Table of Contents

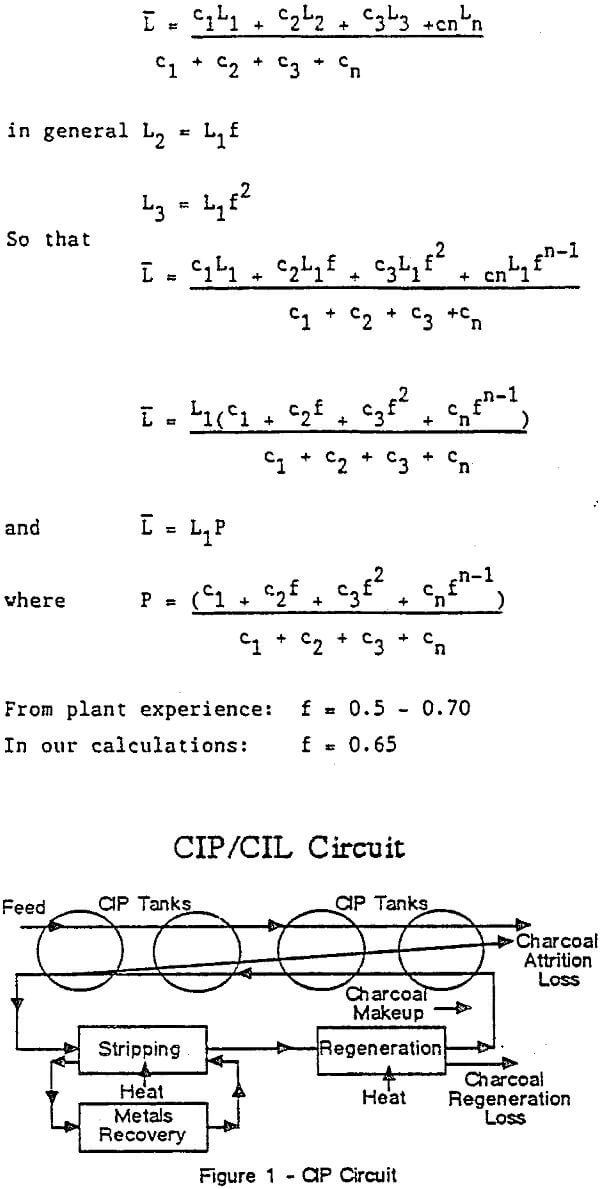

Figure 1 simplifies a CIP circuit, implied are the transfer and screening mechanisms. Gold/silver are dissolved, activated charcoal (carbon) is moved countercurrently to the flow of ore adsorbing gold/silver. The charcoal is removed from the circuit, stripped of its metal content, regenerated and then returned to the circuit to continue the cycle. The amount of charcoal moved through the process is dependent on the quantity of gold/silver present in the ore and the level to which these metals are loaded on the charcoal. There is also a substantial quantity of charcoal, present in the circuit, which holds precious metal inventory. The areas in which costs are incurred in this operation are as follows:

Loading of Carbon

Symbols used in the development of the optimum loading equation are:

A – Attrition Loss – units lbs/ton

Ch – Cost of Charcoal – units $/ton

E – Energy Cost – units S/gallon (diesel & propane, S/kwh (electricity)

F – energy factor – units gal. or kwh/ton of charcoal (66.7 gals, diesel, 98.9 gals, propane, 2638 kwh electricity)

H – Head Grade – units oz/ton

i – Annual Interest Rate – units percent

K – Fraction of charcoal lost during regeneration – units none

L – Metal loading of charcoal removed from circuit – units oz/ton

M – Metal Price – units S/oz.

