In the last several years the coal industry has intensified its effort to solve the growing problem of cleaning and recovering fine mesh coals. On one hand there has been increasing civic pressure for cleaner streams, and on the other hand there has been increasing production of fine mesh coal, resulting directly from adoption of the modern mining methods so essential to the economy of the coal mining industry.

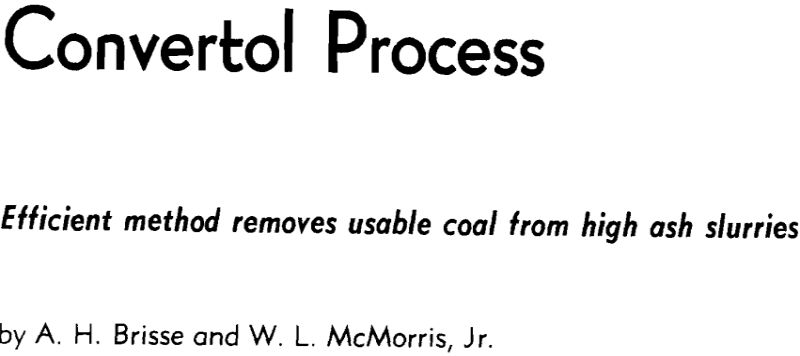

Fundamentals of the Convertol Process: In the Convertol process, droplets of dispersed oil are brought into intimate contact with the solids suspended in the coal slurry to be treated. This contact causes oil to displace the water on the surface of the coal by preferential wetting, or phase inversion, after which the coal particles are allowed to agglomerate in a manner permitting their removal from the slurry by centrifugal filtration. The clay and other particles of mineral matter suspended in the slurry do not have the affinity for oil the coal particles have. Consequently the oil treatment is preferential to coal to the extent that more than 95 pct of the oil used reports with the clean coal recovered.

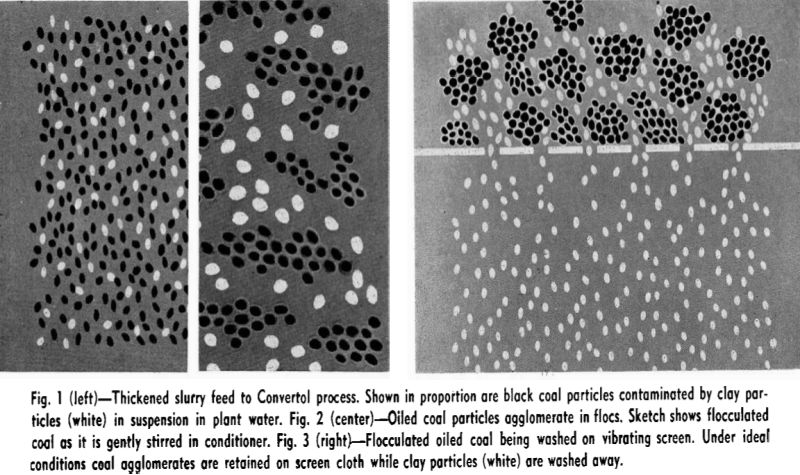

Commercial Application of the Convertol Process in Germany: The original Convertol process was developed by Bergwerksverband zur Verwertung von Schutzrechten der Kohlentechnik, G.m.b.H., a German research organization controlled by the Coal Operators Assn. of the Ruhr Valley. In this process a thickened slurry (40 to 45 pct solids) mixed with a predetermined percentage of oil is fed from a surge tank to the phase inversion mill. After the phase inversion step, the slurry is usually discharged directly to a high-speed screen centrifuge. From 3 to 10 pct oil is used, depending on type of oil, size consist of coal to be recovered, and operating temperature.

The top size of fine coal cleaned in Germany by the Convertol process is limited by the size of the openings in the centrifuge screen basket. Any mineral matter coarser than the basket opening, which is generally 60 to 80 mesh, must remain with the oiled coal. If the coal fines have been effectively cleaned down to about 80 mesh, the cleaning performance of the process is practically unaffected by the presence of coarse coal particles. However, since recovery of coal much coarser than 80 mesh is more economical by conventional methods, it normally becomes more costly to allow substantial percentages of this coarse coal in Convertol process feed.

The high-speed centrifuges employed in Germany for dewatering the Convertol product are centrifugal filters in which the bowl is slotted and backed up by a very fine mesh screen. Fig. 6 shows a unit with the hood removed. In general, they resemble scaled-down models of the CMI or Rheinevelt centrifugal driers common in the U. S.

Most German Convertol installations are processing a thickened slurry of 40 to 50 pct solids analyzing 15 to 18 pct ash (dry basis), containing 55 to 65 pct —200 mesh material with a top size of about 100 mesh. The recovered product usually contains 5 to 6 pct ash and 6 to 10 pct oil (dry basis). Moisture of the product is 15 to 20 pct and ash content of the dry refuse 60 to 70 pct.

Results obtained were highly satisfactory. Initial slurry feed consisted of 40 pct —200 mesh and 30 pct +100 mesh with a small percentage of material above 48 mesh. This feed material, containing 14 to 16 pct ash and 0.70 pct sulfur (on a dry basis), was obtained from the thickener underflow as shown in Fig. 7. About 80 pct of this material was recovered as coal containing approximately 9.5 pct ash, 0.70 pct sulfur, and about 20 pct moisture.

Whereas formerly material from the conditioner was of firm consistency, the changes in feed conditions noted above resulted in a material that was thinner and more fluid as discharged from that unit. This change was accented by further modification of the washing plant water circuits which eliminated nearly all the +100 mesh material from the thickener feed. This last change further reduced feed particle size and increased the dewatering burden on the high-speed screen centrifuge.