Table of Contents

Large tonnages of high-grade sylvinite ores, containing low concentrations of water insolubles, have been processed in the Permian basin region near Carlsbad, N. Mex., during the past 40 years. The high-grade ores are rapidly being depleted, leaving large reserves of lower grade ore. This lower grade ore contains 1 to 8 percent water-insoluble slimes. These insoluble slimes must be removed prior to potash flotation owing to their high adsorptive capacity for the amines used in potash flotation. The insoluble slimes are conventionally removed by scrubbing the ore particles, followed by hydroclassification to separate the slimes from the coarse sylvinite ore.

Residual insoluble slimes not removed by the desliming procedure are blinded with reagents such as guar gum or starch to prevent interference in subsequent potash flotation.

Potash losses in the discarded insoluble slimes and the amount of process brine required for desliming increase as the insolubles content increases. Therefore, improved methods to remove insoluble slimes are needed that will (1) reduce potash losses to the insoluble-slimes product, (2) lower the process brine requirements, and (3) increase subsequent potash recovery after insoluble-slimes removal. In this regard, several insoluble-slimes flotation methods have been offered as alternatives to mechanical desliming. These methods require that the insoluble slimes be flocculated prior to collector addition in order to reduce their surface area and thus, reduce collector consumption.

In one process an acrylamide polymer flocculant and a frother such as cresylic acid or methylisobutyl carbinol (MIBC) were used to float insoluble slimes from low-insoluble-slime potash ore without an insoluble-slimes collector. No data were given regarding insoluble-slimes flotation recovery; however , subsequent K2O flotation recovery was greater than 83 percent. In another process, a high-molecular-weight cationic polymer and a long-chain carboxylic-amine reaction product were used to float insoluble slimes from a potash ore containing less than 2 percent insoluble slimes. Over 80 percent of the K2O in the feed reported to a subsequent potash rougher concentrate.

In a third process, synthetic oxyethylated fatty acids and oxidized mixtures of white spirits and acidol were used as flotation collectors for flocculated insoluble slimes. Over 95 percent of the insoluble slimes were removed from a potash ore containing 5 to 7 percent insoluble slimes using a large-volume, deep-foam separator. A fourth process employed a nonionic poly-acrylamide flocculant and a cationic surfactant to float insoluble slimes from potash ore containing 5 to 7 percent insoluble slimes. Over 85 percent of the insoluble slimes present were removed in a rougher concentrate. None of the processes considered the effect on subsequent potash flotation of residual insoluble slimes not removed during flotation desliming.

The mission of the Bureau of Mines metallurgy research program is to help improve minerals processing technology so that the Nation’s mineral needs can be fulfilled in a manner that reduces waste and that ensures minerals and metals are processed, used, and recycled at acceptable economic, social, and environmental costs. In accordance with this mission, the Bureau of Mines is currently investigating and evaluating selective flocculation-flotation techniques to remove insoluble slimes from sylvinite ores that are compatible with existing potash flotation processes. During this research program, a new flocculation-flotation technique was discovered. Additionally, means to debrine the insoluble slimes flotation concentrates are being investigated in order to increase potash recoveries and lower process brine requirements.

Experimental Materials

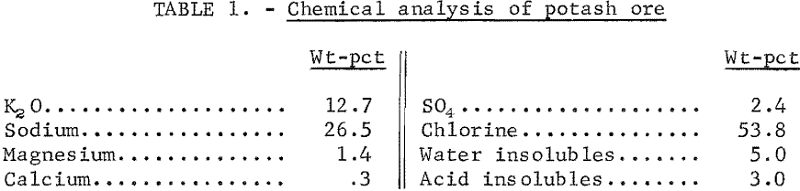

A run-of-mill potash ore sample with a high water-insolubles content from the Carlsbad, N. Mex., area was used in this study. Chemical analysis of the ore is shown in table 1.

Petrographic and X-ray diffraction analysis of the ore indicated that sylvite (KCl) and halite (NaCl) were the major minerals present. The sylvite contained minor amounts of included hematite, which gave this mineral a distinct red color. Minor amounts of polyhalite (MgSO4·K2SO4·2CaSO4·2H2O), leonite (MgSO4.KgSO4.4H2O), and kainite (KCl.MgSO4.2.75H2O) were also present. The water-insoluble fraction of the ore contained abundant magnesite, chlorite, and illite.

