Table of Contents

Wear of grinding media represents a significant cost in the wet grinding of ores in commercial ball mills. The total wear process of grinding involves a number of mechanisms including abrasive and corrosive wear. More knowledge about the wear mechanisms and the relative importance of each wear component would enable one to better select grinding media for specific applications, and could lead to the development of alloys with improved resistance to wet grinding wear.

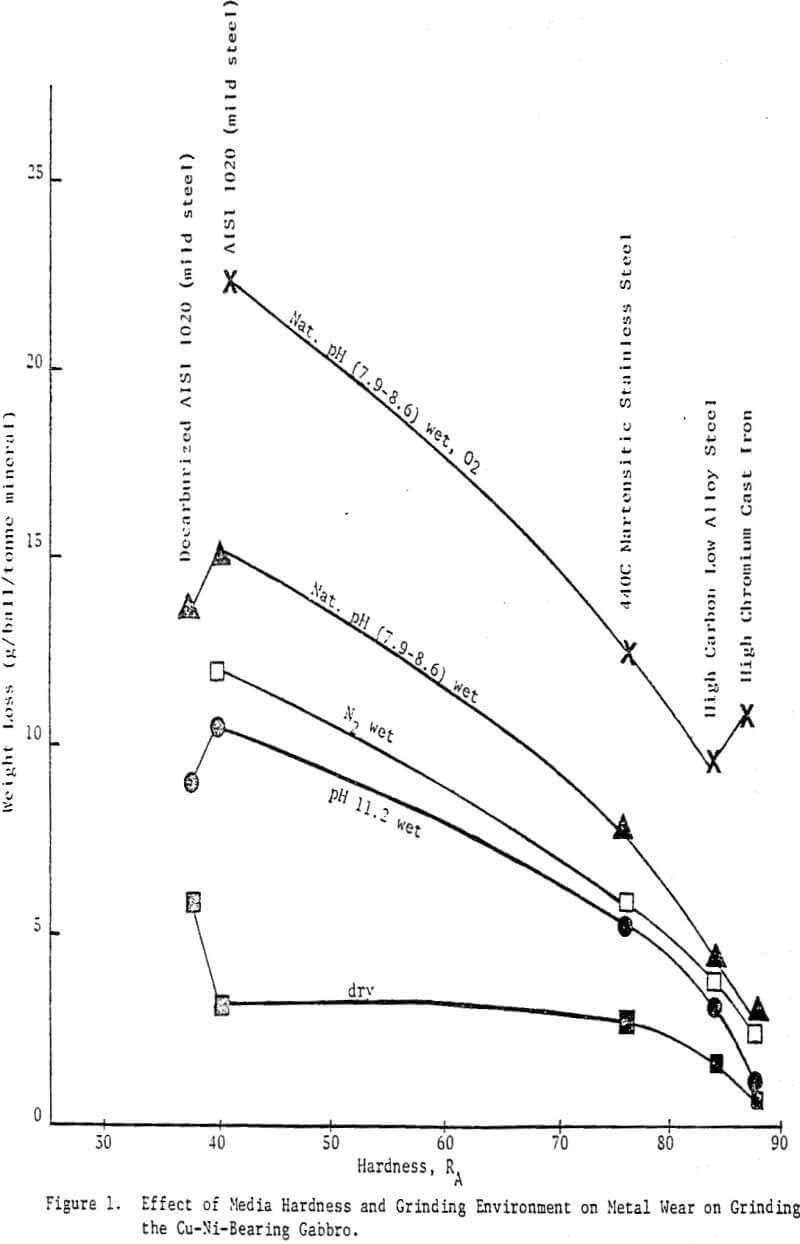

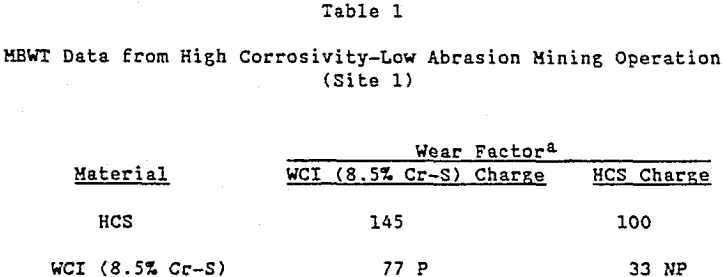

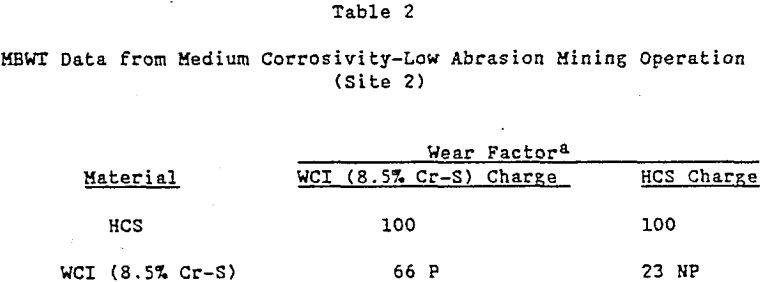

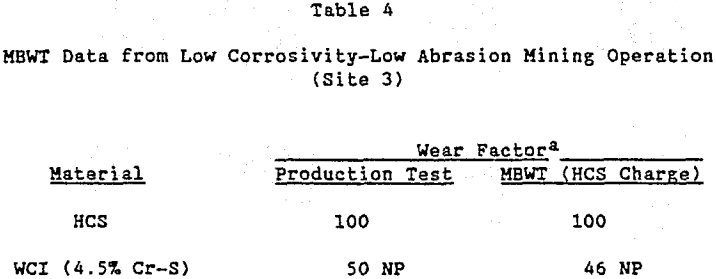

