Design, fabricate, and test a machine capable of operating in coal seams 48-inches and thicker that can reduce the time, expense, and injury potential inherent in extending and retracting mine-wide section belt conveyors, while eliminating the need to use additional machinery or equipment in accomplishing such moves.

The Problem

Many underground coal mines use a belt haulage system to move cut coal from the face to the loading area. This system usually consists of a main line belt conveyor fed by section belt conveyors. A shuttle car at the face carries the coal cut by a continuous mining machine to a feeder breaker that breaks the large lumps of coal into smaller, transportable pieces and unloads them onto the tail piece of the section conveyor. This tail piece is skid-mounted so it can be readily moved as needed. The conveyor is kept close to the face during mining in order to shorten the haul distance of the shuttle cars. Section belts can be lengthened by adding belting,

wire rope, and support hardware. During pillar retreat mining, these section belts are shortened to keep pace with pillar extraction operations. However, these belt moves, either the extensions or retractions, usually require six to eight workers and three to eight hours to complete. In addition, a 100-foot belt move requires workers to handle up to 4,000 lbs. of material, not including the tail section. Strain and sprain injuries can be incurred during this heavily labor-intensive task. The time required to move the section belt can also create losses in the mine’s production. To help solve this problem, the Bureau of Mines

designed a conveyor belt service machine that can handle the heavy portion of this task while reducing the time and number of workers required to perform it.

Functions of the Machine

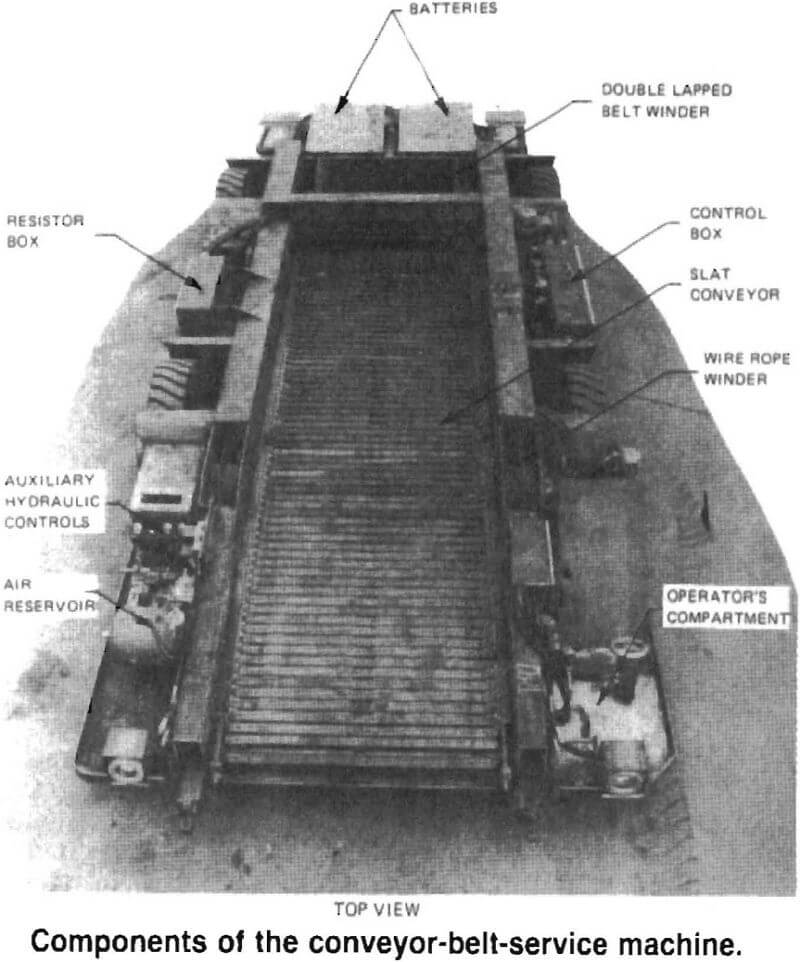

The conveyor belt service machine is self-contained, rubber-tired and capable of handling, storing, and transporting the conveyor belting, wire rope, and support structures needed for section conveyors. A hydraulic system powers the steering and brakes; winds and unwinds the belting and wire rope under controlled tension; operates a load-bed slat conveyor; raises, lowers and locks connection hitches; and powers external hydraulic tools. The conveyor belt service machine:

- operates in coal seams as low as 48-inches

- can load, transport, and unload belting from 20- to 300-feet long

- can load, transport, and unload two 120-foot lengths of ¾-inch diameter wire rope

- has draw-bar pull capability sufficient to push/ drag a conveyor tail piece to a new location

- has battery capacity to operate for a full shift without recharging

- performs critical tasks (those requiring operating downtime) of a 100- foot belt move in 15 minutes

The system can be used on floor-mounted, sectional conveyor belts and also has the potential for use with roof- suspended belts.

Test Results

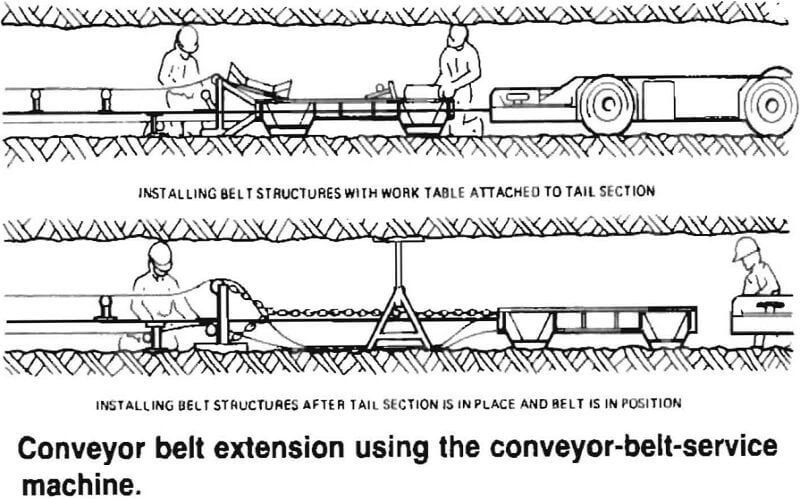

A machine able to perform each of these functions was built and successfully tested above ground and in three different operating underground coal mines under a variety of conditions. In one underground test, the machine was used for a conveyor belt retraction of 160 feet. Three hundred and twenty feet of Winch by 36-inch conveyor belt was double-wound on the machine’s belt reel. The tail section was pushed to its new location and 35 support structures, two sail anchors, and eight 20-foot lengths of 2-inch pipe were loaded and transported along with wire rope and belting to a storage area in the mine.

The results of additional tests indicated that under ideal conditions, a belt extension/retraction of 80-100 feet can be accomplished by four to six workers in 15 to 30 minutes of shut-down time following adequate preparation for the belt move.