- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Gravity Separation/Concentration.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

Compare High-G & Low-G Centrifugal Concentrators (2 replies)

It really depends on what your ore is and what it needs. It is irrelevant of sales pitches. If you have no gold finer than 200 mesh (74um) you might be OK with that low-G machine.

If you have only "coarse" +200 mesh gold = you are OK low-G

Otherwise.... you need high-G

If you look carefully a Oro Low-G Horizontal Centrifuge Primary Concentrators is just another name for a multi-gravity separator.

The principle of the multi-gravity separator (MGS) can be visualized as rolling the horizontal surface of a conventional shaking table into a drum, then rotating it so that many times the normal gravitational pull can be exerted on the mineral particles as they flow in the water layer across the surface. Below is a cross section of the pilot scale MGS. The Mine Scale MGS consists of two slightly tapered open-ended drums, mounted "back to back.” rotating at speeds variable between 90 and 150 rpm, enabling forces of between 5 and 15 G to be generated at the drum surfaces.

A sinusoidal shake with an amplitude variable between 4 and 6 cps is superimposed on the motion of the drum, the shake imparted to one drum being balanced by the shake imparted to the other, thus balancing the whole machine.

A scraper assembly is mounted within each drum on a separate concentric shaft, driven slightly faster than the drum but in the same direction. This scrapes the settled solids up the slope of the drum, during which time they arc subjected to countercurrent washing before being discharged as concentrate at the open, outer, narrow end of the drum. The lower density minerals, along with the majority of the wash water, flow downstream to discharge via slots at the inner end of each drum.

They were known as Johnson Drums or the old Denver Gold Saver. The primary concentrators are typically Johnson drums, the concentrate being cleaned either by shaking tables or endless-belt strokes to produce a high grade concentrate suitable for amalgamation.

The Johnson concentrator consists of a continuously rotating cylindrical drum, which is tilted slightly and lined internally with riffled rubber sheeting. Pulp flows through the drum, and the concentrate collects in the riffles. As the drum turns, the concentrate is carried to the top and washed into a launder. The endless-belt strake, which is usually used to clean the concentrate, consists of a flat, endless rubber belt, inclined slightly to the horizontal. The upper surface has saw-tooth riffles running across the belt. The belt moves continuously against the pulp stream and spray water washes the concentrate from the riffles after the belt passes over the head pulley. All similar to https://www.911metallurgist.com/blog/mechanical-automatic-gold-panner

The plane table is a high capacity roughing device used on some of the South African mines. It consists of riffled rubber, covering a series of inclined smooth surfaces with steps between them. Pulp flows down the length of the riffles, which collect the concentrate, which is drawn off through the slots and is collected at the end of the table. The concentrates are then cleaned, usually by shaking tables.

Spirals have also been installed at one operation as have other machines such as centrifugal concentrators.

If you have fine gold under 200 mesh, you will loose.