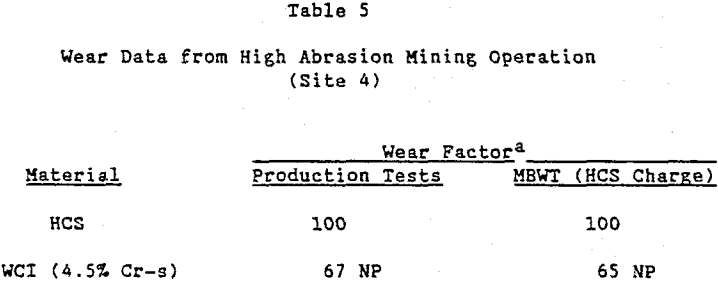

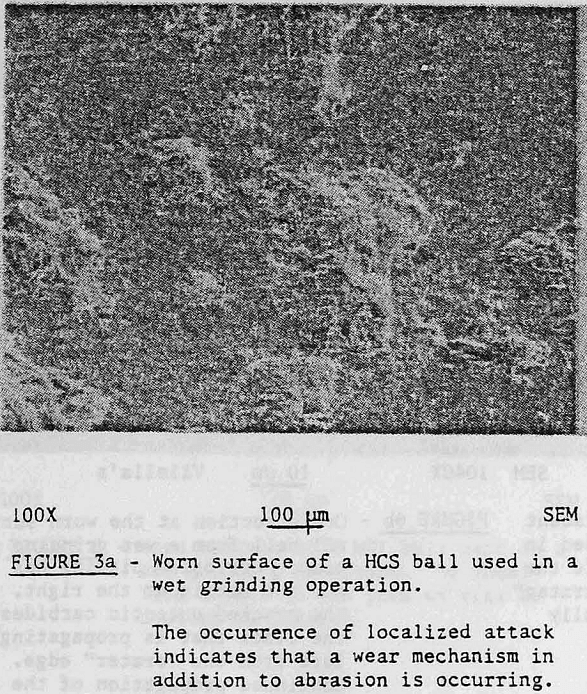

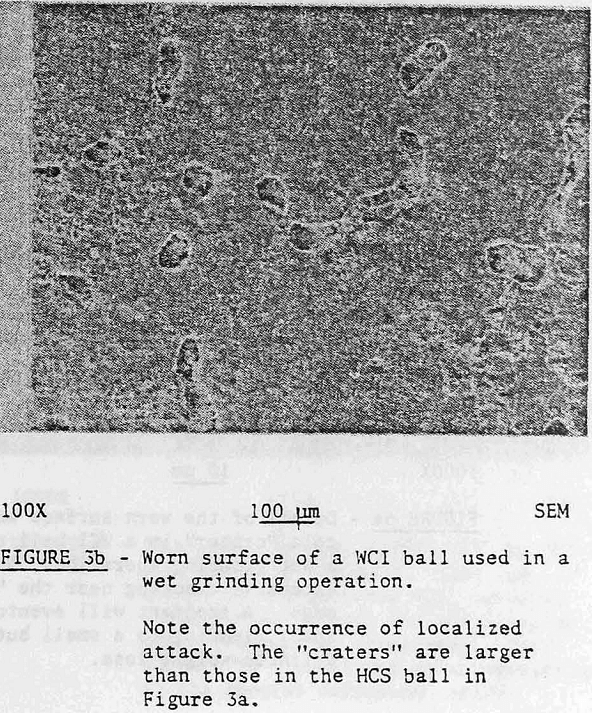

The operative corrosion mechanism for each specific application, however, depends on both the abrasiveness and corrosivity of the ore slurry environment. High abrasion rates are more conducive to a general corrosion mechanism, while high corrosivity favors pitting/spalling. The precise positioning of the curve shown in Figure 1 also depends upon the relative abrasion and corrosion resistance of the grinding media itself. Two general types of grinding media are widely used in the mining industry; Cr alloyed white cast iron (WCI) and high carbon low alloy steels (HCS).

