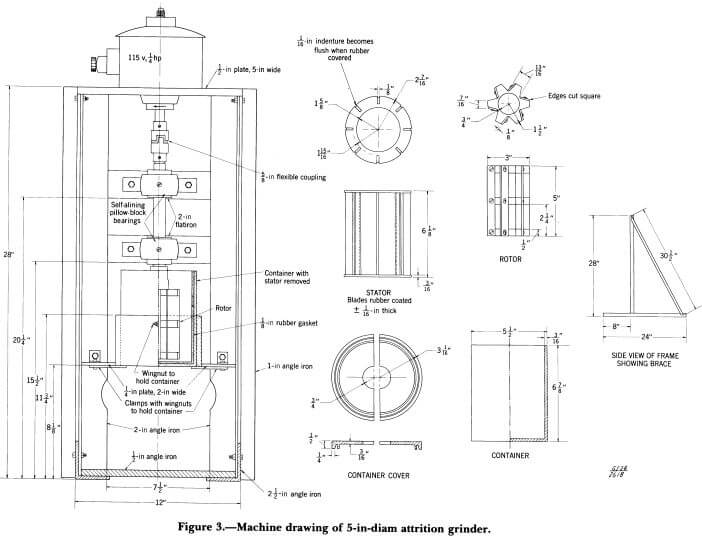

A survey of the literature pertaining to wet grinding of materials to the minus 2-micrometer size range indicated that there was no generally accepted method in use; therefore, cursory tests were made to evaluate standard grinding methods and to develop new or improved techniques. These tests were made on a sample of coarse Georgia kaolin, which was nearly all finer than 40 micrometers and which contained about 13 percent minus 2-micrometer-ESD (equivalent spherical diameter) material. The tests were made on a batch scale using various types of grinding equipment, including a small porcelain jar mill, a high-speed blender, an ultrasonic-energy unit, a colloid mill, and an attrition grinder. The attrition grinding machine used was a 5-inch-diameter unit, originally developed by Bureau personnel (6, 10) as a scrubbing device for beneficiating glass sand. The machine consisted of a cylindrical container, a cage-like stator composed of vertical bars fixed to rings at top and bottom, a cagelike rotor composed of vertical bars fixed to an upper disk attached to a drive shaft, and a frame that holds the motor and machine components. The unit was converted to a grinder simply by using a charge composed of the material to be ground, water, and a spherical sand grinding medium. The details of this machine are shown in figures 1-3.

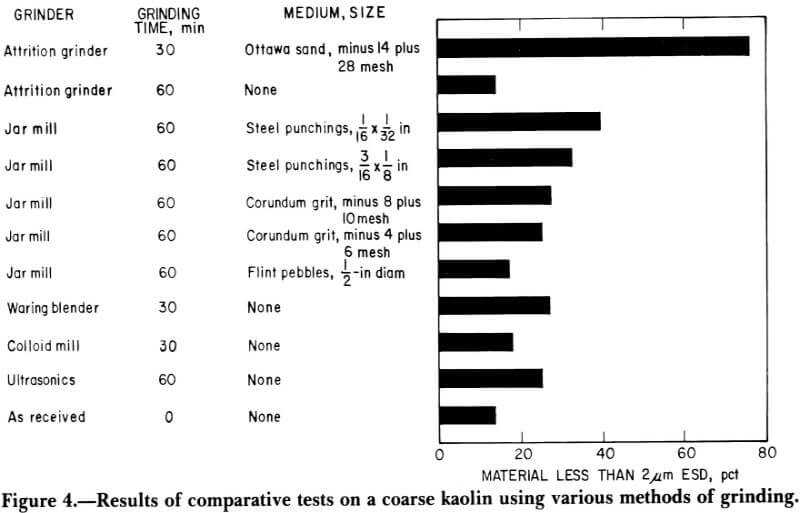

Summarized in figure 4 are the results of the comparative kaolin grinding tests made in the various grinding machines. These data agree with the general precepts of grinding; that is, an increase in the rate of fine grinding was achieved as the size of the grinding medium decreased and the density of the medium increased. The bar graph shows distinctly that particle size reduction achieved by attrition grinding was much greater than that obtained by any of the other methods tested. As a result, subsequent research was focused on the attrition grinding process.

in the rate of fine grinding was achieved as the size of the grinding medium decreased and the density of the medium increased. The bar graph shows distinctly that particle size reduction achieved by attrition grinding was much greater than that obtained by any of the other methods tested. As a result, subsequent research was focused on the attrition grinding process.

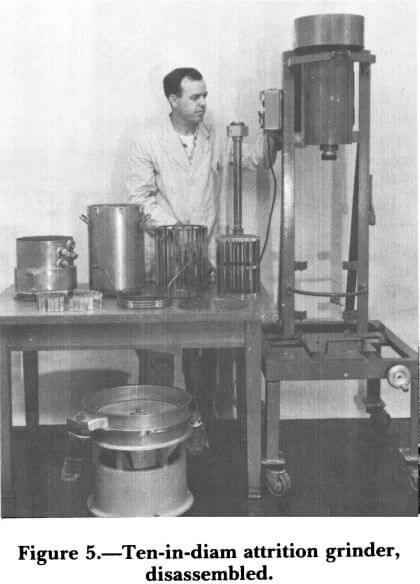

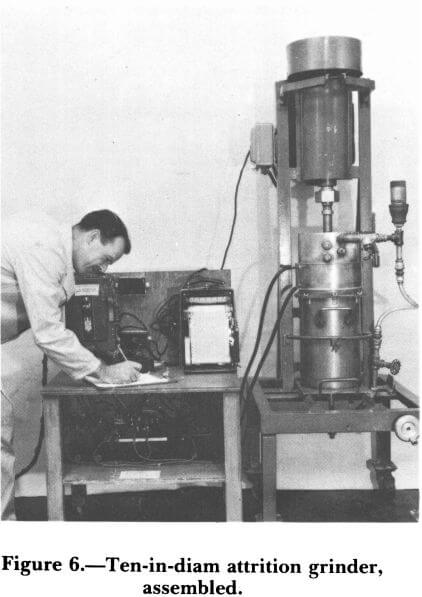

Following the tests made in the 5-inch-diameter unit, a 10-inch-diameter unit was constructed to develop performance data and power requirements in a larger unit. This unit was designed to duplicate the physical characteristics of the smaller unit so as to obtain comparable grinding action and to permit comparison of both particle size reduction of the material being ground and energy consumption of the two grinders. In all tests described in this section, the grinding medium used was minus 14- plus 28-mesh Ottawa sand. Figures 5 and 6 show the 10-inch-diameter grinder disassembled and assembled for batch testing, respectively.

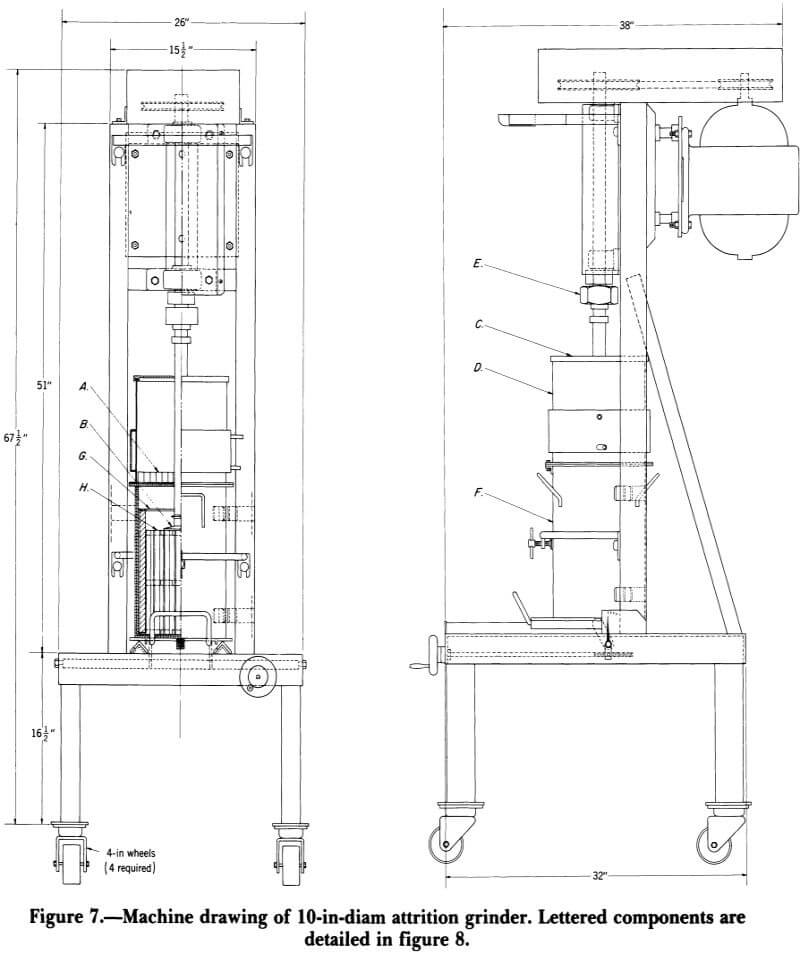

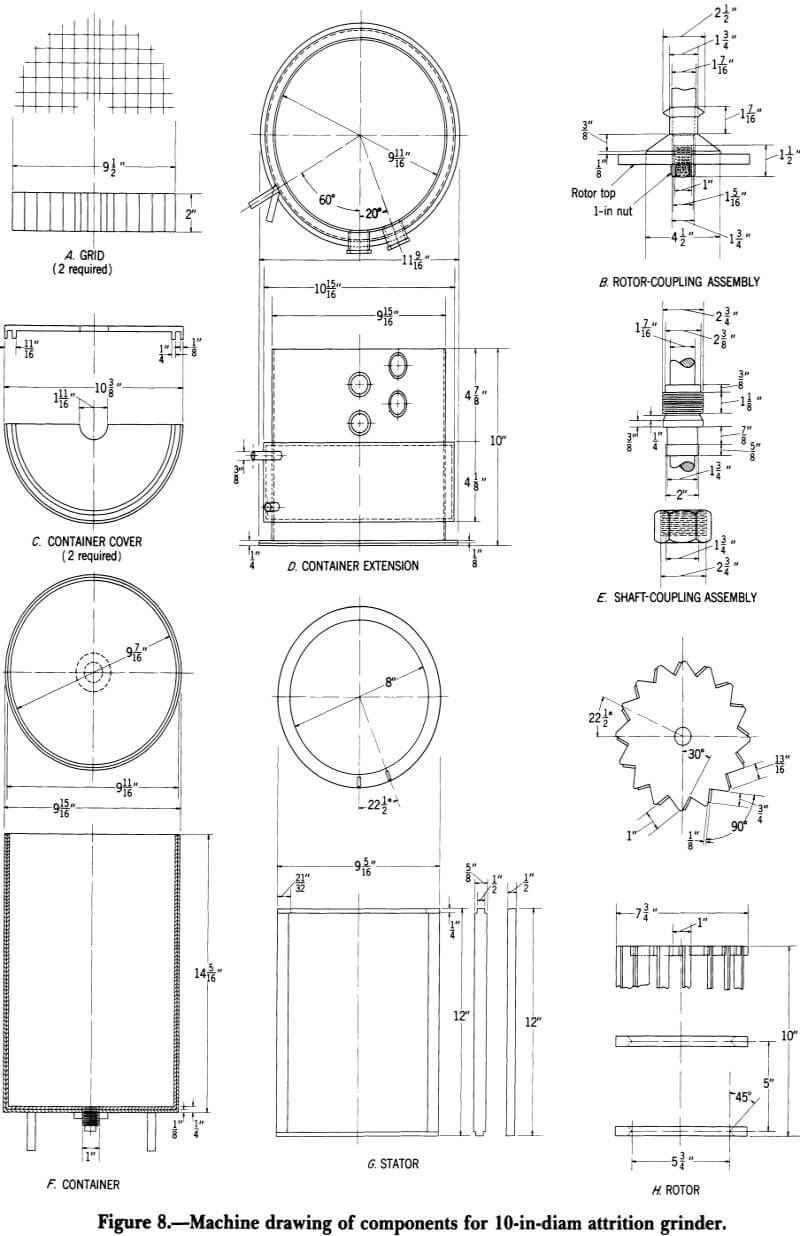

Machine drawings of the 10-inch-diameter grinder shown in figures 7 and 8 present details of various components of the unit.

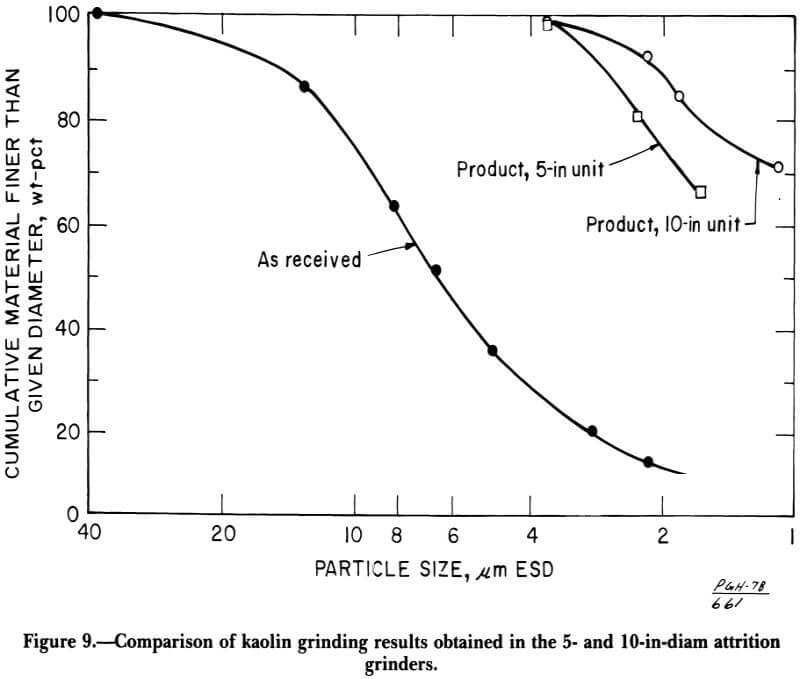

Figure 9 presents size distribution curves of an “as-received” clay after a 30-minute, batch grinding test in both the 5-inch- and 10-inch- diameter units. The curves show that, for the same grinding time, more minus 2-micrometer- ESD material was present in the ground product from the larger unit. Extrapolated energy consumption data revealed that, for a ground product containing 88 percent minus 2-micrometer- ESD material, the 5- and 10-inch grinders would require 620 and 390 kilowatt-hours per ton of clay feed, respectively. These figures indicated the larger grinder was the more efficient unit.