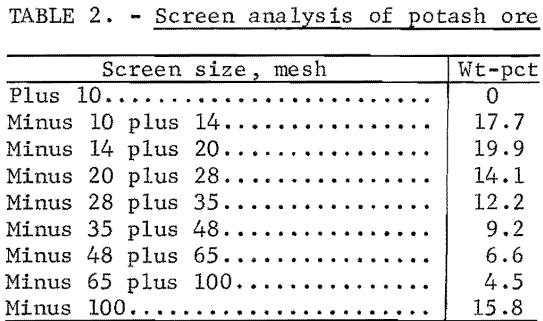

The minus-1.9-centimeter (¾-inch) run-of-mill ore sample was split into two equal parts for equilibrium brine production and flotation experiments. Samples for flotation testing were prepared by stage-crushing the ore through 10 mesh using a roll mill and then splitting the crushed ore into 1-kilogram charges. Stage crushing was used to avoid producing excessive fines, which report to the slimes product and reduce the overall potash recovery. Screen analysis of the ore, shown in table 2, indicated that less than 16 percent of the final crushed weight was finer than 100 mesh.

Equilibrium brine was prepared by mixing 41 kilograms of ore with 57 liters of tapwater and agitating for 24 hours. The slurry was allowed to settle at least 2 days , and the clear brine was decanted for use in test work.

Potash flotation reagents used in this study are all commercially available and included Armeen TD³ (a primary aliphatic tallow amine), neutralized with HCl, Barrett’s 634 flotation oil emulsified in tapwater, and MRL-201 guar gum insoluble-slime blinder.

The insoluble-slimes flocculants included high-and medium-molecular-weight cationic, anionic, and nonionic polyacrylamide flocculants, natural organic flocculants , and polyvalent inorganic cations.

Insoluble-slimes flotation collectors included (1) a cationic surfactant, which is a mixture of octadecyl amine and octadecyl guanidine salts of octadecyl carbamic acid reacted with ethylene oxide, (2) an anionic flotation collector, caprylic acid, (3) an emulsion of caprylic acid and a glycol ester, and (4) an emulsion of fuel oil No. 2 and a glycol ester.

Glycol esters were prepared at the Bureau by acid esterification of ethylene glycol with acetic anhydride to produce a mixture of ethylene glycol monoacetate (EGM) and ethylene glycol diacetate (EGD). Commercial defoamers, which contain mixtures of glycol and petroleum ester distillates, were also used as collectors. Hexanol frother was used as needed in all tests. All reagent consumptions are expressed as kilograms of reagent per metric ton of ore (abbreviated as kg/t) and pounds of reagent per short ton of ore (abbreviated as lb/ton).

Experimental Procedures

Settling Tests

Settling tests were performed to select the most effective insoluble-slimes flocculant. The insoluble-slimes fraction was separated from minus 10-mesh ore by hydroclassification and repulped to 1 percent solids with saturated brine . The slurry was gently conditioned with freshly prepared flocculant in a 200-milliliter graduated cylinder. The slurry was allowed to settle, and pulp-level readings were taken at specified times until no change in pulp level was observed.

Two-Stage Mechanical Desliming

One-kilogram samples of ore were scrubbed with saturated equilibrium brine at 27-percent-solids pulp density for 15 minutes in a Fagergren laboratory flotation cell, using a peripheral impeller speed of 4.22 m/sec (830 ft/min). The slurry was allowed to settle for 1 minute, and the remaining suspended solids were decanted onto a vibrating 150-mesh screen. After the screen oversize was washed back into the deslimed sample, the decantation procedure was repeated. The final deslimed material was used as potash flotation feed. This procedure was adopted to simulate actual commercial operating conditions.

Insoluble-Slimes Flotation

Batch insoluble-slimes flotation tests were conducted in a Fagergren laboratory flotation cell. In each test, 1 kilogram of ore was scrubbed 5 minutes at 27-percent-solids pulp density in a saturated brine at a 4.22-m/sec (830-ft/min) peripheral impeller speed. The impeller speed was adjusted to 3.65 m/sec (720 ft/min), flocculant and collector were added, air was immediately introduced, and an insoluble-slimes froth product was collected for 2 minutes. The flotation procedure was repeated one, two, or three times, depending on the type of collector used. Total insoluble-slimes flotation time ranged from 5 to 10 minutes. All tests were performed at a natural brine pH of 7.0, except for a few tests in which concentrated HCl was used for pH adjustment.

Potash Flotation

Various combinations and additions of potash flotation reagents were tested on a laboratory scale. This test work led to the adoption of the following standard procedure. The deslimed pulp was diluted to 23-percent-solids pulp density in a Fagergren laboratory flotation cell. The pulp was conditioned for 2 minutes with 0.150 kg/t (0.30 lb/ton) of MRL-201 insoluble-slime blinder and for 2 additional minutes with 0.115 and 0.040 kg/t (0.23 and 0.08 lb/ton) of amine and flotation oil, respectively. After conditioning, a drop of frother corresponding to 0.010 kg/t (0.02 lb/ton) was added, and a potash flotation rougher concentrate was collected for 2 minutes at a peripheral impeller speed of 4.72 m/sec (930 ft/min). Potash rougher concentrates from two tests were combined in a 500-gram Denver laboratory flotation cell to provide enough material for a cleaner flotation. The combined pulp was conditioned for 2 minutes at a 23-percent-solids pulp density with 0.150 kg/t (0.30 lb/ton) of insoluble-slime blinder (MRL-201), and for 2 additional minutes with 0.025 and 0.015 kg/t (0.05 and 0.03 lb/ton) of amine and flotation oil, respectively. Cleaner flotation lasted 2 minutes.

