Table of Contents

We investigated methods for the recovery of byproduct heavy minerals from sand and gravel operations in Oregon and Washington. These heavy minerals are not currently recovered except for gold in a few areas. The recovery of byproduct heavy minerals would provide a domestic source of minerals presently imported, and a more efficient use of domestic resources would be accomplished. Samples from more than 40 locations were treated by gravity separation to yield heavy mineral concentrates (black sands). Magnetite, ilmenite, zircon, rutile, chromite, platinum-group minerals, radioactive minerals and gold were identified in the concentrates. Individual zircon, ilmenite, chromite, magnetite, and gold products were recovered from selected concentrates by low- and high-intensity magnetic, high-tension, and heavy-medium separation techniques. The recovery for the individual mineral products ranged from 67 to 95 pct.

The Bureau of Mines has investigated the heavy minerals in samples obtained from active sand gravel operations in Oregon and Washington. Earlier, similar investigations were reported for northern California and central and southern California. The recovery of byproduct gold from some sand and gravel operations in southwestern and northeastern Oregon has been practiced for many years, but the recovery of other heavy minerals has not. Recovering byproduct heavy minerals has the following incentives:

- the value of heavy minerals would be a financial help to marginal operations and

- more efficient use of domestic resources would be accomplished.

Heavy minerals occurring in Oregon and Washington alluvial deposits include magnetite, ilmenite, hematite, chromite, zircon, garnet, radioactive minerals, gold, and platinum-group minerals. An extensive study of the heavy minerals (black sands) in the Northwest was reported by Day and Richards of the U.S. Geological Survey in 1905. Several of these minerals have economic potential because their value continues to increase more rapidly than the inflation rate. The recovery of byproduct zircon, chromite, and platinum- group minerals is of national interest because more than 90 pct of these minerals are imported.

Washington and Oregon produce about 50 million tons of aggregate annually. The majority of the aggregate is produced in the populated western areas of the two States. The sand and gravel deposits are situated in alluvial or glacial deposits derived from mineralized areas in the Cascade, Olympic, and Klamath-Siskiou Mountains. Sand and gravel deposits in the eastern parts of the States are derived from mineralized areas in the Blue, Wallowa, and Bitterroot Mountains. Large sand and gravel deposits are also located in the flood plains of the Columbia and Willamette Rivers.

Placer gold was discovered in Oregon and Washington in 1845 and 1853, respectively, but was not actively mined in Oregon until 1851 and in Washington until 1860. The major gold areas are located in southwestern and northwestern Oregon and north-central Washington. In both States, mining districts with limited gold production are located in the Cascade Mountains. In addition to gold, Oregon and Washington have sizable occurrences of other heavy minerals, such as chromite and ilmenite.

Only a few successful attempts on recovering heavy minerals other than gold as byproducts from sand and gravel operations have been reported in the literature. Iron oxides were recovered from sand and gravel in England.

The Bureau of Mines has investigated the recovery of ilmenite, zircon, kyanite and rutile in the Southeastern United States.

The objectives of this investigation were (1) to determine the heavy mineral contents of individual sand and gravel deposits, (2) to investigate the recovery of heavy mineral concentrates from deposits that showed significant quantities of heavy minerals, and (3) to investigate the preparation of market-grade mineral products from selected concentrates.