To further explore the potential of the units, coarse kaolin samples obtained from five commercial paper-coating-clay producers were attrition ground. The ground products were tested for such properties as gloss, brightness, and viscosity by the commercial operators themselves. Reports by the operators revealed that nearly all the gloss and brightness values obtained on test sheets coated with material prepared from the ground clay were superior to those containing unground clay. All evaluated samples of ground kaolin displayed higher clay-water viscosities than those of commercial coating clays having similar particle size analyses. This, however, did not preclude the use of the clays for paper-coating purposes, because in every instance reported, the viscosity of the coating mixture prepared from the ground clay was within acceptable limits.

Small-Scale Continuous Grinding Studies

With the establishment of the attrition grinder as a potential method for producing paper-coating-grade clay from coarse filler material, the Bureau continued its research with the objective of adapting the process to a continuous operation.

Open-Circuit Tests

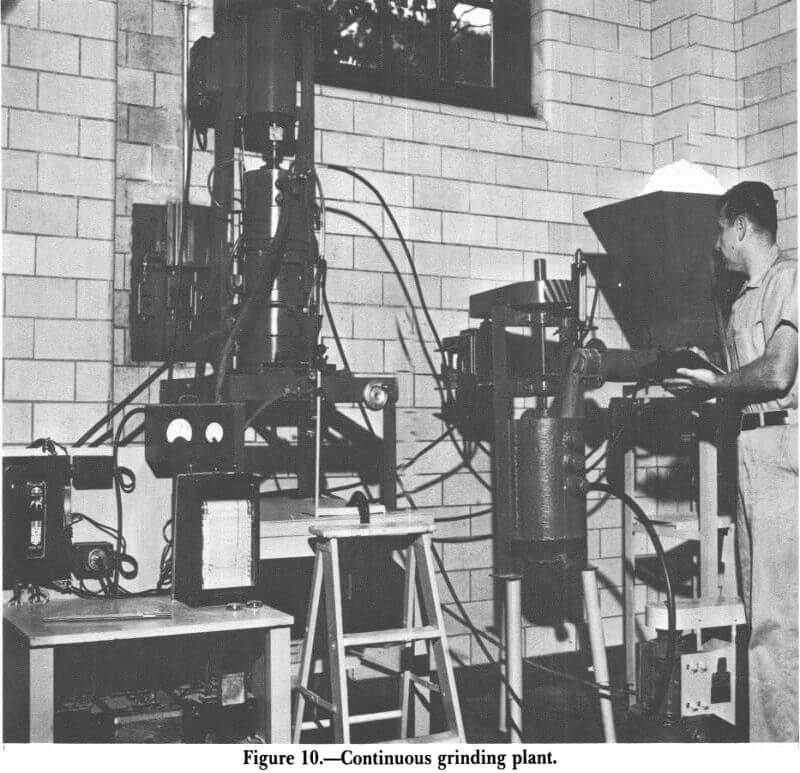

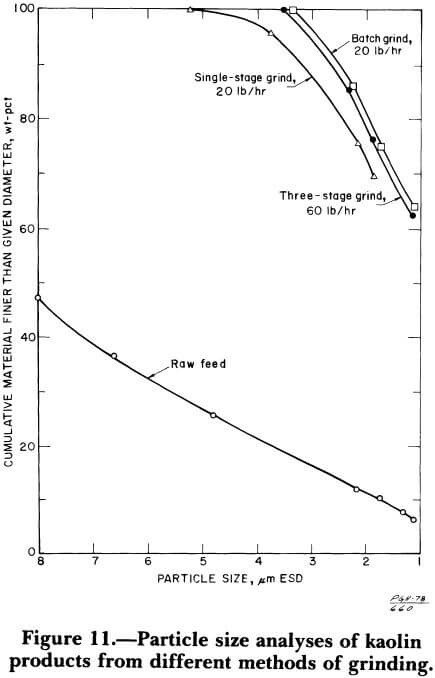

The continuous open-circuit grinding plant, shown in figure 10, was comprised of an auger-type clay feeder, a wet chemical reagent feeder for dispersants, a pulp conditioner, and the 10- inch-diameter attrition grinder. The open-circuit tests were made using single-and multiple-stage grinding techniques with feed rates ranging from 10 to 480 pounds per hour of kaolin. The distribution of subsieve-size particles obtained by batch grinding and several different continuous circuits are presented graphically in figure 11. The data show that the particle size distribution obtained in the batch test and the continuous three-stage grind were nearly identical, and that continuous single-stage grinding was not as effective as either batch or multiple-stage milling. The diversity of results was attributed to short circuiting and disruption of the slurry flow pattern achieved in the batch grinding. During batch grinding, the flow pattern of the slurry was different from that in the continuous test.

Closed-Circuit Tests

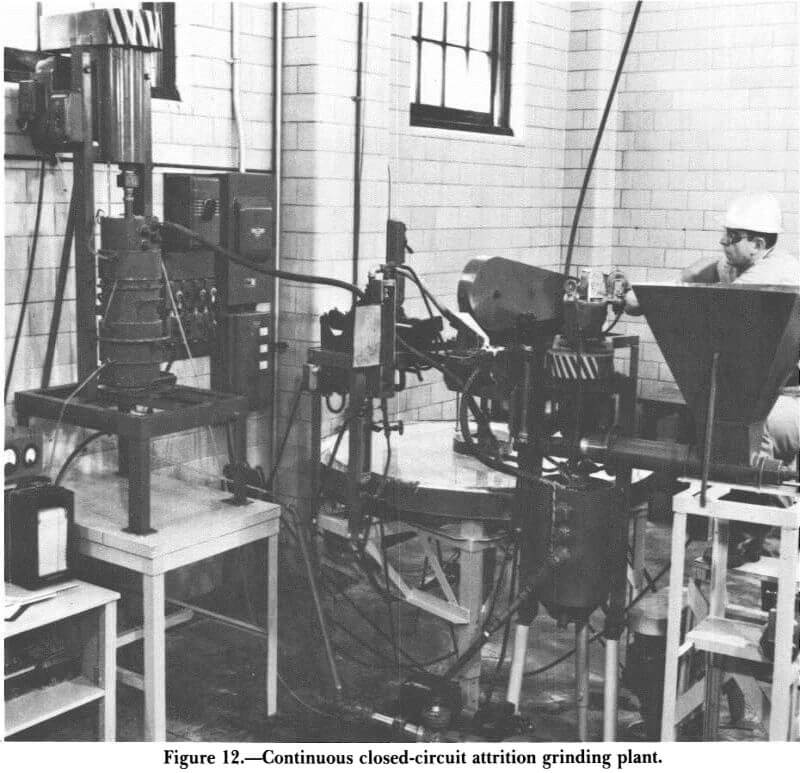

The closed-circuit grinding plant, shown in figure 12, consisted of an auger-type clay feeder; a wet chemical reagent feeder for dispersant; a pulp conditioner; a variable speed, screw-type, positive-displacement pump; the 10-inch-di-

ameter attrition grinder; and a 5-foot-diameter bowl classifier. The classifier overflow was the finished product. The classifier underflow was returned to the grinder as circulating load for additional comminution. Circulating load, feed rate, pulp density of feed, and the quantity of grinding medium in the mill were also studied.

Results indicated that the overall capacity and effectiveness of the attrition mill were influenced by the limited capability of the bowl classifier to make a good separation of the clay particles in the 2-micrometer range. Nevertheless, the tests did demonstrate the feasibility of continuously grinding coarse paper-filler-grade kaolin to produce a clay product meeting particle-size specifications for commercial paper-coating-grade clay.

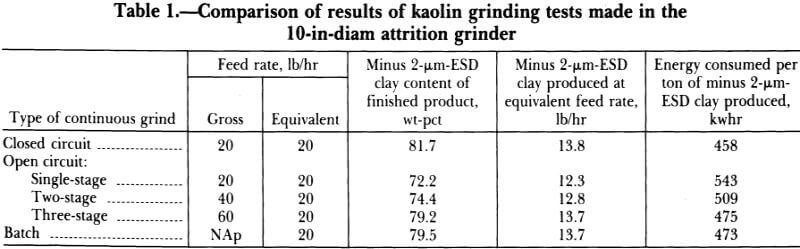

Table 1 presents data comparing selected results of the closed-circuit tests with those of the continuous open-circuit study. Closed-circuit grinding achieved a slightly greater rate of particle size reduction and consumed less energy per unit of minus 2-micrometer-ESD material produced than open-circuit and batch grinding.

Large-Scale Grinding Studies

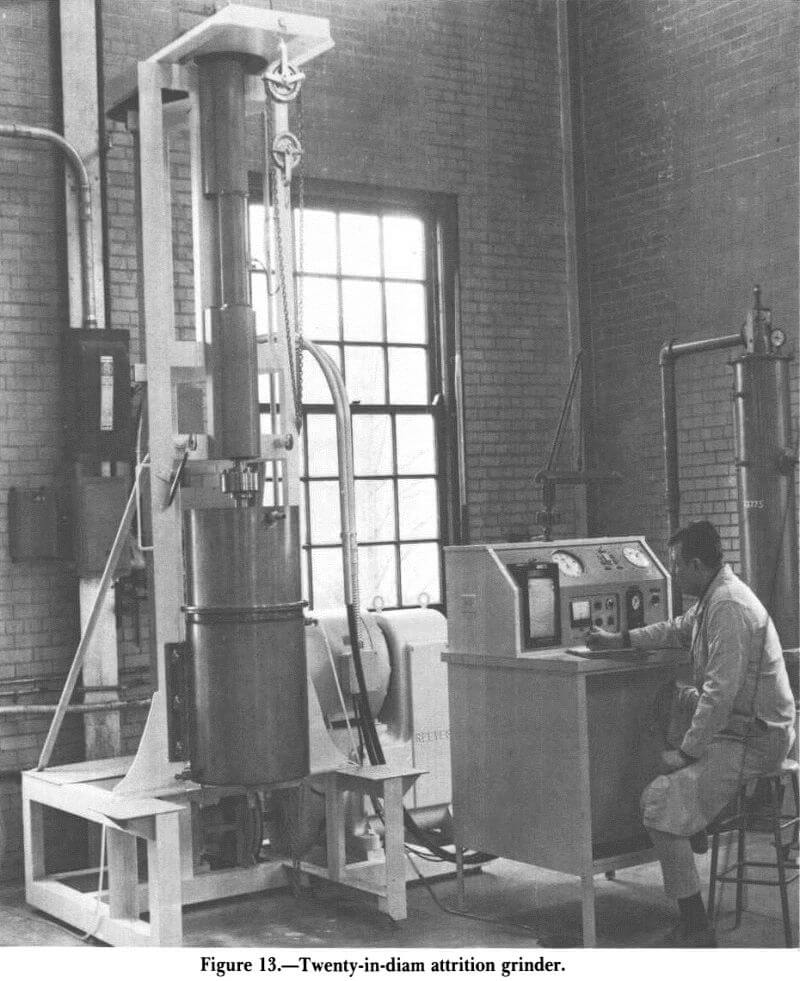

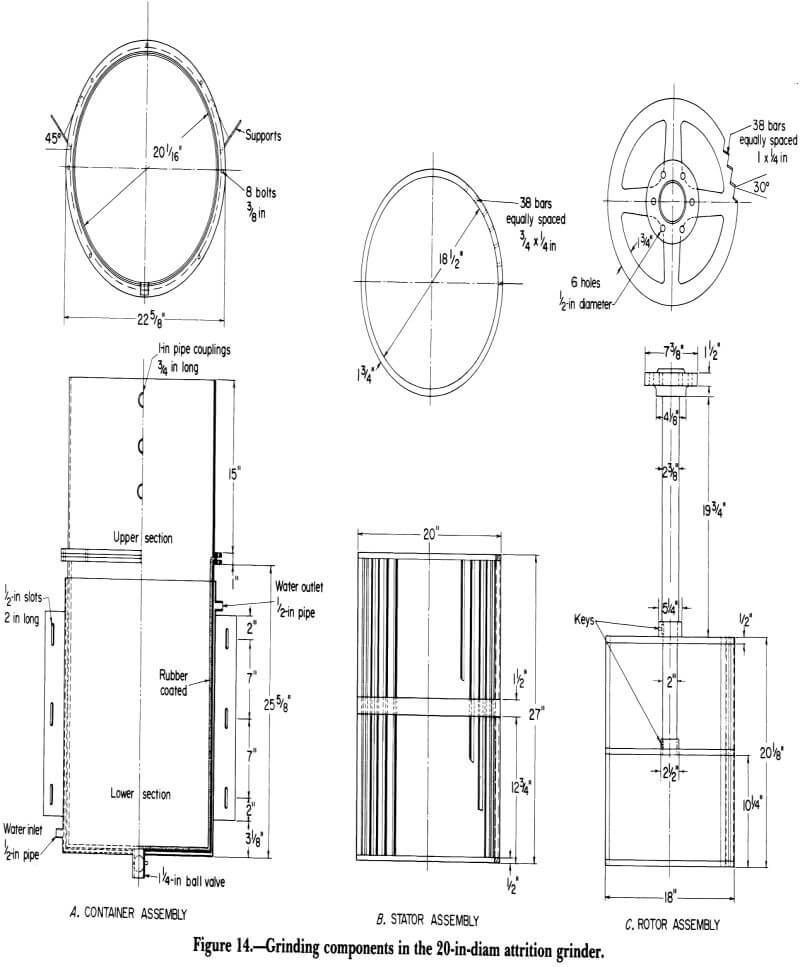

As a result of the success achieved in scaling up from the 5-inch-diameter grinder to the 10- inch-diameter grinder, a 20-inch-diameter unit was designed and constructed. The grinder and control panel is shown in figure 13. Figure 14 presents details of the container, stator, and rotor assembly.