Leaching Insoluble-Slimes Flotation Concentrates

Leaching tests were performed on insoluble-slimes flotation concentrate to reduce the potash loss in these concentrates. Approximately 1,200 milliliters of insoluble-slimes flotation concentrate were transferred to a baffled 2-liter beaker, and enough fresh water was added to dissolve all the KCl and NaCl into a saturated brine. Approximately 290 kilograms of fresh water per metric ton of flotation feed (580 lb/ton) was required for leaching. The concentrate was leached for 10 minutes at a peripheral impeller speed of 3.65 m/sec (720 ft/min).

Filtration Tests

Standard submerged filtration testing was performed on the leached and thickened insoluble-slimes flotation concentrate using a 0.009-square-meter (0.1-square-foot) filter test leaf. Top-loading mixed-bed filtration tests were performed using the 0.009-square-meter filter leaf with a 7.6-centimeter (3-inch) collar attached. The test procedure consisted of conditioning potash flotation tailings with flocculant in a drum conditioner for 5 minutes.

Leached and thickened insoluble-slimes concentrate was then added to the flocculated salt tailings, conditioned for 2 minutes, and transferred to the filter leaf. All filtration tests were made under 635 millimeters (25 inches) of mercury vacuum.

Experimental Results and Discussion

Settling Tests

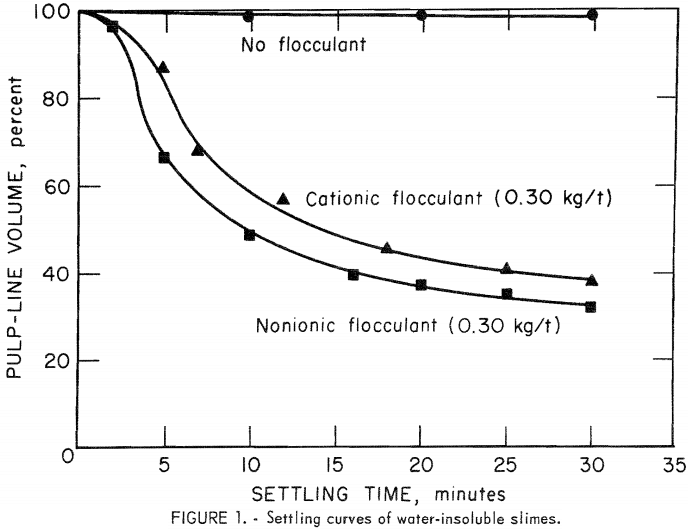

Settling tests were performed to select the most effective flocculants for insoluble-slimes flotation testing. Flocculants tested included high-molecular-weight cationic, nonionic, and anionic flocculants, medium-molecular weight nonionic and anionic flocculants , natural organic flocculants such as starch, quebracho, and guar gum, and polyvalent metal cations. The flocculants that gave the most rapid settling rates were a high-molecular-weight cationic acrylamide copolymer and a high-molecular-weight nonionic polyacrylamide Figure 1 shows settling curves for insoluble slimes using no flocculant, nonionic polyacrylamide, and cationic acrylamide copolymer. The settling curves for all other reagents tested fell above the curves shown for these two

flocculants. The slow settling characteristics were due to the high clay content of the insoluble-slimes fraction of this ore. Based upon the results of these tests, the nonionic polyacrylamide and the cationic acrylamide copolymer were selected as flocculants for subsequent insoluble-slimes flotation studies.

