Heavy media separation is one of a number of pre-concentration techniques for coarse feed which, when the ore is amenable, offers economic advantages in the mining stage and/or the processing stage. In mining, simpler and cheaper methods may be used if a greater proportion of waste material can be included in the mining blocks that can later be removed efficiently at a coarse size. In the mill, pre-concentration can mean considerable savings in capital and operating costs by down-scaling of equipment sizes particularly in the grinding section. Conversely, throughput may be increased using the equipment already installed in the concentrator.

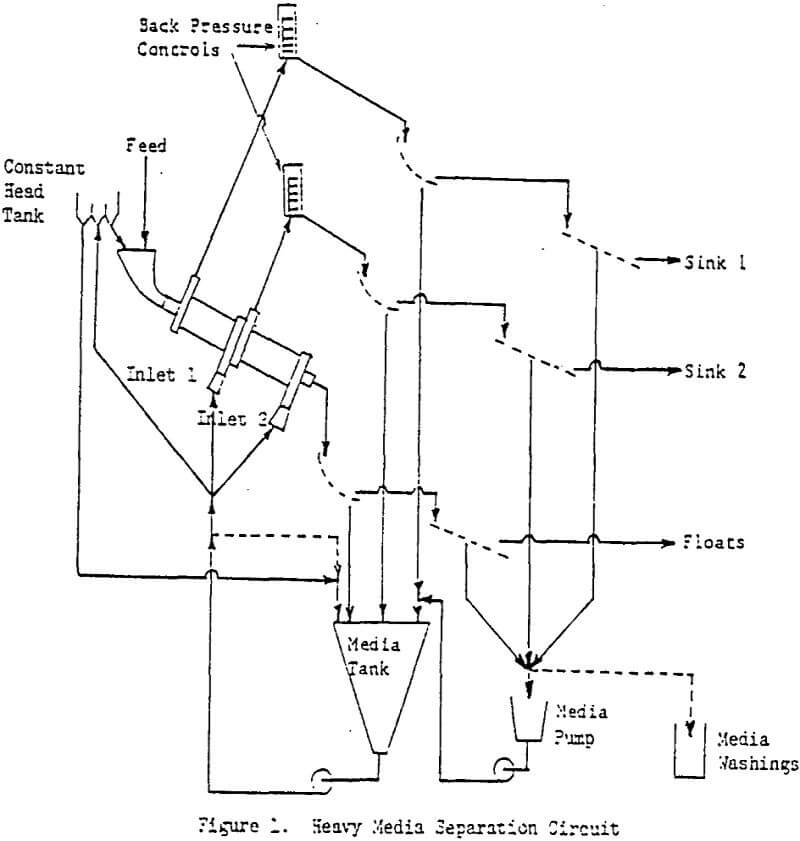

The Equipment

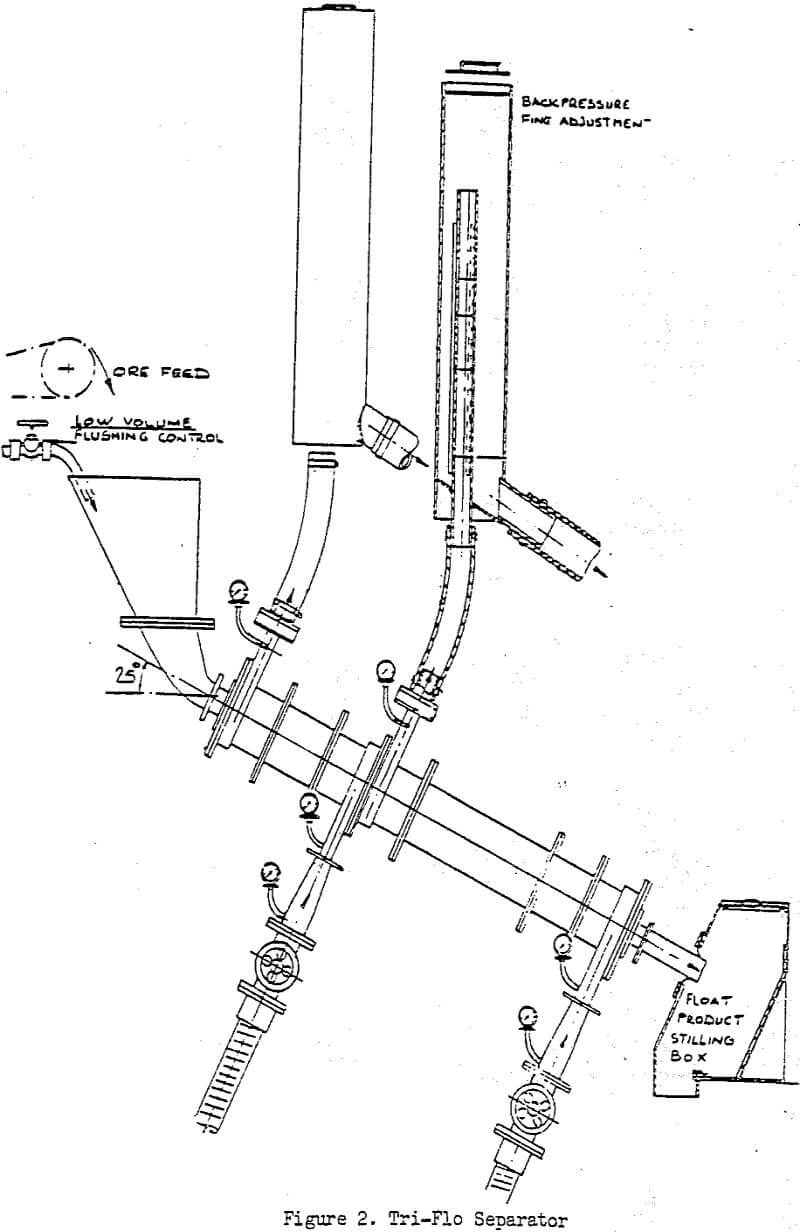

A Tri-Flo separator was chosen because of the fact that two sink products, rougher and scavenger, are produced. This has the advantage of providing two points on a grade vs recovery or metal loss vs weight rejection curve for each test performed.

Operating Variables

The only variables now studied during normal test runs are:

- Media composition

- Media density

- Back pressure fine adjustment by stand-pipes.

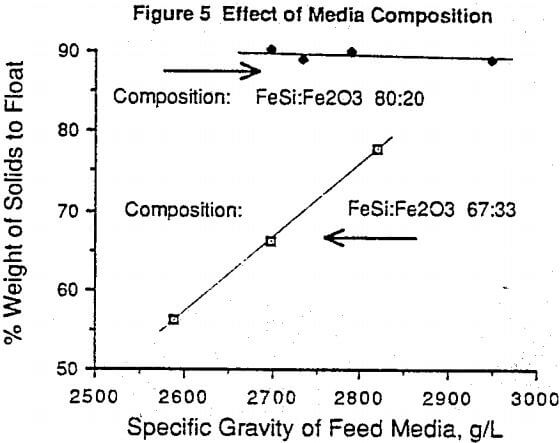

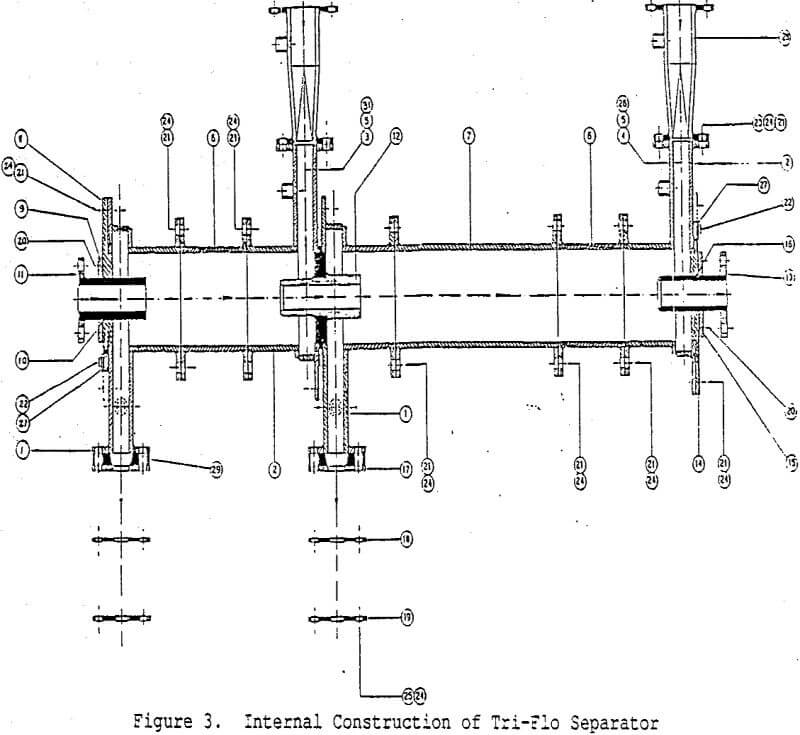

The two components that make up the medium are ferrosilicon and magnetite. Ferrosilicon can be obtained in three basic forms – regular, milled and atomized – showing successively increased sphericity. Early in the set-up testwork it was found that neither the regular nor the milled grades of ferrosilicon couid be used with the laboratory model, TF150, because no “Sink 1” product could be produced.

Test Procedure

Tests are run on batches of about 20 kg of ore, prescreened at 10 mm and 0.83 mm (20 mesh Tyler). The upper size is limited by the diameter of the feed tube. On larger Tri-Flo models particles up to 40 mm can be handled. The fine size limit is set by our screen openings. Separation down to 0.15 mm (100 mesh Tyler) can be obtained on some ores using specially designee screening and media handling facilities. Generally, 15% to 30% of an ore crushed to 10 mm is passing a 0.83 rare screen.

Separations are made over a series of media densities, which are usually determined by the specific gravities of the minerals to be separated or from previously performed heavy liquid separation tests. A typical range for a sulphide ore would be 2700 g/L to 3000 g/L using intervals of 50 g/L between tests. If a dramatic change in the split occurs at one particular media density then further tests are performed around this density using the fine back pressure adjustments to produce intermediate results.

