Laboratory and industrial grinding tests have shown that the process of size reduction can be significantly influenced by chemicals added to the powder or slurry being ground. The terms grinding aid or grinding additive refers to a substance which when mixed into the mill contents causes an increase in the rate of size reduction. The increased rate can be used to grind a higher feed rate to the desired product size or it can be used to produce a finer product size at a fixed feed rate.

Wet Grinding of Ores

The most important “grinding additive” in the strict sense of the definition of a grinding aid is, of course, water. As is well known in practice, grinding in water is advantageous over dry grinding, in tumbling ball mills. One needs hardly look for any chemomechanical action here, however, since the effect must surely be one of bringing and keeping the particles in advantageous positions to receive a breakage action. Mass transport of the slurry within continuous tumbling ball mills is complicated and difficult to predict using known scientific principles.

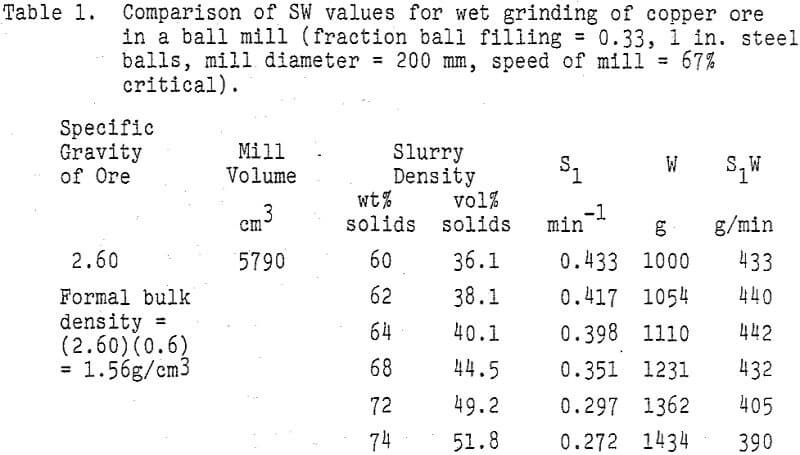

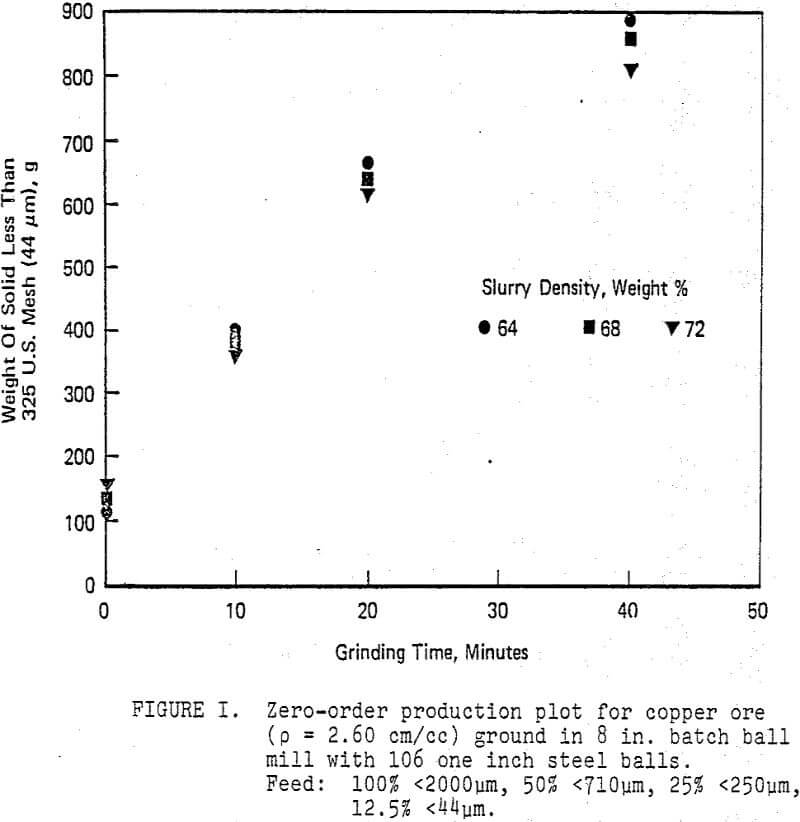

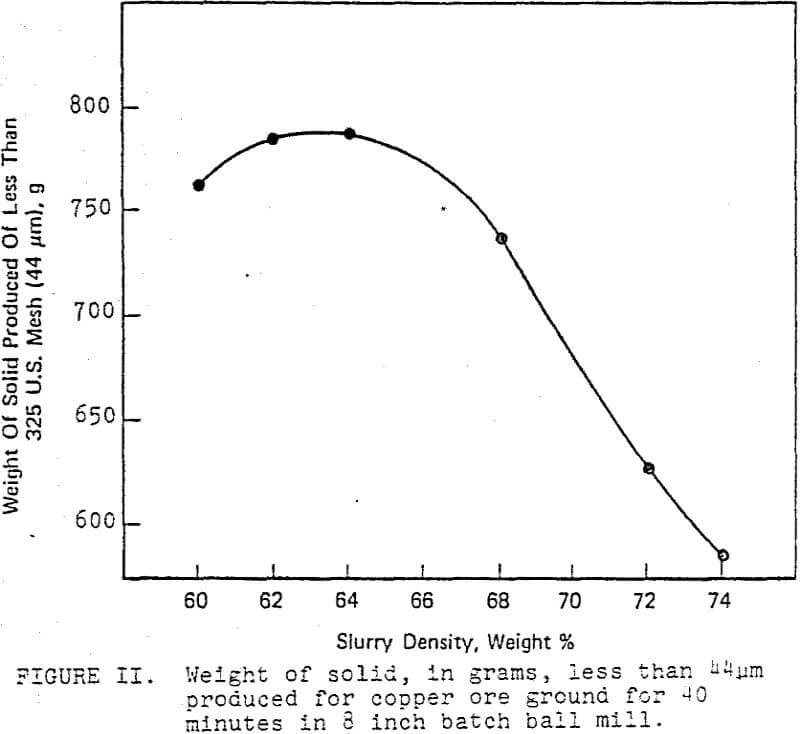

There were carried out a series of experiments in a laboratory batch ball mill, giving results which were then scaled-up and verified on several over-flow discharge ball and rod mills of industrial size. It was studied the effect of the water-to-solids ratio under well controlled experimental conditions in which a constant slurry volume was maintained in the test mill, to correspond with a continuous overflow mill. The volume of solid plus volume of water was held at a value sufficient to occupy 120% of the void volume of the ball charge.

A series of batch grinds, at 10, 20, and 40 minutes, were performed on the same feed for various slurry densities. Using the S and B back-calculation technique, the appropriate shifts in S and B can be quantified. It is difficult to get the correct values of the primary breakage distributions by back-calculation on a distributed feed, so that the confidence levels on B tends to be rather wide.

With regard to the use of this information on continuous over-flow discharge mills, although the residence time of the solid is changed by water addition, the fact that SW remains constant maintains a constant rate of production of fines, because T=W/F and hence ST is also constant for a constant mill feed. On the other hand, for grate discharge mills variations of slurry density also have large effects on the hold-up and breakage rates in the mill.