Insoluble-Slimes Flotation Using Various Reagent Schemes

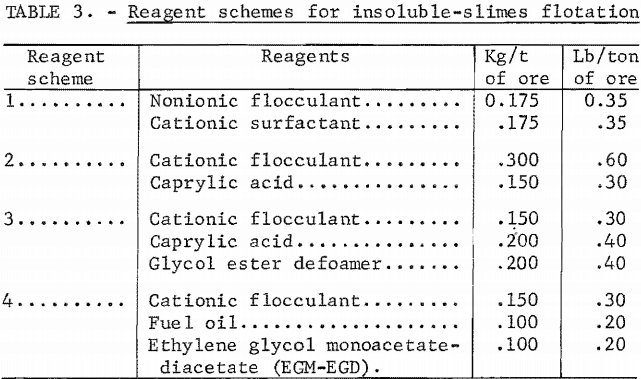

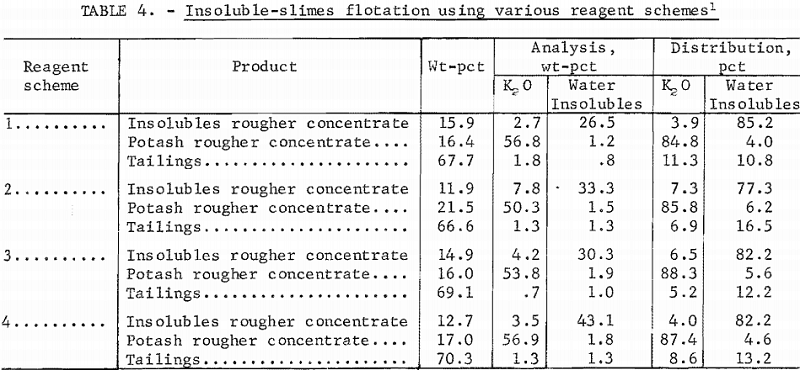

Bench-scale flotation tests were performed to select the most effective reagent schemes for insoluble-slimes flotation. The reagents showing the most promise were combinations of (1) nonionic flocculant and cationic surfactant, (2) cationic flocculant and caprylic acid below pH 4, (3) cationic flocculant and caprylic acid plus a commercial glycol ester defoamer at pH 2 to 8, and (4) cationic flocculant and fuel oil No. 2 plus an ethylene glycol monoacetate-diacetate (EGM-EGD) mixture at natural pH. Reagent scheme 1 is used commercially in Canada; reagent schemes 2, 3, and 4 were devised by the Bureau of Mines. Reagent schemes and metallurgical results are given in tables 3 and 4, respectively.

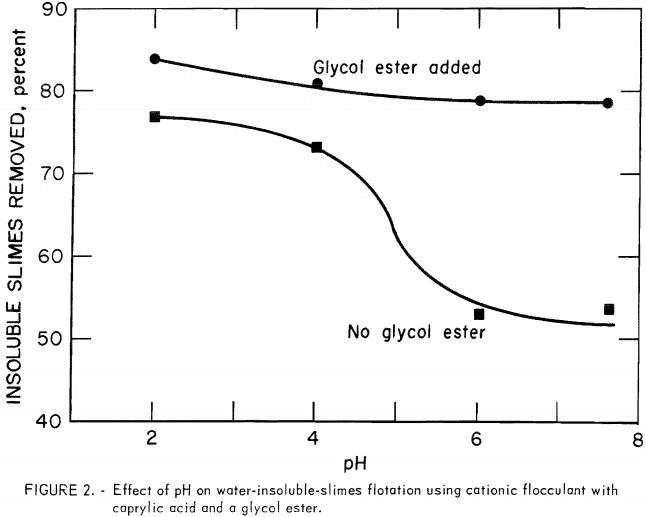

Insoluble-slimes flotation using caprylic acid alone (reagent scheme 2) was pH sensitive. As shown in figure 2, insoluble-slimes flotation recovery decreased drastically, from over 70 percent at pH 4.0 to less than 55 percent at pH 6.0. This phenomenon suggested that the free fatty acid was responsible for insoluble-slimes flotation because as the pH was increased, insoluble magnesium and calcium fatty acid salts precipitated, reducing the amount of free available fatty acid in the system and thus reducing insoluble-slimes flotation recovery. When a commercial glycol ester defoamer was added with the caprylic acid, as in reagent scheme 3, the pH effect was not observed and insoluble-slimes flotation recovery remained higher than 79 percent (fig. 2). The defoamer also aided in controlling the voluminous insoluble-slimes concentrate froth.

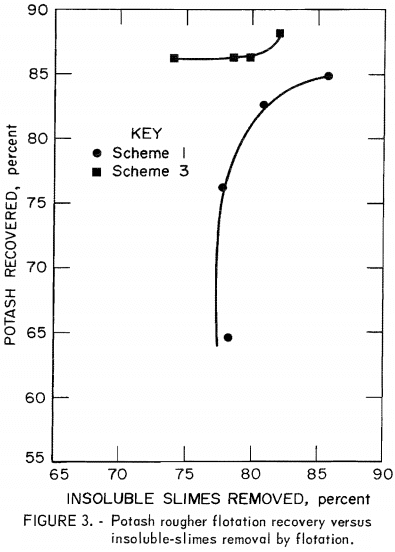

Insoluble-slimes flotation using reagent scheme 3 was compared with flotation using reagent scheme 1. Figure 3 shows K2O recovery in the potash rougher

as a function of insolubles recovery in the insolubles rougher using both reagent schemes. Results indicated that reagent scheme 3 renders residual insolubles, not removed by flotation, inert during subsequent potash rougher flotation. The difference in sensitivity of the potash rougher to residual insoluble slimes is striking. Using reagent scheme 1 for insoluble-slimes flotation, subsequent potash rougher flotation recovery decreased drastically, from 85 percent at 85-percent insoluble-slimes removal to 65 percent at 77-percent insoluble-slimes removal. When reagent scheme 3 was used to float insoluble slimes, subsequent potash recovery remained constant at 86 percent as insoluble-slimes removal decreased from 80 to 74 percent. However, as insoluble-slimes removal fell below 70 percent subsequent potash recovery decreased markedly.