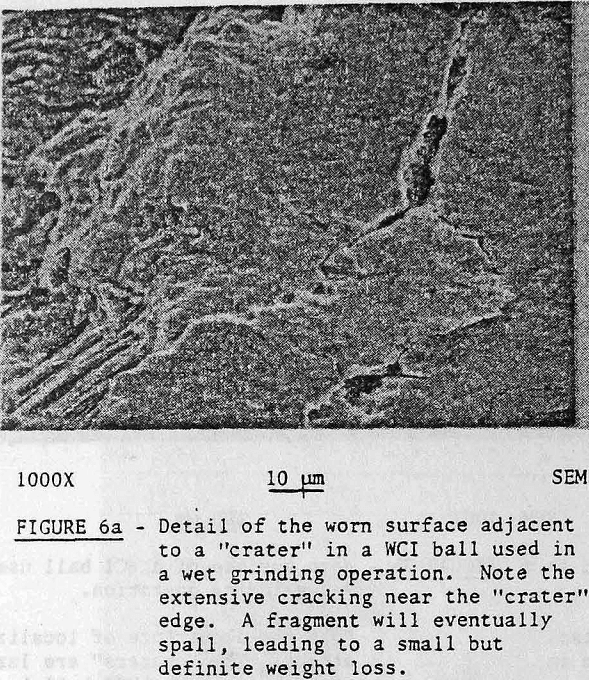

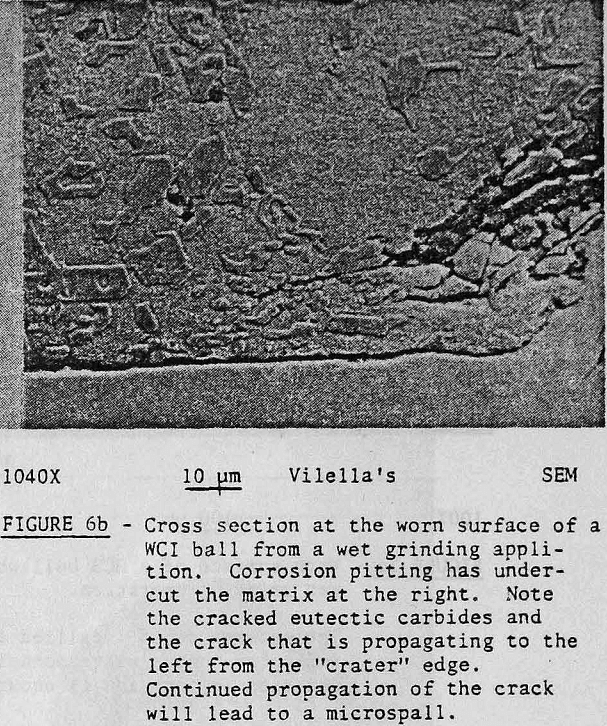

Pitting Spalling of Grinding Balls

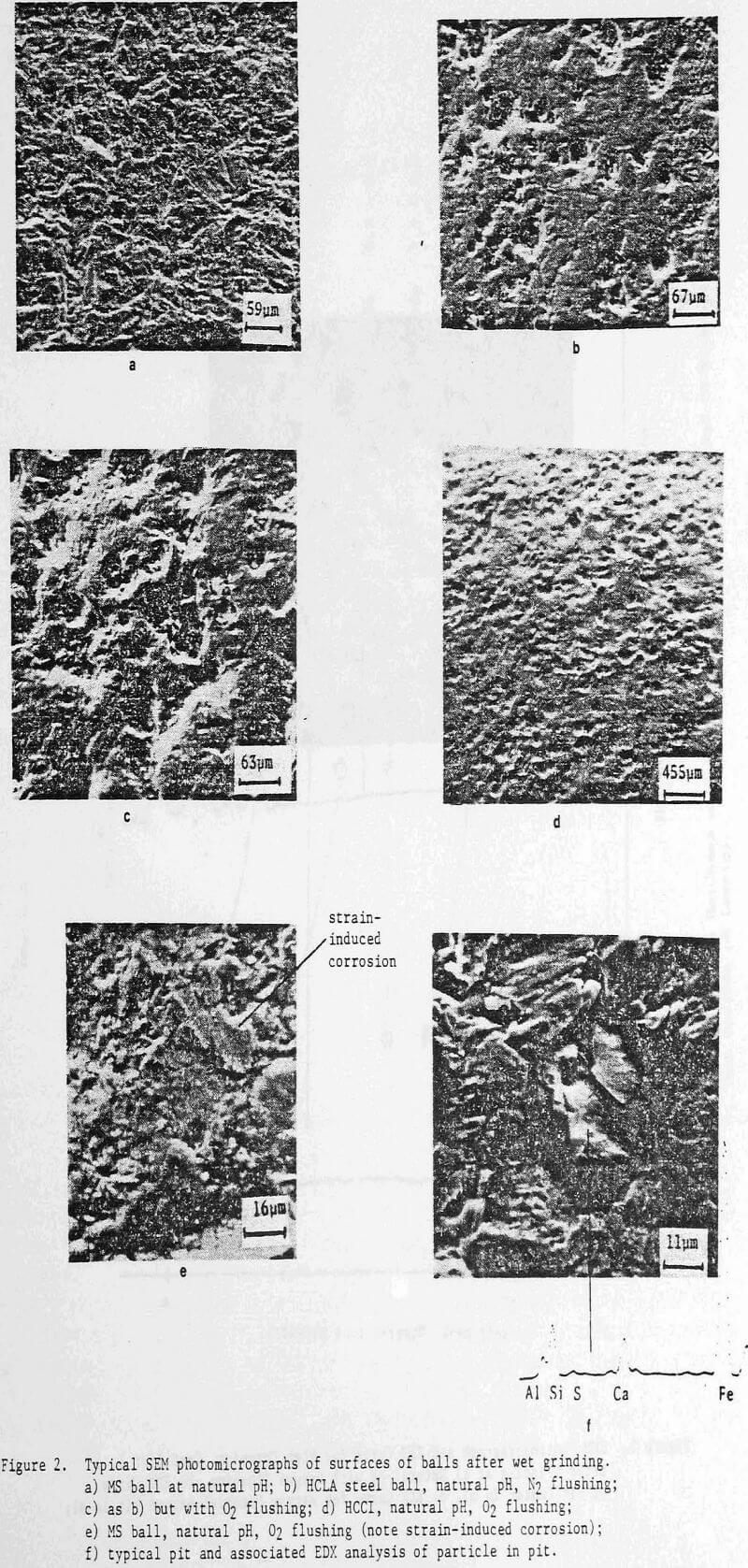

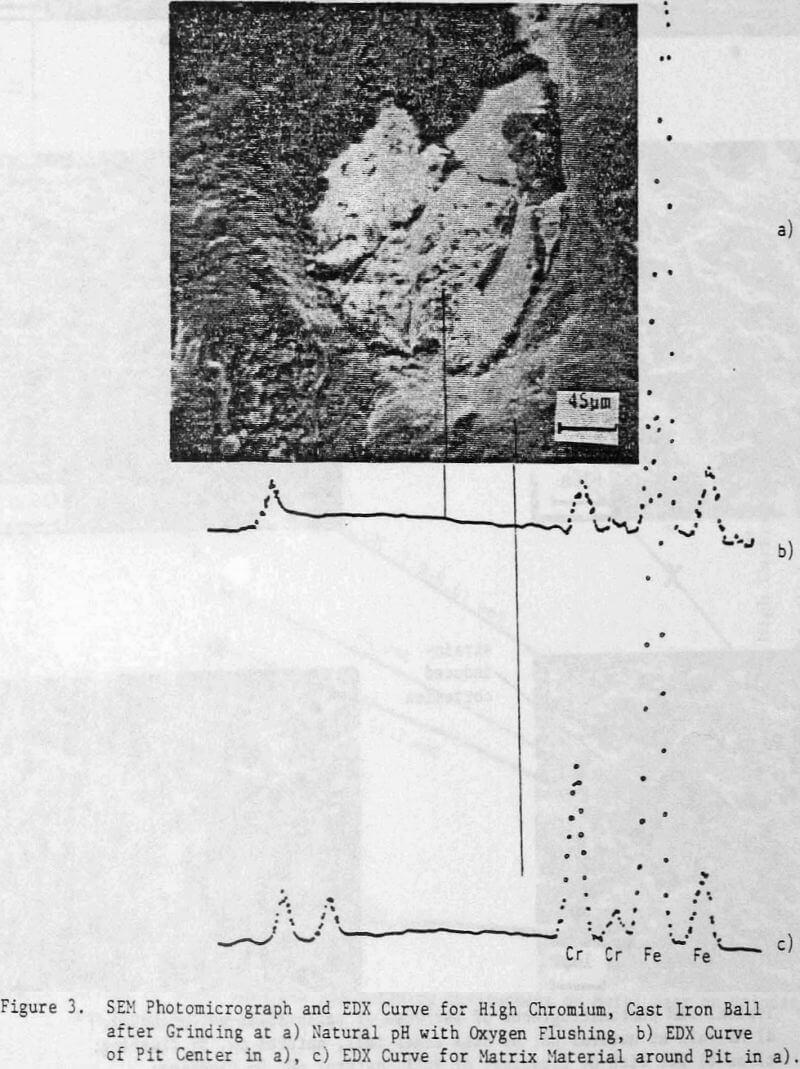

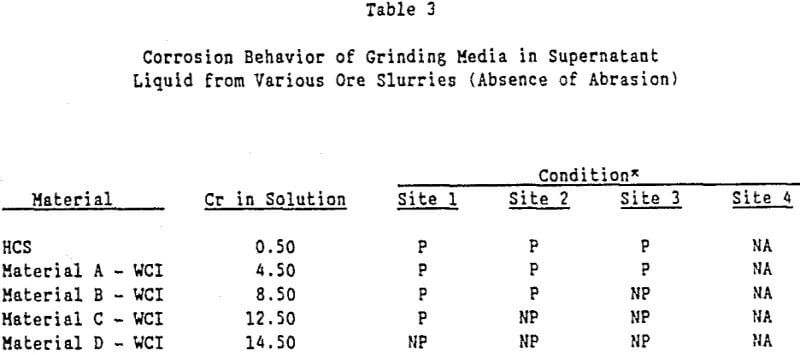

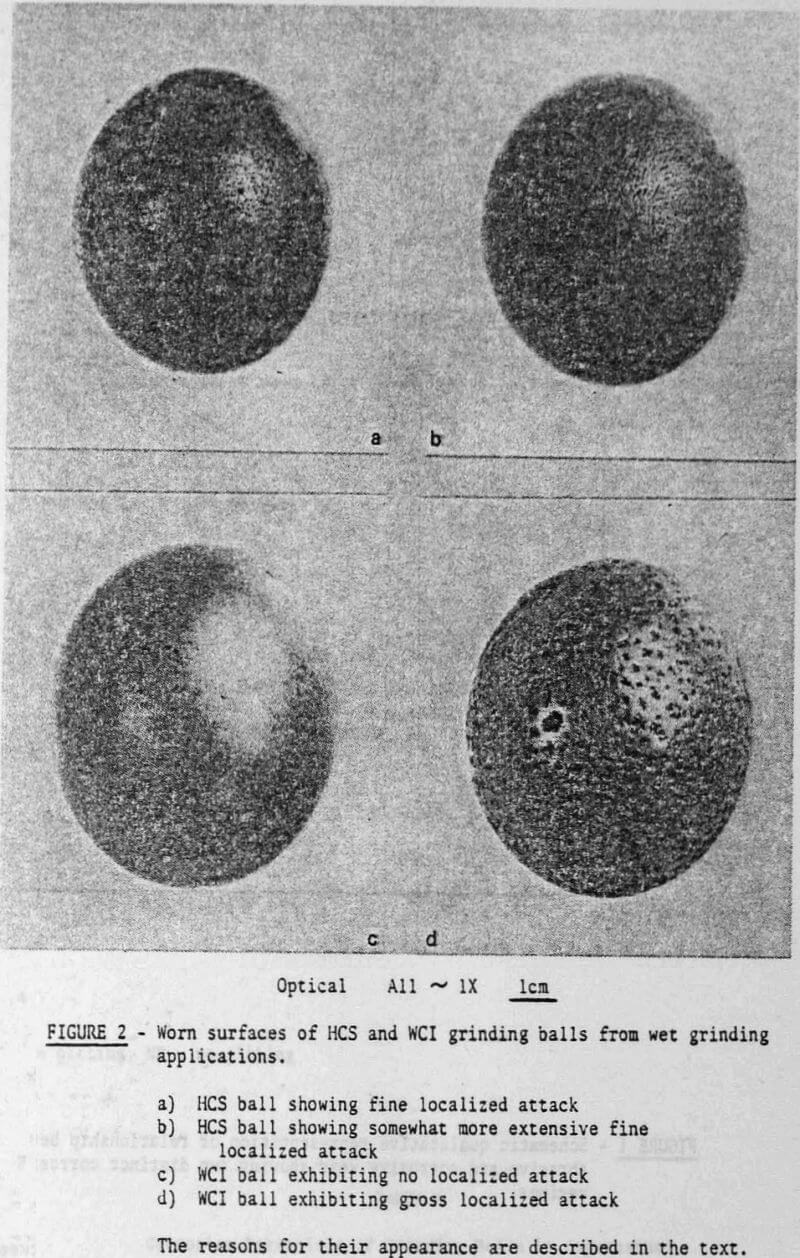

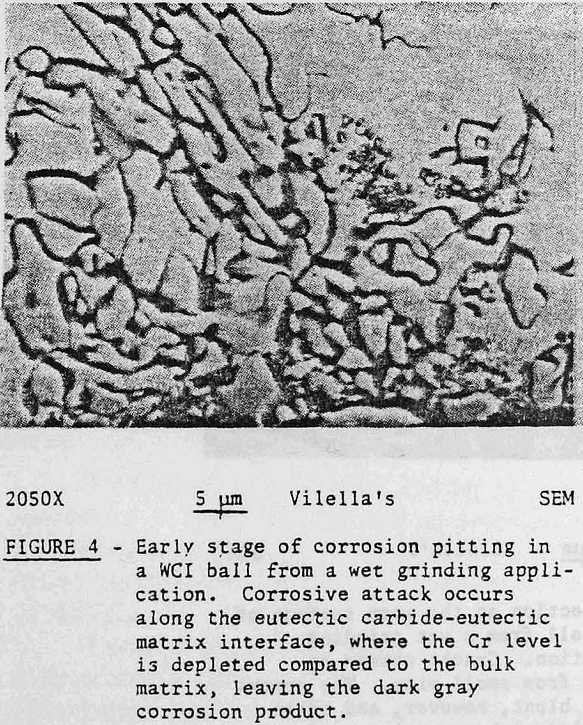

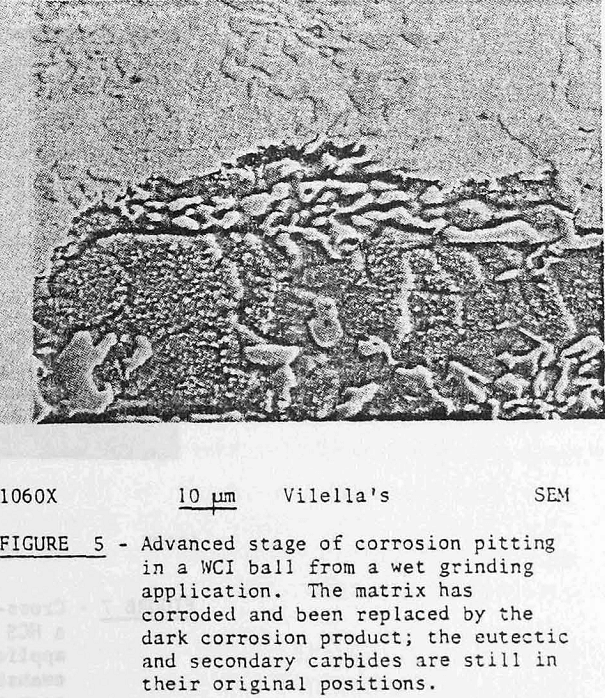

Pitting generally initiates by the breakdown of a passive film or at sites exhibiting