- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Hydrometallurgy.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

Please join and login to participate and leave a comment.

hello metallurgist;

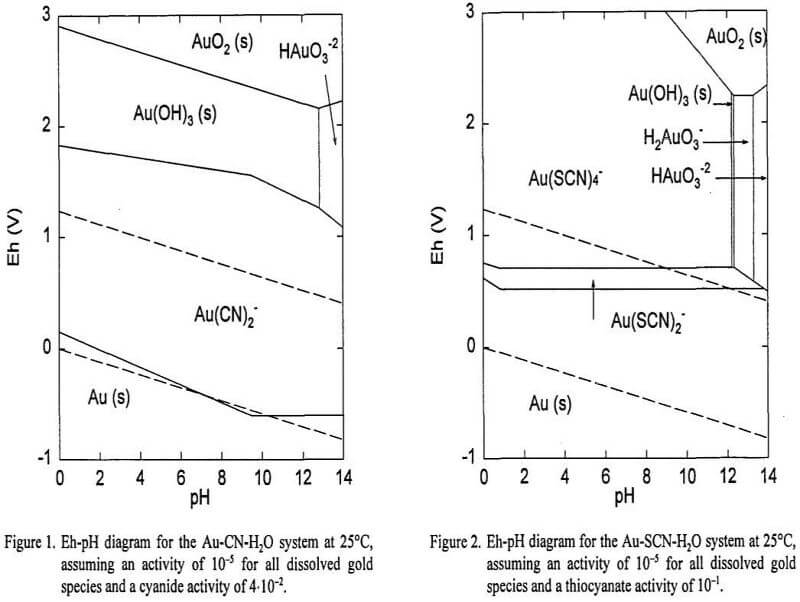

please, what is the function of iron (Fe) in gold leaching process with thiocyanate as a Gold Dressing Agent composition?