Results

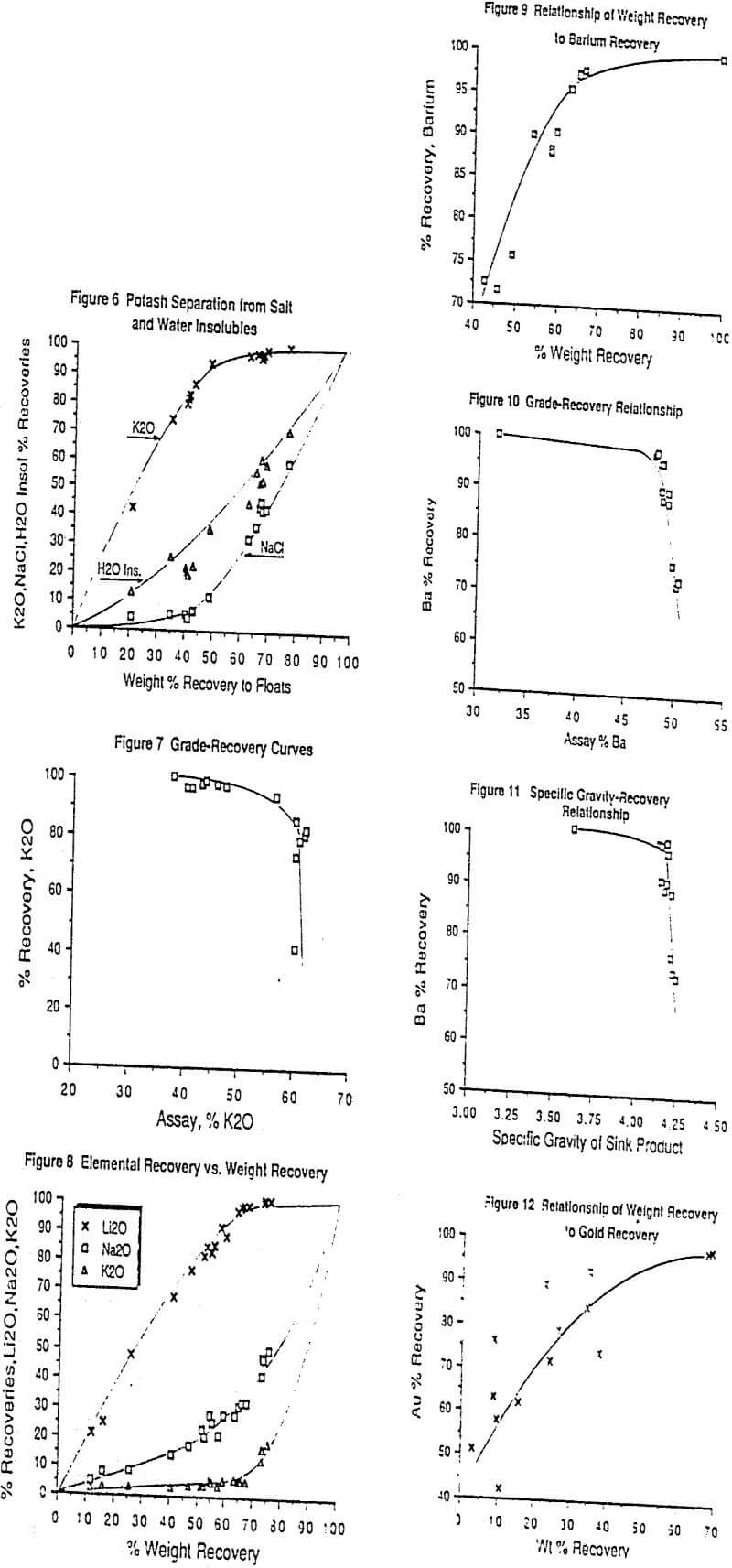

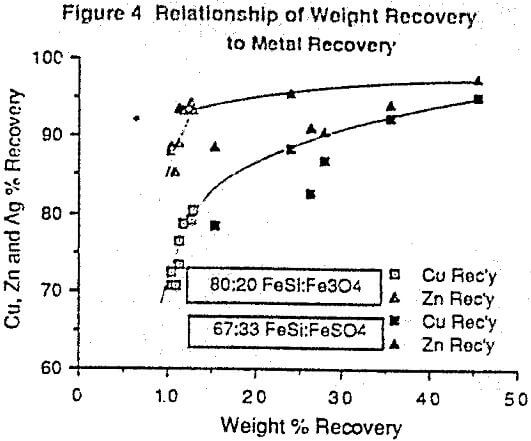

The test results can be presented in a number of ways, some of which are shown in Figures 4 to 11. Even though tests have not been run under optimum conditions, enough points will be available to predict the obtainable metallurgical results.

Figure 4 shows the results of a separation on a Cu-Zn ore which has since been run through a larger scale continuous pilot plant and is presently being engineered to plant scale. The change from the hollow symbols to the solid symbols reflects a change in media composition.