Heavy Mineral Sampling and Characterization

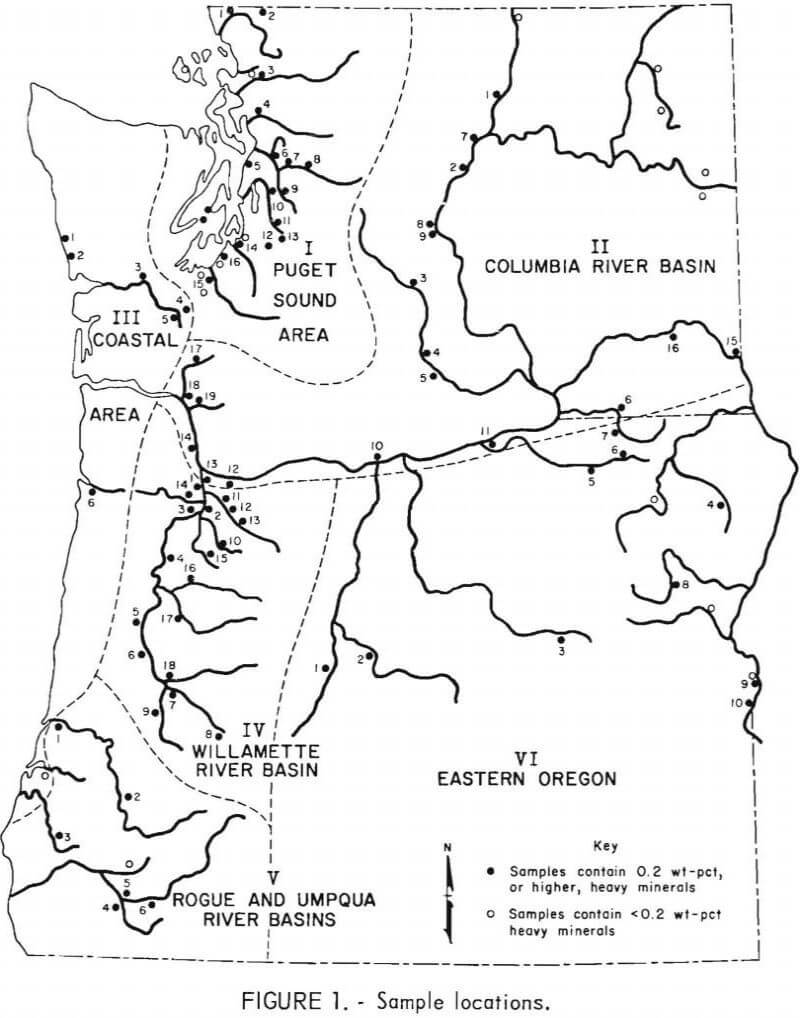

The locations of Oregon and Washington operations that provided samples for this investigation are shown in figure 1. To simplify the tabulation of results, Oregon and Washington were divided into six areas: (I) Puget Sound, (II) Columbia River Basin, (III) coastal area, (IV) Willamette River Basin, (V) Rogue River and Umpqua River Basins, and (VI) eastern Oregon. The sand and gravel operations are located in alluvial deposits in stream channels and flood plains and in glacier deposits. The heavy minerals (HM) are mainly derived from the weathering of mineralized areas in the major mountain ranges.

Forty- to fifty-pound grab samples from stockpiles of washed cement or mortar sand were obtained from the sand and gravel operations. No attempts were made to obtain representative samples of the deposits, as that would have involved extensive sampling and considerable work at each operation. A spiral concentrator was used to prepare HM concentrates from the sand samples.

The concentrates were microscopically examined, chemically analyzed for Cr2O3, total iron, ZrO2, TiO2, gold, silver, and platinum-group metals, and spectrographically analyzed for other metals of economic significance. The approximate concentrations of chromite, ilmenite, and zircon in the sand fraction were calculated. An electron microprobe analysis was made on some samples to determine mineral associations and trace elements. The total HM content was determined by heavy-medium separation using diiodo-methane (specific gravity of 3.3). The HM concentrate also contained heavy silicate minerals, such as garnet, hornblende, kyanite, olivine, and sphene. Low-intensity magnetic separation and chemical analysis were used to define the magnetic separation characteristics of the samples.

Samples containing less than 0.2 wt-pct HM were not reported in the tables, but their locations (open circles) are shown in figure 1. The results reported in the tables are based on the sand fraction, which was usually 95 pct minus 4- plus 100-mesh. The heavy minerals were usually liberated at minus 20-mesh. Because of the varying sand contents in the deposits, the amounts of minerals in the inplace deposits were not calculated.