chemical or microstructural inhomogeneities. The eutectic matrix immediately adjacent to the eutectic carbide has a lower Cr content than the rest of the matrix because more of the Cr will partition to the adjacent carbide phase than to the adjacent eutectic phase. Therefore, this Cr-depleted region will have lower corrosion resistance than the bulk matrix and will be a preferential site for initiation of pitting.

Since the pitting/spalling mechanism can represent a significant portion of the overall wear, one would want to avoid this type of mechanism from an engineering standpoint. This is accomplished by using WCI alloys with sufficient Cr-S to avoid pitting in the absence of galvanic protection since for each environment, a critical Cr-S level exists above which pitting/spalling will not occur.

General Corrosion Regime

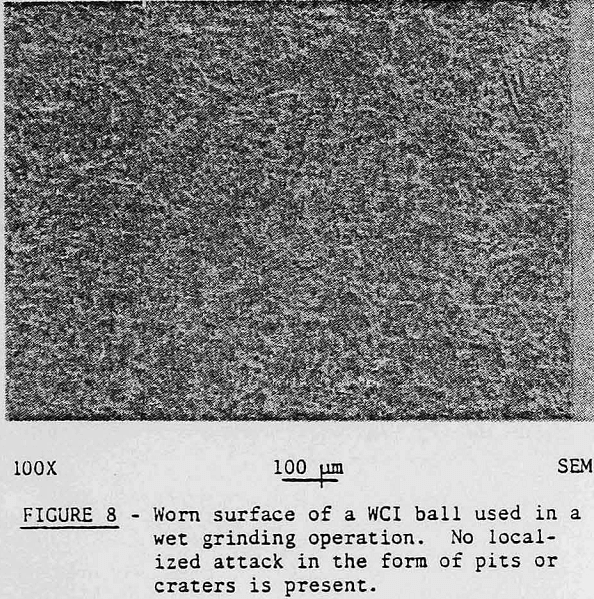

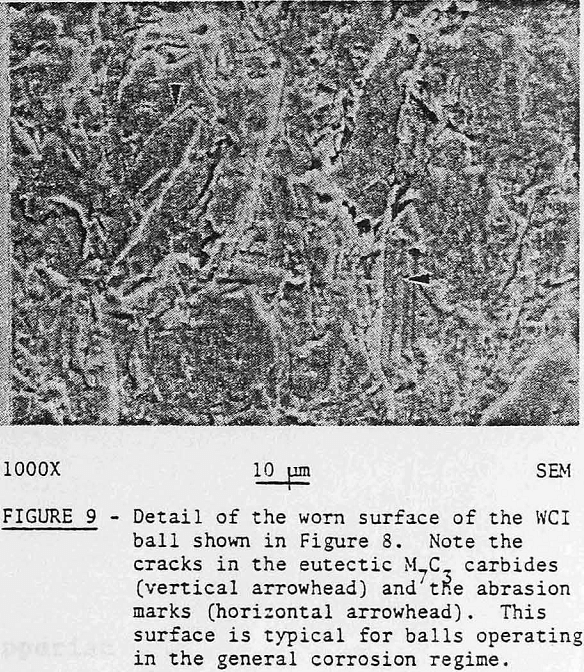

In many grinding environments, pitting is not observed on the surface of grinding balls (Figure 8). As abrasion rates exceed pit initiation and propagation rates, pitting will not occur and another type of corrosion mechanism will become operative. Certainly, abrasion creates surfaces of greater chemical activity which leads to higher uniform corrosion rates, but more work is needed to elucidate the corrosion mechanism in this regime.

