Table of Contents

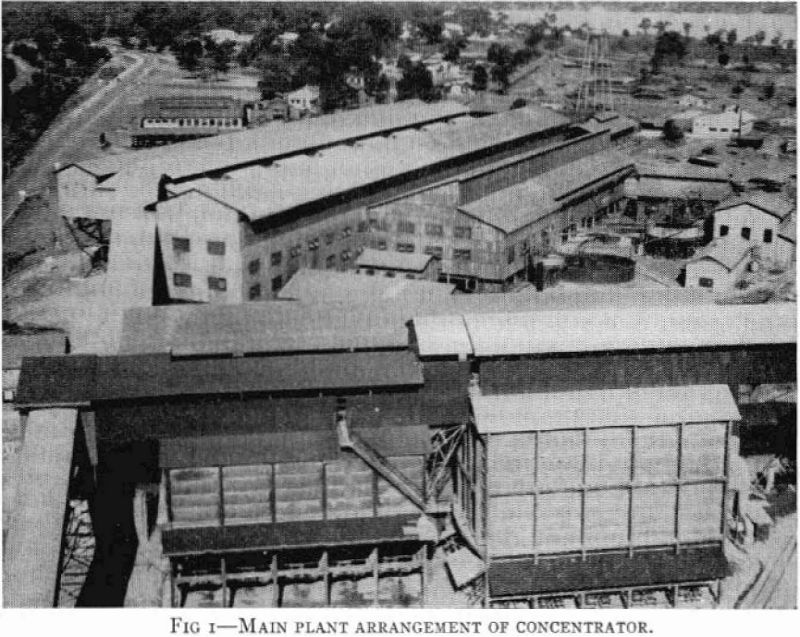

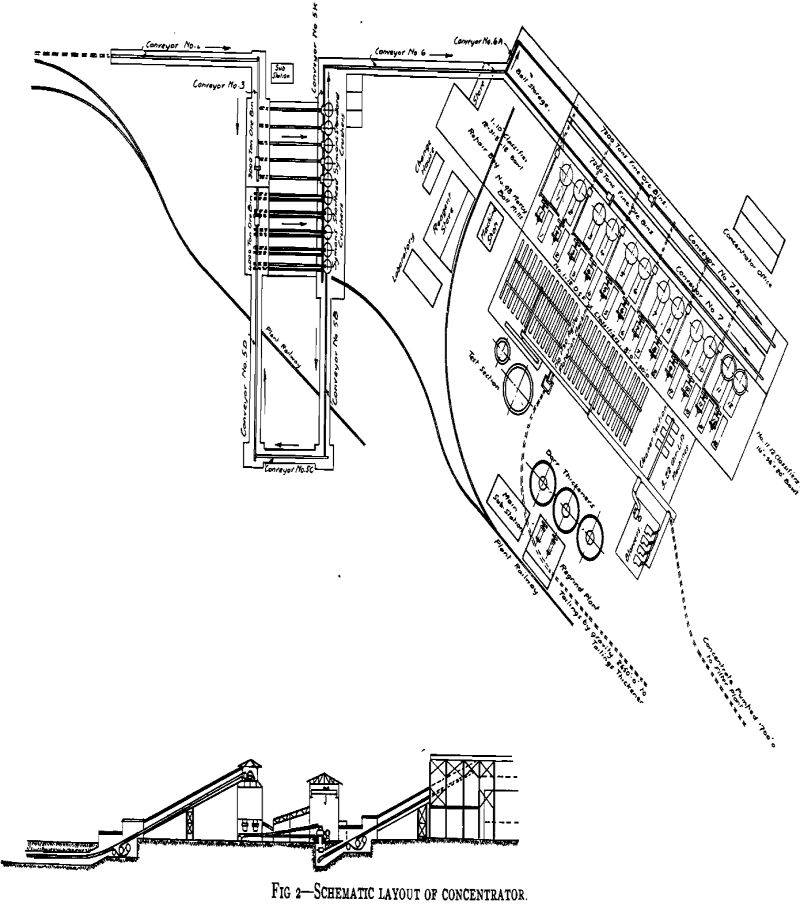

The Roan Antelope concentrator was originally designed with a nominal milling capacity of 6000 tons of copper ore per day but this was subsequently considerably exceeded. In broad outline the plant consisted of two No. 30 McCully gyratory crushers for coarse crushing, five 5½-ft Standard Symons crushers in open circuit for secondary crushing, ten No. 98 Marcy ball mills arranged in five sections, each two-mill section with primary and secondary Dorr classifiers for two-stage grinding. One stage of flotation roughing was followed by two stages of cleaning, all in airlift type pneumatic flotation machines, with the final concentrates filtered on Oliver drum filters. Tailing was thickened in a 250-ft Dorr traction type thickener before pumping to the tailing dam.

Ore Treated

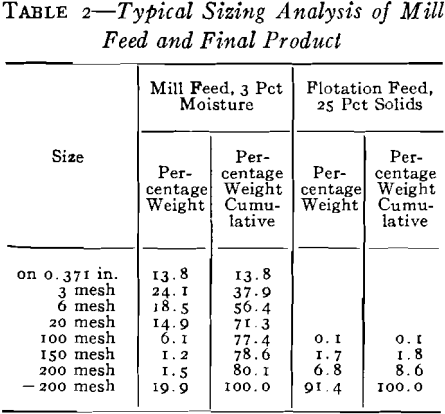

Typically the ore treated consists of metamorphosed shales and sandstones with shales as the principal mineral-bearing rock carrying chalcocite, bornite and chalcopyrite as the main copper minerals. Chalcocite predominated in the original eastern end of the ore body but there is a pronounced trend to an increased proportion of the copper-iron sulphides as mining proceeds westward. Although the ore can be described as soft, this advantage is offset by the extremely fine dissemination of the copper minerals which calls for a high degree of comminution of the ore (90 pct minus-200 mesh Tyler standard) to give a reasonably satisfactory separation of mineral from gangue.

Plant Layout

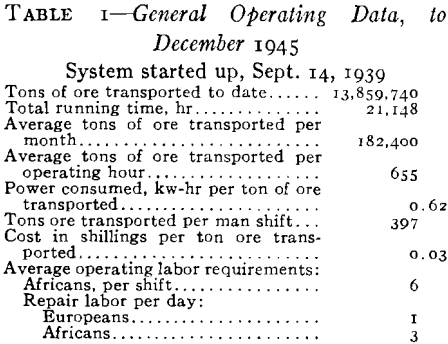

The coarse crushing plant is situated at Storke shaft and the broken ore is transported some 7000 ft to the secondary crushing plant by a five-section, 42 in. wide, belt conveyor system.

