- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Grinding.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input.

- Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

-

https://www.911metallurgist.com/wp-content/plugins/wp-symposium-pro/forums/../css/images/wait.gif

Suggested rubber shell liners & lifter bar thickness (4 replies)

Please join and login to participate and leave a comment.

i am designing rubber lining for ball mill with below given operating condition can you please suggest me approximate thickness of shell liners and lifter bar ?

OPERATING CONDITIONS:

1. MATERIAL : MAGNETITE ORE + URANIUM ORE (COMBINED)

2. FEED SIZE : MAGNETITE ORE, 80% (-) 125microns & URANIUM ORE, 80% (-) 75MICRONS

3. PRODUCT SIZE : 90% (-) 53microns (+/- 5microns) AT HYDROCYCLONE OVERFLOW.

4. TYPE OF GRINDING : WET, continues

5. CAPACITY

(i) COMBINED FRESH FEED RATE : 11.0 tph DESIGNED & RATED

(iI) MAGNETITE ORE : 6.6 tph DESIGNED & RATED

(iII) URANIUM ORE : 4.4 tph DESIGNED & RATED

6. MILL SPEED : 22rpm (APPROX).

7. BALL SIZE DISTRIBUTION : 40mm DIA. - 12.5mt; 25mm DIA. - 8.5mt

8. MATERIAL OF : HIGH-CHROME

GRINDING MEDIA

9. WT. OF GRINDING MEDIA : 21mt.

10. MILL HEAD ANGLE : 11.5 DEGREE

11. SP. GR. OF MAT'L. : 5.15 FOR MAGNETITE ORE & 2.80 FOR URANIUM ORE

12. BWI : MAGNETITE ORE - 17.2kWh/mt. & URANIUM ORE - 11.0kWh/mt.

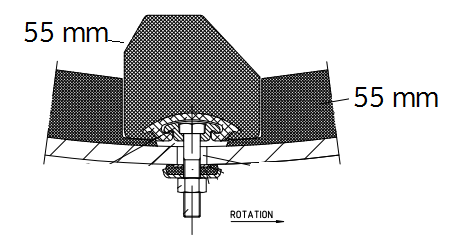

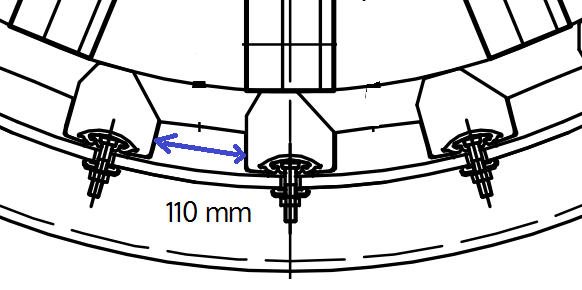

13. LINING TYPE REQD. : MILL SHELL SHALL BE LINED WITH SUITABLE RUBBER LIFTER BAR WITH INTERMEDIATE LINER ALONG EACH ROW. MILL HEADS (FEED END & DISCH. END) SHALL BE LINED WITH SUITABLE RUBBER LIFTER BAR WITH INTERMEDIATE LINER.

14. FIXING WITH SHELL : BOLTED & HEADS

15. Mill ROTATION : C.C.W. LOOKING FROM FEED END.