Galvanic Corrosion Effects

The differences in corrosion potentials among various grinding ball materials indicate galvanic corrosion effects must be considered in interpreting grinding media behavior in ore slurry environments. Galvanic corrosion is the accelerated corrosion of a metal because of electrical contact with a dissimilar metal in a corrosive electrolyte. If two corroding metals are galvanically coupled, corrosion of the metal (anode) with the more active (negative) corrosion potential is accelerated while the other metal’s (cathode) corrosion rate is reduced.

Interaction of Corrosion and Abrasion in Grinding Media Wear

Steels and cast irons have been used for many decades as grinding ball materials (grinding media) in ore dressing operations. The wear of this media under wet grinding conditions is a net result of the metal loss due to the conjoint action of impact and abrasion, i.e., erosion, and corrosion. However, at the present time, there is some considerable debate as to the dominating influence of these two wear mechanisms in wet grinding operations since no detailed research work has been conducted to date in order to obtain fundamental data with respect to wear mechanisms in the various mineral-ball systems.

Experimental Procedure

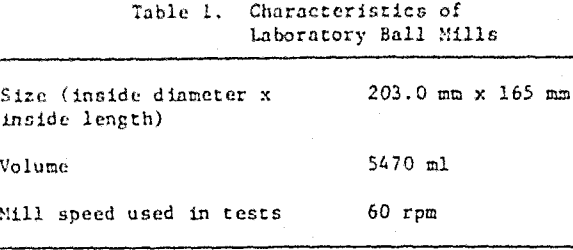

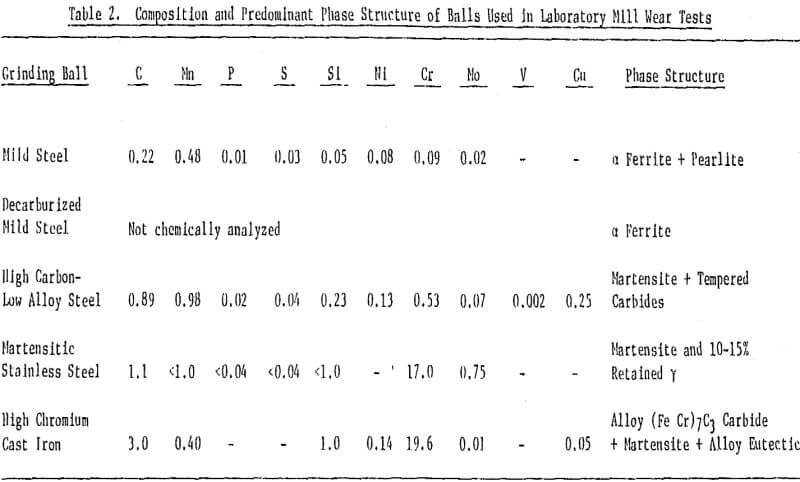

Grinding balls of different compositions ranging from mild steel (MS), martensitic stainless steel (MSS), high carbon low alloy (HCLA) steel and high chromium cast iron (HCCI), each of 25.4 mm diameter, were wear tested in a 203-mm diameter porcelain mill (see Table 1) under different conditions. In each test 15 balls out of a total ball load of 9000 g, i.e., 126 balls (136 for HCCI balls), were marked and their weight loss recorded after a certain grinding time. The surface layer of each ball type was removed prior to conducting the marked ball wear tests by grinding for 30 hours in the porcelain mill.