Preliminary batch tests in the unit indicated that scaling up the 10-inch-diameter unit to a 20-inch-diameter machine required some design modifications to achieve similar grinding efficiencies.

The modifications were made to approximate the flow patterns generated in the 10-inch-diameter unit and included increased

stator bar height, the use of a grid above the stator to prevent swirling and insure thorough mixing and turbulence, and the closure of the opening in the top rotor hub.

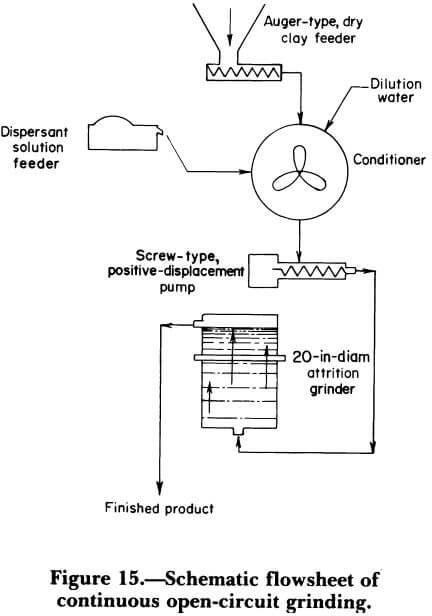

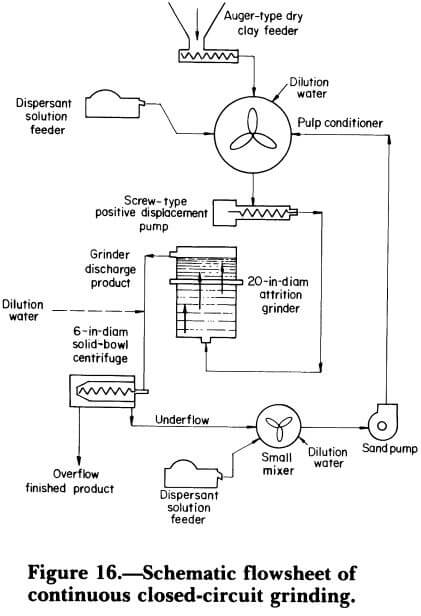

On the basis of the batch tests, continuous- grinding-circuit flowsheets were designed. The basic components of the continuous open-circuit and closed-circuit grinding plants were essentially the same as in the smaller scale tests. In the larger closed-circuit plant, however, a 6-inch-diameter, solid-bowl centrifuge was used as a classifier. Schematic flowsheets of the continuous open-circuit and closed-circuit plants are shown in figures 15 and 16, respectively.

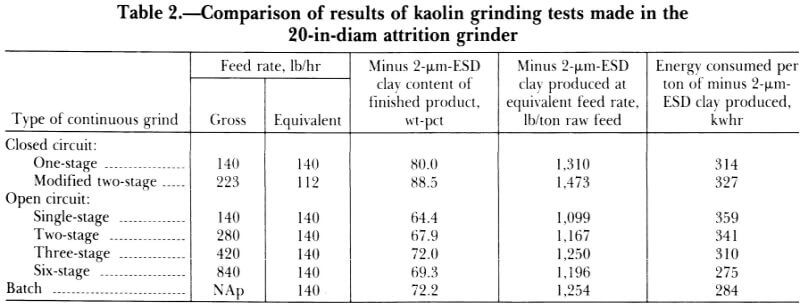

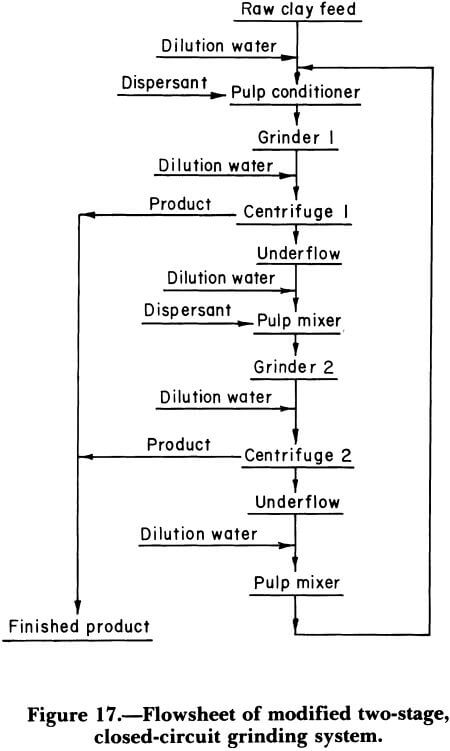

Results from the various grinding tests (table 2) show that closed-circuit grinding yielded higher grade products than open-circuit batch grinding. The highest grade product, which contained 88.5 percent minus 2-micrometer- ESD material, was obtained by a modified two- stage technique. A flowsheet depicting the modified two-stage, closed-circuit system is shown in figure 17. Although the total equivalent feed rate in this test was somewhat lower than the equivalent feed rates used in the other tests, it was concluded that the modified two-stage, closed-circuit flowsheet was the best continuous system tested for obtaining the greatest amount of particle size reduction.

In general, results obtained with the 20-inch-diameter grinder were analogous to those obtained in earlier research on the smaller 10- and 5-inch-diameter units. Of the three sizes of machines, best particle size reduction was achieved with the 20-inch unit, indicating that grinding results should be satisfactory for even larger units. Furthermore, the energy required to produced a similar product was about 31 percent lower in the 20-inch unit than in the 10-inch unit.

Operating Variables

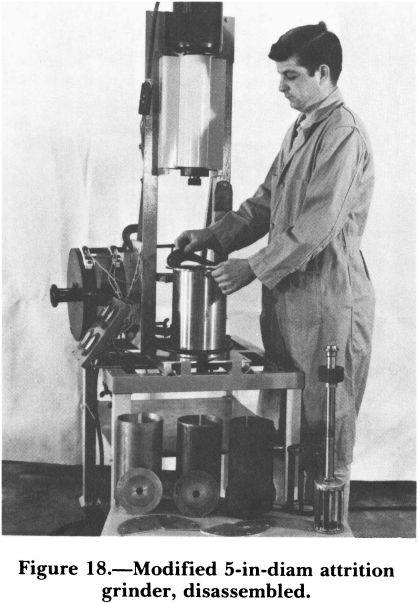

To develop basic data pertaining to attrition grinding, a study was initiated to establish the effect of a number of basic operating variables on grinding efficiency and energy consumption. A modified 5-inch-diameter attrition grinder, which was designed to duplicate the basic physical characteristics of the 10-inch-diameter unit, was constructed for the study. Figure 18 shows the grinder disassembled, and figure 19 shows the machine assembled for batch testing.

The machine frame was constructed to allow adjustment of clearance between the bottom of the rotor and the grinding chamber. To provide cooling or heating of the charge during grinding, the machine was constructed with a stainless steel outer casing through which liquid at a controlled temperature could be circulated to maintain the grinding chamber and its contents at a desired temperature.

The rotor and stator parts were constructed to allow setting at several angles of pitch to study the effect of various angular positions of the rotor and stator bars on the grinding process. By alternately changing the rotor and stator bar arrangements, nine different combinations were obtained. A direct-current motor controlled by a rheostat was used to drive the rotor and allow variations of rotor speed.

|

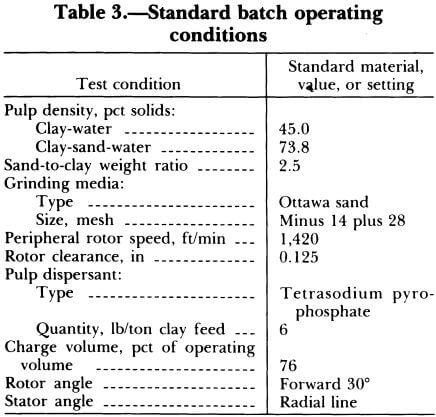

|

Previous research had shown that, in the attrition grinding process, several variables simultaneously influenced the degree of clay comminution and energy requirements. These basic operating factors are shown in tabular form in table 3. In this particular investigation, the parameters recorded in table 3 were considered to be standard operating conditions. A detailed investigation was made to determine the effect on particle size reduction and energy consumption of changes in these basic factors and of other operating variables such as pulp temperature during grinding, rotor design, and the degree of pulp aeration during grinding. Tests also were made to determine the effect of the degree of pulp dispersion and the use of reagent

grinding aids on comminution efficiency. In addition, tests were made to study the effect of various types and shapes of grinding medium on grinding efficiency, degradation of media, and abrasion to machine parts. In conjunction with the study on abrasion to machine parts, a series of tests was made in which grinding chamber liners of mild steel and stainless steel were used in place of the conventional rubber liner.

Results showed that the operating variables having more influence on the efficiency of kaolin comminution and energy consumption requirements were type, size, and shape of grinding media, the ratio of medium weight to clay weight, peripheral rotor speed, clay slime pulp density, degree of pulp dispersion, and the angular arrangement of the rotor and stator bars. The variables having less influence on grinding efficiency and energy consumption were pulp temperature, design of rotor cage, clearance between the rotor and chamber bottom, rotor-stator bar interval, additives, pulp level, degree of pulp aeration, and chamber liner material. The type of grinding medium used had the greatest influence on abrasion of machine parts, and spherical-shaped grinding media were superior to sharp angular or fibrous-type media with respect to media degradation, machine abrasion, and grinding efficiency.

Comminution of Industrial Minerals

Following the investigations detailed above, the Bureau initiated an investigation to determine the extent of particle size reduction obtainable with other industrial minerals. Using a statistically designed experimental program, 30-minute batch grinding tests were made on mica, pyrophyllite, talc, marble, barite, and fluorite in the Bureau’s 10-inch-diameter machine. The tests were made to investigate the influence of feed pulp density, weight ratio of Ottawa sand grinding medium to mineral, and size of the sand grinding medium on particle size reduction, bulk density of the ground product, and electrical energy consumed during grinding. The primary objective of the investigation was to establish trends rather than optimum grinding conditions for the various minerals.