This is not a gravity flow layout in the generally accepted sense but in this plant, with large quantities of various circulating loads, the benefits to be gained by gravitational flow of all of the main products would be largely offset by the added structural complications of a sloping plant site.

Coarse Crushing

The coarse crushing plant is situated at the side of Storke shaft headframe where ore skips dump into storage bins of 2000-ton capacity. All ore is passed through 18-in. spaced grizzlies before loading into skips but occasionally large slabs occur and runs of wet fines cause difficulties. All crushing equipment is in duplicate.

Ore is removed from the bin by 72-in. wide, heavy-duty, variable speed, apron feeders delivering onto spring supported grizzlies. The grizzly oversize passes to No. 30 McCully gyratory crushers set to about 4 in.; the crusher discharge and the grizzly undersize both drop onto 48 in. wide, variable speed, apron feeders which deliver to the first section of the surface ore transport system. The 72-in. apron feeders provide a positive and controlled rate of feed to the crushers while the 48-in. feeders protect the conveyor belt from the severe treatment that it would otherwise receive from large pieces of ore dropping onto it from the crusher discharge and the grizzly undersize.

Fine Crushing

Fine crushing is carried out in two stages; the first stage in open circuit and the second stage in closed circuit to produce a final product of minus-3/8 in.

Ore from the surface ore transport conveyors delivers onto a 42-in. wide belt conveyor which elevates the ore 72 ft and, in turn, delivers to a distributing conveyor passing over the secondary (Standard Symons) ore bins of 3000-ton capacity.