P – Decimal fraction relating the average metal loading in the system to the loading in CIP tank 1 – units – none

R – Metal Recovery (Percent)

T – Tons of charcoal in CIP tank inventory per ton milled per day – units days

The impact of unit cost elements on the process are as follovs:

During the loading process, attrition of charcoal takes place and its replacement cost in cents/ton is given by:

the attrition loss x cost of charcoal = ACH/2000 x 100 = 0.05ACH cents/ton

and the cost of the metal lost to tailings in the form of attrited charcoal is:

the attrition loss x average loading x metal price = APLM/2000 x 100 = 0.05APLM cents/ton

In regeneration the cost of fuel to regenerate charcoal is:

the amount of charcoal regenerated x fuel cost x energy factor HR/L.100 x F.E. x 100 = HRFE/L cents/ton

and the cost in cents/ton of replacing the charcoal lost during regeneration is:

the fraction of charcoal lost x cost of charcoal kHRCH/L.100 x 100 = kHRCH/L cents/ton

In the circuit the total quantity of charcoal required for adsorption carries a precious metal inventory whose cost of maintaining that inventory is:

charcoal in inventory x average loading x cost of metal x daily interest TLPMi/100 x 365 x 100 = 0.0027TLPMi cents/ton

The total contribution to the costs (C) of operating a CIP circuit that are attributed to charcoal and its metal loading is the sum of the above components:

C = 0.05ACh + 0.05APLM + HRFE/L + kHRCH/L + 0.0027TLPMi

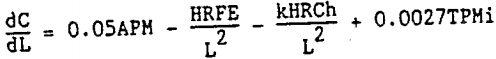

differentiating with respect to loading we have:

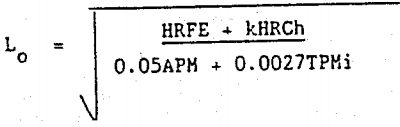

When this differential is made to equal zero, Cost C is at a minimum and the loading L which yields this minimum cost (note: d2C/dL2 is positive), known as the optimum loading can be derived as being:

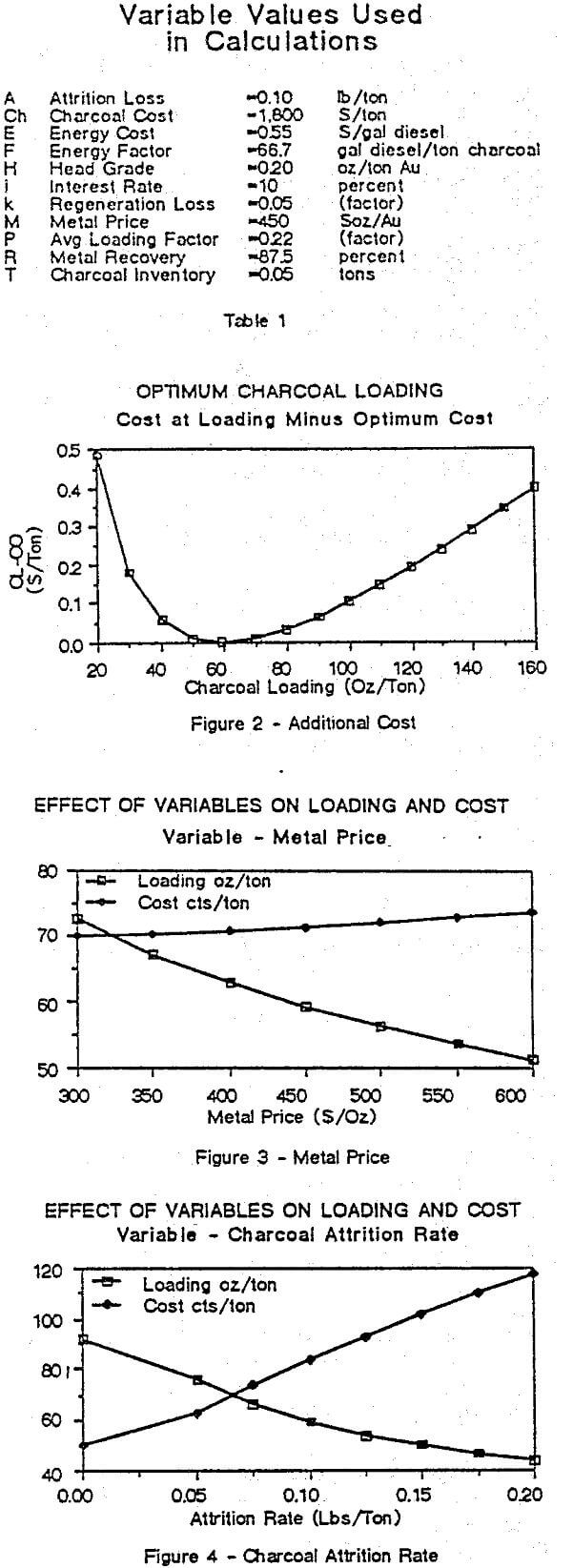

With this equation in hand, we can now evaluate the effect that variables have on the charcoal loading that should be removed from a CIP circuit to yield the lowest operating cost. Table 1 shows the values of variables used to calculate an optimum loading and costs, and to obtain the data presented in the respective graphs.

