Laboratory Flotation Testing Services

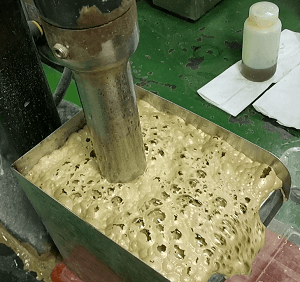

Flotation tests are used to evaluate a materials amenability to froth flotation processing. 911 Metallurgy can provide you with the flotation processing test work that you need, at both the laboratory and pilot plant scale. What is flotation? Flotation is a process that is used to concentrate a constituent or remove a constituent by exploiting … Continue reading Laboratory Flotation Testing Services