Table of Contents

A continuous on-line particle size analysis system for solid/liquid suspensions is described. The basic sensor utilizes a centrifugal principle to separate particles according to size, the resultant separation being measured by means of beta-ray attenuation. Results obtained when analyzing a variety of materials at sizes from 65 mesh (210 microns) to 20 microns are discussed in detail. Accuracies better than 2% are demonstrated.

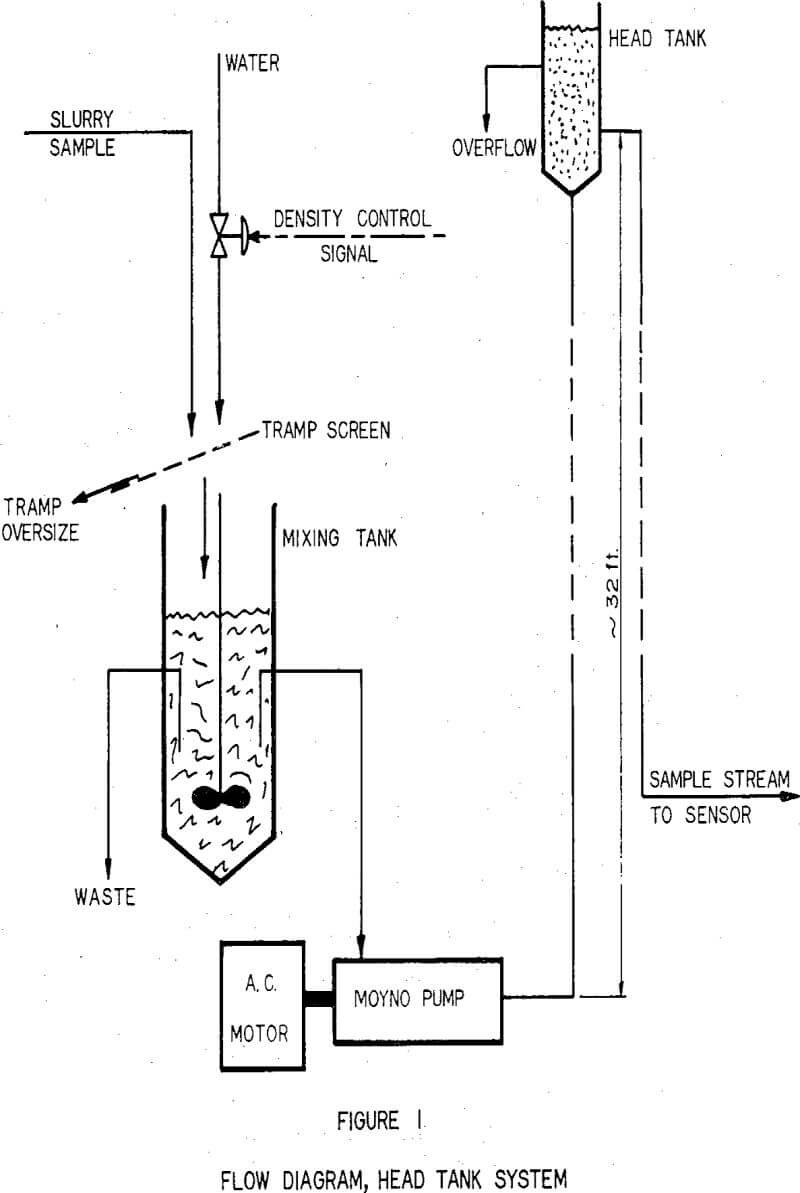

Sampling and Slurry Handling

A suitable sampling device for the abstraction of a small continuous, representative sample from a closed pipeline has been described in an earlier paper. The instrument detailed in this article requires a constant sample flowrate at a reasonably constant solids content. The flowrate required depends upon the size at which a measurement is required. The importance of this will be discussed later. The flowrate required for a measurement at 150 mesh (105 microns) is. 2.2 GPM (flow velocity 13.9 ft/sec), and this is achieved by means of a head tank system. The slurry stream from the sampler passes through a 16 mesh screen, designed to remove tramp oversize. Dilution water, controlled by means of a density signal from the analyzer, also is added via the screen. The diluted slurry passes to a small baffled mixing tank, equipped with a shrouded propeller.

Sensor and Analyzer

The sensor has been described in detail elsewhere, but for the sake of completeness, a brief description of its salient features will be given here.

The sensor consists essentially of the following components:-

a) a slurry flow channel

b) a radioactive source/radiation detector

c) a traversing system for the source/detector.

The slurry flow channel comprises two parts – a density measuring section, and a particle size measuring section. The density measuring section consists of a length of rectangular pipe of large aspect ratio (15.0 x 2.8mm) through which the slurry first flows. In the centre of this pipe is the measuring cell, equipped with “windows”, and collimation slits top and bottom. After passing through this section, the slurry flows through a single turn helix of the same dimensions. The centrifugal forces generated within the helix cause the particles to separate according to size, resulting in an increased solids concentration near the outer wall, and a decreased solids concentration near the inner wall. (it is appreciated that drag forces and secondary flow forces also influence the motion of the particles.

The yoke carrying the detector and source is designed to traverse across the cell, such that it can be positioned above and below any one of the four measuring positions. The solids concentration at the selected measuring station is sensed by means of beta ray attenuation. This technique is analogous to that used in the measurement of solids concentration in a pipeline by means of a gamma gauge. The signals from the four measuring positions are in the form of pulse counts.

Typical Results

The system has been evaluated on a number of materials, ranging from nepheline syenite (S.G. 2.6) to iron ore (S.G. 5.2). The evaluation procedure consists of calibrating the analyzer, and then passing a number of slurries of unknown particle size through the sensor at the correct flowrate and solids content. Samples taken at the sensor exit are screened; these analyses being compared with the readings displayed on the analyzer. Some typical measurements are below,

65 mesh- (210 microns), 28 observations, particle size range 76-91% passing, standard deviation of errors = 1.3% passing.

150 mesh- (105 microns), 17 observations, particle size range 34-89 passing, standard deviation of errors = 1.5% passing.

270 Mesh- (53 microns), 67 observations, particle size range 73-92% passing, standard deviation of errors = 1.2% passing.

325 Mesh- (44 microns), 62 observations, particle size range 31-85% passing, standard deviation of errors = 1-5% passing.

20 microns- 53 observations, particle size range 47-71% passing, standard deviation of errors = 1.2% passing.

The above results indicate that it is possible to measure the proportion of material smaller than a chosen size with a high degree of accuracy. This holds even when the material is 100% minus 325 mesh and measurement is being made at 20 microns.

The Analysis of Heterogeneous Mixtures

The Milltronics On-Stream Particle Size Analyzer operates on a centrifugal principle, i.e. a centrifugal force separates the particles according to size. The magnitude of the centrifugal force acting on any one particle is proportional to the mass of that particle. It might be thought, therefore, that a small particle of high S.G. would act in a manner similar to a larger particle of low S.G. If this were so, then as the proportion of heavy component in a mixture increased, so would the amount of material separated, and hence the apparent particle size would appear coarser.

A series of tests were performed to determine the magnitude of this effect. Samples of quartz (S.G. 2.7) and magnetite (S.G. 5.1) were screened into closely sized fractions. From these several samples having identical distributions, with varying proportions of magnetite from 0 to 100%, were prepared. These were passed through the size sensor at a constant solids content, and readings of ΔS, proportional to particle size, were noted. The material, as used, had 47$ passing 150 mesh.