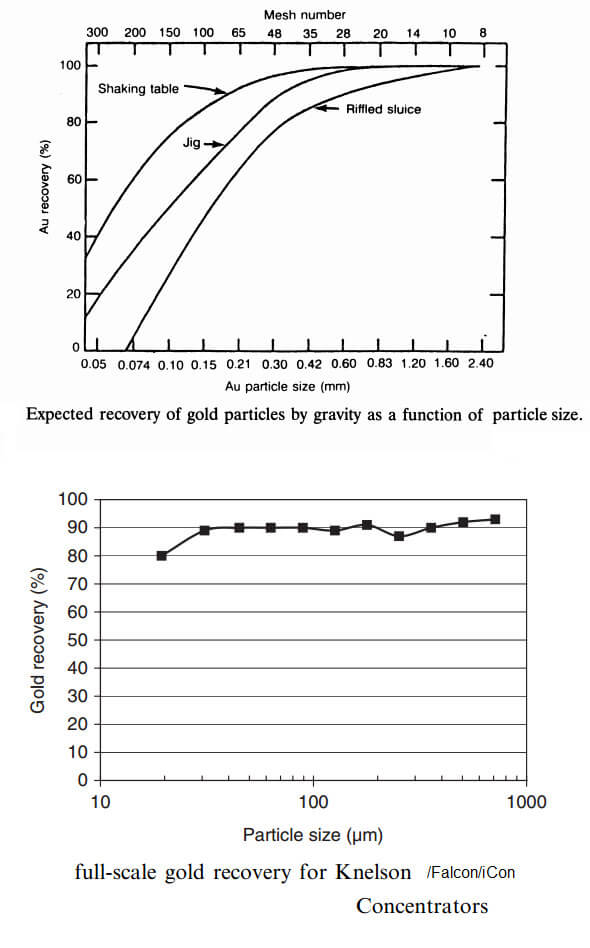

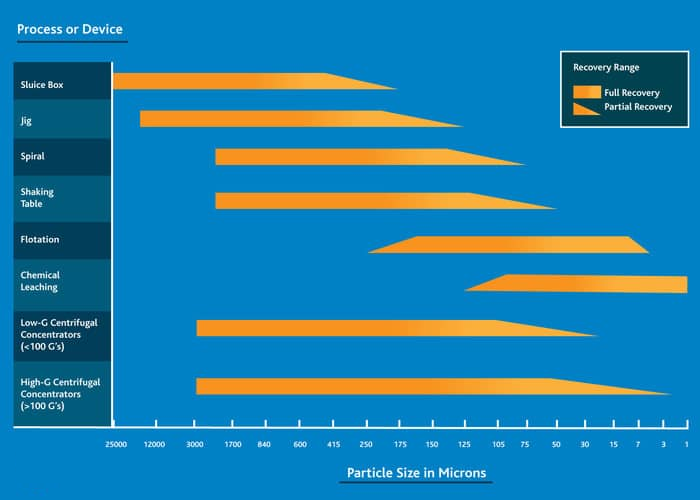

Gravity concentration plants are very effective at recovering fully liberated gold of sizes greater than 50 μm, and some equipment is effective at sizes down to about 10 μm. However, gold can be lost in the following forms:

Fine gold, which is too small to be recovered by the these gravity equipment:

- <500 um: sluices

- <200 um: jigs

- <50 to 100 um: spirals/tables

- <20 um: centrifugal concentrators (and down to about 10 pm in some cases)

Flakey gold or gold grains or flakes with a median diameter of 20 to 30µm were captured into the gravity concentrates, which presents a larger surface area in one plane, allowing it to be carried away with lighter particles in flowing film separators, such as shaking tables

Hydrophobic gold, which adheres to the water-air interface, giving the particle an artificially low apparent density and reports to the tailings (e.g., gold coated with fine hydrocarbon or sulfurous material)

Unliberated gold, which is associated with oxide, silicate, or sulfide gangue particle and for which the average particle density is substantially lower than that of gold.

Flakey, Hydrophobic gold particles are highly likely to go unrecovered to tailings using a low-G concentrator.

Since a Low-G machine is a rotating shaker table, look below at the size recovery % of a shaking table. As your salesman tells you, recovery on gold finer than 200 mesh drops fast. On the bottom graph you see the by-size recovery of a High-G holds up until 20um.

Knelson/Falcons/iCon will recover gold grains or flakes with a median diameter of 20 to 30µm were captured into the gravity concentrates.

You need to test and understand what type/size gold you are dealing with.

Source 1 and Source 2 and Source 3

Anyone else please join/add.

Yes, if you have no gold finer than 200 mesh (74um) you might be OK with that low-G machine.

Otherwise.... you need high-G for better recovery of fine gold.

Can you perform that type for test?

Below is an APPROXIMATION.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

We are considering acquiring an iCON-i350 Centrifugal Concentrator ( http://www.iconcentrator.com ); a Falcon SB350 equivalent. However, we got an attractive offer of two units of “Oro Low-G 16” Horizontal Centrifuge Primary Concentrators” (used, but in excellent condition); for the price of one gravity iCON-i350.

The company’s brochures ( http://www.oro-industries.com/centrifuge_oro-industries.php ) promote the Low-G Horizontal Primary Concentrators as “High volume, zero loss and capable of recovering 80% to 90% of free gold down to 200 mesh.” These claims, together with the attractive offer price, surely got our attention.

However, it also presents a sort of contradictory dichotomy; in the sense that the common rule of thumb in gravity concentration states that: “Highest G-Forces = Highest Fines Recovery” – Hence my confusion.

Does anyone here have actual experience or familiar with these Low-G Horizontal Concentrators, that could corroborate such claim of high recovery efficiency?

Any useful suggestion would be greatly appreciated. Thank you for your time and attention.