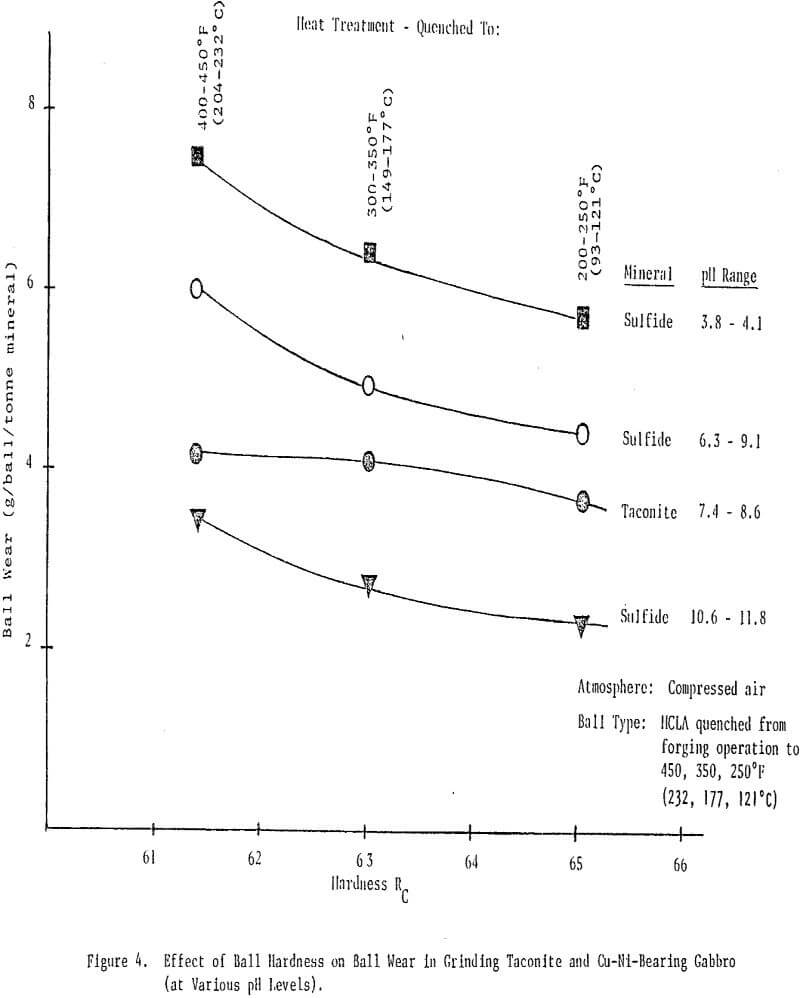

Most of these initial grinding tests were conducted in a slurry comprised of a Cu-Ni bearing gabbro at -10 mesh. Some tests were also conducted to compare taconite with the gabbro in compressed air conditions. Although the range of slurry compositions being investigated has been increased recently, the present paper will discuss only these initial slurry systems.

Experimental Results and Discussion

Dry grinding may be used as an indicator of the abrasion resistance of the grinding media. From this data it appears, in general, that increasing the hardness of the grinding media decreased the amount of media wear during dry grinding, as one would expect. However, although there is a considerable difference in hardness between the MSS ball and the MS ball there is only a small difference in their wear under dry grinding indicating the importance of microstructure. This latter point is also emphasized in wet grinding the Cu-Ni-bearing gabbroic rock in certain instances.

In this latter respect the single phased (a ferrite) structure of the decarburized layer in the mild steel ball provided a lower wear rate on wet grinding compared with that of the more abrasion resistant two-phased (ferrite + pearlite) structure found in the bulk MS ball. This suggests a galvanic effect is produced between these two phases (a and pearlite) which has resulted in increased corrosive wear.

The origin of these second-phase particles is, at the present time, somewhat speculative but appears to be mainly from two possible sources. FeS, silica/silicates and alumina/aluminates are present in the ore and may become embedded in the abraded ridges of the surface of the balls on impact. Alternatively, similar compounds, e.g., Al2O3, SiO2, FeS, CaS, are present as deoxidation and desulfurization products during the steelmaking and alloy iron production processes and may be retained within the bulk steel during subsequent solidification and fabrication into grinding media (balls).

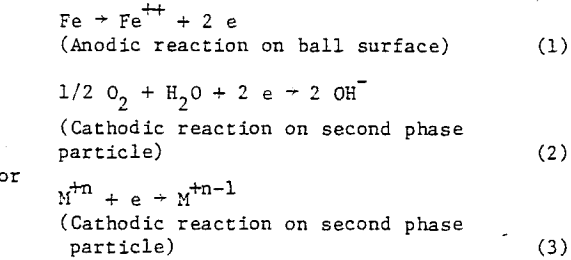

The major corrosion reactions that may have occurred can be summarized as:

O2 + 4H+ + 4e → 2H2O………………………………………………..(4)

2H+ + 2e → H2……………………………………………………………..(5)

Conclusions

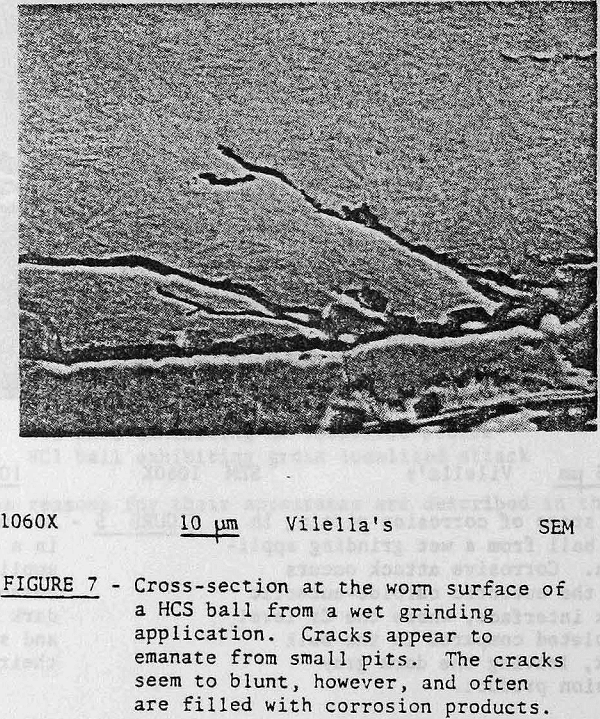

Two types of wear mechanisms were identified in grinding the Cu-Ni-bearing sulfide gabbroic rock: (1) a strain-induced corrosion mechanism associated with abrasive gouging was prevalent in softer grinding media such as mild steel while, (2) a pitting corrosion mechanism associated with segregated areas in the ball, inclusions or impacted minerals on the ball surface predominated in the more abrasive resistant grinding media such as high carbon low alloy steel or high chromium white irons.