as a function of insolubles recovery in the insolubles rougher using both reagent schemes. Results indicated that reagent scheme 3 renders residual insolubles, not removed by flotation, inert during subsequent potash rougher flotation. The difference in sensitivity of the potash rougher to residual insoluble slimes is striking. Using reagent scheme 1 for insoluble-slimes flotation, subsequent potash rougher flotation recovery decreased drastically, from 85 percent at 85-percent insoluble-slimes removal to 65 percent at 77-percent insoluble-slimes removal. When reagent scheme 3 was used to float insoluble slimes, subsequent potash recovery remained constant at 86 percent as insoluble-slimes removal decreased from 80 to 74 percent. However, as insoluble-slimes removal fell below 70 percent subsequent potash recovery decreased markedly.

Best results were obtained with reagent scheme 4. Using this reagent scheme, over 82 percent of the insoluble slimes was removed in two rougher flotation stages. Subsequent potash rougher flotation recovered about 87 percent of the potash in a concentrate assaying nearly 57 percent K2O. On the basis of these tests, reagent scheme 4 was selected for further study.

The potash rougher concentrate was contaminated with mechanically entrained halite and insoluble slimes containing adsorbed flotation reagents. Cleaner flotation tests were therefore performed to upgrade the product to market specifications of 60 percent K2O. Results showed that direct cleaner flotation upgraded the rougher concentrate to 59 percent K2O at a recovery of 81 percent. Sizing the rougher concentrate at 150 mesh followed by cleaner flotation of the plus 150-mesh fraction upgraded the product to 60 percent K2O at a recovery of 77 percent.

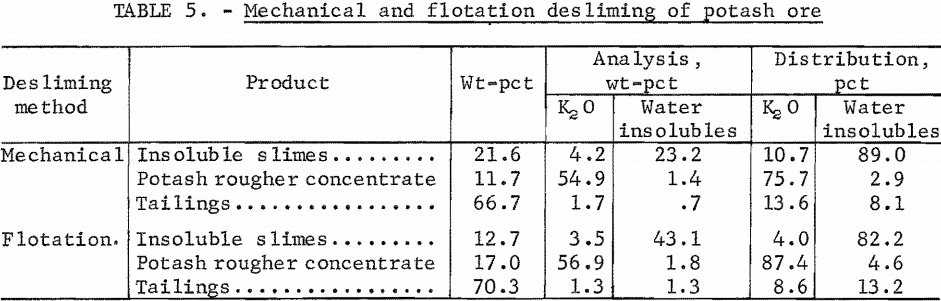

Comparison of Mechanical Desliming with Insoluble-Slimes Flotation

Two-stage mechanical desliming tests were performed to provide a comparison with insoluble-slimes flotation using reagent scheme 4. Test results, shown in table 5, indicate 89-percent removal of insoluble slimes using mechanical desliming. However, potash losses to the slimes product were greater with mechanical desliming. Approximately 11 percent of the potash in the ore reported to the mechanical deslime product, compared with a 4-percent potash loss to the insoluble-slimes concentrate when using flotation desliming.

Potash recovery in the subsequent potash rougher flotation was only 75 percent after mechanical desliming, compared with 87 percent after flotation desliming. These batch tests also indicated that mechanical desliming required larger volumes of process brine than flotation desliming.

The advantages of using flotation to remove insoluble slimes are (1) lower potash losses in the deslime product, (2) lower brine requirements, and (3) improved potash recoveries in subsequent potash flotation.

