- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Flotation.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

Paper deinking flotation machine (17 replies and 30 comments)

Hi Mostafa,

If a gravity feed, a 25 to 30 cm diameter pipe would certainly do.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Dear David,

this is diameter for feed pipe for total flow rate about 580m3/h of bank of flotation cell and whats is the dimensions of the impeller used in dr300 denver flotation as blades length and height and the width of the integrated end of the blades and diffuser out diameter and there is a picture of the cell.

Mostafa, I guess I do not understand your question(s).

Please restate what you need. thanks.

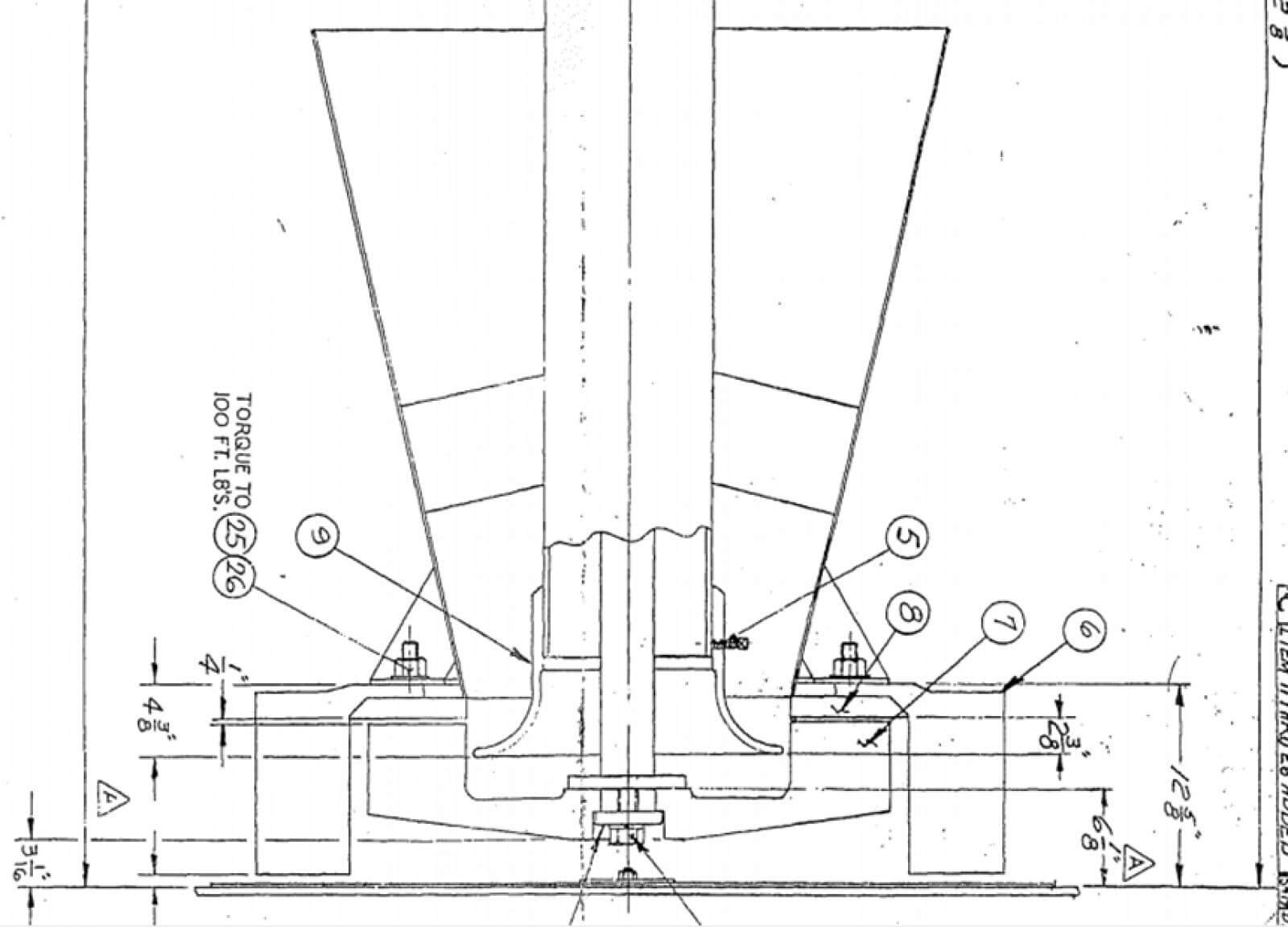

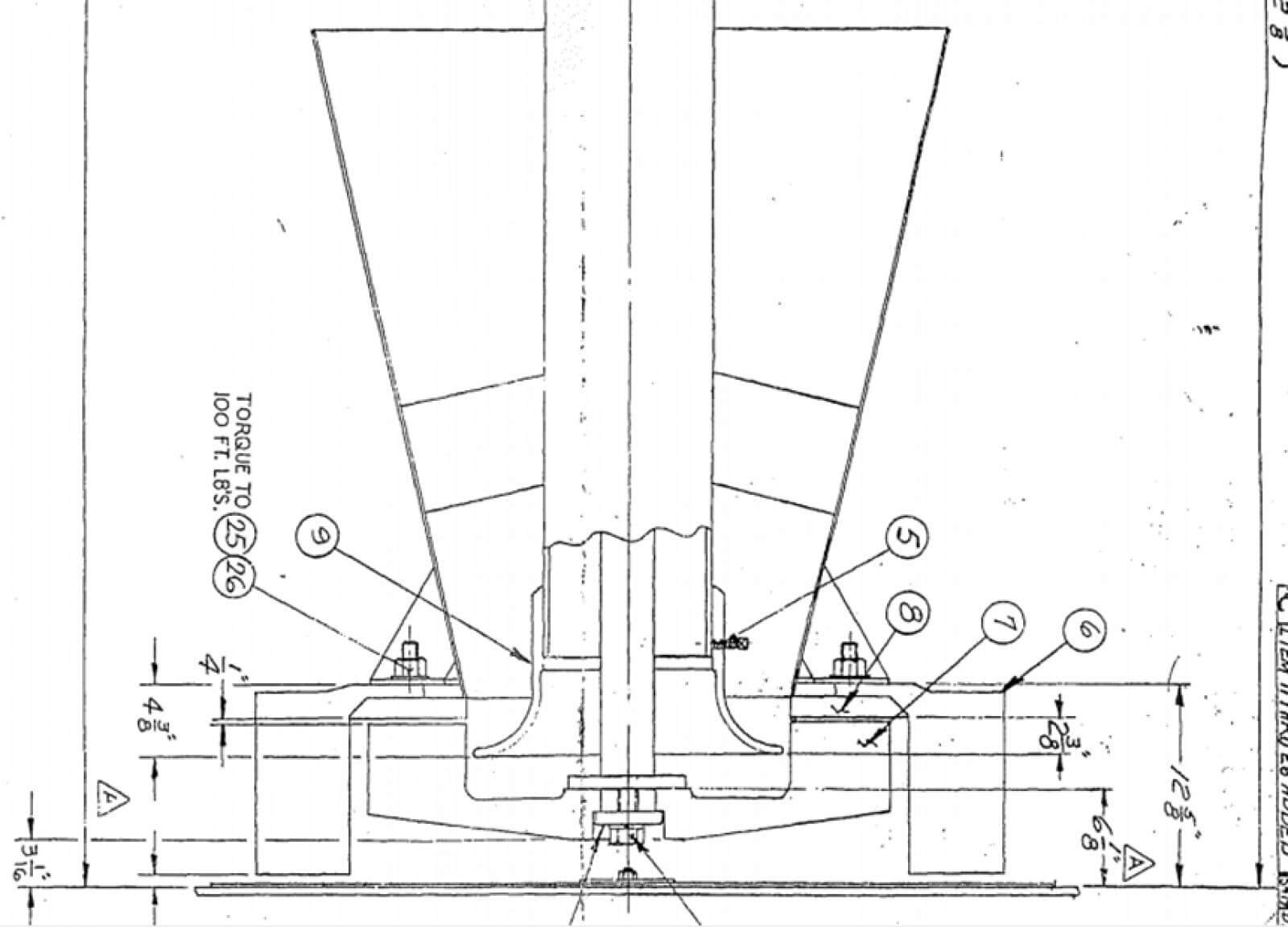

+ this drawing here may help.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

These are DR 300 drawings.

I know nothing about paper de-inking, Mostafa. BUT if you tested this in a Lab on standard D12 or similar; the DR 300 will work the same.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Everything I have is at https://www.911metallurgist.com/blog/dr-300-flotation-agitator-mechanism-drawings

Click the links on the page for PDFs for the drawings.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

If this does not work, contact Aammar Abdullah, Product Support Engineer, Process Equipment, Metso Minerals, York PA at aammar.abdullah@metso.com

Dear david, thanks for you help ..and you tell that if i tried D12 and worked in paper deinking ,so i can used denver dr300 in paper deinkng because they are the same ..thanks alot

The D12 test results can be used to scale-up the DR300.