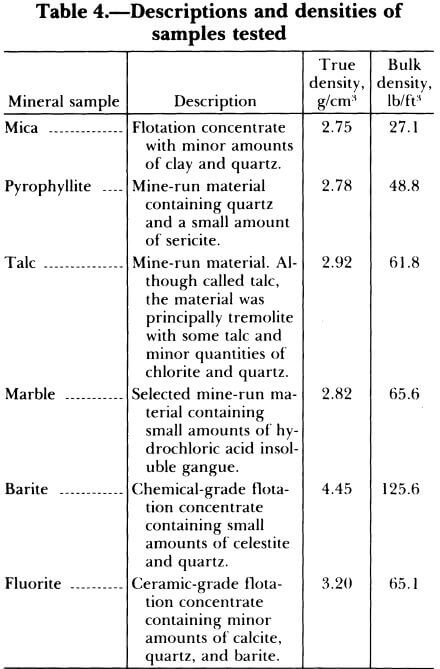

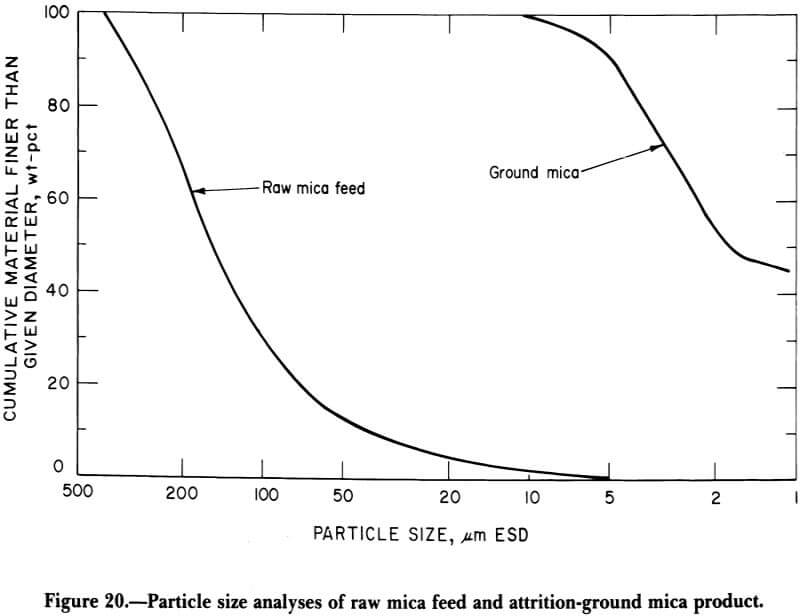

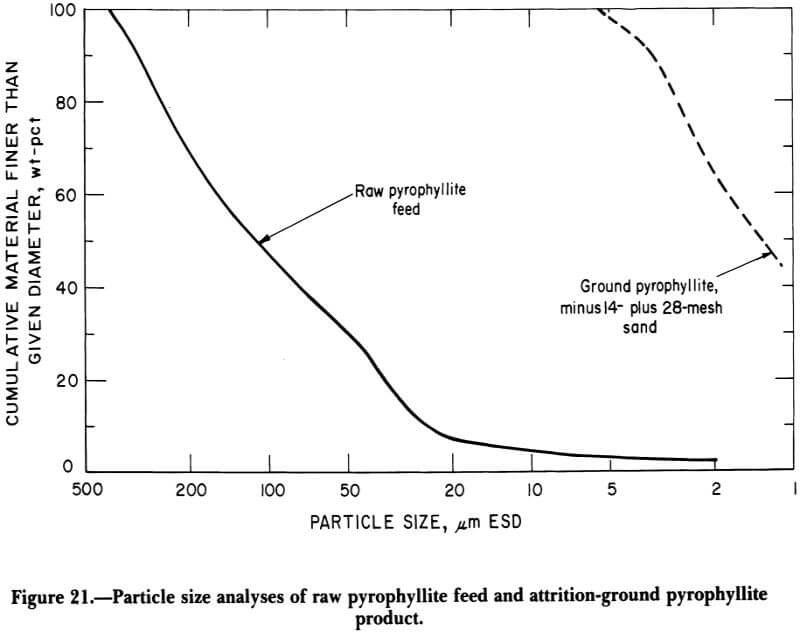

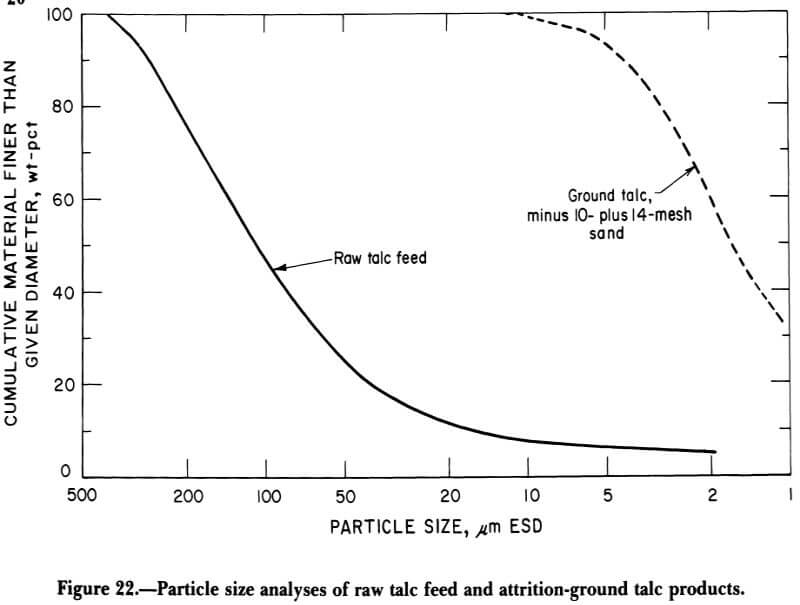

The industrial minerals used in the investigation were obtained from commercial producers. Brief descriptions of each of the products tested, with their true and bulk densities, are given in table 4, and the better test results are summarized in sections dealing with each mineral.

Attrition Grinding of Mica

Figure 20 shows that the feed, which contained 11.1 percent minus 325-mesh material and essentially no minus 2-micrometer mica, was ground to a product analyzing 100 percent minus 325-mesh and 52.3 percent minus 2-micrometer particles. The electrical energy consumed when grinding the mica sample at a feed pulp density of 50 percent solids with minus 10- plus 14-mesh sand was 304 kilowatt-hours per ton of dry raw feed. Based on the amount of new 2-micrometer mica produced, the electrical energy consumption was about 581 kilowatt- hours per ton. The bulk density of the ground product was 9.9 pounds per cubic foot.

Attrition Grinding of Pyrophyllite

The pyrophyllite was ground to a product containing 64.3 percent of minus 2-micrometer material (fig. 21). The feed material contained only 1.6 percent minus 2-micrometer particles. Bulk density of the ground material was 10.8

pound per cubic foot. Electrical energy consumed was 274 kilowatt-hours per ton of raw feed.

Attrition Grinding of Talc

The talc feed, which contained less than 10 percent minus 10-micrometer particles, was ground to essentially all pass 10 micrometers in size (fig. 22). The bulk density of the ground products was 11.2 pounds per cubic foot. Electrical energy consumed was 244 kilowatt-hours per ton of talc feed.

Attrition Grinding of Marble

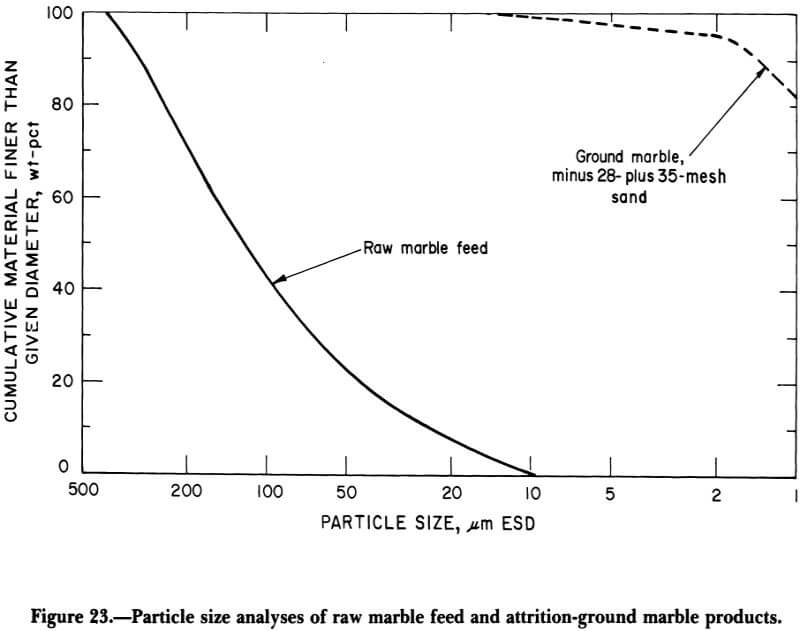

The curves in figure 23 show that attrition grinding a marble feed product containing vir-

tually no minus 2-micrometer particles yielded a product that contained about 95 percent minus 2-micrometer material. Bulk density of the ground material was 20.6 pounds per cubic foot. Electrical energy consumption per ton of marble feed was 339 kilowatt hours.

Barite Attrition Grinding

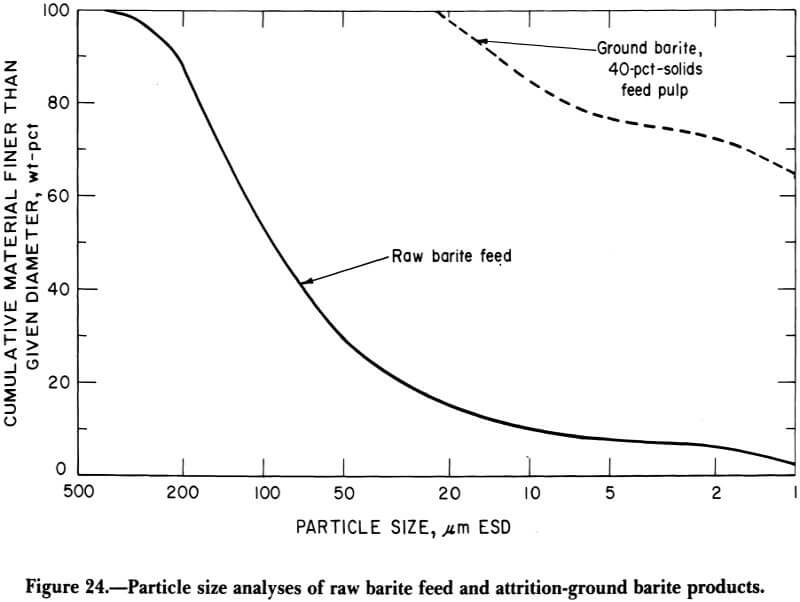

Because barite is soft, 30-minute grinding tests, regardless of the conditions of trial, resulted in 100 percent minus 20-micrometer particles. Analysis of the data indicated that a statistical difference in test conditions regarding the particle size reduction of the barite could not be established until the minus 1-micrometer content of the ground products was compared.

To establish more reliable data regarding the grinding conditions more suitable for optimum particle size reduction, 15-minute grinding tests were made. Figure 24 shows that comminution of the barite feed even in 15 minutes was considerable. A product containing 85.0 percent minus 10-micrometer and 64.6 percent minus 1-micrometer particles was obtained. The bulk density of the ground sample was 28.7 pounds per cubic foot. Electrical energy consumption was only 190 kilowatt-hours per ton of barite feed.

Grinding of Fluorite by Attrition

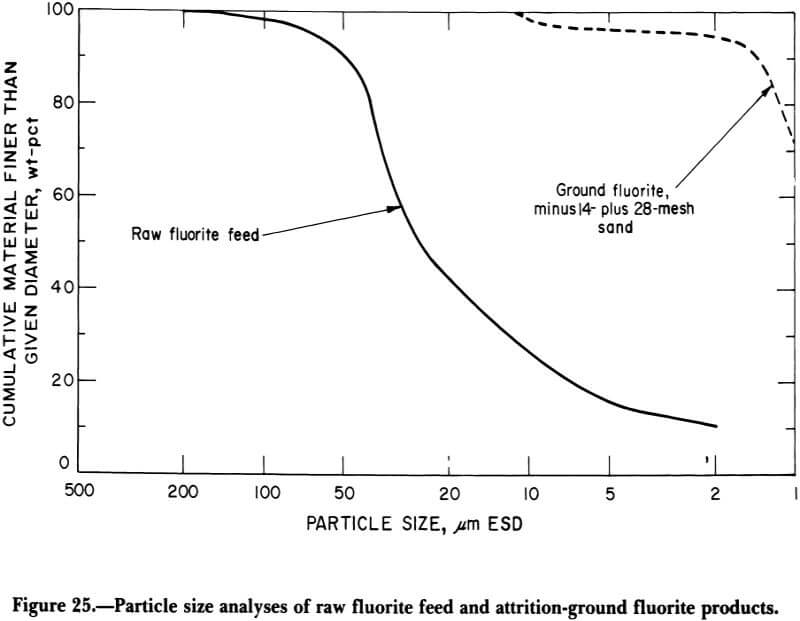

In the tests with fluorite, extremely good particle size reduction was obtained (fig 25). The raw material, which contained only 10.5 percent minus 2-micrometer particles, was ground to a product analyzing 93.8 percent minus 2-micrometer fluorite particles. Bulk density of the ground material was 18.0 pounds per cubic foot. Electrical energy consumed was 306 kilowatt- hours per ton of flourite treated.

Other Comminution Studies

As a result of the publication of Bureau research on attrition grinding of industrial minerals, various research groups from the public and private sectors, as well as commercial operators, contacted the Bureau’s Tuscaloosa Research Center to obtain additional information concerning the fine-grinding technique. To stimulate technology transfer, tests were made on other materials, including natural and synthetic mica, sericite, fluorite, anthracite, leonardite, metal powders of aluminum and copper, marginal clays, waste gypsum, and olivine. The data reported herein can be verified by logs, internal reports, memoranda, and correspondence filed at the Bureau’s Tuscaloosa Research Center in Tuscaloosa, Ala.

Grinding Mica

Beneficiated mica concentrates from a number of operators located in Alabama and North Carolina were attrition milled on both a batch and continuous basis. The conclusions reached in the batch studies were generally the same as those obtained in the study described earlier, namely that the mica products ground readily to an extremely fine product, bulk densities of the milled products were as low as conventionally ground mica products, and the energy consumed in grinding was not extremely high. Generally speaking, commercial wet-ground mica products contain 88 percent minus 35-mesh material.

During these investigations, some exploratory batch tests were made to determine the merit of using nylon media to “polish” the mica surfaces after a conventional sand-grind, to explore the use of nylon pellets as the actual grinding medium and to establish the feasibility of autogenously grinding mica in the attrition mill. In addition, a cursory study was made to determine the effect of a number of operating variables on grinding mica on a continuous basis. In the study, mica was ground with a sand medium in open and closed circuits, and autogenously in closed circuit. The results are described in the following sections.