Fluidity Control Using Chemical Additives in the Wet Grinding

The use of chemicals such as silicates, phosphates, sulfonates, etc. as grinding aids in wet grinding circuits is well known. Their use, however, has been limited by several factors such as the lack of a consistent engineering characterization of their behavior, the relatively large amounts of additive sometimes required to “see” an effect, and the downstream processing problems in flotation filtration, thickening, etc. that often accompany the use of grinding additives. As a result, the Industrial use of additives has been most successful in selected grinding applications involving high grinding costs due to excessive ball or liner wear, long grind times for materials of low grindability or very fine product size, or higher value products such as pigments, speciality chemicals, etc.

A number of industrial grinding circuit trials involving rod and ball mills with overflow discharges have been performed using these efficient chemical additives. The initial results have been very encouraging, with several trials demonstration an ability to increase the rates of production between 9 and 15% in both open and closed circuit operations. This has been done while maintaining a similar product size distribution and keeping the total mill power draw the same as for no additive.

When the additive is shut-off, the % greater than the control size goes back to its original level. At time 4 the additive was again used with a subsequent increase in fineness of grind. After time 5, the feed rate was slowly increased. After three hours with the aid, the feed rate was 10% higher than earlier, but with the product size being the same as the base case without additive.

It is not possible to maintain a grate discharge mill at its best filling if the slurry density, fluid properties and feed-rate are not closely controlled, because the discharge area cannot be opened and closed like a valve. Wet overflow ball or rod mills are made-more flexible and are preferred in practice. It is for this type of mill that the fluidity modifiers will have a very important economic impact in coming years.