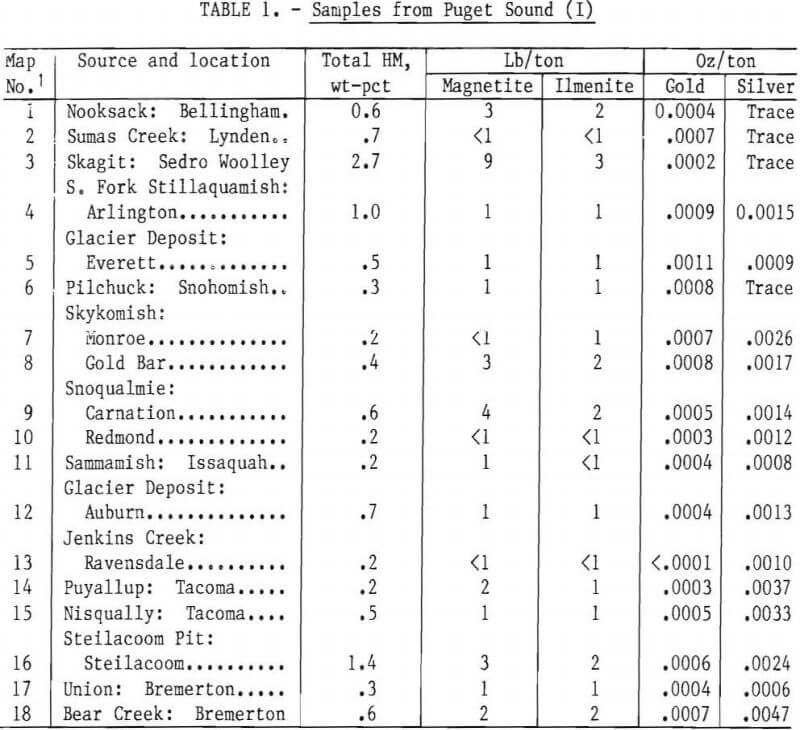

Results for samples from the Puget Sound area are shown in table 1. The samples contained 0.2 to 2.7 wt-pct HM. The major nonsilicate heavy minerals were magnetite, up to 9 lb/ton, and ilmenite, up to 3 lb/ton. Gold and silver ranged from less than 0.0001 to 0.0011 oz/ton, and from a trace of 0.0047 oz/ ton, respectively. The discussion of heavy minerals in the concentrates will be concerned with minerals having potential industrial interest. A major quantity of heavy silicate minerals such as hornblende, sphene, epidote, and olivine were identified in many concentrates, but these minerals will not be discussed.

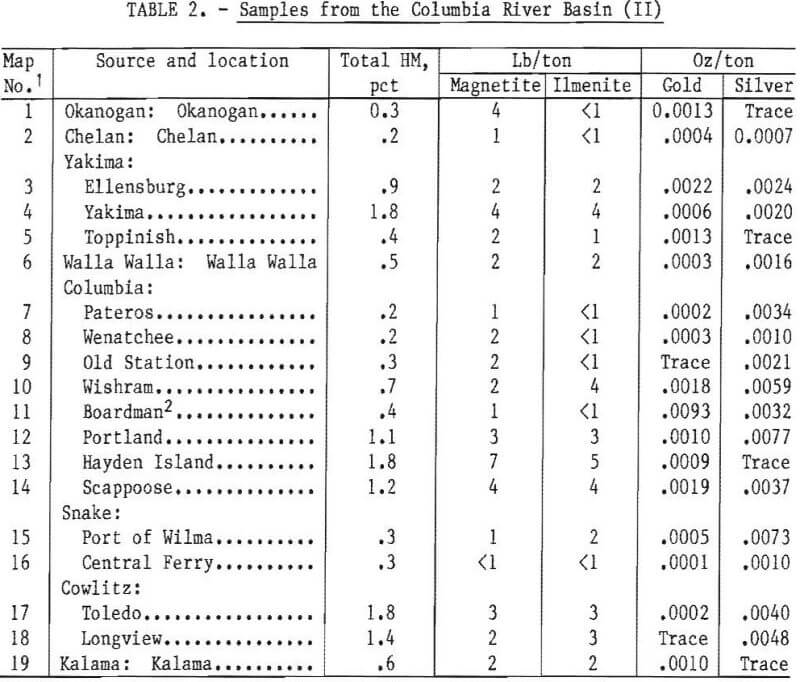

Results of samples from the Columbia River basin are shown in table 2. The samples contained 0.2 to 1.8 wt-pct HM; magnetite, up to 7 lb/ton, and ilmenite, up to 5 lb/ton, were the major minerals. Gold and silver ranged from a trace to 0.0093 oz/ton and from a trace to 0.077 oz/ton, respectively. The platinum content of the Boardman sample was 0.0001 oz/ton.

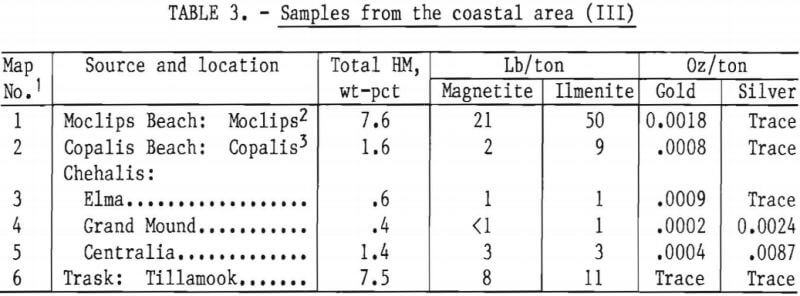

Results of samples from the coastal area are shown in table 3. The HM content ranged from 0.4 to 7.6 wt-pct. The major heavy minerals in the samples were magnetite, less than 1 to 21 lb/ton, and ilmenite, 1 to 50 lb/ton. Gold ranged from a trace to 0.0018 oz/ton, and silver from a trace to 0.0087 oz/ton. The Moclips Beach sample contained 2 lb chromite, 14 lb zircon, 50 lb ilmenite, and 1 lb rutile per ton of sand. This sample contained the largest amounts of chromite, ilmenite, rutile, and zircon of all the samples in this study.