If you see good results on the D12, you'll be OK with a DR 300 or appropriate other size.

You should not buy industrial size machines without first testing in the laboratory. The "D" in D12 and DR300 stands for Denver... now Metso. Same technology.

Do you have a D12 to test with? Or a Laboratory to use?

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

LOL you must think I work for Metso Mostafa.

Here is the best and only drawing PDF I have on DR300

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Already on https://www.911metallurgist.com/blog/dr-300-flotation-agitator-mechanism-drawings

DR-300 9 VAIN IMP FIN and DR-300 12 VAIN IMP FIN

DR-300 Diffuser Assembly and DR300 FLOTATION AGITATOR DRAWINGS and DR-300 WEAR RING FINISHED

HERE I dont think you took the time to look at what I gave you already.

DR-300 Flotation cell cross section profile Drawings and DR Flotation Cells-Machines brochure and DR 300 500 1500 Flotation Cell Drawings

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

yes i see it already but the internal diameter of diffuser and outer diameter not clearly please tell me the dimesions and i want also to make the feed pipe in like this picture and need to know it's diameter and it's position in side the tank (height)https://goo.gl/photos/gFsKHKQzDHgoBtw29

trying to clone a one to ensure that if i buy an industrial cells it will work so. can you help me

I do not have the information you are looking for. Engineering is about good guessing and good estimating... you will need to test your "Engineering" skills with what you have now.

Mostafa, as I said "I do not have the information you are asking me for." Maybe... somebody else here does. Contact http://is.gd/39HSBz maybe they can help you some more.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

All the Drawing I have are at https://www.911metallurgist.com/blog/dr-300-flotation-agitator-mechanism-drawings

If you can't see it.... neither can I.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

https://www.911metallurgist.com/blog/wp-content/uploads/2016/02/DR-300-Diffuser-Assembly.pdf .........................i ask about this not the impeller

Since the impeller rotates inside the diffuser, you will use those measurements to infer/estimate the dimensions you are missing.

?

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Use the image below to infer the inner diameter of your diffuser. You see from the photo, a gap of 1" from the tip of the impeller and edge of diffuser. = 2 x (16 1/2" + 1") = 35" would be your inner diameter & 47 5/8" your outer.

This leaves about 6 1/3" for each diffuser blade.

Your turn now to be the Engineer and check my math.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Ok i got it, now 16 1/2" is the redius of impeller so the diameter of impeller is 16 1/2" *2 equal 33" and then the gap 1" refer to the distance between the baldes tip and diffuser vanes and so the inner diameter of diffuser in 35" and outer diameter 47 5/8 " of the diffuser and 6 1/3" is the width of each vanes in diffuser

Thank you .. Help me now to detect two things the feed pipe location from the tank bottom and slope and also the height of recirculation well

I don't have what you want. Write to johnathan.puppelo@metso.com or susan.carter@metso.com

I will be in contact in all steps i do to get your opinion and your experince in flotation thanks alot

