Table of Contents

The U.S. Bureau of Mines is conducting an ongoing research project to better understand the phenomena involved within electric arcs utilized in electric furnace steelmaking. With a better understanding of the physical and electrical characteristics involved, dynamic or predictive control of electric arc furnaces may be possible. A mathematical model is presented, but not solved, and the system of coupled equations is analyzed. Characteristic parameters are used to determine relative importance. In this manner, significant quantities are defined. The parameters found to contribute little to the system of equations of motion are ignored. A resultant simplified system is identified, and directions for further study are indicated toward control of electric arc furnaces.

The electric arc furnace (EAF) has been used since the early 1900’s for the efficient conversion of scrap steel to molten metal. The power of these furnaces is used to melt scrap quickly for the production of a wide variety of steels. This method is particularly well suited for steelmaking owing to the temperatures reached and the widespread availability of scrap. The electric furnace scrap process is more economical than other standard methods of reducing scrap.

Since the introduction of the EAF, little has been done to improve the basic design. Because of competition from foreign industrial nations, the U.S. steel industry needs to improve existing technology to increase production efficiency and steel quality. With this in mind, the U.S. Bureau of Mines is investigating the physical phenomena of electric arcs used in EAFs. A goal of this project is to determine how today’s furnaces can become more efficient and less noisy through a fundamental understanding of the physical processes in the arc. This research is directed toward a better understanding of arc behavior in the hope that improved understanding will lend itself to dynamic control of EAF’s.

Research by the Bureau has been geared toward diagnostics of a single-phase ac furnace. The experimental furnace (X-furnacc) has been modified to allow the acquisition of reliable data as well as to be able to control several parameters including atmosphere and gas flow. Typical atmospheres used are 95 pct He, and 5 pct Ar at 1 atm. Data acquisition includes current and voltage measurements, power measurements, high-speed photography (44,000 frames per second), and calorimetry. The high-speed photography is correlated with the waveforms to allow visual identification of individual events seen as voltage or current spikes in the waveforms. Quantities such as resistance, power loss, and energy transfer are calculated.

With the information gained by the X-furnace, fundamental understanding of some of the phenomena involved in arc furnaces has been achieved. The ability to take large amounts of high-speed data and correlate these data with high-speed photography has allowed Bureau investigators to recognize discrete fluctuations in the arcs and to identify electrical signatures corresponding to these fluctuations. It also became apparent to Bureau investigators that rapid motion of the arc and rapid change in attachment points (at the cathode and anode) are intimately coupled. These attachment points are thus viewed as a series of discrete boundary conditions. This information has allowed researchers to identify the arc as being deterministic in nature (where the current state and past history uniquely determine future evolution of the physical system), discarding the idea that the electric arc is random and unpredictable.

To better understand the phenomena involved, researchers have begun to develop a mathematical model of the physical system. As the basis of this model, a system of coupled, nonlinear, partial differential equations has been derived. This system was then analyzed to determine the predominant forces acting on and within the electric arc in the X-furnace. Particular attention was paid to the interactions of the gas flow in the arc column with the magnetic fields produced by the high currents. This analysis took into account such limiting factors as He atmosphere, low power, and low temperatures (T ≤ 15,000 K) found in the X-furnace. In so doing, it was found that the system of equations cannot be decoupled. This is unfortunate from a computational standpoint, but logical from a physical standpoint.

Together with the system of equations and physical data gathered, it has become apparent that electric arcs are not random in nature as previously thought. It is believed that arc motion is chaotic in nature, exhibiting random-seeming motion subject to strict deterministic laws. Several key ingredients for chaos in the arc system have been identified, and investigations continue in this area. With the emerging realization that electric arcs are chaotic in nature comes the hope that this system can be controlled dynamically. Since the arc system is deterministic in nature, the ability to predict arc motion over short periods of time is possible. This ability leads researchers to the conclusion that control may be possible over this time interval. Further research into this area has begun.