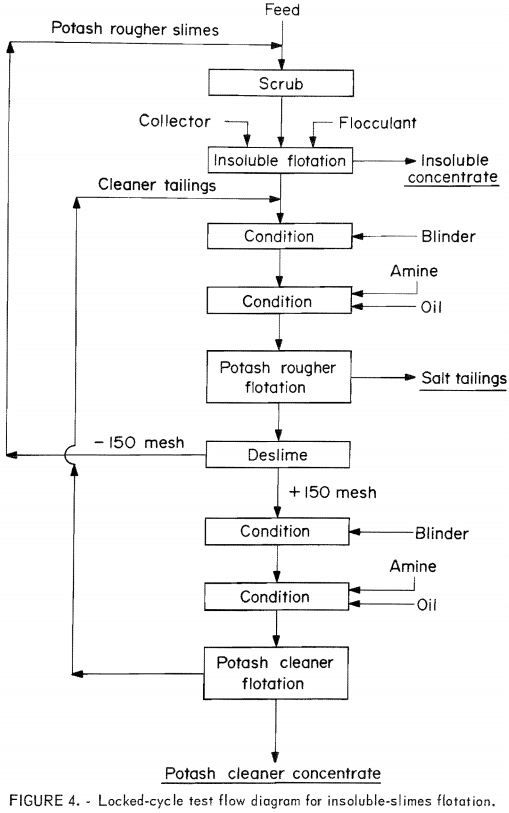

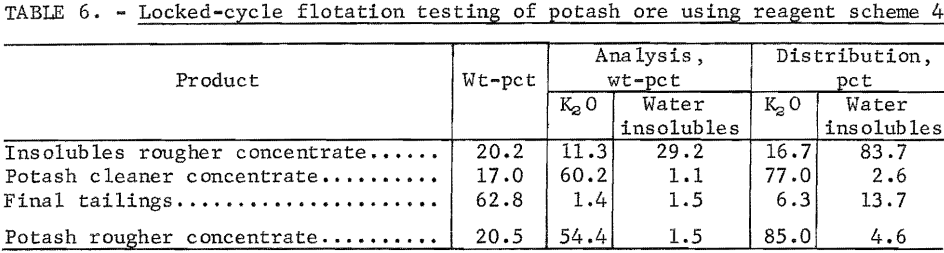

Locked-Cycle Flotation Testing

Locked-cycle flotation testing was performed using reagent scheme 4 to determine the effect of middling products and brine recycle on insoluble-slimes flotation and subsequent potash flotation, and to obtain data for process scale-up. As shown in figure 4, minus 150-mesh fines from the potash rougher sizing operation were recycled back to insolubles scrubbing to remove insoluble minerals containing adsorbed flotation reagents, which floated with the potash, while potash cleaner tailings were recycled back to potash flotation. Brine was recycled as completely as possible, while new brine was added to replace brine lost in the filter cakes. Insolubles flotation required 0.150 kg/t (0.30 lb/ton) each of cationic flocculant, EGM-EGD mixture, and fuel oil No. 2.

Four complete tests were made to insure that the circuit was at equilibrium. Metallurgical results, shown in table 6, are an average of the second and third tests. The assay and distribution of the potash rougher concentrate were calculated from the final test. Almost 84-percent insoluble-slimes removal was achieved, but almost 17 percent of the K2O in the feed reported to the insoluble-slimes concentrate. This high K2O loss was due to (1) flotation

of recycled KCl fines from the potash rougher sizing step and (2) fine KCl in the feed which, during the scrubbing step, had adsorbed small amounts of residual potash flotation reagents present in the recycle brine. Potash rougher flotation recovered 85 percent of the K2O in a concentrate assaying 54 percent K2O. Sizing of the potash rougher concentrate at 150 mesh, followed by cleaner flotation of the plus 150-mesh fraction, increased the concentrate grade to 60 percent K2O at a reduced recovery of 77 percent.

Leaching insoluble-slimes flotation concentrates with fresh water was investigated separately as a method for recovering the substantial amounts of fine potash that report to the concentrates. Tests performed on the final insoluble-slimes concentrate in the locked-cycle test indicated that over 80 percent of the potash in the insoluble-slimes concentrate could be leached in 10 minutes at ambient temperature using 290 kilograms of fresh water per metric ton of flotation feed (580 lb/ton). The leach solution can be used for process brine, or treated by evaporation to recover additional potash.

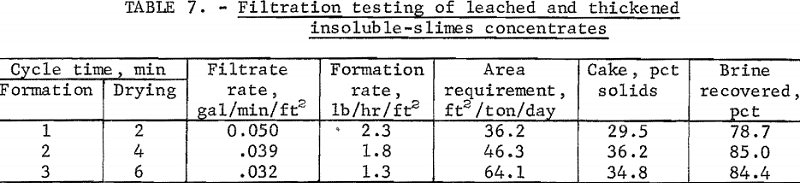

Filtration Testing

Insoluble-slimes concentrates were dilute, with a maximum pulp density of 7 percent solids after leaching and settling. Filtration was therefore investigated as a method for recovering the large amounts of brine entrained in these concentrates. Results of submerged filtration tests performed on leached and settled insolubles concentrates are given in table 7 and presented graphically in figure 5. The 3- and 6-minute tests produced extremely thin filter cakes of less than 1/16 inch, the 9-minute test produced a cake of exactly 1/16-inch thickness. The extremely low formation rate of 1.3 lb/hr/ft² obtained using a 9-minute cycle time is too slow for commercial application.