Five 5½-ft Standard Symons crushers are used in the first stage of fine crushing. Ore for the crushers is taken from the bins by five roll feeders, each of which is driven from the tail pulley of the 28-in. wide belt conveyor that supplies each crusher. Protection against tramp steel is provided for each crusher by a 42 in. diam iron-clad type electromagnet that is suspended over the bronze conveyor head pulley. A type 60 Hummer screen (area 6 x 4 ft) is set at 37° ahead of each crusher and is normally fitted with screen cloths of ½ x 1¼ in. openings which remove approximately 15 pct of the original feed as undersize. Latterly, because of an increased proportion of moisture in the fines in the ore, it has been found advantageous to increase the screen mesh to 1 in. wide so as to minimize screen blockages and delays.

Grinding and Classification

The ball milling section was originally laid out for two-stage grinding using No. 98 Marcy ball mills for both primary and secondary grinding. With this arrangement considerable difficulty was experienced in maintaining a correct balance of loads between the two mills and finally this scheme was abandoned in favor of single-stage grinding which has been found more flexible and generally more efficient.

Two parallel sets of fine ore storage bins are provided holding a total of 14,400 dry tons of ore, about 75 pct of which is live load although this proportion varies appreciably with the moisture content of the ore. This tonnage is sufficient to run the plant through Sunday when no ore is hoisted or crushed.

Ball mill discharge is held at between 78 and 84 pct solids as this range covers the most satisfactory pulp density for efficient grinding. The circulating load is about 400 pct of the new feed to the mills with the primary classifier responsible for 150 pct and the secondary classifier for the remaining 250 pct. Final grinding product is maintained at 90 to 92 pct minus-200 mesh (Tyler Standard) and at this fineness the ball mills have a capacity of some 800 tons per ball mill day, varying with hardness of the ore milled.

Flotation

Because the sulphide minerals are very finely and uniformly disseminated through the ore, the main problem is essentially that of freeing these minerals. Microscopic examination of flotation tailing shows that 85 to 90 pct of the sulphides are in the form of attachments even when grinding to 90 pct minus-200 mesh. The relatively high sulphide-iron ore from the western section of the mine contains an increased proportion of chalcopyrite which is freed at a much coarser degree of comminution than is required for the predominantly chalcocitic ores but, as a considerable proportion of the latter ore will also be milled, it will still be necessary to grind to the usual fineness. The operation of the scalper flotation machines, mentioned when describing the grinding section, has been of considerable assistance in removing the chalcopyrite and bornite as soon as freed at floatable size and thus preventing the overgrinding of these minerals.

The intimate association of mineral and gangue also dismisses the possibility of coarser grinding followed by bulk flotation to produce a low grade concentrate which could be reground for further elimination of unwanted gangue. Present practice is to provide a flotation feed ground to 90 to 92 pct minus-200 mesh and with an ore containing 2.6 pct total copper and 0.12 pct oxide copper. An overall recovery of 91 to 92 pct copper can be made in a concentrate containing 50 to 52 pct copper.

A typical analysis of final concentrate is: total Cu, 51.6 pct; oxide Cu, 0.6 pct; SiO2,14.9 pct; Al2O3, 4.1 pct; Fe, 6.9 pct; S, 18.0 pct; CaO, 0.4 pct; MgO, 0.6 pct; undetermined, 3.5 pct.

Concentrate Handling

Cleaner concentrate at 50 to 55 pct solids is pumped 1700 ft to the filter plant using 3 in. Model CA Wilfley pumps driven by 40 hp motors, one pump usually being sufficient. These pumps are a special high-pressure, heavy-duty type with feed inlet at shaft height and have given very good service.

Originally, the concentrate was thickened to about 70 pct solids in a 50-ft diam “Geco” traction-type thickener and then pumped to the filters. With the production of concentrate by the scalper flotation machines the final concentrate increased in coarseness from 98 pct minus-200 mesh to the present figure of around 82 pct minus- 200 mesh. The coarser product settled rapidly and this, together with an increase in concentrate production, tended to overload the thickener.