Average Carbon Loading Factor

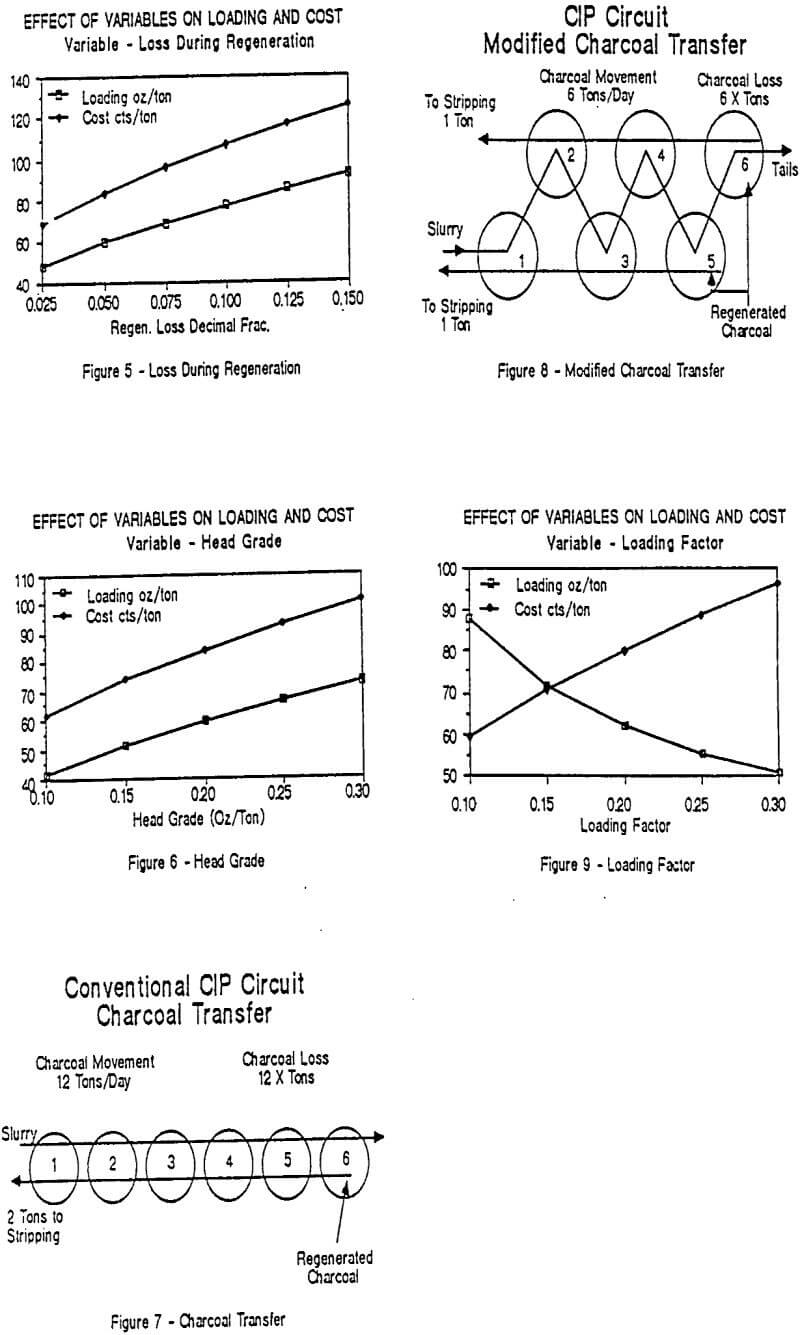

While initially it would appear that the operator can do little to affect the average loading in a circuit, there is something that can be done. If one agrees that it takes a certain total amount of charcoal in tank inventory to achieve maximum adsorption, then the way this amount is distributed throughout the circuit can have significant impact on the average loading of charcoal in the tanks. If the majority of the charcoal is placed in the last stages of adsorption, then the average loading on the charcoal is lower than when charcoal is distributed evenly throughout the adsorption stages. See Figure 9 for effect of reducing loading factors.

