This paper describes a new development in the cyanidation of gold ores, which we expect will result in a major improvement in the way many gold ores are treated. The process has evolved through work at Hazen Research, Inc. for Kamyr, Inc. and in brief, the consists of utilizing oxygen rather than air in the carbon-in- leach (CIL) process. We refer to this improved process for all ores amenable to cyanide leaching as carbon-in-1each with oxygen or CILO.

Laboratory Test Work

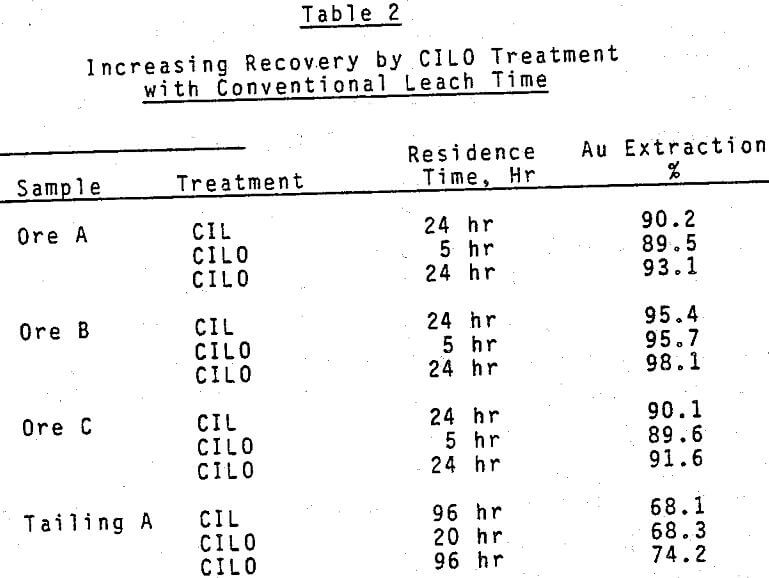

Exploratory bottle-roll tests were made on three South African ore samples to explore cyanide leaching in an oxygenated slurry, followed by CIP for gold adsorption. The samples were leached for six hours with an oxygen atmosphere, then carbon was added and the bottles rolled for another four hours. The oxygen atmosphere was inadvertently maintained for the four-hour CIP treatment.

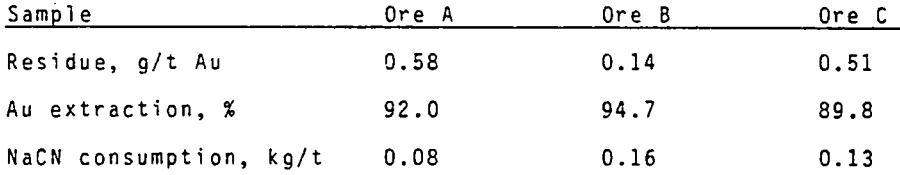

The results of these tests were quite interesting. As summarized below, they showed gold extractions that were higher than previously obtained in 24-hour conventional leach tests.

To explore the general applicability of the CILO process, comparative tests were made on a wide range of gold and gold-silver ores from the United States, Canada, and South Africa. Standard conditions for the tests were: 45% solids, 0.3 g/l initial NaCN concentration, and 11.0 initial pH. All tests were performed at local atmospheric pressure (12.2 psia) in a rotating bottle. The grind varied from sample to sample, but was the same for each pair of comparative tests on a sample.

The cyanide consumption in the CILO tests was significantly reduced; less than half the amount of cyanide required in the CIL tests was typically used with CILO. The lower cyanide consumption is presumably due to shorter treatment time and to the reduction of carbon dioxide in solution. The CO2 content of the air is known to account for part of the cyanide consumption in conventional cyanide processes using aeration. To minimize cyanide consumption in this process, it is desireable to maintain a pH of about 11.0 or higher, because carbon-catalyzed oxidation of cyanide increases sharply as the pH is decreased below this value.

