Table of Contents

The nature of the atomic rearrangement involved in the precipitation of the compound γ-Cu-Be from supersaturated solid solutions of the copper-base alloys has been the subject of two extensive investigations. The precipitate in this alloy system has a rather simple structure; at equilibrium it has a body-centered cubic unit cell with copper atoms on the corner sites and beryllium atoms on the center site. While a simple mechanism would be expected to obtain for the precipitation process, those which have been proposed do not adequately explain all of the reported data. The purpose of the present report is to rationalize some of the previous observations and to contribute new data on the subject obtained by the usual techniques of structure analyses. The Cu-Be system of alloys represents one of the most extensively investigated precipitation systems, so a detailed review of the pertinent literature on structure is in order.

Recrystallization Reaction: The second prominent feature that has been observed in the microstructure of Cu-Be alloys appeared as lamellar nodules of matrix plus equilibrium precipitate located at grain boundaries of the parent grains. These formed and grew as aging progressed. The reaction has all the characteristics of a recrystallization process and thus has been referred to as such in a recent report where the data are reviewed in detail. It will suffice to state here that this is a supplementary reaction and

that studies of the mechanism of precipitation should be concerned only with the formation of precipitate particles that are uniformly distributed within the parent crystals. While the phenomena of striations and recrystallization play a part in the precipitation process, they are not considered to be features directly inherent in the crystallographic mechanism of the formation of the phase.

Lattice Distortion and Transition Structure: A prominent feature that has been observed in X-ray patterns of Cu-Be alloys has been the extreme broadening and diffuseness of matrix lines which

develop during precipitation. On aging at 300°C the lines at high angles in the back-reflection portion of the pattern become so broad and diffuse that they were not detected. The broadening on aging at 350°C could be due to change in concentration of the matrix alone, but that observed on aging at 150° to 250°C was considered in part to be due to stresses accompanying the formation of the γ particles.

Experimental Technique

The X-ray diffraction studies were conducted on two single-crystal samples that had been prepared by Guy. Their composition was 1.73 pct Be, and they had been thinned to 0.005 in., heat treated in vacuum for 1½ hr at 800°C, and quenched directly to the aging temperature. Since 100 hr aging at 300°C was required to develop diffraction spots from three-dimensional precipitate in Laue patterns, aging times of 1, 3, and 18 hr were chosen in order

to assure that they represented early stages of precipitation. According to the electrical resistance measurements for the single crystal aged at 300°C (Fig. 12 of ref. 3), these time periods corresponded to approximately 10, 25, and 50 pct respectively of the total decrease that was due to precipitation.

