- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Crushing.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

Cone Crusher Optimization (5 replies and 4 comments)

Hello Salomon, I really do not understand your question. Could you upload/attach the complete assignment here please. It is OK if it's in Portuguese or other. I need details.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Hi David, Find the attachment document. Thanks

There is no attachment. It will not attach if >10MB please use https://my.pcloud.com

Hi Solomon, to your original problem:

Mineral Processing Flowsheets and Unit Operation Models

Crusher Lynch Model

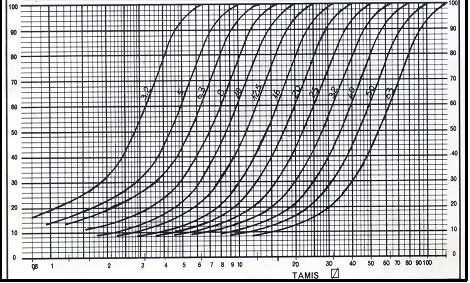

The Graph Displays Size Analysis of Crushing Products Produced in Cone Crushers (Symons Type), Which Are according To Gaudin’s Laws.

Confirm that the rejected material to the size equivalent to the Setting (Close Side Setting – CSS) is constant and equal to 40%. Pay attention that CSS between 10 and 63 mm exhibit the same standard (shape), which is slightly different for settings between 3,2 and 8 mm.

ØConsidering as Input the condensed parameters for each Selection (Pa, Pk) and Breakage Functions

Ø(m1, m2), the first step of the work is to develop the Lynch Model. The model should also include the CSS and OSS (Open Side Setting = CSS + eccentricity) as a parameter;

ØDo not forget to choose a standard size sequence to discretize the size axis ([1, 200] ). Consider that Feed has only material uniformly distributed by the 2 greatest size classes;

ØOnce the model is built, the second step will be to choose one value for CSS and to find the 4 parameters of the model that produce a good adjustment to the respective plotted size analysis. Before using the Excel Solver tool, try manually your guess to improve the adjustment;

ØIn a second step, repeat item 3. with another value for CSS. What can be concluded?

ØFinally, the model should be validated by testing it in different realistic situations.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

I have this PDF on Cone Crusher Modeling and you should read on the topic of population balance modelling.

Honestly, I do not understand why they would try to teach you this kind of useless stuff.

I hope this is a statistics and not a mineral processing class.

Let's hope somebody else can help you better...

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

I am currently on an Optimization project and only given the data as products produced from the cone crusher (symons) which are on the Gaudin's Laws distribution. Now I am ask to develop the model based on the Lynch Model.

Can any one help me were should I start?