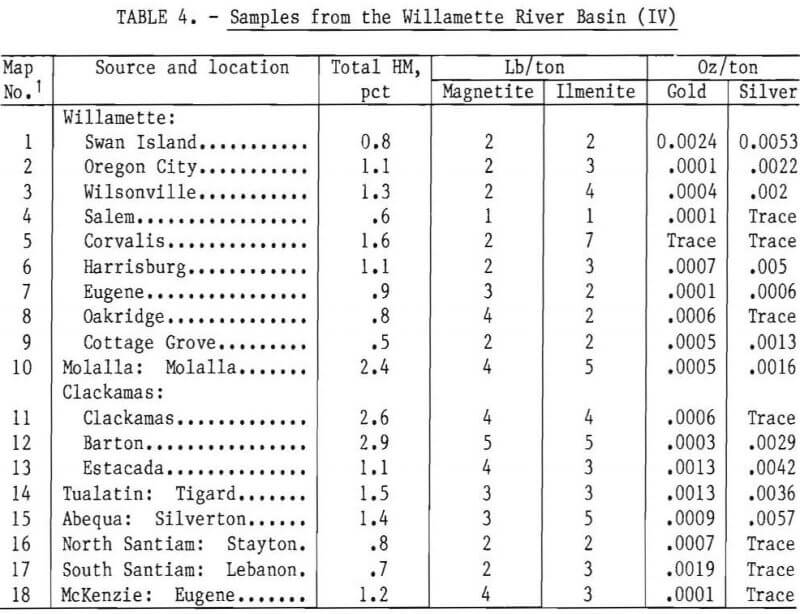

Results of samples from the Willamette River Basin are shown in table 4. These samples showed HM contents of 0.5 to 2.9 wt-pct. The major heavy minerals were magnetite, 1 to 5 lb/ton, and ilmenite, 1 to 7 lb/ton. Gold and silver ranged from a trace to 0.0024 oz/ton, and from a trace to 0.0057 oz/ton, respectively.

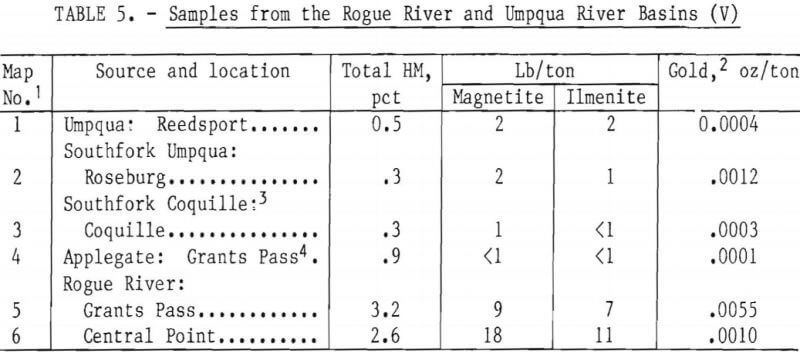

Results of samples from the Rogue River and Umpqua River basins are shown in table 5. The HM contents ranged from 0.3 to 3.2 wt-pct. The major heavy minerals were magnetite, less than 1 to 18 lb/ton, and ilmenite, less than 1 to 11 lb/ton. Gold content ranged from 0.0001 to 0.0055 oz/ton. Silver was not detected in this group of samples. The Applegate sample contained little gold because gold had been removed from the material by treatment in a sluice.