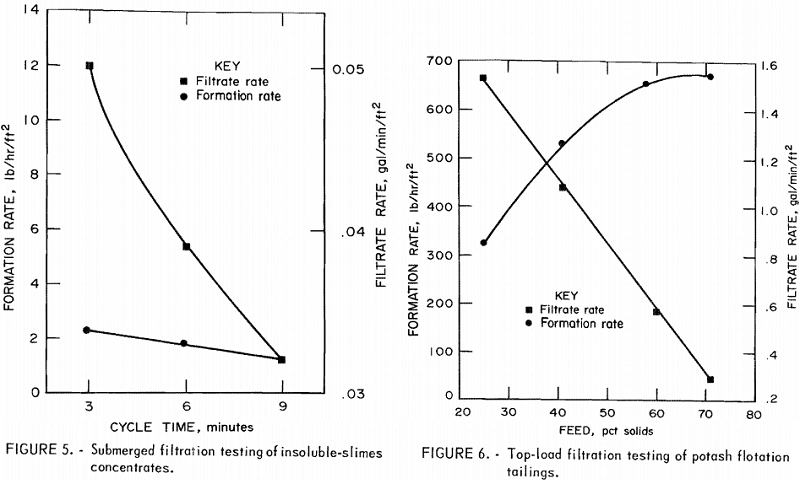

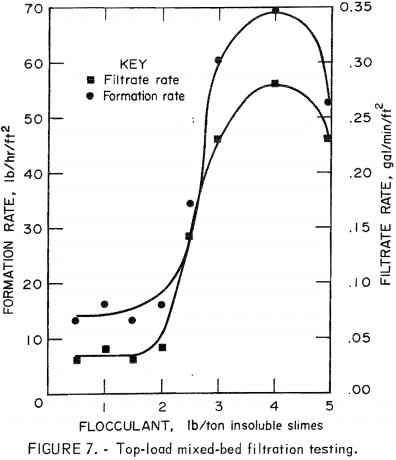

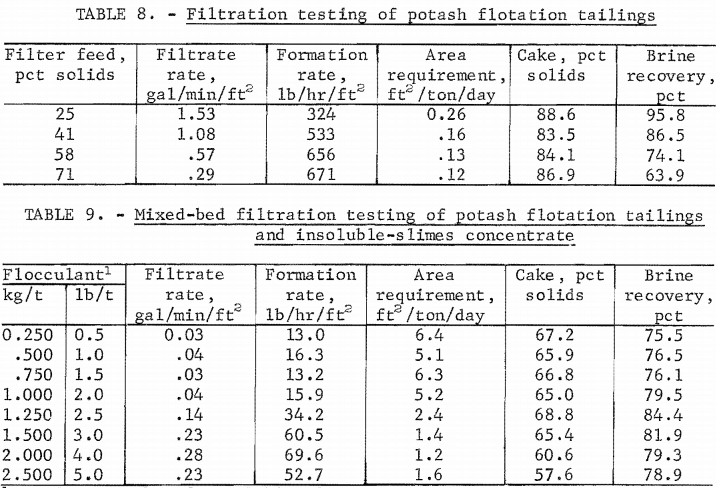

A mixed-bed filtration procedure, similar to the method patented by Dancy, was investigated in an effort to increase the filtration rates of the insoluble-slimes concentrates. Top-loading filtration tests were performed on the potash flotation tailings, which act as a support for the insoluble-slimes concentrate, to determine the optimum pulp density of the filter feed. Test results are shown in table 8 and figure 6. All tests were run at a filter loading of 14 pounds of slurry per square foot of filter area. A pulp density of 60 to 70 percent solids gave the fastest form rates of 650 to 670 lb/hr/ft². Brine recovery under these conditions decreased from 74 to 64 per¬cent as the filter feed pulp density increased from 58 to 71 percent solids. Mixed-bed filtration test results are shown in table 9 and figure 7. Leached and settled insolubles concentrate at 7 percent solids was added to a potash tailings slurry at 60 percent solids that had been flocculated with increasing amounts of high-molecular-weight non-ionic polyacrylamide. A weight ratio of 1 part leached insoluble-slimes concentrate to 10 parts potash flotation tailings was used in these tests. This ratio represents all the solid waste streams from potash flotation. The cake formation rate increased drastically, from about 16 lb/hr/ft² at 1 kilogram of flocculant per metric ton of insoluble slimes (2 lb/ton) to a maximum of almost 70 lb/hr/ft² at 2 kilograms of flocculant per metric ton of insoluble slimes (4 lb/ton). The filtrate rate followed the same trend, reaching a maximum of 0. 28 gal/min/ft² at 2 kilograms of flocculant per metric ton of insoluble slimes (4 lb/ton). Brine recovery under these optimum conditions was 79 percent. Cake thickness was approximately 1 inch. The increased formation rates obtained using mixed-bed filtration are commercially attractive. For example , a 9,100-metric ton-per-day (10,000-ton-per-day) potash plant treating a 7-percent-insolubles ore would require approximately 9,000 square feet of filter area using the mixed-bed filtration process, whereas approximately 80,000 square feet of filter area would be required if the insoluble slimes and potash flotation tailings were filtered separately.