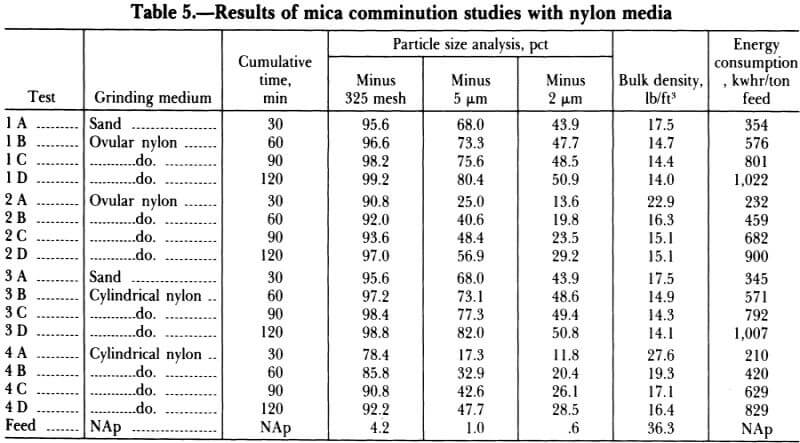

Comminution With Nylon Media

The mica product used was obtained from an operator in North Carolina. The material, which was considered high-density mica, had a true density of 2.89 grams per cubic centimeter. The product was screened to remove plus 35-mesh material to facilitate recovery of the ground mica from the sand grinding medium used in the batch tests. The tests were made in the 10- inch-diameter grinder to determine the effect of “polishing” the mica with nylon pellets subsequent to comminution of the mica with minus 14- plus 28-mesh sand. For comparative purposes, attrition grinding tests also were made using nylon pellets without a preliminary sand grind. The grinding tests were made using a mica-water pulp density of 50 percent solids. In the segment of the tests using a sand medium, the total pulp density was 77.8 percent solids. When grinding with nylon, the volume occupied by the sand was displaced by an equal volume of nylon. The total pulp density when using nylon particles was 67.4 percent solids. The results of tests made using ovular- and cylindrical-shaped nylon pellets are given in table 5. The diametrical dimensions of the ovular nylon used were approximately 2.9 by 3.5 millimeters; the cylindrical nylon was 2.5 millimeters long and 2.2 millimeters in diameter.

The results of the tests show that the nylon medium was effective at particle size reduction of the mica (tests 2A and 4A) but was considerably less effective than sand (tests 1A and 3A). In all tests, particle size of the mica decreased progressively as the grinding time was increased. The data also show that, after a preliminary sand grind, the shape of the nylon medium made no difference in comminution of the mica, since the size analysis and bulk density results of tests series 1 and 3 were essentially the same. However, if no preliminary sand grind was done, the shape of the nylon was a definite factor in reducing the particle size of the mica. Particle size reduction of the mica was, in most cases, greater and bulk densities of the finished products were lower when processing the mica with the ovular nylon rather than the cylindrical-shaped plastic particles.

As expected, electrical energy consumption for a given grinding time was much less when grinding with nylon than when grinding with sand. Total electrical energy consumed when grinding with ovular nylon with and without a preliminary sand grind was slightly higher than when milling with the cylindrical pellets.

Although the extent of particle size reduction of the mica was more pronounced after grinding for 30 minutes with sand than 120 minutes with nylon, the bulk density of the nylon-treated material was less than the sand-ground product. The data show that in test 1A, a product containing 43.9 percent minus 2-micrometer particles had a bulk density of 17.5 pounds per cubic foot. In tests 2D and 4D, products containing 29.2 and 28.5 percent minus 2-micrometer particles had bulk densities of 15.1 and 16.4 pounds per cubic foot, respectively.

Continuous Open Circuit Grinding Tests

The purpose of these tests was to establish operating conditions for continuously grinding a coarse mica concentrate and to obtain a product with particle size characteristics of wet-ground mica. The mica was ground in the 10-inch-diameter, open-circuit plant at a feed rate of 50 pounds per hour; the mica feed slurry contained 20 percent solids, and minus 14- plus 28-mesh Ottawa sand was the grinding medium.

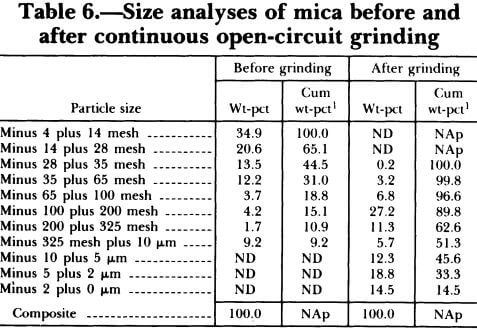

In the open-circuit grinding plant, a pre-mixed, dispersed slurry of mica and water was fed to the attrition grinder by means of a positive-displacement pump. Particle size analyses of the feed and the ground product are given in table 6.

The data show that the mica feed, which contained approximately 35 percent minus 4- plus 14-mesh material, was ground to contain almost 100 percent of minus 35-mesh material. Comminution of the feed to minus 325 mesh was pronounced; the feed, which analyzed only 9.2 percent minus 325-mesh mica, was ground to a product that contained 51.3 percent of minus 325-mesh particles. Electrical energy consump-

tion during grinding was only 80 kilowatt-hours per ton of feed. Based on the production of new minus 325-mesh mica, the electrical energy consumed was 190 kilowatt-hours per ton of new minus 325-mesh material produced.

Continuous Closed Circuit Grinding Tests

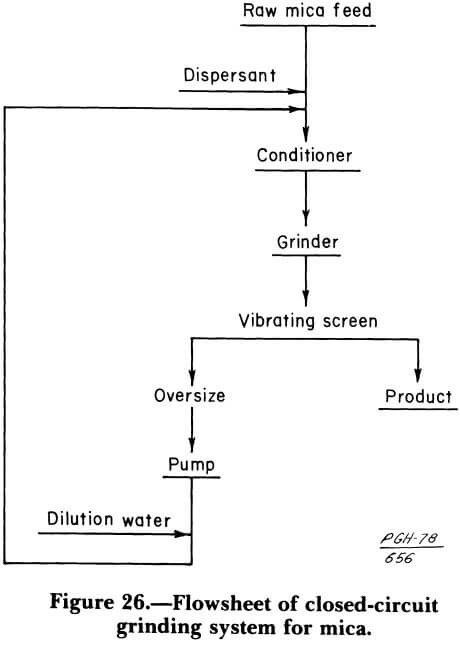

Grinding With Sand Media

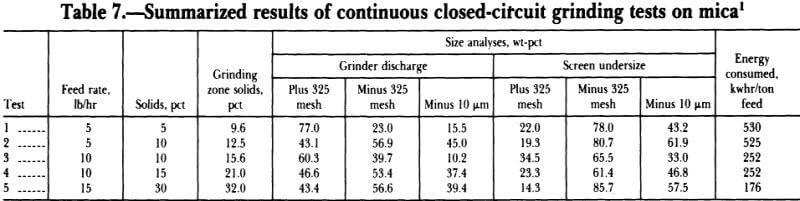

Following the schematic flowsheet shown in figure 26, a number of continuous closed-circuit grinding tests were made to determine the effect of feed pulp density and feed rate on particle size reduction of mica. A 150-mesh screen was used to remove oversize mica, which was recirculated to the grinder. The objective of using the 150-mesh screen was to produce a mica product that would contain approximately 90 percent minus 325-mesh particles with a maximum of about 40 percent minus 10-micrometer particles. Discussions with commercial wet-ground mica producers indicated these limits were ideal for a wet-ground mica product.

The tests were made in the 10-inch-diameter attrition grinder using minus 8-plus 10-mesh

Ottawa sand as the grinding medium. To eliminate problems in feeding the relatively coarse mica, a tank with a conical bottom was attached to the side of the grinder so that slurry in the grinder, above the grinding zone, could flow to the feed tank. The connection between the grinder and feed tank was located below the grinder discharge port; thus, the suction developed by the grinder was used to circulate the slurry without disturbing the actual discharge. Raw, dry mica was fed into the open top of the feed tank where it was wetted and mixed with the circulating slurry and screen oversize. This feed procedure eliminated the use of a positive-displacement pump. The results of the cursory tests (table 7) indicate generally that, at the same feed rate, more minus 325-mesh and minus 10- micrometer material was produced when the feed-pulp density was increased.

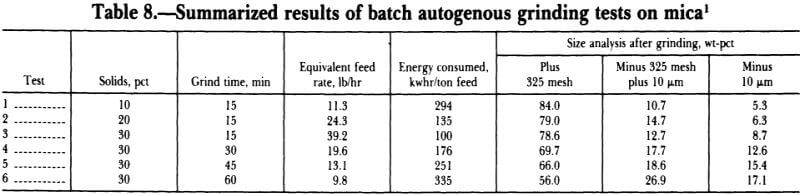

Autogenous Grinding

Exploratory tests were made to determine the feasibility of grinding mica autogenously. Cursory batch studies were made in the 10-inch-diameter grinder to outline a few operating variables prior to investigating a continuous circuit. The results of the batch tests (table 8) indicated generally that, for the same grinding time, more minus 325-mesh material was produced as the percent solids of the feed was increased, and longer grinding time at the same percent solids produced a greater amount of minus 325-mesh material.

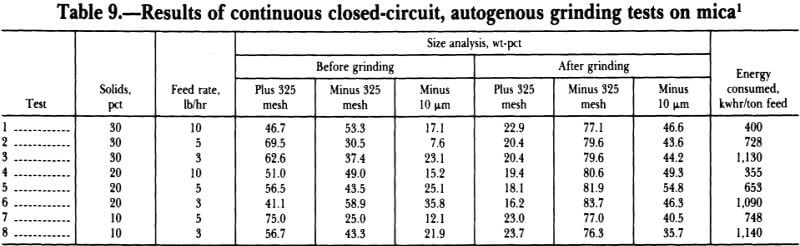

Because the batch tests indicated that autogenous grinding of mica is feasible, a number of continuous closed-circuit, autogenous grinding tests were made on another sample of mica to determine some of the conditions needed to produce a mica product that met the specifications for wet-ground mica. Using the same circuit shown in figure 26, the continuous tests were made to explore the effect of percent solids of the feed and feed rate on comminution of the mica. The results of the tests are summarized in table 9.

The data show that, although an ideal product was never obtained, the screen undersize products approached the desired size limits (88 percent minus 325 mesh). The cursory study indicated that autogenous grinding of mica in the attrition mill is technically feasible, but additional research would be required to optimize operating conditions.

Synthetic Mica Grinding

Prior to its closing in 1965, the Bureau of Mines Research Laboratory at Norris, Tenn., investigated the feasibility of synthesizing mica to supplement domestic natural mica resources. During these investigations, samples of two synthetic products, fluorphlogopite and barium disilicic fluormica, were milled in the 5-inch-diameter, stainless steel attrition grinder to determine the extent of comminution obtainable.

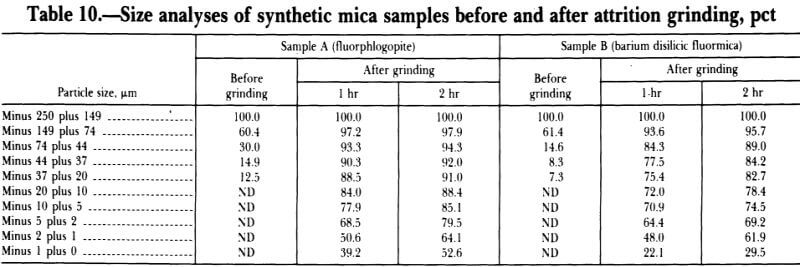

The two samples were ground for 1- and 2- hour periods at a mica-water pulp density of 45 percent solids with minus 14- plus 28-mesh Ottawa silica sand as the grinding medium. The pulp density of the mica-sand-water slurry was about 74 percent solids.

The results of the tests (table 10) show that fluorphlogopite (sample A), which contained about 12 percent minus 37-micrometer material, was ground to contain approximately 89 percent minus 37-micrometer particles in 60 minutes. Grinding for 120 minutes resulted in a product analyzing 91 percent minus 37 micrometers. The difference in particle size reduction between the two tests was greater in the fine fractions of the mica.

Good particle size reduction also was obtained in tests on barium disilicic fluormica (table 10, sample B). The barium-bearing fluormica, which contained only 7 percent minus 37-micrometer particles, was ground to contain 75 percent minus 37-micrometer material in 60 minutes; grinding for 120 minutes resulted in a product analyzing 83 percent minus 37-micrometer particles. Again, the difference in particle size reduction between the two grinding tests was much more evident in the finer size fractions.

Grinding Sericite

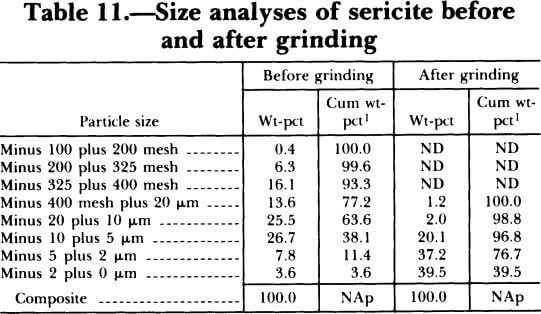

Described in this section are the results of a batch test made on a small sample of California sericite. Sericite is a fine, scaly variety of muscovite with a silky luster. The purpose of the single test was to prepare a sample of attrition-ground sericite containing about 100 percent of minus 10-micrometer particles and having a bulk density lower than the feed material.

To determine the extent of grinding obtainable, a 30-minute batch test was made in the 10- inch-diameter attrition grinder using a sericite- water feed-pulp density of 40 percent solids, with minus 14- plus 28-mesh Ottawa sand as the grinding medium. The particle size analysis (table 11) shows that comminution of the sericite was appreciable. The feed product contained 38.1 and 3.6 percent of minus 10- and minus 2- micrometer particles, respectively. The ground product contained 96.8 and 39.5 percent of minus 10- and minus 2-micrometer material, respectively. The electrical energy required to grind the charge was only 270 kilowatt-hours per ton of sericite feed. Bulk density determinations indicated that the feed material had a bulk density of 20.1 pounds per cubic foot, whereas the ground product had a bulk density of 12.8 pounds per cubic foot.

Grinding Fluorite

The present study was carried out because of an interest generated by the Division of Dental Health, U.S. Department of Health, Education, and Welfare, and the World Health Organization of the United Nations. Both organizations were involved in a study to determine the merit of using finely divided fluorite as a source of insoluble fluoride to fluoridate a municipal water supply system in Georgia. The results of a long-term study using insoluble fluoride were to be compared with results obtained using soluble fluorides for fluoridation.

