This new high energy or power rate crushing brings a different perspective to comminution flow sheet selection. Generally, up until the early 1960’s the classical flow sheet for a beneficiation plant was primary crushing followed by two stages of cone crushing in closed or open circuit, making feed for rod mills, followed by ball mills. The rod mill was needed to reduce feed size to the ball mill because crushing plant output was normally coarser than 80% passing 10,000 microns. Such feed causes power inefficiency if fed directly to a, ball iriill. Even though the rod mill could be a relatively inefficient device for both energy and metal consumption, as was evidenced by Bond it still made the overall circuit energy consumption more efficient.

Under the right operating conditions, high power rate crushing can bring mill feed size down to near 80% passing 7,000 microns and finer, which can be handled

more efficiently by ball mills. Based on average field observations, the crushers can do this for less than half the energy and between one-tenth and one-twentieth of the metal consumed in a rod mill.

It is, therefore, feasible to look at designing more efficient single stage ball mill circuits following two stages of fine crushing. The result will be an overall reduction in total applied crushing and milling energy for the same size reduction.

To make the most efficient use of both the crushing and grinding comminution energy, both reductions should be treated as dynamic components of the same system. When the feed to the grinding mills gets coarser and/or harder and the production rate drops, the crushing plant feed rate should be readjusted to a lower level to maximize power rate, which will flow on as a benefit helping to increase the mill output. Allis-Chalmers has patents granted and applied for on some such arrangements.

The advantages of such schemes will become more obvious when an ore of varying hardness is fed to the crushing and milling systems.

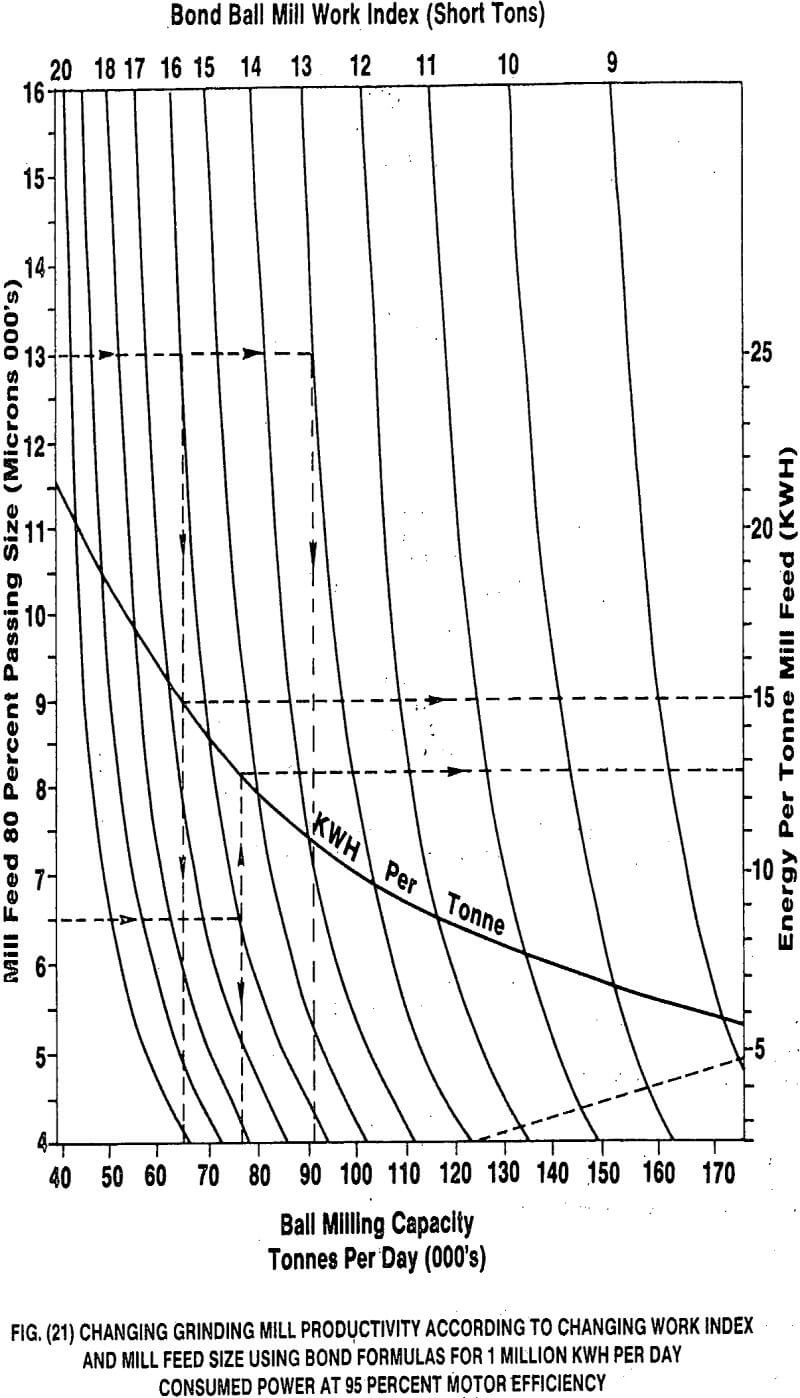

We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed power. For the particular mill configuration, a performance graph, Fig. (21), has been constructed according to Bond’s methods.

Providing the crushing plant design allows for the machines to be fed continuously and the power on each crushing unit is maximized by adjusting both the feed rate and settings. The power drawn and reduction achieved to the grinding mill feed will be maximized.

The grinding mill output will vary considerably with the Work Index. If the feed size was 13,000 micrometers for the same grind production size, theoretical output from Fig. (21) would change from about 90,000 tons per day on the 13 Work Index down to 65,000 tons per day on the 16 Work Index.

Because of the superior energy efficiency of crushing over milling type processing, when the ore becomes harder in this system significant gains will be made if the feed rate to the crushing plant is reduced to closely match the mill production rate. If we consider the crushing plant runs at an average of 100,000 kilowatt hours per 20-hour day, the available energy for reduction will be:

Soft ore Work Index 13 = 100,000/90,000 = 1.1 kwh/t

Hard ore Work Index 16 = 100,000/65,000 = 1.54 kwh/t

For the purposes of this example, we will hypothesize that the the crushing index of the hard ore with the increased energy input of 1.54 kw/t reduces the ball mill feed size to 6,500 micrometers. As a result, the mill output will increase with this reduced size to approximately 77,000 tons per day. The gain in production compared to the 13,000 micrometer feed will be:

(78,000 – 65,000)/65,000 x 100 = 20%

The theoretical gain will actually be greater because the graph in Fig. (21) is constructed according to the Gates-Gaudin-Schuhmann size distribution used by Bond. We have already shown that this does not. apply to crushing processes, which generate increased proportions of fines with higher energy input levels. As a consequence of this, the actual, gain is likely to be closer to 25% and the mill production increased to 65,000 x 1.25 = 81,250 tons per day.

Obviously, this will increase the capacity of the crushing plant and coarsen its reduction, again influencing mill output. Ideally a control system for the whole plant would balance both crushing and milling operations to maximize the benefits described.

Again, we might hypothesize that the crushing and milling output would fluctuate between rates of 78,000 and 90,000 tons per day instead of 65,000 and 90,000 tons per day. The advantages are obvious to all.