Orientation Relationship

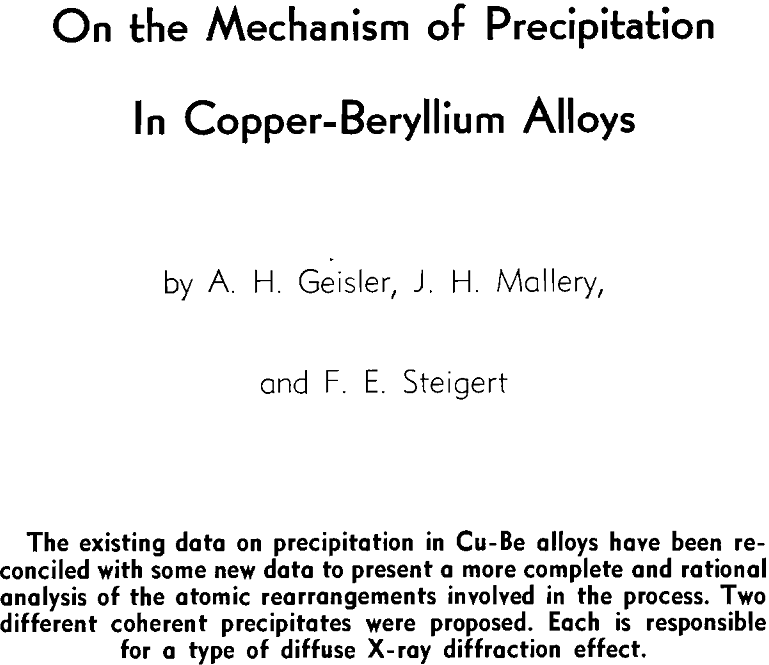

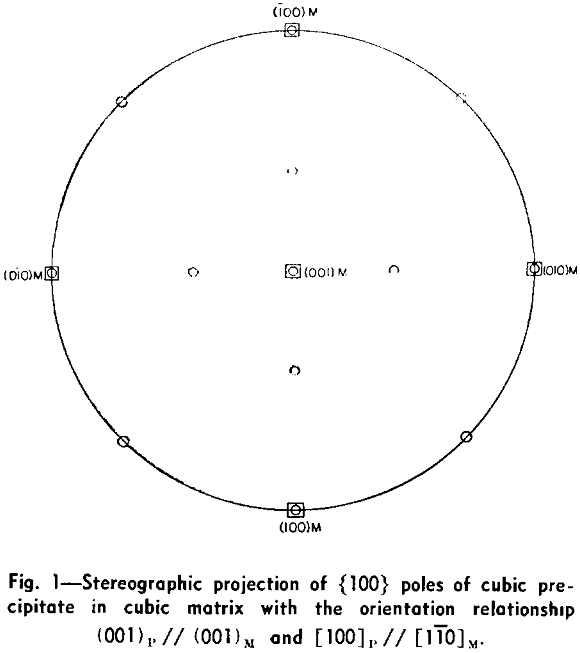

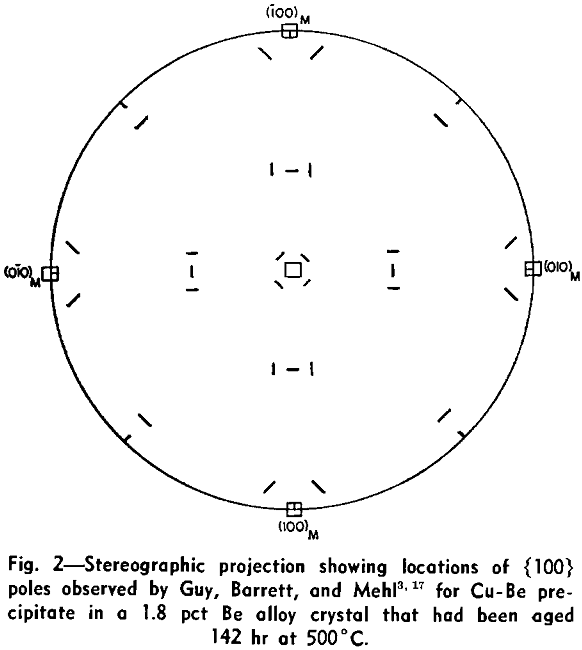

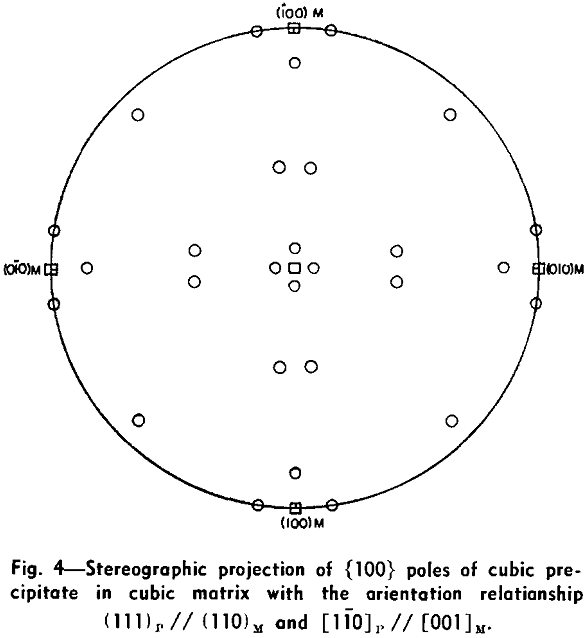

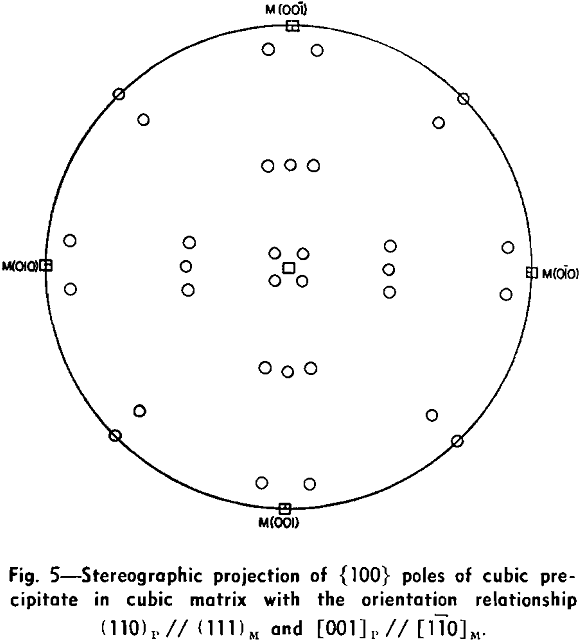

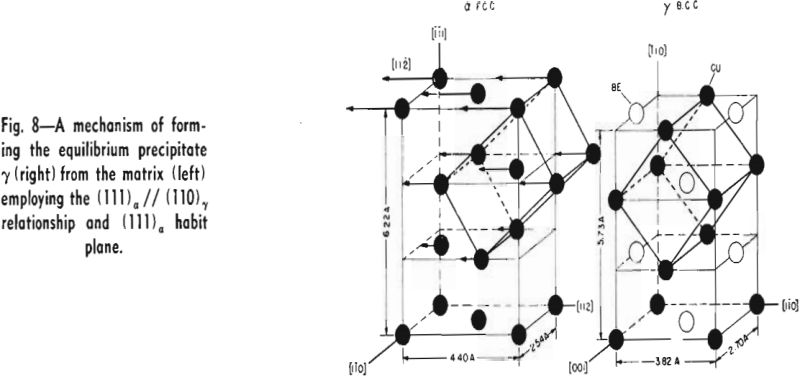

In order to explain the orientation relationship that had been determined , the atomic arrangement on various low index planes of the matrix (α) and equilibrium precipitate (γ) were compared. The interatomic distances are given in Angstrom units, while the column at the right lists the required changes of the matrix spacing or strain in percent in the three orthogonal directions. Relationship A or its equivalent B is that proposed by pre-

vious workers as an approximation. Relation C involves only slightly more total strain; however, the locations of cube poles for this relationship.