A mixed-bed filtration procedure, similar to the method patented by Dancy, was investigated in an effort to increase the filtration rates of the insoluble-slimes concentrates. Top-loading filtration tests were performed on the potash flotation tailings, which act as a support for the insoluble-slimes concentrate, to determine the optimum pulp density of the filter feed. Test results are shown in table 8 and figure 6. All tests were run at a filter loading of 14 pounds of slurry per square foot of filter area. A pulp density of 60 to 70 percent solids gave the fastest form rates of 650 to 670 lb/hr/ft². Brine recovery under these conditions decreased from 74 to 64 per¬cent as the filter feed pulp density increased from 58 to 71 percent solids. Mixed-bed filtration test results are shown in table 9 and figure 7. Leached and settled insolubles concentrate at 7 percent solids was added to a potash tailings slurry at 60 percent solids that had been flocculated with increasing amounts of high-molecular-weight non-ionic polyacrylamide. A weight ratio of 1 part leached insoluble-slimes concentrate to 10 parts potash flotation tailings was used in these tests. This ratio represents all the solid waste streams from potash flotation. The cake formation rate increased drastically, from about 16 lb/hr/ft² at 1 kilogram of flocculant per metric ton of insoluble slimes (2 lb/ton) to a maximum of almost 70 lb/hr/ft² at 2 kilograms of flocculant per metric ton of insoluble slimes (4 lb/ton). The filtrate rate followed the same trend, reaching a maximum of 0. 28 gal/min/ft² at 2 kilograms of flocculant per metric ton of insoluble slimes (4 lb/ton). Brine recovery under these optimum conditions was 79 percent. Cake thickness was approximately 1 inch. The increased formation rates obtained using mixed-bed filtration are commercially attractive. For example , a 9,100-metric ton-per-day (10,000-ton-per-day) potash plant treating a 7-percent-insolubles ore would require approximately 9,000 square feet of filter area using the mixed-bed filtration process, whereas approximately 80,000 square feet of filter area would be required if the insoluble slimes and potash flotation tailings were filtered separately.

Summary

Bench-scale investigations have shown that flotation is an effective means of removing insoluble slimes from lower grade potash ore containing high concentrations of water insolubles. Best results were obtained using a Bureau-developed reagent scheme. Over 82 percent insolubles limes removal was obtained, and subsequent potash flotation recovered 87 percent of the potash in a rougher concentrate assaying 57 percent K2O. Sizing and cleaner flotation upgraded the product to market specifications of 60 percent K2O.

Tests indicated that filtration of a 1-to-10 mixture of insoluble slimes and flocculated potash flotation tailings required only 11 percent of the filter area needed when Insoluble slimes and potash flotation tailings were filtered separately. A formation rate of 70 lb/hr/ft² and a brine recovery of 80 percent were obtained under optimum conditions.

Bench-scale investigations of insoluble-slimes flotation procedures are complete. Based on the data presented in this report, a continuous 45-kg/hr (100-lb/hr) process investigation unit will be constructed and operated to further evaluate the Bureau-developed insoluble-slimes flotation reagent scheme.

A part of the Bureau of Mines mission is to help improve the Nation’s mineral posture by providing the technology for utilizing low-grade ores. In this regard, laboratory testing by the Bureau of Mines has shown that the removal of insoluble slimes using selective flocculation and flotation is a viable method for treating low-grade potash ores that have a high content of water- insoluble impurities. Results indicated that over 82 percent of the insoluble slimes could be removed from sylvinite ore containing 5 percent water insolubles and 13 percent K2O by using nonionic or cationic polyacrylamide flocculants and cationic, anionic, and/or nonionic collectors. Subsequent potash flotation recovered 87 percent of the potash in rougher concentrates containing 57 percent K2O. Sizing and cleaner flotation of the rougher concentrates upgraded the products to 60 percent K2O.

Filtration of the water-leached insoluble-slimes flotation concentrates on a bed consisting of leached insoluble-slimes concentrate mixed with potash flotation tailings recovered 80 percent of the brine. Filtration rates using the mixed bed were nine times faster than filtration rates obtained when the insoluble-slimes flotation concentrates were filtered separately.