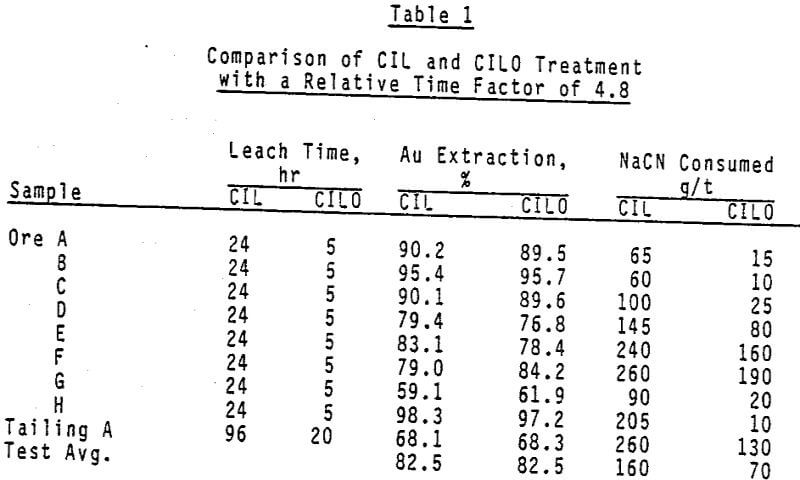

An alternative application of CILO is to increase gold recovery rather than to reduce treatment costs. If the same treatment time is used as in conventional CIL, the effect will be similar to that obtained if the conventional CIL time were increased by a factor of about 4.8. In this way, the maximum possible recovery can be approached more closely, in the same time. The work was performed on three South African ore samples and a Canadian tailings sample.

Industrial Process Application

Applicability of the technology for industry is now being tested in a South African gold mill on a pilot scale. Preliminary results to date in the pilot scale tests ‘nave indicated similar results to those achieved in the laboratory.

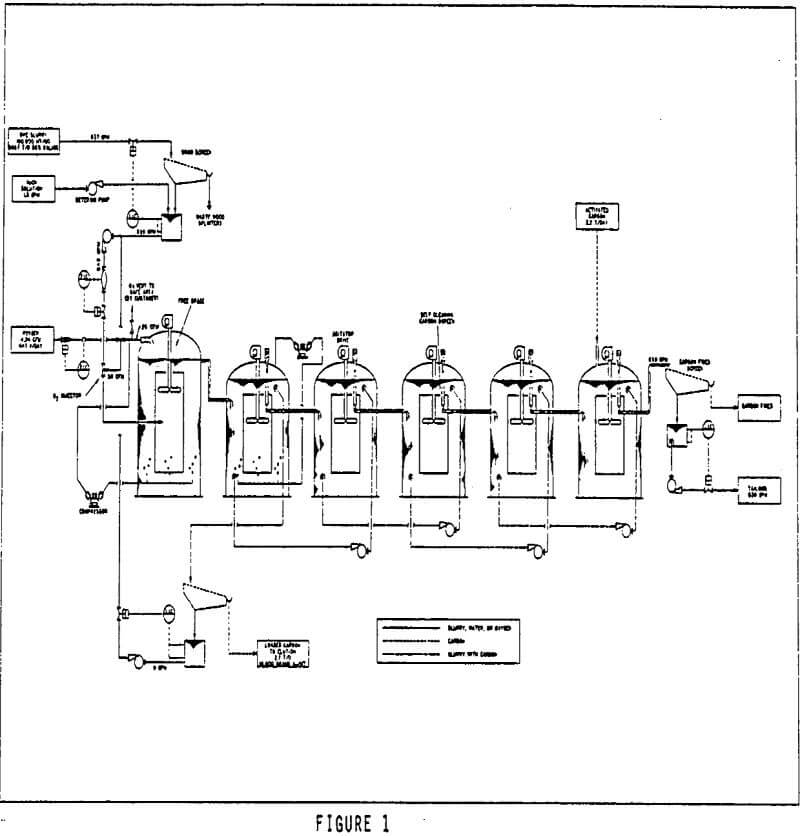

To obtain maximum benefit from CILO, it is desirable to maintain near- saturation and for maintaining saturation during the process with minimal usage of oxygen.

Test work has indicated that the slurry can be readily oxygenated in the first CILO tank by maintaining an oxygen atmosphere and injecting oxygen near the bottom of the tank. Most of the injected oxygen can be recycled from the top of the tank by means of an ejector or compressor, while a small part may be provided from an oxygen storage tank as makeup.

In the subsequent CILO tanks, it is only necessary to maintain any oxygen atmosphere or to maintain each tank completely full of slurry; in most cases, no significant consumption of oxygen occurs during leaching, based on our experience on ores tested to date.