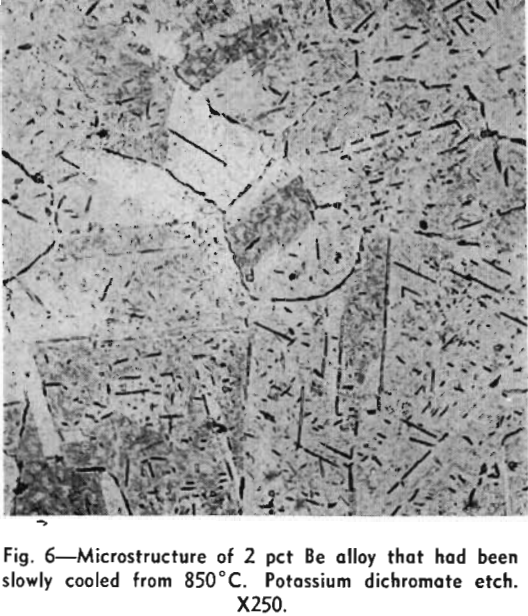

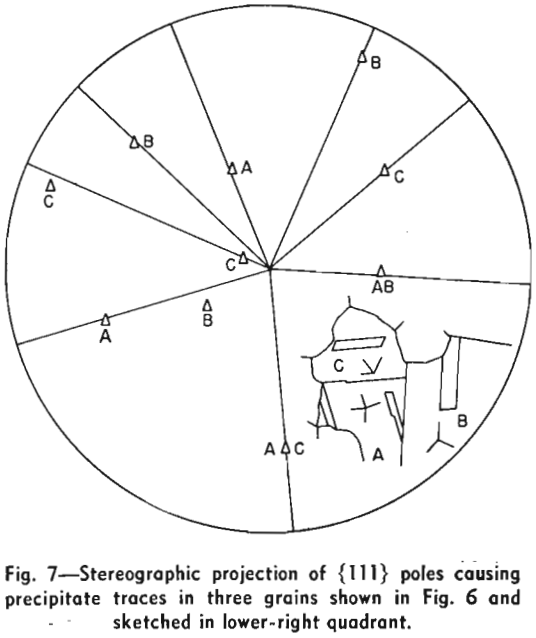

In order to determine the habit plane of the precipitate, attempts were made to grow a well-developed Widmanstatten pattern by a variety of treatments. Microscopically resolvable precipitates were present after aging for 100 hr at 600° and after slowly cooling (50°C per hr) from above the solvus temperature. The latter treatment provided the best structure for analysis. While some of these were along twin boundaries and might represent localized precipitation as at grain boundaries, others appeared throughout the grains and twins. The three largest crystals in the bottom half of the micrograph were separated by straight boundaries which proved to be twin boundaries.

With the two new facts concerning the equilibrium precipitate in Cu-Be alloys its mechanism of formation can be postulated. It would be expected that the precipitate structure would evolve by movement of atoms in the (111) plane of the matrix in such a manner as to assume the (110) stacking of the precipitate, since (111)α is the habit plane and (111)α is parallel to (110)γ.

Intermediate Structure—γ’