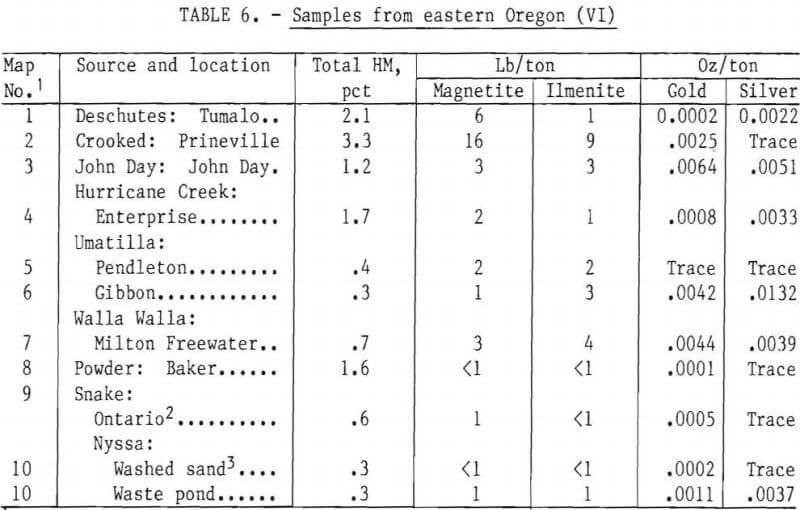

Results of samples from the eastern Oregon area are shown in table 6. The HM contents ranged from 0.3 to 3.3 wt-pct. The major heavy minerals were magnetite, less than 1 to 16 lb/ton, and ilmenite, less than 1 to 9 lb/ton. Gold and silver in the samples ranged from a trace to 0.0064 oz/ton and from a trace to 0.0132 oz/ton, respectively. Samples from the Ontario and Nyssa plants contained 0.0003 and 0.0008 oz/ton platinum, respectively. Gold has been recovered at the Baker plant.

Beneficiation

Gravity Concentration

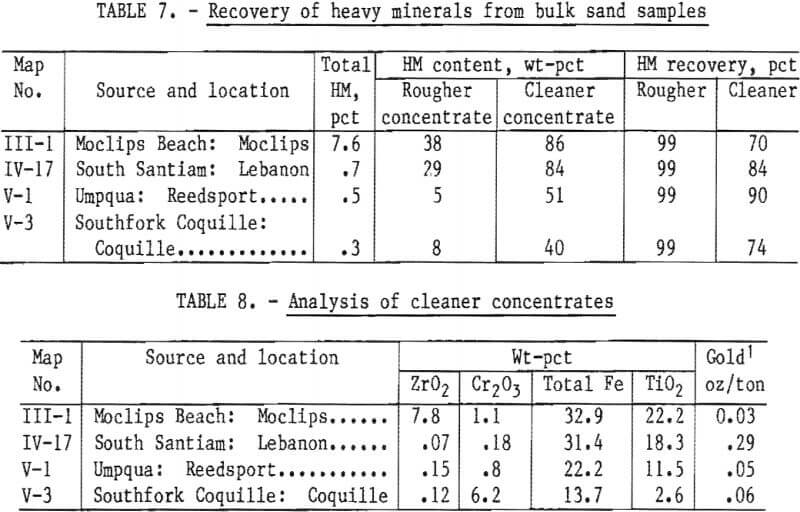

Because of the quantity of zircon, ilmenite, chromite, or gold present, four samples were selected for beneficiation studies: the Moclips sample from Moclips Beach in area III (coastal area); the Lebanon sample from South Santiam in area IV (Willamette River Basin); the Reedsport sample from Umpqua in area V (Rogue River and Umpqua River Basins); and the Coquille sample from Southfork Coquille in area V (Rogue River and Umpqua River Basins). For each sample between 300 and 500 lb of cement or mortar sand were treated in a spiral concentrator. The rougher concentrates weighing 20 to 30 lb were cleaned in a spiral to obtain cleaner concentrates containing 40 to 86 wt-pct HM. Recoveries of HM in the cleaner concentrates, shown in table 7, ranged from 70 to 90 pct. The analyses of the cleaner concentrates are shown in table 8, The Moclips Beach sample was subsequently beneficiated to recover gold, ilmenite, and zircon. The South Santiam and Umpqua samples were treated to recover gold and ilmenite, and the Southfork Coquille sample was beneficiated to recover gold and chromite,