Calculation of Carbon Loading Factor

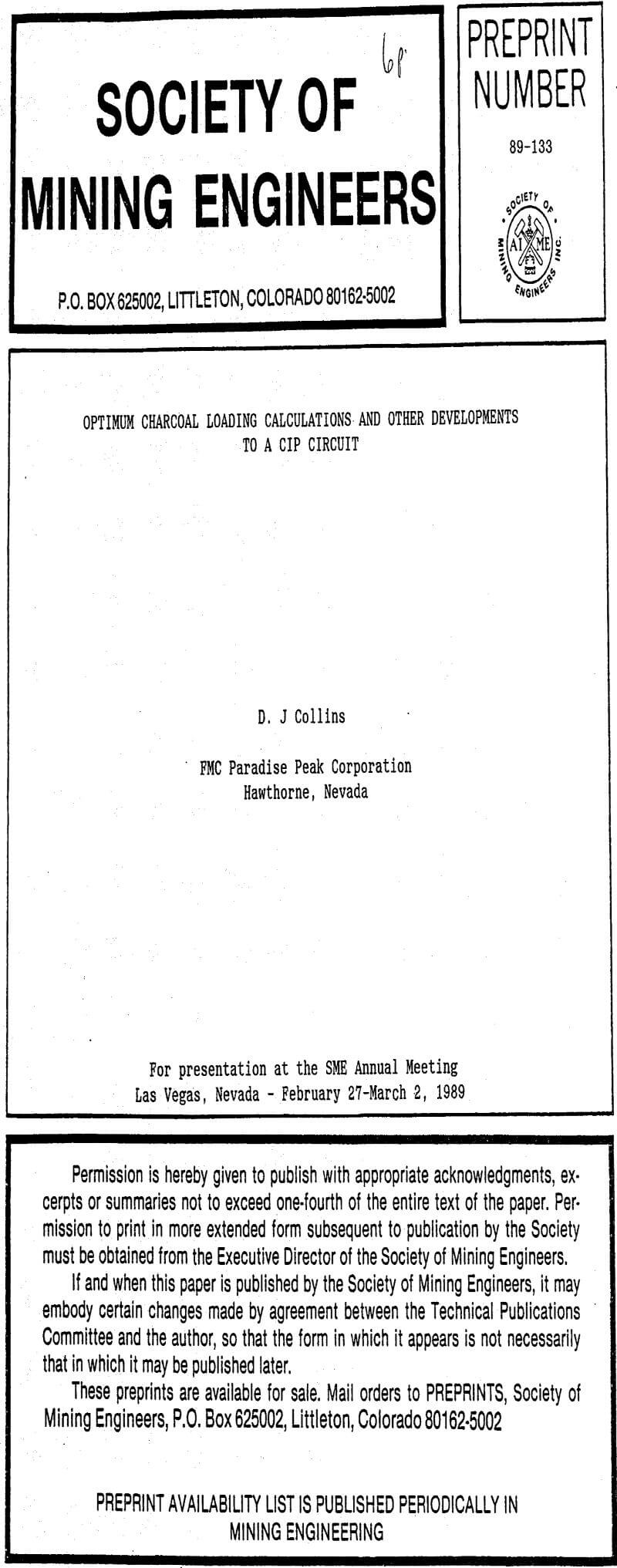

The loading factor (P) which relates the average loading of metal in the CIP circuit to the loading of charcoal removed from the circuit (charcoal in stage one) can be obtained from actual assays and charcoal concentration in the circuit or approximated as follows:

Let c1, c2, c3 — cn equal the charcoal concentrations (gpl, lbs/cu. ft., etc.) in each stage of adsorption (n stages).

L1, L2, L3 — Ln equal the charcoal loadings in each stage.

then the average loading L is: