Filtration of the insoluble slimes flotation concentrates recovered 87 to 90 percent of the brine. Flotation concentrate filtration rates were 7 times faster than the filtration rates of mechanically deslimed products.

Potash losses in the deslime product and process brine requirements increase as the insol content increases. Therefore, improved methods to remove inso lslimes are needed that will (1) reduce potash losses in the insol slimes product, (2) lower the process brine requirements, and (3) increase subsequent potash recovery after insol slimes removal. In this regard, several insol-slimes-flotation methods have been offered as alternatives to mechanical desliming.

Experimental Materials

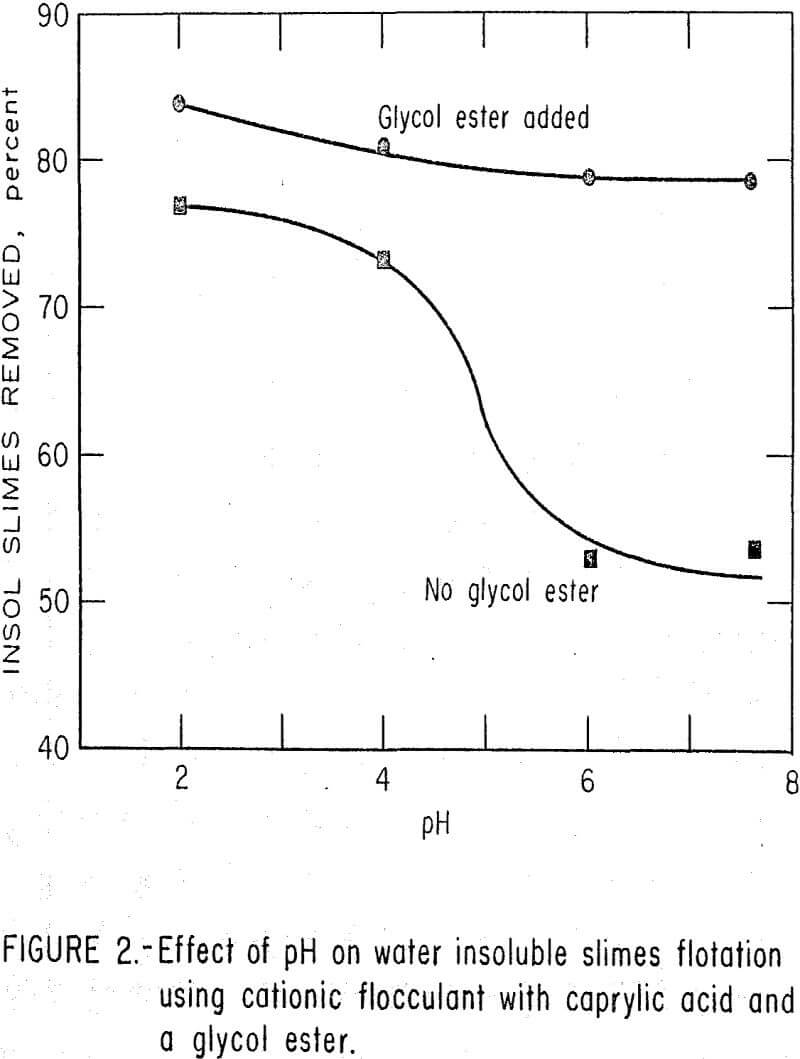

A run-of-mill potash ore sample with a high water-insol content from the Carlsbad, N. Mex. Petrographic and X-ray diffraction analysis of the ore indicated that sylvite (KCl) and halite (NaCl) were the major minerals present. The sylvite contained minor amounts of included hematite, which gave this mineral a distinct red color. Minor amounts of polyhalite (MgSO4·K2SO4·2CaSO4·2H2O), leonite (MgSO4·K2SO4·4H2O), and kainite (KCl·MgSO4·2.75H2O) were also present. The water-insoluble fraction of the ore contained abundant magnesite, chlorite, and illite.

Experimental Procedures

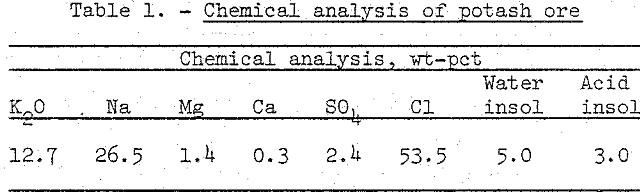

Settling tests were performed in 200-milliliter graduated cylinders on the insol-slimes fraction of each ore. The feed for these settling tests was prepared by diluting the insoluble material with saturated brine to 1.0 percent solids pulp density. The freshly prepared flocculants were mixed with the slurry for 1 minute, and the insoluble slimes were allowed to settle.