Separation of Heavy Mineral Concentrates

Moclips Beach Sample

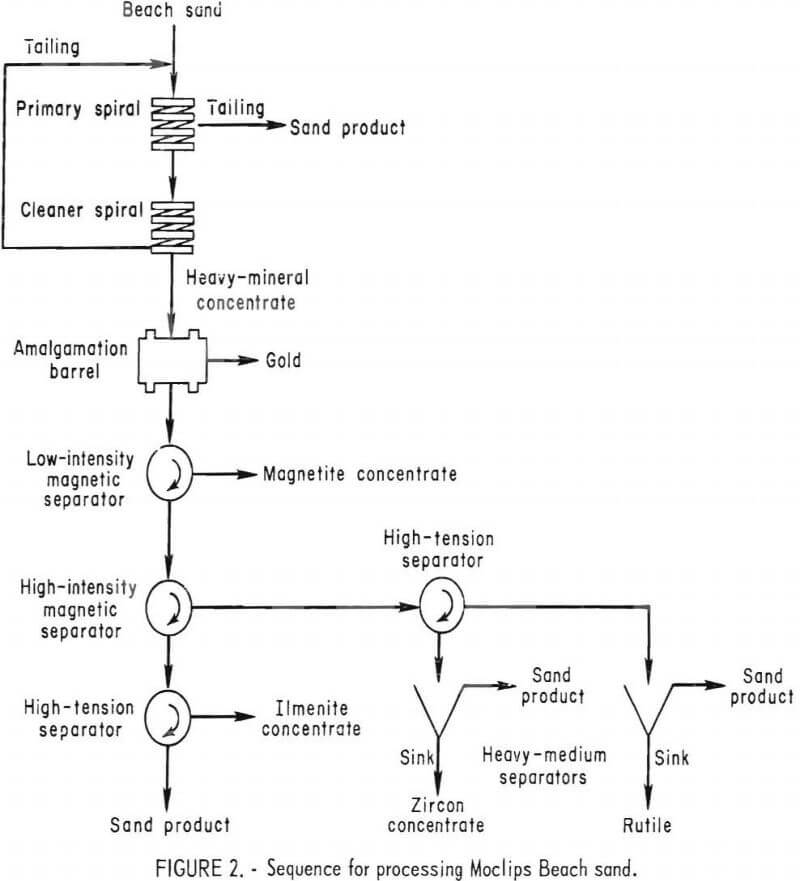

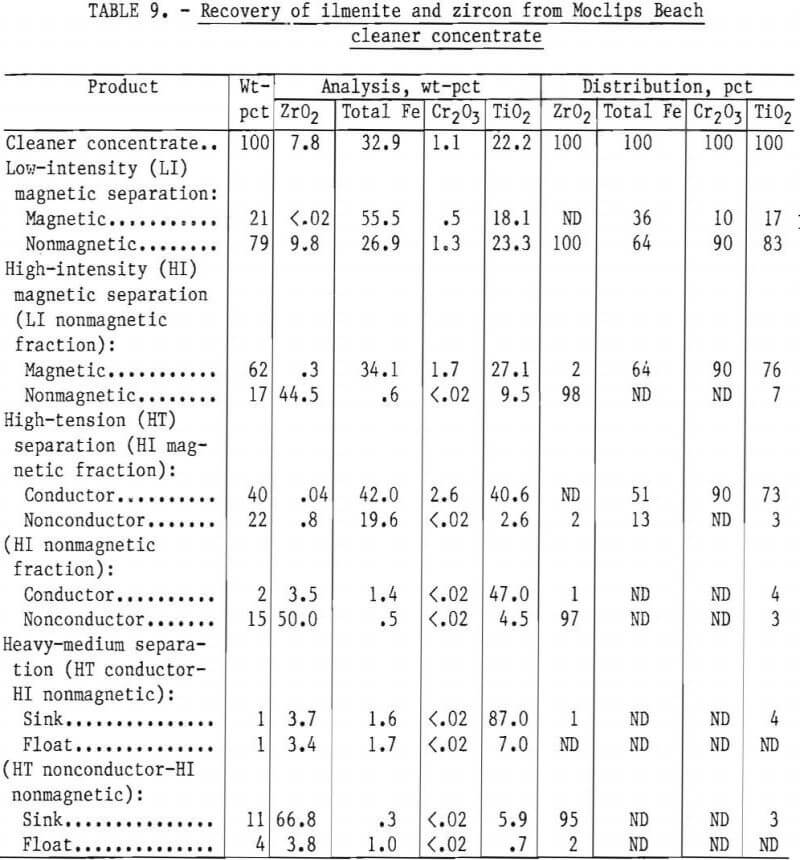

The processing sequence for the recovery of gold, ilmenite, and zircon from the Moclips Beach sample is shown in figure 2. This sample contained more ilmenite and zircon per ton of sand than any of the other samples obtained from the sand and gravel plants. Analyses of products and distribution of major constituents are shown in table 9. Amalgamation of the concentrate,

which contained 0.03 oz of gold per ton, recovered approximately 100 pct of the gold. A magnetite product was recovered by low-intensity (LI) magnetic separation. The LI nonmagnetic fraction was treated in a high-intensity (HI) magnetic separator, which yielded zircon and ilmenite fractions. Both the zircon and ilmenite fractions were upgraded by high-tension (HT) separation. The heavy-medium sink from the HT conductor-HI nonmagnetic fraction contained 87.0 wt-pct TiO2 and represented about 1 pct of the concentrate. X-ray diffraction analysis indicated that rutile was the major mineral present. The magnetic fraction from HI magnetic separator was treated by a HT separator. X-ray analysis showed that ilmenite was the major mineral in the HT conductor fraction. This fraction contained 40.6 wt-pct TiO2 and recovered 73 pct of the TiO2 that was originally in the feed. The heavy-medium sink fraction from the HT nonconductor-HI nonmagnetic fraction contained 66.8 wt-pct ZrO2 with an accompanying recovery of 95 pct of the zircon. The rutile product could possibly be used as a chlorinator feed material, and the ilmenite product for the preparation of pigment by the sulfate process.