Magnetohydrodynamics

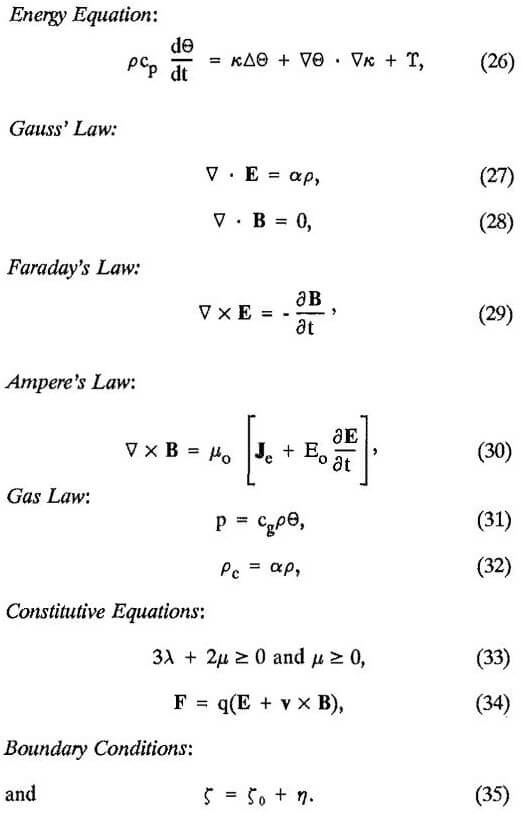

The mathematical model consists of (1) the equations of motion of the fluids, (2) the equations governing the electromagnetic fields, (3) the equations of state relating physical quantities such as density and pressure, and (4) the constitutive equations. A brief explanation of these equations is in order. The equations of motion are given by-

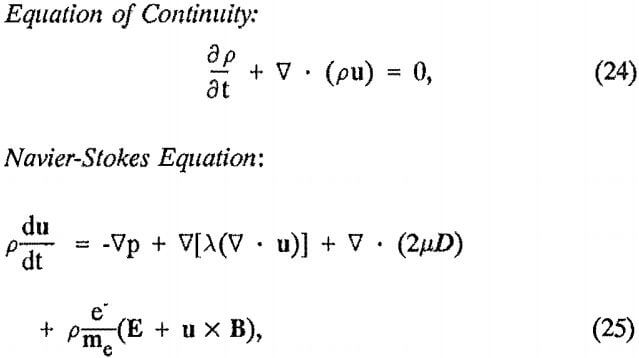

The equations governing the electromagnetic effects are given by the Maxwell equations for slowly moving, non- magnetizable media:

together with equations 1 through 9 and appropriate boundary and initial conditions, complete the mathematical model of magnetohydrodynamics governing electric arcs at low temperatures and monatomic atmospheres found in the Bureau’s X-furnace.

Discussion of Equations

Equation of Continuity

The continuity equation (equation 1) states that the rate of change of mass in an arbitrary volume of fluid is just exactly equal to the mass flow out through the boundary of this arbitrary volume. In essence, mass is neither created nor destroyed within the volume, but flows through it in a continuous manner.

The fundamental principle of the dynamics of fluid motion is realized as the principle of conservation of linear momentum. The conservation of linear momentum states that the time rate of change of linear momentum of a material volume equals the resultant force on that volume. If it is realized that the stress forces are in local equilibrium and that the Cauchy stress tensor is symmetric (appendix A), then conservation of angular momentum holds, and the arbitrary instantaneous flow is, at each point, a superposition of a uniform velocity of translation, a dilation along the axes of strain, and a rigid rotation about these axes. Thus, the stress tensor governs the dynamic response of the medium.

The Stokes postulate (appendix A) suggests that there is a linear relationship between the stress tensor and the deformation tensor, with the constants of proportionality being the shear and bulk viscosities and the fluid pressure (Cauchy-Poisson law). When the conservation of linear momentum is applied and this linear relationship is represented as the internal resultant forces, the well-known Navier-Stokes equation (equation 2) is yielded. The Navier-Stokes equation states that the time rate of change of the velocity field of a fluid element equals the rate at which the pressure changes across the element, plus the rate at which the velocity field is changing along the field lines (governed by the shear viscosity), plus the rate at which the fluid element is being deformed (governed by the bulk viscosity), plus the effects of the external forces.

The external forces within the arc system are those given by the force on a fluid element due to gravity and by the force due to the electromagnetic effects. This last force is realized as the Lorentz force, which gives the force on a volume element due to the combination of both the electric field and the magnetic field. As is evident, the fluids are intimately coupled to the electromagnetic fields.

Energy Equation

The energy equation (equation 3) is a combination of the thermodynamic equations of state and heat conduction. The energy equation states that the time rate of change of temperature within an arbitrary fluid volume element is equal to the heat flow out through the boundary of the volume (Newton-Fourier law of cooling), plus the rate at which heat is generated within the volume by deformation. This heat generation is a direct consequence of energy loss due to the mechanical interactions of particles within the volume element, i.e., mechanical energy lost to the physical system by the deformation of the fluid element is equal to the energy gained within the system as heat, where the heat is generated by the deformation. This states that energy is being conserved within the system.

Maxwell’s Equations

The equations governing the electric and magnetic fields are the well-documented Maxwell’s equations for a slowly moving, nonmagnetizable media. This is a set of four vector equations relating the divergences and curls of the electric and magnetic fields.

The first of these equations is Gauss’ law (equation 4), Gauss’ law states that the flux due to the electric field through an arbitrary surface is proportional to the field lines passing through that surface.

Conversely, the second of Maxwell’s equations (equation 5), which incidently is nameless, states that the flux of the magnetic field through an arbitrary surface is zero. This is evident from the fact that the magnetic field lines close upon themselves, while the electric field lines connect positively charged areas to negatively charged areas. The reason for this phenomenon of the field lines is that there exist no magnetic monopoles, while discrete electric charges or electric monopoles (i.e., an electron) exist.

The third of Maxwell’s equations is Faraday’s law (equation 6), Faraday’s law states that a changing magnetic field induces an electric field. Conversely, when an electric field is placed into motion (by some external means), then it induces a magnetic field. These are two different phenomena that manifest themselves as the same mathematical result. In the first case, it is the changing magnetic field that induces an electrical force, while in the second case, the changing electric field induces an electromotive force via the Lorentz force law. The Lorentz force, in turn, generates a magnetic flux change, causing the changing magnetic field.

The final equation due to Maxwell is Ampere’s law (equation 7). Ampere’s law states that the motion of magnetic field lines within an arbitrary volume is caused by the free current enclosed within the volume, plus the rate of change of the electric field across the volume, plus a current induced by the bulk motion of the volume, plus a current due to the internal motions of the volume constituents (i.e., the motion of the polarized molecules within the volume). Since the arc column is in motion, there exist currents induced into the arc system because of this motion, coupling to the fluid equations again.

Maxwell’s equations bring to light an interesting and important fact regarding plasmas and plasma arcs. If there exist any external potentials in the arc system caused by induced or introduced electromagnetic fields, these potentials are shielded out of the plasma by a phenomenon called plasma shielding. Thus, the bulk of the plasma column is in a state of electric neutrality, and the system is called quasineutral. Quasineutrality implies that the number of ions and free electrons are approximately the same, defining a plasma density, This becomes important when there exist large external magnetic fields introduced into the system (i.e., by the current-carrying electrodes, etc.). These magnetic fields are able to interact only with the plasma sheath (outer surface). Within the plasma column itself, the ionized molecules feel very few effects of the external field.

Equations of State

The equations of state, relating the fluid density, pressure, temperature, and ionization rates, are given by the gas law (equation 8) and the Saha equation (equation 9). The gas law is simply a proportionality relationship of pressure, temperature, and density and can be obtained by realizing that since the fluid in this case is an ionized gas, one can use the physical laws given for an ideal gas. As a first approximation, this is an adequate assumption, but as the arc system is studied in much greater detail and in a more realistic setting, the gas law will need to be modified. Saha’s equation gives the percent of each fluid constituent that is ionized with respect to temperature.

Boundary Conditions

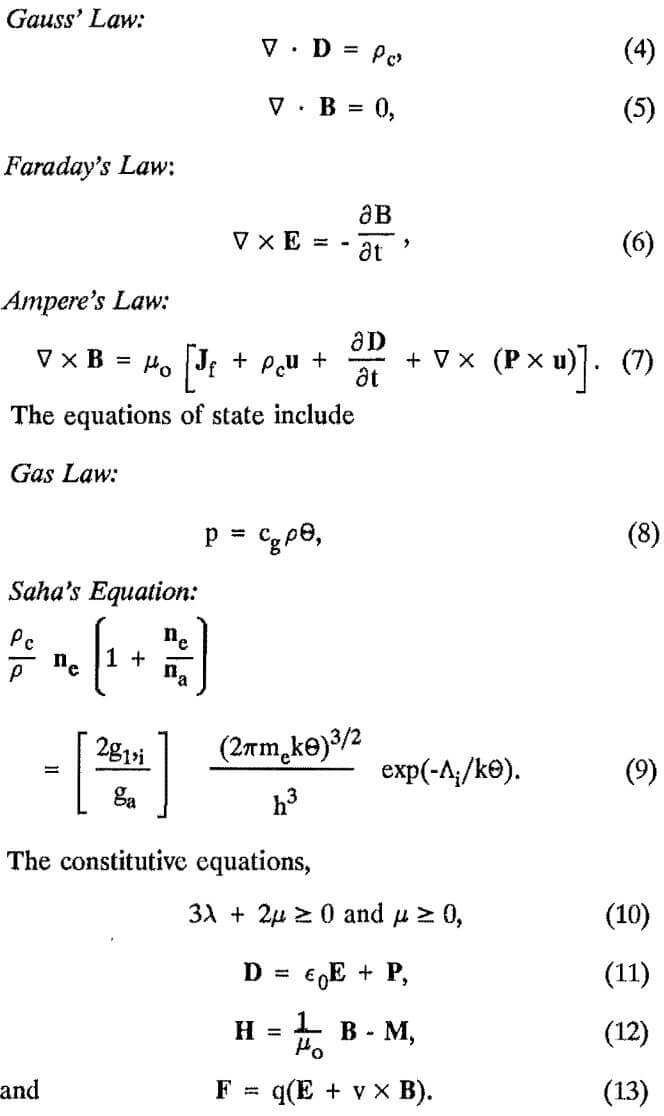

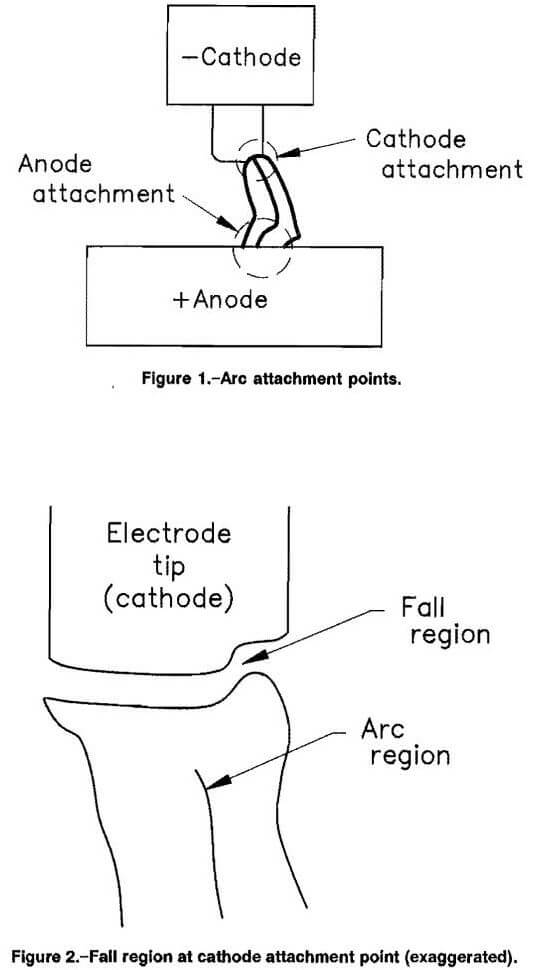

To conclude this part of the modeling, boundary condition must be defined. For this, the arc attachment points, at the cathode and anode, were used (fig. 1). It has been seen experimentally that the cathode plasma jet dominates the anode jet. It also has been seen that the cathode and anode jets leave the attachment points on orthogonal trajectories. This is most likely due to thermal and magnetic pinch effects in the fall region (fig. 2). The cathode attachment point depends directly on the ability of the cathode to emit electrons. Two means of liberating the electrons have been identified: (1) thermionic emission, which is temperature dependent, and (2) field effects, including magnetic pressures. Hence, the attachment point tends to be in areas with a high temperature gradient or extreme field strengths. The heat generally comes from two sources: resistive heating at the surface of the electrode due to the physical composition of the electrode

and skin effect, and heat generated by thermionic emission at positions corresponding to previous attachment points. As the cathode ablates, the attachment point necessarily moves owing to the changing geometry. Moreover, because the plasma jet leaves the cathode and anode on orthogonal trajectories and because the normal to the surface is changing owing to loss of mass via ablation, etc., the attachment points are in a state of motion viewed as discrete jumps. The discrete fluctuations caused by this motion necessitate viewing the arc motion itself as a series of discrete movements, each with a different set of boundary and initial conditions.

Viewing arc motion in this manner allows researchers to define what boundary conditions should be. In general, the boundary conditions can be broken up into at least two components (8): a purely deterministic component that depends on measurable or determined quantities and a purely random component that depends on quantities in which no physical data can be obtained. It has been seen that the attachment points depend on previous attachment points in the form of “hot spots,” which can be defined by the temperature and temperature gradients. Thus, the deterministic component of the boundary conditions depends on temperature and temperature gradients, as well as on the instantaneous current and voltage, position and time, and actual geometry of the electrode (i.e., the unit normal to the surface). The random component of the boundary conditions embodies such intrinsic quantities as electrode composition, pitting, spalling, and erratic release of electrode material in the form of particulate matter of varying sizes. It may be found that the random component also depends on the rapidly varying electromagnetic fields. The pitting, spalling, etc. affect the actual surface geometry of the electrodes in one manner or another. Thus, the random component is defined by those quantities that force a random shift of the unit normal (either a directional shift and/or a spatial translation).

To embody these phenomena in a single set of equations would be rather difficult. As a first attempt, consider a function that maps the state of the system just prior to the fluctuation to a set of new boundary and initial conditions. This function is then a composition of deterministic quantities, (for example, (V,I,Θ,∇,Θ;n) where V is the instantaneous voltage, I is the instantaneous current of the system, Θ is the temperature distribution, ∇Θ is the temperature gradient) and a purely random component (n (x;n). Because of its nature, the deterministic part of the function depends implicitly on position and thus on the outward unit normal (n) to the surface of the electrode, so this fact is shown here explicitly, while the random component depends on position as well as on the outward unit normal. The random component must take into account those factors that cause the instantaneous movement of attachment points, whether it is a translation or a reorientation of the unit normal. i.e., the random component gives a means of modeling the random-seeming positional changes of the attachment points owing to the surface effects pointed out earlier. These assumptions lead to a vector equation of the form

![]()

where the parameters depend on the instantaneous condition of the system. From a combination of physical measurements and calculated results, this system of conditions can be represented with relative ease.

It must be remembered that at this point the random component is not well understood and implementation may cause unrealistic or transient computational motion.

Steelmaking

Equations 1 through 13 make up the model of magnetohydrodynamics. This is a system of 13 coupled, nonlinear, partial differential equations and 13 unknowns, the unknowns being pressure, density, charge density, temperature, velocity field (3 equations), magnetic field (3 equations), and electric field (3 equations). The coupling of the fluids to the electromagnetic fields appears in the form of a Lorentz force, while the coupling of the magnetic fields to the fluids appears as an induced polarization current owing to the motion of the current-carrying fluid.

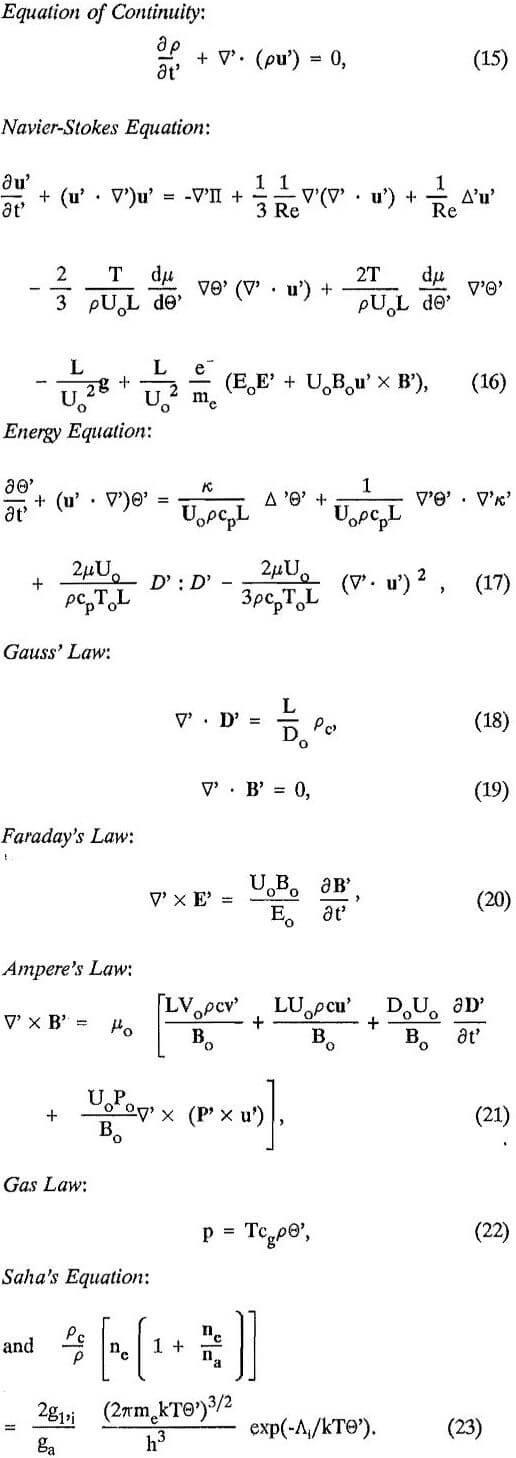

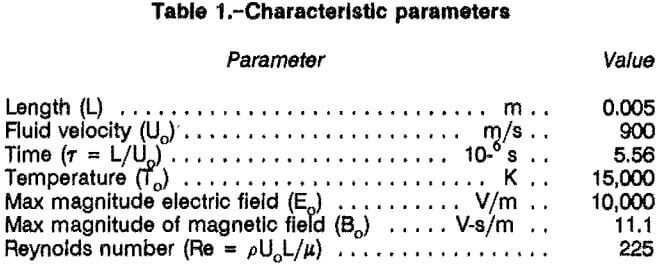

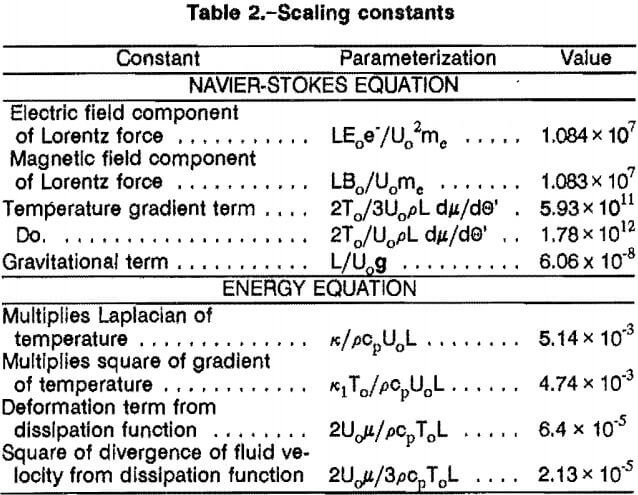

To gain insight into the relative contributions of each of the terms, a nondimensionalization technique was applied to the mathematical system, and the resultant magnitudes of the terms were investigated to determine their importance to the system. To do this, the following definitions are used: x = Lx’ and u = U0u’, where x is the coordinate space, u is the velocity field, L is a characteristic length, and Uo is a characteristic fluid velocity. Then r = L/U0 is a characteristic time. Similar parameters are defined for the electric field (E = E0E’), magnetic field (B = B0B’), temperature (Θ = TΘ’), pressure (II = p/pUo2), polarization (P = PoP), and charge velocity (v = V0v’) to give dimensionless variables. In this manner, the equations of motion are transformed into a set of dimensionless equations with terms of order 1 on the left-hand side and constants of proportionality on the right-hand side. These constants, which include such parameters as the Reynolds numbers, indicate which of the terms in the set of equations are predominant and which set can be neglected. These equations are-

Physical characteristic data of the fluid properties gathered by the Idaho National Engineering Laboratories and data on arc motion gathered by the Bureau were used to define the characteristic parameters. The figures used apply to the electric arcs produced in an experimental furnace used by Bureau researchers. A list of the parameter values appears in table 1.

It was found that the Lorentz force is a major contributor to the fluid dynamics in the arc region (see table 2 for constant values and explanations of the constants). It was also found that only the gravitational term can be neglected in the Navier-Stokes equation. This is unfortunate from a mathematical standpoint in that the fluid equations cannot be decoupled from the electromagnetic equations, thus elevating the degree of difficulty in solving the system of coupled equations. This is logical though, since the fluid is the medium by which the electric current is transferred across the arc gap. It is reasonable to expect that the fluid equations and the electromagnetics remain coupled. The magnetic component of the Lorentz force causes the arc to be pushed away from an external magnetic field, thus illustrating the electromagnetic coupling to the fluid flow.

It was found that the dissipation function can be neglected in the energy equation because the amount of heat transferred to a control volume by deformation is orders of magnitude less than the amount of heat generated by the ionization process. Since the temperature range is high and the energy put into the system is high, this is expected.

In the case of the experimental apparatus used at the Bureau, the polarization, and hence the magnetic displacement current, can be neglected. Also, because the charge velocity is so much higher than the bulk gas velocity, the two velocities can be combined into an effective free current. In this manner, the bulk gas velocity can be neglected since it will not affect the charge carriers enough to be noticeable. These reductions lead to the fact that the Maxwell’s equations do not depend explicitly on the fluid motion, but only on the gas density.

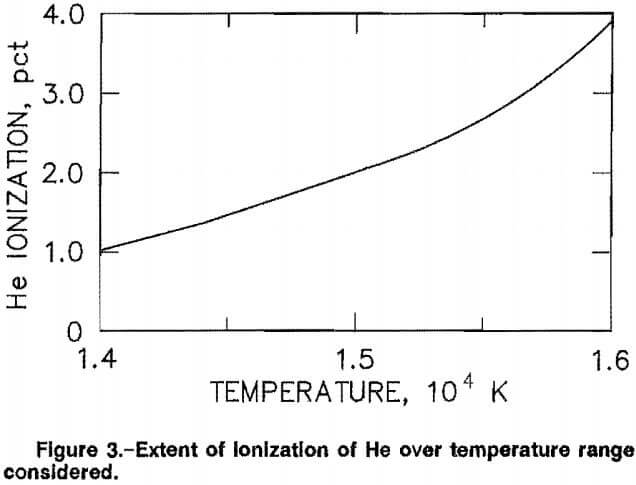

A closer look at the Saha equation reveals that, in the path of conduction (i,e., in the center of the arc column), the extent of ionization of the gases used by the Bureau is approximately 2 pct (in an He atmosphere at 15,000 K) (fig. 3); this level was maintained across the conduction path. With this fact, the charge density reduces to a constant multiple of the gas density. This realization permits the omission of the charge density in lieu of a constant multiple (α) of the gas density.

The reduced system is given by-

As has been mentioned, the arc system undergoes rapid attachment point fluctuations due to a combination of random perturbations and deterministic forces. A consequence of this is sensitivity to the initial conditions. i.e., a small difference in initial conditions causes a large difference in the final outcome. Viewing the system as a series of discrete motions with different initial and boundary conditions has allowed researchers to identify SIC in the arc furnace. With the aid of the high-speed photography and correlated waveforms, evidence indicates that this phenomenon is prevalent.