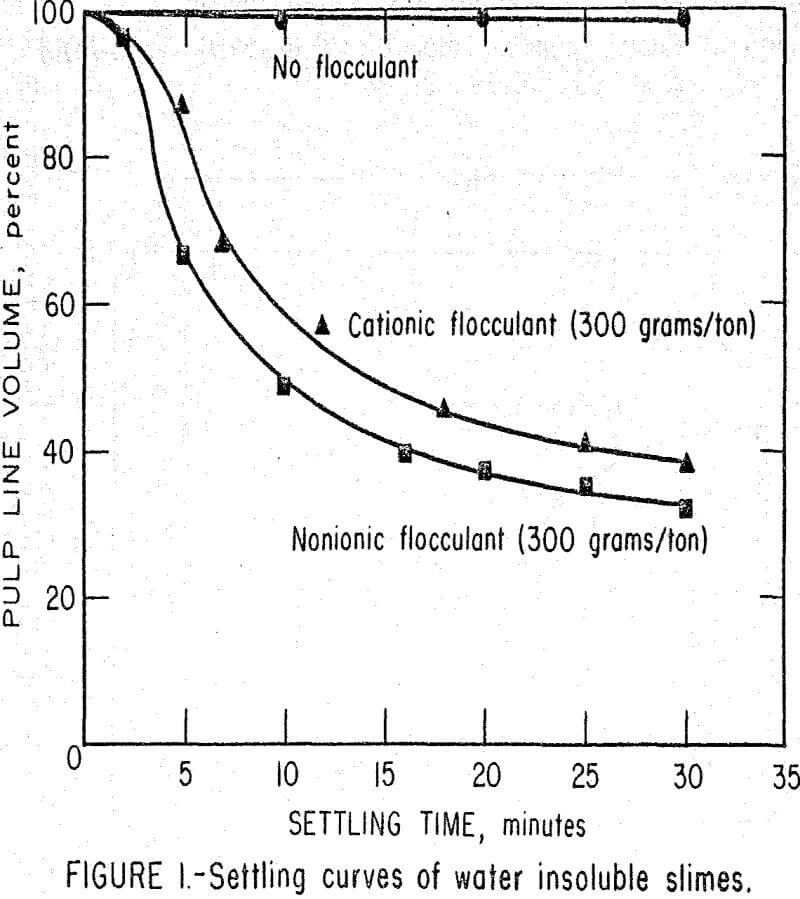

Batch insol-slimes flotation tests were conducted in a Fagergren laboratory flotation cell. In each test, 1 kilogram of ore was scrubbed 5 minutes at 27-percent-solids pulp density in a saturated brine at 4.22 meters per second (830 feet per minute) peripheral impeller speed. Concentrated HCl was used for pH adjustment. Flocculant and collector were gently folded into the pulp with a spatula for a conditioning period of 2 minutes.

The deslimed pulp was diluted to 23-percent-solids pulp density in a Fagergren laboratory flotation cell. The pulp was conditioned, for 2 minutes with 150 grams per ton (0.3 pound per ton) of insol slime blinder and for 2 additional minutes with 40 and 115 grams per ton (0.08 and 0.23 pound per ton) of flotation oil and amine chloride, respectively. After conditioning, a drop of frother was added, and a potash flotation rougher concentrate was collected for 2 minutes at a peripheral impeller speed of 4.72 meters per second (930 feet per minute). Potash rougher concentrates from two tests were combined in a 500-gram Denver laboratory flotation cell to provide enough material for a cleaner flotation.

Experimental Results and Discussion

Settling tests were made to select the most effective flocculants for use in flotation testing. Flocculants tested included high-molecular-weight cationic, nonionic, and anionic flocculants, medium-molecular-weight nonionic and anionic flocculants, natural organic flocculants such as starch, quebracho, and guar gum, and polyvalent metal cations. The settling curves for all other reagents tested fell above the curves shown for these two flocculants. The slow settling characteristics were due to the high clay content of the insol slimes fraction of the ore. Based upon the results of these tests, the nonionic polyacrylamide and the cationic acrylamide copolymer were selected as flocculants for subsequent insol slimes flotation studies.

Best results were obtained using emulsions of fatty acids or fuel oil mixed with glycol or polyglycol esters. Cleaner flotation tests were performed on rougher concentrates produced by reagent scheme 2. Results showed that direct cleaner flotation upgraded the rougher concentrate from 54 percent to 59 percent K2O at a reduced recovery of 82 percent. Desliming of the rougher concentrate followed by cleaner flotation upgraded the product to 60 percent K2O. Overall recoveries ranged from 78 to 82 percent.

Insol slimes flotation using a nonionic flocculant-cationic surfactant reagent scheme was compared with the Bureau developed cationic flocculant-caprylic acid-glycol ester defoamer reagent scheme. Results indicate that the Bureau reagent scheme renders residual insols, not removed by flotation, inert during subsequent potash rougher flotation.

Insol slimes concentrate slurries were dilute, ranging from 6 to 8 percent solids. Filtration was therefore investigated as a method of recovering the large amounts of brine entrained in these concentrates. Comparison of an insol slimes flotation concentrate with a flocculated, mechanically deslimed product using the Buchner funnel apparatus is presented. The marked increase in filtration rate observed for the flotation concentrate was due to entrained air in the floated floccules producing a permeable filter cake.