South Santiam and Umpqua Samples

South Santiam and Umpqua Samples

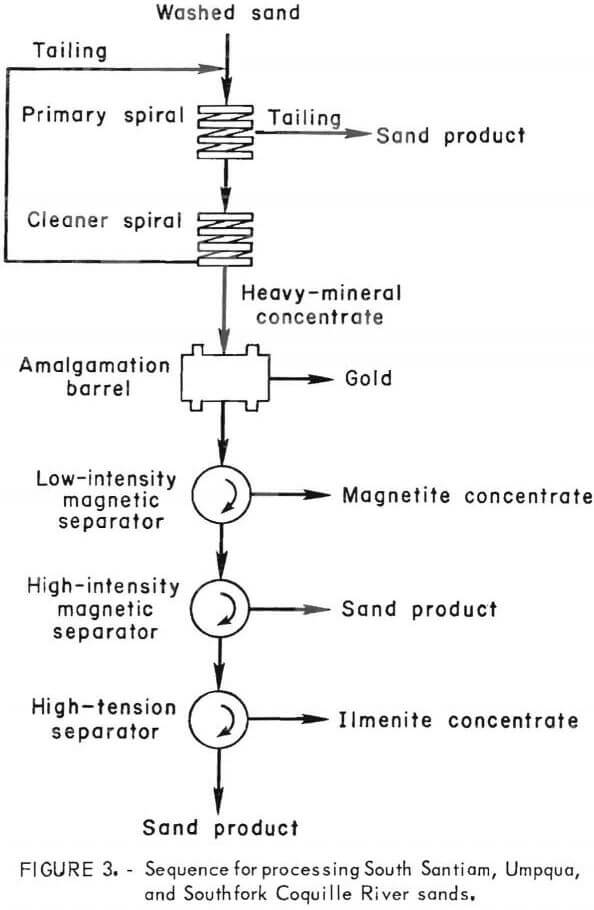

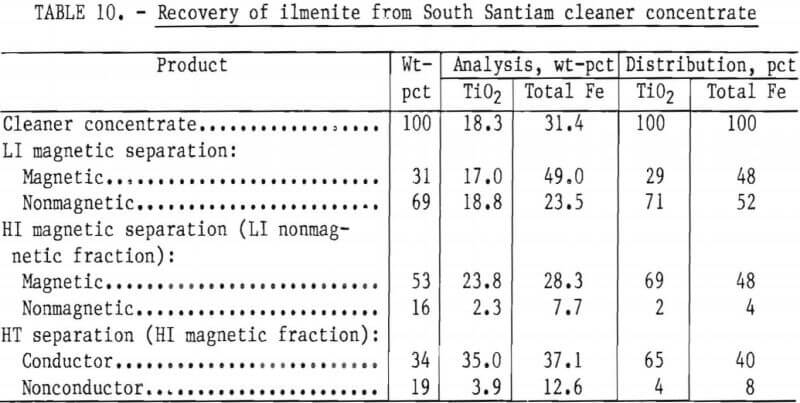

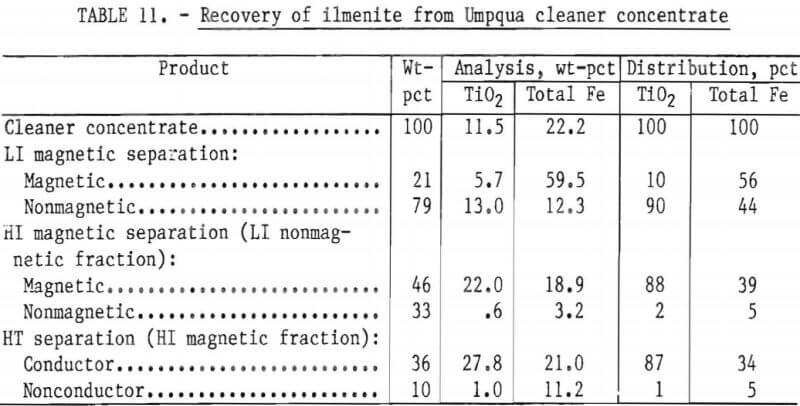

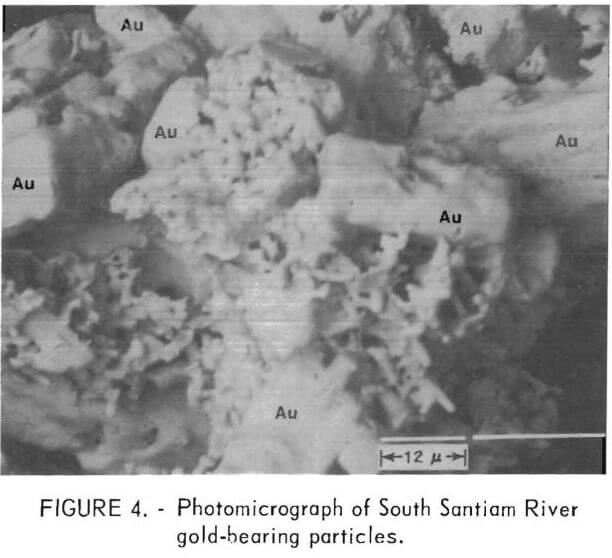

A processing sequence developed for the recovery of gold and ilmenite from the South Santiam and Umpqua samples is shown in figure 3. The analyses of the individual products and distribution of the major constituents are shown in tables 10 and 11. The South Santiam and Umpqua HM cleaner concentrates contained 0.29 and 0.05 oz of gold per ton, respectively. Gold recovery by amalgamation was almost 100 pct for both samples. A photomicrograph of South Santiam River gold particles is shown in figure 4. The major gold species are native gold and amalgam. Gold is not presently being recovered at either operation. Sixty-five percent of the TiO2 in the South Santiam cleaner concentrate was recovered in an ilmenite product containing 35.0 wt-pct TiO2. An ilmenite product containing 27.8 wt-pct TiO2 with an 87-pct recovery was obtained from the Umpqua cleaner concentrate.

Southfork Coquille Sample

Southfork Coquille Sample

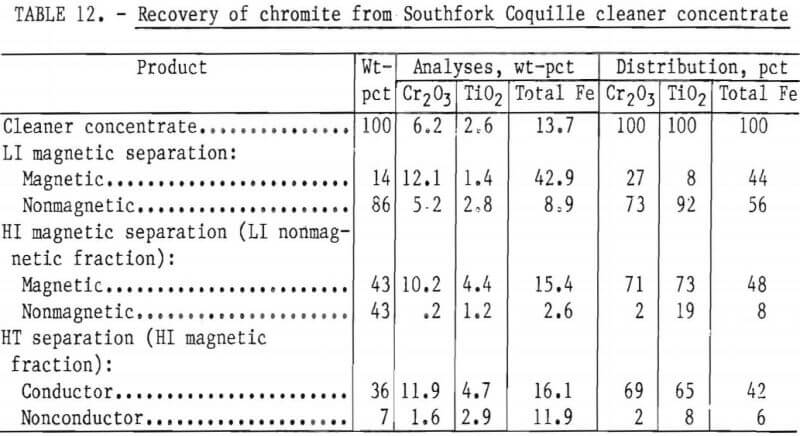

A processing sequence for the recovery of gold, magnetite, and a low-grade chromite concentrate from Southfork Coquille River is shown in figure 3. Analyses of the products are given in table 12. Almost 100 pct of the gold in the concentrate was recovered by amalgamation. The LI magnetic fraction contained 42.9 wt-pct total iron and 12.2 wt-pct Cr2O3. This product would be considered a chromium-bearing magnetite. Seventy-one percent of the Cr2O3 was recovered in the HI magnetic fraction containing 10.2 wt-pct Cr2O3 or about 15 wt-pct chromite (FeCr2O4). HT separation upgraded the product to 17 wt-pct chromite.