The samples tested were obtained from a commercial fluorspar producer. As described by the company, sample A was a regular flotation concentrate that was difficult to wet owing to a flotation reagent coating; sample B was a flotation concentrate that had been calcined to destroy any residual flotation reagent coatings, thereby improving the relative wettability of the product.

It was established that installation of an attrition grinder in a Georgia water treatment plant would probably have to be made in a location where headroom was limited. In anticipation of this difficulty, a study was made to determine the feasibility of continuously grinding fluorite by using a gravity feeding arrangement that introduced the material at the side of a 10-inch- diameter attrition grinder, rather than through the bottom as is conventionally done. Tests were made in a 10-inch grinder that had a ¼-inch tube inserted through a hole in the top ring of the stator. The bottom or discharge end of the tube was placed at various depths adjacent to the side of the stator bar exposed to the grinding action, as well as on the sheltered side of the stator bar. The results of the tests showed that, when grinding with the feed tube outlet placed on the sheltered side of the stator bar at depths ranging from one-half inch to 11 inches above the bottom of the grinding chamber, a vacuum of about one-half inch of water prevailed. Suction of air into the pulp was evident under these conditions. The tests further showed that grinding with the feed tube placed on the exposed side of the stator bar produced an average positive pressure of about 1 inch of water. Since past experience has shown that pulp aeration during grinding reduces grinding efficiency, the continuous grinding tests were made with the feed tube outlet placed on the exposed or “pressure” side of the stator bar, rather than the sheltered or “vacuum” side of the bar.

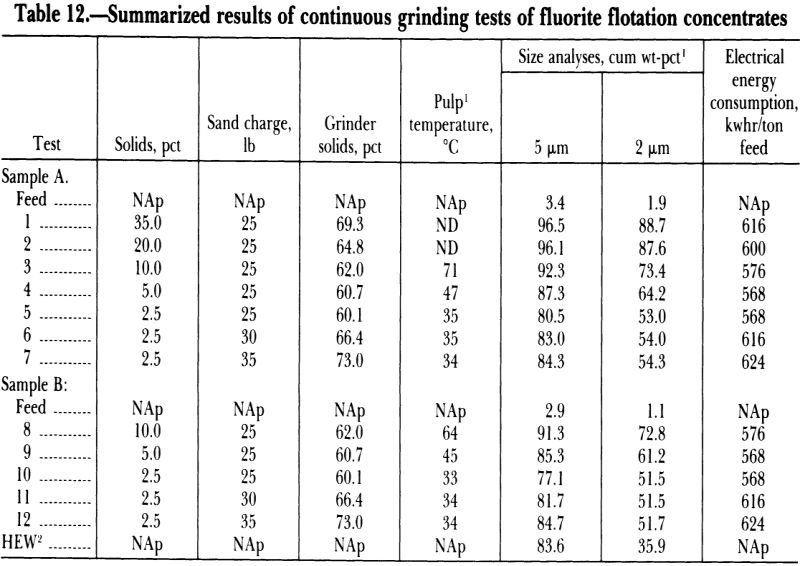

Continuous attrition grinding tests were made using a feed rate of 10 pounds per hour of fluorite and minus 14- plus 28-mesh Ottawa sand as the grinding medium. Tests on sample A were made using feeds containing from 2.5 to 35 percent solids; tests on sample B were made using pulps ranging from 2.5 to 10 percent solids. To ascertain the rise in temperature of the pulps during the grinding tests, no cooling water was used when treating pulps containing 10 percent solids or less. Cooling water was required in the tests of pulps containing 20 to 35 percent solids. Results of the continuous tests are given in table 12. The test results show that particle size reduction of both samples decreased with a decrease in feed pulp density. For example, when treating sample A at a feed pulp density of 35 percent solids, the minus 5- and minus 2-micrometer content was 96.5 and 88.7 percent, respectively. When treating a pulp containing 10 percent solids, the respective minus 5- and minus 2-micrometer content of the ground product was 92.3 and 73.4 percent. Furthermore, the minus 5- and minus 2-micrometer content of the test at 2.5 percent solids was even lower—only 80.5 and 53.0 percent, respectively. The electrical energy consumed in the grinding tests increased from 568 to 616 kilowatt-hours per ton of feed as the percent solids of the feed pulp was increased. Similar trends were observed in the tests made on sample B.

Also recorded in table 12 is the minus 5- and minus 2-micrometer content of a dry-ground product actually used by HEW to fluoridate the municipal water supply. Comparison of these data with those of the tests made using 25 pounds of Ottawa sand show that, in each case, the minus 2-micrometer content of the attrition-ground products was greater than that of the fluorite used by HEW for fluoridation. However, the minus 5-micrometer content of products from tests made at a feed pulp density of 2.5 percent solids was slightly lower than the dry-ground product. To increase the quantity of minus 5-micrometer material in the ground

products, tests were made to determine the effect of increasing the quantity of minus 14- plus 28-mesh Ottawa sand grinding medium, thereby increasing the total pulp density in the grinding zone and the overall particle contact. The results of these tests (table 12) show that ground products containing more than 84 percent of minus 5-micrometer particles were obtained from both feed concentrates by grinding with a 35-pound sand charge. The electrical energy consumed in grinding both fluorite samples increased from 568 to 624 kilowatt-hours per ton of feed as the quantity of sand medium in the grinder was increased from 25 to 35 pounds.

The pulp temperatures recorded during the tests indicated that, when treating a feed pulp containing 10 percent solids or more, the grinding charge would require an external cooling source.

Anthracite

The Bureau’s Pittsburgh (Pa.) Coal Research Center (now with the U.S. Department of Energy) for a number of years investigated comminution of anthracite to determine the finest anthracite particle that could be produced by dry grinding in an air-swept ball mill. To determine the effect of attrition milling on particle size reduction of anthracite, several tests were made on a sample of anthracite obtained from an operating coal company in Pennsylvania.

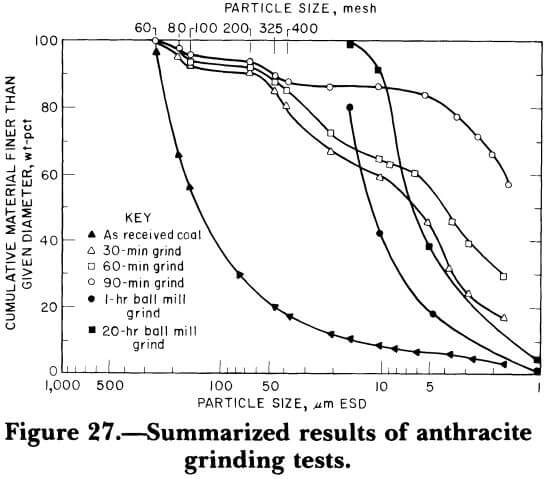

Tests were made in the 5-inch-diameter attrition grinder for 30, 60, and 90 minutes using a minus 60-mesh anthracite feed and minus 14- plus 28-mesh Ottawa silica sand as the grinding medium. The pulp density of the coal-sand- water slurry was about 74 percent solids. Size analyses of the products before and after grinding are graphically presented in figure 27. Although not directly comparable, summarized results of batch grinding tests made in the air- swept ball mill for periods of 1 and 20 hours using ½-inch balls are also shown in the figure to demonstrate relative grinding efficiencies.

The ball milling work indicated that, in general, most of the size reduction during batch grinding took place in the first hour. Extending the grinding time to as much as 20 hours had only a limited effect on particle size distribution. In the attrition grinding tests, however, size reduction of the anthracite at the minus 5- and minus 2-micrometer level continued to increase with time up to a period of 90 minutes. For example, the pulps obtained in 30- and 90-minute grinds contained 18.6 and 65.2 percent minus 2-micrometer particles, respectively.

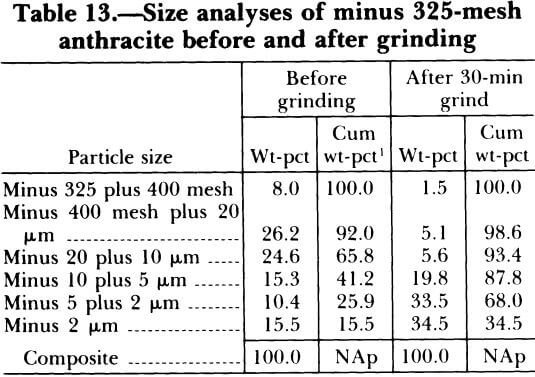

One additional attrition grinding test was made on a sample of the anthracite from which all plus 325-mesh material had been removed, to ascertain the extent of grinding when processing a finer feed. The minus 325-mesh coal was ground for 30 minutes using the same conditions as were employed in the previous tests. Particle analyses of the minus 325-mesh feed and the ground product are given in table 13. The data show that the feed, which contained 41 percent minus 10-micrometer particles, was ground to a product that contained approximately 88 percent minus 10-micrometer material. The percentage of minus 2-micrometer material in the ground product was more than twice that of the feed.

Leonardite

As part of Bureau research to determine the feasibility of using bacteria to generate protein from lignite, a sample of lignite, which was predominately leonardite, was processed by attrition grinding. To determine the extent of grinding obtainable, a 60-minute grinding test was made in the 5-inch-diameter, stainless steel attrition grinder using a leonardite-water feed pulp density of 50 percent solids and a 2.5-to-1 weight ratio of sand to leonardite. The grinding medium used was minus 14- plus 28-mesh Ottawa sand. During the first 5 minutes of the test, however, the slurry gelled. It was necessary to dilute the pulp to a leonardite-water pulp density of 35 percent solids. Size distribution data of both the feed and ground product (table 14) show that comminution of the leonardite was appreciable. The feed product, which contained 38.6 and 14.1 percent of minus 10- and minus 2-micrometer particles, respectively, was ground to contain 92.7 and 84.8 percent of minus 10- and minus 2-micrometer material, respectively. The electrical energy required to grind the charge was 866 kilowatt-hours per ton of leonardite feed.

Manganese Dioxide

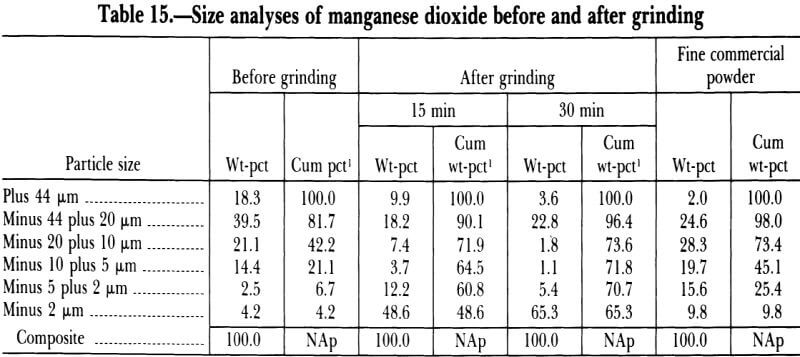

The purpose of the investigation was to determine the extent of comminution obtainable when grinding a relatively coarse commercial manganese dioxide product and to compare size analyses of the ground products with that of a fine commercial manganese dioxide powder used in the manufacture of battery cases.

The tests were made in the 5-inch-diameter, stainless steel attrition grinder using 15- and 30- minute grinding periods. The manganese dioxide-water pulp density used was 45 percent solids; total percent solids (manganese dioxide- sand-water) was 74 percent. The tests were made using a peripheral rotor speed of 1,400

feet per minute and with tetrasodium pyrophosphate, added in the amount of 6 pounds per ton of manganese dioxide feed, as a dispersing agent. Minus 14- plus 28-mesh Ottawa sand was the grinding medium. Size distribution of the coarse and fine commercial manganese products as well as the ground materials are given in table 15.

Comminution of the manganese dioxide feed was appreciable. The manganese dioxide feed containing about 4 percent minus 2-micrometer particles was ground to contain 49 percent minus 2-micrometer material in 15 minutes. The ground product contained more minus 10-micrometer particles than a commercially available fine manganese dioxide powder. Greater particle size reduction in the 2-micrometer range was obtained when grinding for 30 minutes. Power requirements based on 1 ton of manganese dioxide feed was only 165 kilowatt-hours for the 15-minute grind and 322 kilowatt-hours for the 30-minute grind.

Metal Powders

Powder metallurgy is defined as the production of coherent metallic objects by compacting metal powders. In general, the finer the metal powder, the better the physical properties of the aggregate. Exploratory tests were made to determine the feasibility of producing extremely fine metallic powders from coarser material by the attrition grinding process.

Grinding Aluminum

This study was made on a sample of commercially available aluminum powder that is normally used as a paint pigment. The sample was ground in a 5-inch attrition grinder for 1 hour at a metal-water pulp density of 49 percent solids; the metal-water-sand pulp density was approximately 81 percent solids. The grinding medium used was minus 14- plus 28-mesh Ottawa sand. Particle size analyses of the feed and the ground powder are given in table 16.

The metal powder did not degrade in size as readily as the minerals previously tested. However, a pronounced reduction in particle size was evident, particularly in the 10-micrometer range. The aluminum feed, which contained less than 1.5 percent 10-micrometer particles, was ground to contain approximately 64 percent 10-micrometer particles.

Grinding Copper

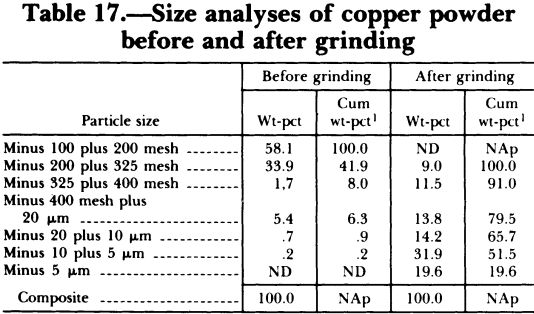

In the present investigation on copper powder, a statistical approach to optimize grinding variables was emphasized.