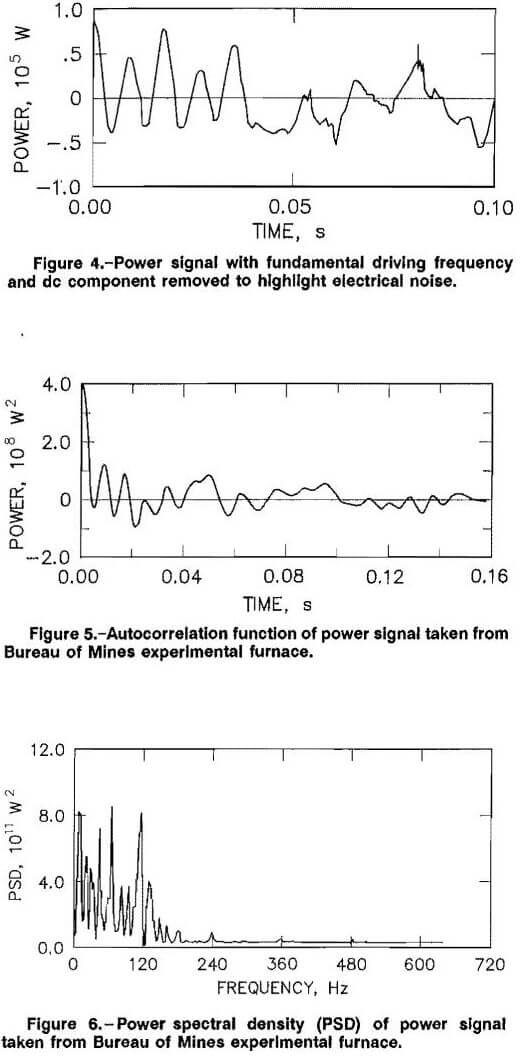

The frequency and the power spectrums have been studied to identify precursors to catastrophic motions. In so doing, several interesting facts have been noticed. When the fundamental driving frequency and dc component are subtracted from the power signal (fig. 4), the noise introduced by various means into the system can be studied. The autocorrelation (fig. 5) of this resultant signal was found to approach zero. This means that the temporal similarity of the signal with itself vanishes and prediction becomes increasingly harder as time progresses. This, together with a study of the PSD (fig. 6), reveals that

the noise is aperiodic in nature. The PSD is becoming continuous, asymptotically approaching zero, implying that the signal is not random, but chaotic.

As defined in reference 11, a chaotic process is one that has the following properties: (1) determinism, (2) random initial conditions, (3) SIC, (4) correlation function vanishes as the lag approaches infinity, and (5) time series that is almost always nonperiodic. i.e., there is order within the arc system, yet an apparent unpredictability. Information of past history is lost through evolution and rarely does there exist any periodicity to these systems. (In rare cases, certain systems have periodic cycles, but only under very special circumstances.) Researchers have identified properties 4 and 5 in the X-furnace. High-speed photography and correlated waveforms indicate property 3, while properties 1 and 2 are tacitly assumed as presented in this report. Because of this, researchers are viewing the system as a chaotic system.

This being so, researchers feel that dynamic control of the arc system can be obtained through computer-aided adjustments of the operating system, fast data acquisition, appropriate identification of precursors to catastrophic events, and high-speed computers. Hence, predictive control may be possible over short time periods. Thus, a control scheme could make decisions to dynamically control the furnace for optimal energy transfer.

Conclusions

A mathematical model for the magnetic fluid flow in an electric arc was presented. The system of equations was examined to determine the relative importance of the constituent forces and a reduced system was defined. The new system provides a model for a low-power, single-phase experimental furnace used at the Bureau.

The study showed that the fluid equations and the electromagnetic equations cannot be decoupled. This suggests that arc fluctuations are due to a combination of the interactions of the fluid and the electromagnetics, as well as the rapid change of the boundary conditions. Because the arc system is nonlinear, SIC is expected and is found to be true experimentally. The rapid change in arc attachment position and the collapse of magnetic fields make predicting column motion difficult. Without knowledge of the arc motion, little can be done to control future fluctuations for increased efficiency.

Because the arc system is deterministic in nature, there exists the ability to predict the arc motion over short periods of time. The arc has exhibited SIC. The arc also demonstrates repetitive patterns manifesting themselves as discrete events. For these reasons, it is apparent that the system is chaotic in nature and a basin of attraction is expected (appendix B). This sheds light on the nature of the system and gives hope that dynamic control is possible.

An extensive search for a basin of attraction is currently under way, while future directions include research into methods of dynamic control of the arc fluctuations by real-time adjustments of the voltage and current and numerical solutions to the reduced set of differential equations.