- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Hydrometallurgy.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

Effects of increasing leaching density on dissolution rate (5 replies and 1 comment)

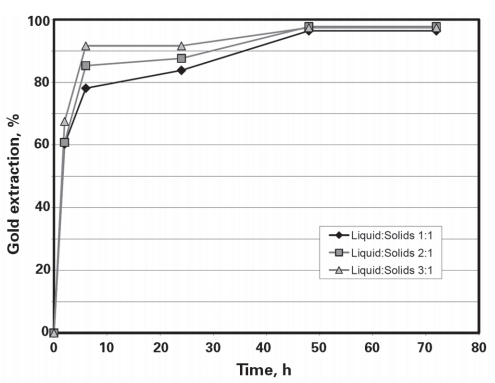

This is usually dependent on the viscosity of the pulp. Typically, "fresh" ores (no clay) give similar leach extractions and kinetics at 50% solids (testwork from a recent study indicated exactly that). However, if the slurry thickens appreciably at 50% solids the oxygen transfer may be impeded, plus, you may see activated carbon floating to the surface which is not a good thing. Plots of pulp density versus apparent viscosity typically see an inflection point around 45% solids but the degree of inflection (upwards) depends on the amount of positively charged slimes particles in the feed (minus 10 microns). This isn't always the case but is a reasonable guide. Testwork at bench scale is always recommended before making big changes in the plant that can cost the owner a lot of revenue. A pair of simple agitated leach or bottle rolls at 40 and 50% solids under identical conditions, taking timed samples at set intervals (2, 4, 8 and 24 hrs), should provide peace of mind. It wouldn't hurt to measure dissolved oxygen as well if you have such a device on site but the proof is in the extraction rates but it is not essential.

An interesting analogue test for pulp viscosity you can use is called a Marsh Funnel test. It was developed for drilling muds in the oil industry but it is also used by labs to establish if a sample's pulp density is adequate for IsaMill testwork. Here's a link to a test method that you can easily do on site if you have a steep walled funnel.

http://hamdon.net/wp-content/uploads/2015/02/Marsh-Funnel-Instruction-Manual.pdf

This is also useful: https://en.wikipedia.org/wiki/Marsh_funnel

To work out the effective viscosity the following formula is used:

μ = ρ (t - 25)

where μ = effective viscosity in centipoise

ρ = slurry density in g/cm³

t = quart funnel time in seconds

For a typical gold ore of 40% solids w/w and 2.70 SG, the pulp density is 1.34 g/cm3. With a proper Marsh funnel, draining in less than 40 seconds is usually indicative of a slurry that is fine for processing. In this case:

μ = 1.34(40-25) = 20.1 cP

It doesn't matter that much if you don't have the right funnel as what you are really after is a comparative measurement. If you measure the effective viscosity for your current operating slurry using the above method and do the same for 50% solids 1.46 g/cm3 density), you can determine if there is a potential problem. If the number ends up being much higher (20 to 30% higher) you may have a problem.

Let me know how you get on!

thank you for your comment, there are planning to use a reagent called, which will allow them to leach at high densities without compromising on the recovery. i think i will do some tests, to see how it affects dissolution and carbon settling. will also check out the links you sent me.

Use the Social Share Bar on the Left. Tell everyone you can about https://www.911metallurgist.com/metallurgy/ It's FREE & GOOD.

FINISHED LAST WEEK

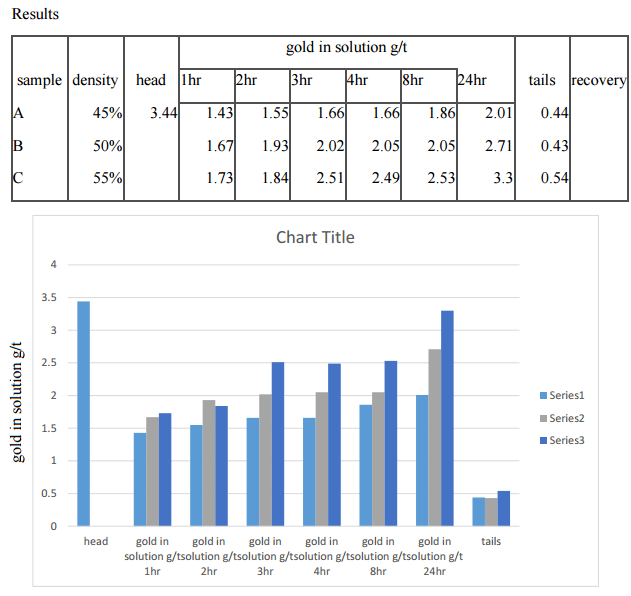

Leach test at different densities Methodology

- Bulk samples of thickener underflow was used for the test work

- All samples were done in triplicate

- Pulp was made up to densities of 45%, 50% and 55% for samples A, B and C respectively.

- Sodium cyanide, caustic soda and hydrogen peroxide were added at a consumption of 1.3kg/t, kg/t

and 0.6kg/t respectively. - All samples were bottle rolled for hours

- pH was at an average 9.12

- Solution samples were taken at hourly intervals for the first four hours, then 8hrs and .

- Head grade for the bulk samples was assayed.

- Tails at the end of the bottle rolls were thoroughly water washed and reassayed.

Please join and login to participate and leave a comment.

A mine is planning on increasing the leaching density from 40% solids to around 50% solids, with the aim of increasing the dissolution rates, although right now they are working at recoveries of 85%. what would be the effect on the kinetics of dissolution.