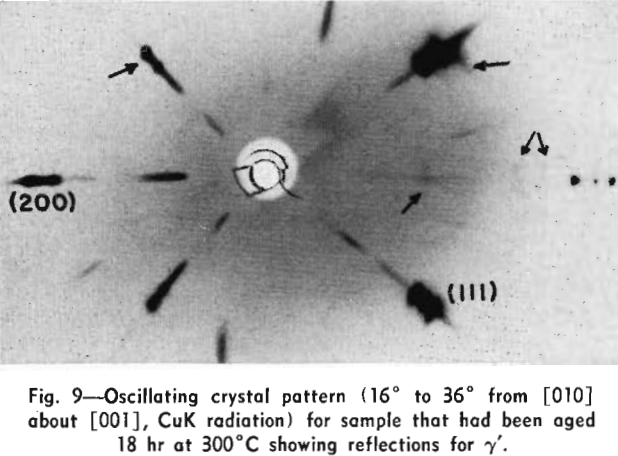

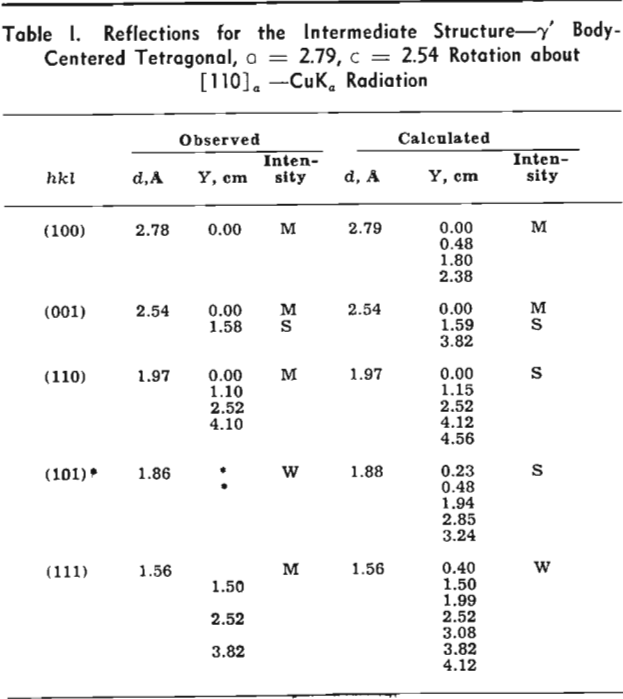

When oscillating crystal patterns were made for the single-crystal sample that had been aged 18 hr at 300°C, several three-dimensional diffraction spots were observed which could not be attributed to the equilibrium precipitate, γ. One reflection with its β component was moderately intense. This reflection appeared in the approximate location for what would be a (110) matrix reflection (d = 2.54), if this were not a forbidden reflection of the face-centered cubic lattice. Among the numerous patterns that were made with 15° oscillation, [001] or [110] axis of oscillation and copper or cobalt radiation, the interplanar spacings corresponding to five definite non-matrix reflections were as follows: -2.78A, 2.54A, 1.97A, 1.86A, and 1.56A. These were used to identify the intermediate structure which was designated γ.

Although five different types of reflections hardly seem enough to determine a new crystal structure, the interplanar spacings in combination with the positions of the spots on the film as determined by orientation relationship were sufficient to dismiss some of the postulated intermediate structures.

The most fruitful attempt to determine the intermediate structure γ’ was made by assuming that a prior structure was formed coherent on the (100) plane as suggested by the analyses of diffuse diffraction effects by Guinier and Guy.

The intermediate structure γ’ is not coherent to the (111) matrix plane; however, examination showed that it could be considered coherent on the (112) type matrix plane. In Fig. 10, the a-matrix structure is drawn at the left with the (112) plane as base while at the right the γ’ structure is drawn with (120) as base. The atomic spacing on the base planes

is the same within experimental error thus satisfying the requirement for coherency.

The identity of the {100} and {112} platelets can be established by comparing the observed diffraction effects with those predicted for the three precipitate structures γ”, γ’, and γ. On the other hand, the observed effects very well agree with some of those predicted for γ” and γ’.

Discussion of Results

The γ” structure is coherent on {100} matrix planes, and it produces the one and two-dimensional diffraction effects that have been observed by accelerated growth respectively along <100> matrix directions and across {100} matrix planes. Although three-dimensional diffraction effects were not observed for γ”, the assumed structure better explains the observed diffuse rods than would a tetragonal structure formed by a simple dilation of the {100} matrix plane stacking as proposed by Guy and Guinier.

The second precipitate, γ’, which coexists with γ” in samples aged at 300 °C grows to a size capable of three-dimensional diffraction. It is coherent on {112} matrix planes; it grows as plates on this family of planes when the thickness is small and causes diffuse diffraction effects that are rod-like and along <112> directions of matrix reciprocal lattice. The orientation relationship of the γ’ structure is the same as that proposed by Neerfeld and Mathieu for ferrite formed by transformation in Fe-Ni alloys.

The overall mechanism of precipitation in Cu-Be alloys should be considered at this time. It is not possible to decide whether the three precipitates form consecutively by transformation of one into the other followed by further growth or whether they are independently nucleated and grow competitively at rates that depend upon temperature and degree of supersaturation.

The nature of the strains which must arise in the partially impoverished matrix as the precipitates form warrants more consideration. Matrix strains are believed to be the source of age hardening. Coherency of the precipitate with the parent matrix requires that the adjoining impoverished matrix be also strained.