The product tested was a copper powder produced commercially by electrolytic precipitation. The initial batch tests were made in the

Bureau’s 5-inch-diameter grinder to investigate the influence of copper feed pulp density (percent solids), the amount of Ottawa sand grinding medium added to the charge, and the size of the sand grinding medium on particle size reduction and energy consumption. Results of 60-minute grinding tests, using water as the suspending medium, indicated that best particle size reduction was achieved when grinding a copper feed pulp containing 50 percent solids, with minus 14- plus 28-mesh Ottawa sand as the grinding medium. Size analyses of the feed and ground product (table 17) shows that the feed containing less than 1 percent minus 5-micrometer particles was ground to a product containing 19.6 percent minus 5-micrometer particles. Electrical energy consumed in grinding the powder was 372 kilowatt-hours per ton of feed.

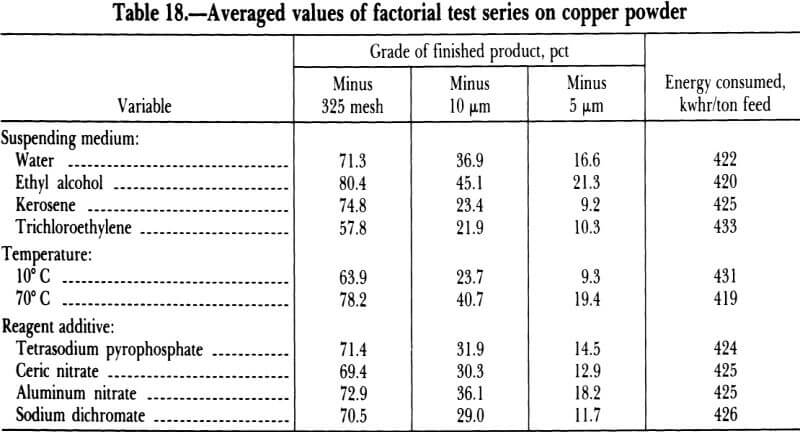

Using the conditions that gave the best particle size reduction, another test series was made to investigate the effects of temperature, suspending media, and reagent additives as grinding aids on particle size reduction and energy consumption. The tests were made to compare the use of water (sp. gr. 1.0), ethyl alcohol (sp. gr. 0.816), kerosene (sp. gr. 0.82), and trichloroethylene (sp. fr. 1.464) as suspending media, and to compare tetrasodium pyrophosphate, ceric nitrate, aluminum nitrate, and sodium dichromate as reagent additives. The liquid media were chosen because of their variation in specific gravity and chemical composition. Three of the reagent additives (ceric nitrate, aluminum nitrate, and sodium dichromate) were selected as grinding aids based on the results of Schafer and Quatinetz in their grinding studies of nickel powder in a ball mill. Tetrasodium pyrophosphate was selected because of its well- known dispersing effect on mineral particles. The reagents were added in the amounts of 5 and 135 pounds per ton of copper feed, and the pulp temperatures were maintained at either 10° C or 70° C to conform to the low- and high- range requirements of the test design. The results of this test series are given in table 18.

Analysis of the data revealed that, regardless of the reagent additive or pulp temperature used during grinding, ethyl alcohol gave some¬what better particle size reduction than the other media tested. Tests with water yielded slightly more particle size reduction than tests with kerosene or trichloroethylene. Energy consumption per unit of feed did not vary appreciably.

Tests made at 70° C gave better results over tests made at 10° C regardless of the liquid medium or reagent used. Particle size reduction was, on the average, almost twice as great at the 10- and 5-micrometer level when grinding at 70° C than when milling at 10° C.

Although not conclusive, tests made using additions of aluminum nitrate as a grinding aid resulted in somewhat more particle size reduction than those made using other reagents tested, regardless of the grinding temperature or liquid grinding medium used. The average energy consumption based on a unit of feed was essentially the same with all four reagents tested.

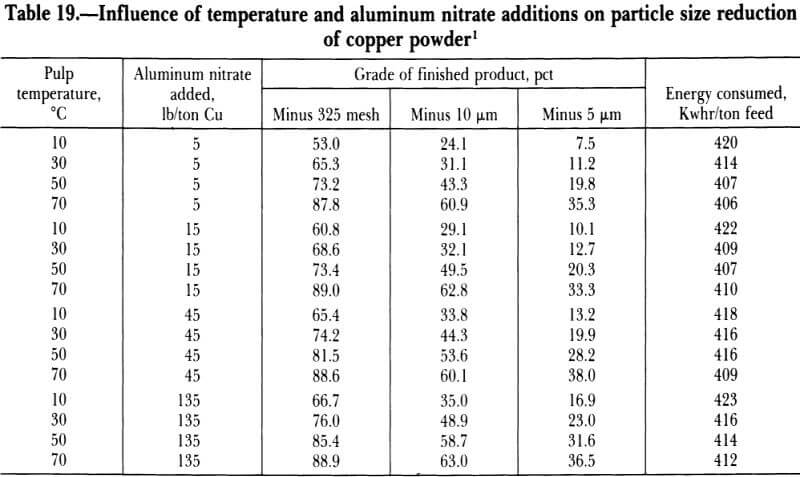

To determine the pulp temperature and the level of aluminum nitrate addition most conducive to good particle size reduction when using ethyl alcohol as the liquid medium, another series of tests was made wherein pulp temperatures ranged from 10° to 70° C and aluminum nitrate additions ranged from 5 to 135 pounds per ton of copper. The results of the tests (table 19) verify that pulp temperature had a pronounced influence on particle size reduction. For example, when the grinding pulp was maintained at 10° C, the minus 5-micrometer-particle content of the finished product was 7.5 percent; when grinding the copper at 70° C, the minus 5-micrometer content was 35.3 percent.

Regarding the quantity of reagent added to the pulp as a grinding aid, the data show that, at the 5-micrometer size range, size reduction was substantially greater when grinding with the addition of 135 pounds of aluminum nitrate than with only 5 pounds of the reagent added per ton of copper. When grinding at a pulp temperature maintained at 70° C, particle size content of the finished products was about the same regardless of quantity of reagent added.

Energy consumption per unit of feed did not vary with increase in the quantity of reagent added but generally showed a slight decrease at the higher pulp temperatures.

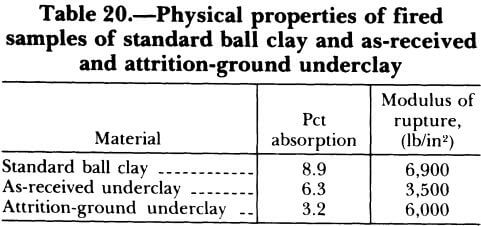

Beneficiating Marginal Clay Deposits

In another area of Bureau research, techniques were investigated for improving the plasticity of coarse kaolinitic clays so that they might be used as a bond clay in ceramic bodies. As part of these studies, a standard ball clay was compared with a typical Alabama underclay before and after attrition milling. The clay was ground batchwise in the Bureau’s 20-inch-diameter mill using minus 14- plus 28-mesh Ottawa sand as the grinding medium. Particle size analyses indicated that the material, which initially contained 30 percent minus 2-micrometer particles, was ground to contain 94 percent minus 2-micrometer material. The standard ball clay contained about 38 percent minus 2-micrometer particles. A comparison of physical properties of the ball clay and the raw and ground under-clay samples after firing at about 2,100° C is given in table 20.

The data show that the modulus of rupture of the attrition-ground underclay was increased by a factor of 1.7 over that of the unground clay and approached that of the standard ball clay.

The ground product could very well be used as a bond clay in many ceramic bodies.

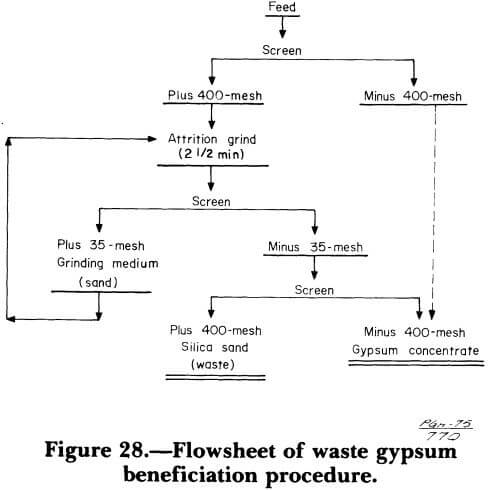

Beneficiating Waste Gypsum

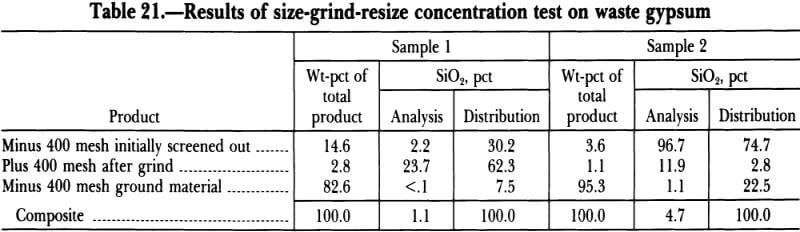

In an investigation conducted by the University of Utah under a Bureau of Mines grant, it was reported that the sand content in waste gypsum produced in the manufacture of phosphoric acid affects compressive strength of plaster by rendering it noncohesive. In view of these findings and considering that most of the silica content in waste phosphogypsum is present in the plus 400-mesh fraction, an attrition grinding procedure was investigated by the Bureau as a method of preferentially grinding waste gypsum to concentrate the silica content in a coarse fraction. Two gypsum samples were treated using a size-grind-resize technique to remove the deleterious silica constituent. The flowsheet used is shown in figure 28. The medium used in the attrition grinding step was minus 20- plus 28-mesh Ottawa sand. The pulp density in the grinding chamber was maintained at 65 percent

solids. Results of typical beneficiation tests of the two samples (table 21) show that sample 1 yielded a product containing less than 0.1 percent SiO2; the total rejection of silica amounted to 92.5 percent. Sample 2 yielded a final product containing 1.1 percent SiO2 with an attendant lower level of silica rejection. The feed, however, did contain 4.7 percent SiO2.

Beneficiating Olivine Foundry Sand

As part of a research program to develop improved foundry practices, investigations were made at the Tuscaloosa Research Center to determine the utility of the attrition grinder as a means of selectively and autogenously grinding soft and/or hydrated minerals in “dunite,” a mineral matrix containing olivine and variable quantities of softer minerals such as serpentine, talc, chlorite, actinolite, and vermiculite. Olivine, a magnesium iron orthosilicate, is used as a foundry sand in both the ferrous and nonferrous casting industries. The beneficiated olivine was subsequently evaluated to establish various molding properties and casting characteristics. Synopsized in this report are the results of the beneficiation tests. As a result of this research, the beneficiation technique to produce an up¬graded olivine was patented.

In preliminary grinding tests, several samples of dunite were ground autogenously in the 5- inch-diameter attrition mill. The ground products, which originally analyzed 2- to 3-percent loss on ignition (LOI), were screened to produce a plus 200-mesh olivine concentrate and a minus 200-mesh tailing. The concentrates in all cases met or exceeded the Steel Founders’ Society of America (SFSA) specifications of a maximum 1.35 percent LOI in olivine aggregate and flour products.

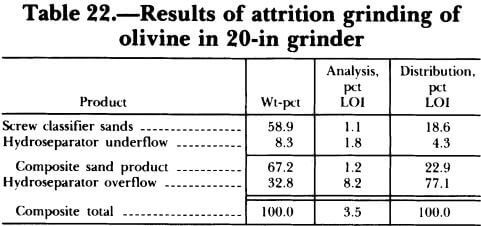

To produce sufficient ground olivine for comparative metal casting studies with commercial olivine products, approximately 1 ton of dunite was autogenously ground batchwise in the 20-inch-diameter attrition grinder. In the test, a slurry of minus 20-mesh dunite ore and sufficient water to yield 40 percent solids was fed to the grinder and ground for 60 minutes. The finished slurry was discharged to a screw classifier. The sand product of the classifier was retained as a finished product. The overflow was directed to a hydroseparator to recover additional coarse material as an underflow product. The hydroseparator overflow product was considered waste.

The average power consumed in grinding was approximately 76 kilowatt-hours per ton of feed.

Data in table 22 show the results of treating the ore by this method. The data reveal that approximately 59 weight-percent of the feed was recovered in the classifier sand product at an LOI significantly lower than SFSA specifications. Although the hydroseparator underflow product did not actually meet SFSA specifications, it could be combined with the classifier sands as shown in the table to yield a combined olivine product having a recovery of 67 weight- percent and an LOI within SFSA specifications.

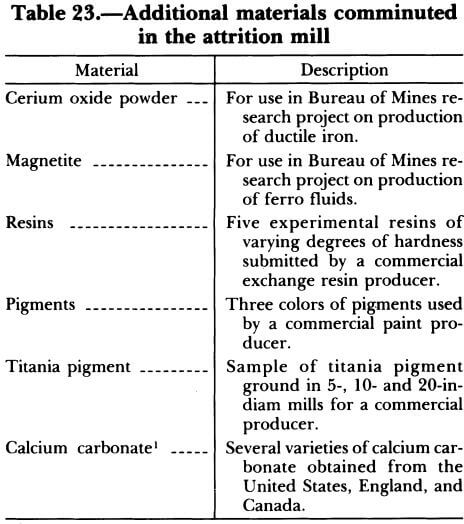

Cursory Tests

The Bureau ran many exploratory and cursory tests on a wide variety of products. Detailed data regarding the size analyses of the feed and ground products as well as the electrical energy required during grinding were in some cases

sparse or unavailable owing to requests of confidentiality by industrial suppliers. These additional tests are mentioned just to indicate the diverse nature of the products evaluated, which are listed in table 23.