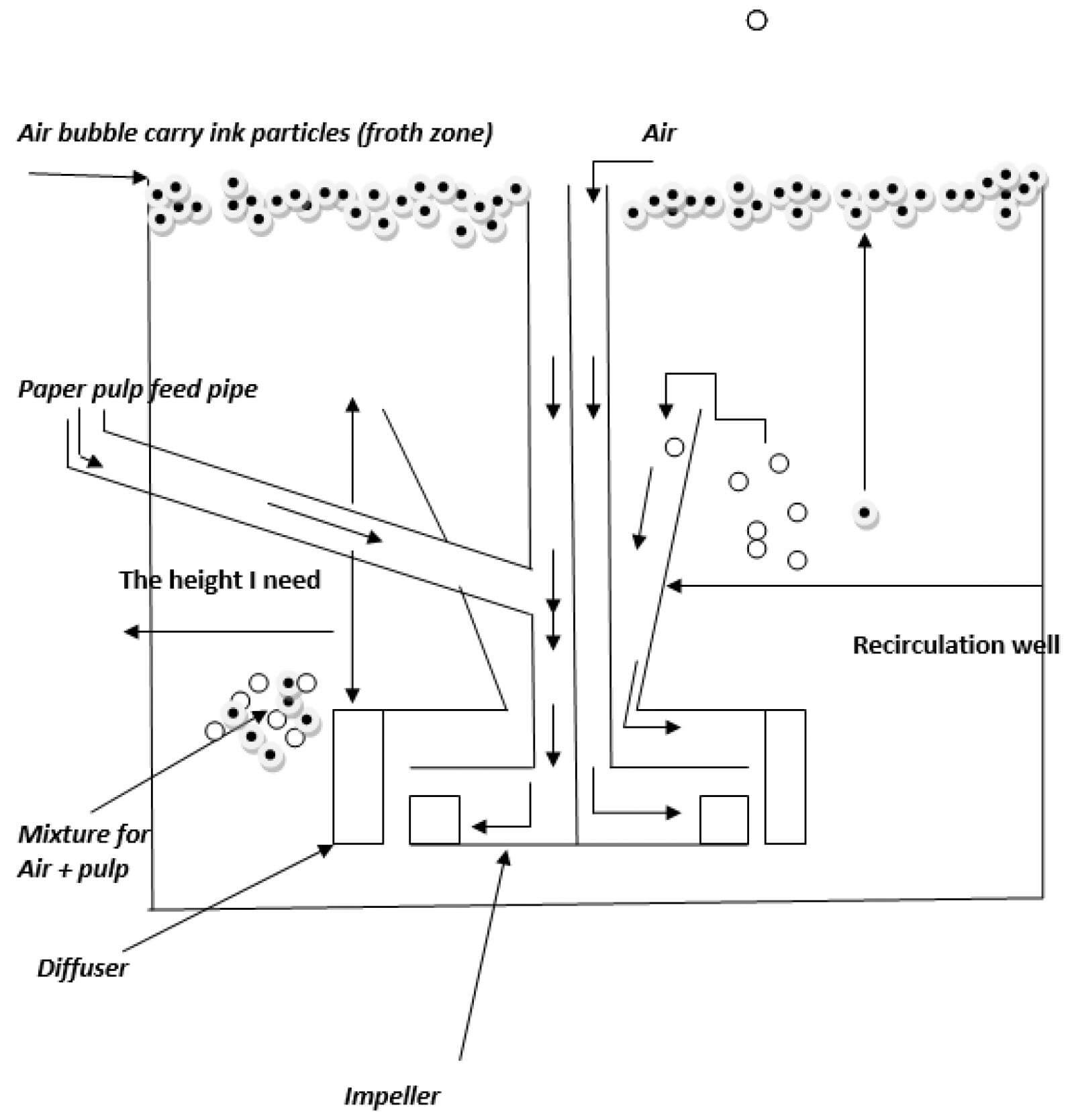

About that; my advice is to print the images and "guesstimate" from scale. A good approximation will work. Exactitude is really not necessary. I build these cells below from graphical estimates.. and it works.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

Please check my idea and give me your opinion..thanks alot.

1- using feed pipe like sub –A-flotation to ensure that the stock entered the vortex zone (impeller & diffuser) and mixed with the Air(Air & pulp mixture and forming fine air bubble capture the ink particles)

2-Using recirculation well to ensure that the pulp particle which not mixed and redeposition of ink particles come back to the eye of the impeller and get mixed with the Air bubble produced.

That could certainly work. Give it a try!

I would use 40" to 50" for the "height you need". The well seems as tall as the diffuser is wide.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

I have a question about the type of air used is that blower or by air compressor or the important is the pressure of air and the volume of it.

Yes the application of flotation for deinking in the recycled paper industry has attracted much attention in recent years. By its chemical nature, ink is sufficiently hydrophobic and docs not require a collector. Ink is first detached from the paper fiber by treatment with sodium hydroxide. The hydroxyl ions cause fiber and ink particles to become negatively charged. An anionic detergent is added. The hydrophobic part of the detergent attaches to the ink particles and helps remove them from the fiber. The ink particles arc dispersed in water and though hydrophobic, do not readily float. In order to form larger flotation aggregates, calcium salts of fatty acids arc added. Little calcium ion concentration is needed to ensure flotation of ink particles. I suggest that a calcium bridge is formed between ink particles and the detergent enabling the ink particles to adhere to air bubbles.

Dear David,

hope you are fine,and i have an very important question about Denver DR flotation machine can i use it in paper de-inking process as a flotation cell because the microprocess are the same in mineral flotation and de-inking flotation and under the parameters required to produce fine air bubble to capture ink particle and dirt stickies and i make a small module like this and it was good but now i need to know the feed pipe diameter to get 116 m3/h flow rate per cell in denver flotation machine type dr300 ,so can you tell me the velocity of flow or diameter of pipe to make a good mixing between pulp and air .please i am really need your help in this question ..

thanks

Mostafa