Discussion and Conclusions

The occurrence of heavy minerals in Oregon and Washington sand and gravel deposits is widespread. The major byproduct heavy minerals of potential economic interest are magnetite, ilmenite, and gold. In some localities, platinum, radioactive minerals, zircon, rutile, and chromite also occur in significant quantities. Recovery of 90 pct of the heavy minerals in concentrates containing up to 86 wt-pct HM was obtained with a spiral concentrator. Gold was recovered by treating the concentrates with a conventional amalgamation technique. Magnetite, ilmenite, zircon, and chromite concentrates were obtained by using low-intensity magnetic, high-intensity magnetic, electrostatic, and heavy-liquid separation techniques.

Additional onsite concentration tests should be performed to accurately determine the heavy mineral content and to evaluate the recovery of byproduct gold, magnetite, ilmenite, chromite, and zircon. Percentage increases in the values of gold and other heavy minerals warrant the development of byproduct recovery data.

Economic justification for recovery of byproduct minerals depends on the development of markets for the mineral concentrates. High-capacity concentrating equipment must be incorporated into the sand plant washing circuit to prepare HM concentrates. Equipment having low initial and operating costs can be used, such as the Reichert cone or Cleveland jig. A plant employing relatively high-cost magnetic and electrostatic separation equipment to produce marketable mineral concentrates could be built in a central location and could treat the HM concentrates obtained from nearby sand and gravel operations.