In the case of testing the titania pigment, the tests were made so that a pigment producer could obtain enough data for use in scaling up the attrition grinder to 60-inch-diameter commercial units. Part of this work is described in the “Commercial Applications’’ section below.

Comminution of Ceramic Materials

In recent years, research at the Bureau’s Tuscaloosa Research Center in part focused on developing improved technology for preparing a variety of powders for use in ceramic products. This research stressed an evaluation of attrition grinding as a means for producing easily sinterable, submicrometer powders. The research was also geared toward developing a mathematical model of the milling process and toward evaluating the catalytic properties of attrition-milled silica flour. The following sections describe the results of those investigations.

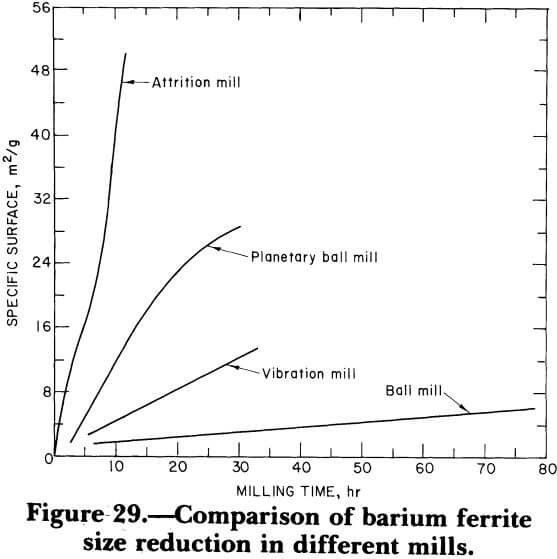

Grinding Ceramic Powders

Research was aimed principally at investigating the attrition grinder for producing submicrometer ceramic powders that could offer low-energy fabrication potential with improved properties for sintered ceramic products. The studies, which used Ottawa sand as the grinding medium, provided data on such ceramic powders as barium ferrite, calcite, dolomite, fluorspar, silica, and zirconia. These tests for the most part verified earlier data in demonstrating that the attrition milling process was much more efficient than other fine-grinding processes. For example, figure 29 presents a comparison of barium ferrite size reduction in

the attrition mill and in ball, planetary, and vibration mills. A considerably higher rate of size reduction was achieved in the attrition mill compared with the other three mills. The data show that 0.1-micrometer-diameter particles were produced in 2 hours with attrition milling, 10 hours with planetary milling, and 30 hours with vibration milling; 0.1-micrometer-diameter particles were not obtained by ball milling for 30 hours.

The sintering properties of the resultant ground products also were evaluated. In general, the attrition-milled oxide powders sintered at reduced temperatures to form ceramic bodies of high strength. As an example, compacts were pressed from attrition-milled zirconia. Green densities of approximately 47, and 50 percent TD (theoretical density) were produced at pressures of 4,000, 8,000, and 16,000 pounds per square inch, respectively. No additives to aid compaction were employed. Pressed compacts were sintered in air at temperatures ranging from 1,000° to 1,400° C for 2 hours. Results revealed that the densities increased rapidly between 1,100° and 1,400° C, exceeding 96 percent TD at 1,400° C, compared with approximately 74 percent TD for a commercial, minus 325- mesh zirconia powder sintered at 1,400° C. The average particle size of the attrition-milled zirconia was approximately 0.1 micrometer.

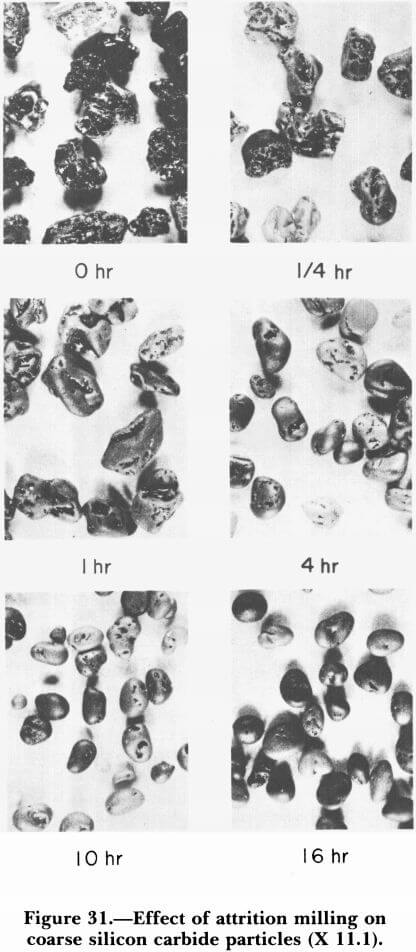

Silicon Carbide Grinding

The ceramic research group also investigated the comminution of silicon carbide using the attrition grinding process. In these studies, a rounded silicon carbide grinding medium was produced by the prolonged autogenous milling of an angular silicon carbide material. Results of the autogenous milling tests are shown graphically in figure 30. The curve shows the effect of milling time on the amount of fine material produced as a result of rounding. The data also show that the degradation rate of the coarse, angular particles decreased rapidly with milling time, resulting in a sizable amount (35 percent of the initial charge) of coarse material remaining, which was relatively resistant to further degradation.

![]()

Figure 31 shows how the coarse particles became rounded as sharp corners and edges were worn away. Very rapid rounding occurred initially. Very little change in shape and only moderate change in average coarse particle size occurred after 4 hours.

To compare the effect of medium type on the rate of particle size reduction, samples of minus 200-mesh silicon carbide were milled with plus 200-mesh rounded silicon carbide and with minus 16- plus 30-mesh Ottawa silica sand. Figure 32 graphically shows that in both cases, specific surface areas equivalent to submicrometer sizes were produced in less than 15 minutes and a particle equivalent to 0.1 micrometer in less than 2 hours. The average rate of surface area generation was 8 square meters per gram per hour for the first 3 hours of milling when using either Ottawa sand or silicon carbide as the grinding medium. Ottawa sand produced the greater size reduction because the sand was much coarser than the silicon carbide medium. This conclusion is substantiated by earlier work.

Catalytic Properties of Milled Silica

Another phase of ceramic research at the Tuscaloosa Research Center focused on an evaluation of the catalytic properties of attrition-ground

silica flour (8, 11). Generally, high-surface-area catalysts are produced by precipitation to obtain the solid material in a porous form. In the present study, two crystalline forms of silica were ground and used as catalysts for the cracking of n-hexane and the dehydration of ethanol. Silica was selected for the study because it is commonly used as a catalyst and catalyst support. Two commercially available amorphous silica catalysts

![]()

also were tested for comparative purposes. The tests demonstrated attrition milling with an Ottawa sand medium to be a promising method of producing a high-surface-area silica catalyst. In both hexane cracking and ethanol dehydration, new silica surfaces created by attrition milling were more catalytically active than two commercially available amorphous silica catalysts. Ethanol dehydration activity, however, was lower for the attrition-milled silica because different active sites were required for dehydration. The attrition-milling technique for producing high- surface-area materials has been patented by the Bureau.

Mathematical Model of the Attrition Mill

As an offshoot of the ceramic milling studies, an investigation was made to develop a mathematical model of the attrition grinder. The investigations centered on determining the effects on the rate of grinding and energy requirements of rotor velocity, Ottawa sand, medium concentration, slurry density, and slurry viscosity. In summation, the investigation concluded that—

- Comminution in an attrition mill was found to be First order, indicating that, at least for coarse particles, size distribution versus milling time could be predicted by application of first-order kinetics considerations.

- The milling rate constant for an attrition mill is sensitive to changes in rotor velocity and increases linearly with the power input to the mill. The amount of medium present also influences the milling rate constant. For example, when milling minus 40- plus 45-mesh dolomite, approximately one-half gram medium per cubic centimeter of slurry was found to give optimum milling rate. This corresponded to a medium mean free path of about 0.7 particle diameter.

- The power characteristics of the attrition mill were comparable to those of a radial-flow turbine mixer in a completely baffled, cylindrical, flat-bottom tank. The breakup of laminar flow occurred at NRe>8,000.

- Suspensions of fine powders exhibit the same linear relationship of power and average density as single-phase liquids. If coarse, millable particles are present, then for the purposes of power prediction, the milling kinetics of these particles must be taken into account because they will be rapidly reduced in size and thus pass from the “coarse particle” category to the “fine particle” category, with the expected change in the relation between power and average density.

Commercial Applications

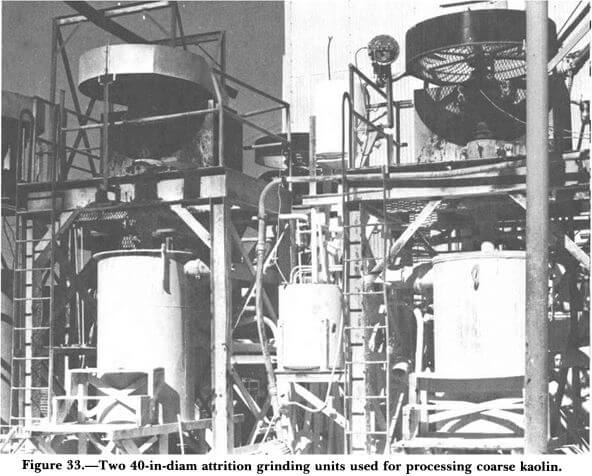

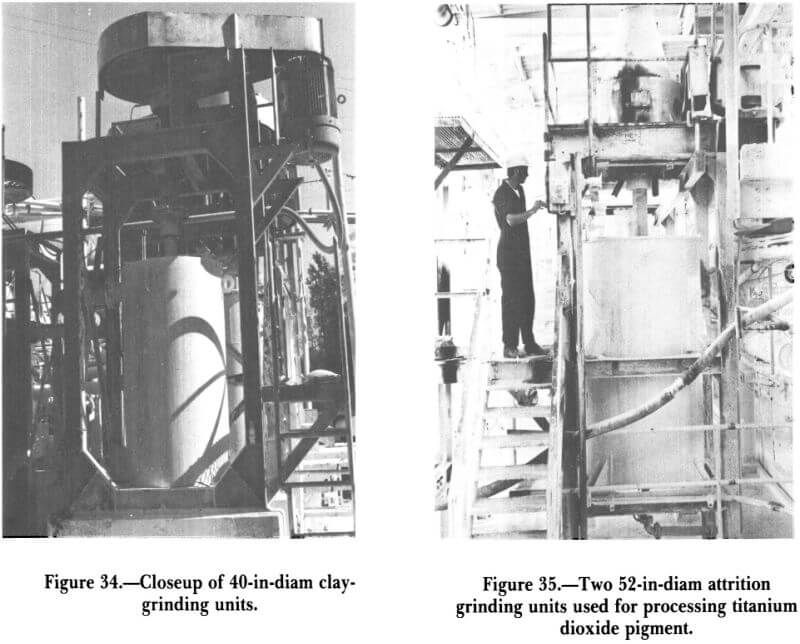

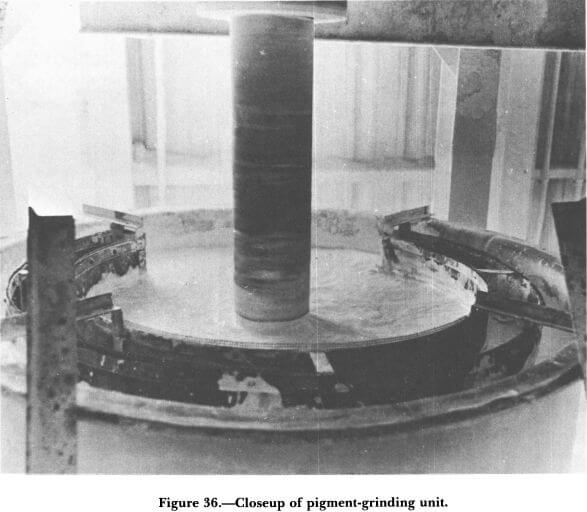

The Bureau-developed attrition grinding technology has been applied on a commercial scale in the paper-coating and titania pigment preparation industries. Two known licensees of the Bureau-patented process are the Georgia Kaolin Co. at Dry Branch, Ga., and the Kerr-McGee Chemical Corp., Titanium Pigment Div., at Hamilton, Miss.

In applying the technology for preparing paper-coating-grade clay from coarse kaolin, the Georgia Kaolin Co. has designed and constructed 40-inch-diameter, 100-horsepower units. Using quartz sand as the grinding medium, each unit is capable of treating about 2 tons of coarse kaolin per hour; about 20 percent of the feed (800 pounds per hour) is recovered as finished product. Figures 33 and 34 show two of the clay-grinding units in operation.

In the processing of titanium dioxide to improve particle size uniformity of the pigment, Kerr-McGee has designed and constructed 52-inch-diameter units that have a capacity of 50,000 tons per year of titanium dioxide. The particle size of the grinding medium used was minus 10- plus 40-mesh sand. Operation of the mills is continuous on a 365-day-per-year basis. Figures 35 and 36 show two of the pigment-grinding units in operation.

The attrition grinding development research has demonstrated the feasibility of the process for comminuting a variety of materials to extremely fine particle sizes. To date, the process has been adopted by industry for producing paper-coating-grade clay and titania pigment.

Within the past few years, research has focused on utilizing the process for milling ceramic materials. These efforts have opened new avenues of potential applications, since many physical properties of ceramic materials have been enhanced as a direct result of attrition milling.