Table of Contents

The location of a prospect usually results from some physical evidence of the presence of gold and/or past mining activity. Any earlier activity that may have produced gold from the prospect, should be investigated before making the trip.

The initial reconnaissance should attempt to verify a near-surface presence and then make observations concerning the geomorphic characteristics that relate to placer gold accumulation. Estimates of the probable depth, breadth and length of mineable gravels can be made from the surface by the experienced placer mining engineer. With this information, he can speculate on whether there is a viable prospect to be pursued. The placer mining engineer should be experienced in panning samples found in shallow diggings or from existing pits. This will give him immediate indications of gold presence without fear of “salting” by an over-ambitious promoter of the project. The same capability of panning is important during the other sampling phases. A thorough knowledge of logging and calculating the results is essential to proper evaluation of the deposit’s tenor.

Evaluation Methods

Depending upon the character of the prospect such as river, benches, terraces, jungle, the type of equipment to conduct sampling of the deposit must be determined. In most cases, the drill has replaced bulk sampling. The churn drill has had the greatest amount of accumulated experience but is slow. The reverse circulation drill(RC), is limited by its lack of verification in subsequent mining in order to prove its reliability. However, in the hands of knowledgeable placer mining engineers experienced with its use and calibration, it may be used. The RC Hammer drill (such as the Becker), can be as much as ten times faster than the churn drill and compress the time necessary to prove a prospect, or, to disprove it. All costs in balance, it is often cost effective over the churn drill.

Drilling Equipment Since we consider that sampling of placer gold prospects can best be done with a drill, the following drills are described first.

Hand Powered Drills: The earliest drill developed for placers is the Banka, developed in the 1800’s in Indonesia for tin placers. Similar hand powered drills are the Empire and Ward. These are particularly useful for exploration in remote regions for shallow deposits and swampy conditions where low cost labor is available. The Banka drill can be purchased for about $10,000. plus the cost of pipe and extra tooling; complete for about $20,000. All can be transported by canoe, beasts of burden or small aircraft. Many successful, placer dredging properties of considerable size were proven with this type of drill and hence can provide a high degree of reliability in the results when handled by experienced placer mining engineers.

Churn Drills The best known of this type is the Keystone; developed and built in Pennsylvania in the mid 1800’s. It first evolved as a water well drill and was then used in hard rock deposits in the mid west before being adapted to placer deposits in the west. This type of drill is built in various sizes from portable with 3-5 hp engines called an “Airplane” drill (because of its light weight for flying), up to 40 hp with correspondingly larger and heavier structures and drives. The casings used may vary from an I.D. of 3″ to 8″. The more commonly used size has been 5“. They all use a simple eccentric drive that lifts and drops a weight that drives the casing. At periodic depths a sample is extracted from the pipe using a bailer.

Mounting this drill on tracks provides the greatest advantage for mobility in rough terrain. Where assessable by roads, a truck or skid mounted system is used.

Reverse Circulation Drill (RC) The most common RC system that has been proven in placer mining, is the Becker Hammer RC drill. The casing used may vary from 3-1/8” to 4-1/8″ I.D., thus producing a smaller sample than the churn drills. The Becker has been proven in its evaluation of offshore tin deposits in Thailand, where substantial drilling was followed by several years of dredge mining (Showing 90% R/E). In the case of gold we are aware of only one project, conducted (by our company) in New Zealand in 1981 drilling ahead of a large bucket ladder dredge then mining the same area, that has verified the results of the RC drill. Similar drills by other manufacturers are available. The advantage of the RC drill is its speed which is about ten times that of the churn drill. The RC’s heavy weight prevents its use in some areas.

Bulk Sampling The earliest placer sampling was conducted by various methods of bulk excavation such as: Shafting, trenching, and pitting.

Shafting A shaft diameter of about 1.0 m is typical and may reach as deep as 30 m but usually 10 to 20 m. A wedge of 12 to 18″ square is cut down one side of the shaft and sampled periodically. Seldom is the entire shaft sampled since the quantity of material to be handled is too large, unless a small trommel wash plant is used. Where low cost labor is available in remote regions, shafting is still used but is slow and not as efficient as the drill.

Trenching & Pitting Another form of bulk sampling is done by trenching or digging a large pit. As with shafting, a wedge is taken from a side of the pit and treated. Otherwise, by using a long riffle box or a trommel, the entire sample can be treated.

One problem with the above approach is that so much effort is expended on a few sites that there is a tendancy to limit the area covered and to extrapolate the results for the total area. This can produce distorted estimates of both the quantity of gold and the physical characteristics of the deposit since placers are typically erratic. This is where the drill is advantageous because of its mobility and less effort required in each location.

Caisson System The more advanced type of bulk sampling is with large diameter, caisson “drills” such as the German—made, Bade. This may have a casing with an I.D. of 1.0 m or less which is handled by a rolling crane. The surface interface equipment may have hydraulic rams that twist the casing while exerting a downward force to aid in the drive. A contoured clamshell just fitting the inside of the casing, is lowered periodically to remove the sample.

The caisson system requires a portable washing plant to process the large samples. Together with the rolling crane, the total cost of the system may exceed $1.3 million. For large and deep deposits such as tertiary gravels over 100 m in depth, this is sometimes the only effective way to conduct the sampling. With placer diamond deposits in Brazil and Africa, the caisson drill has proven to be essential. For small- scale deposits however the caisson drill is clearly too expensive.

Sampling Phases Evaluation may be conducted by either drilling or bulk sampling, depending upon conditions. The following phases are described with drilling because of its dominant use but is applicable in principal to bulk methods as well.

Scout Drilling: This initial sampling phase is intended to delimit the area and tenor level of gold in the deposit. While the Reconnaissance phase may have established the presence of gold in surface observations, it must then be determined if gold continues in commercial quantities down to bedrock. In most placers, the majority of gold is concentrated near or just above bed rock, and may be also locked in clay lenses above. If it is seen to continue and increase with depth, combined with some consistency throughout the prospect, then some confidence can be developed in the potential for a mining project.

When the practical limits of the project have been established within the budget constraints of the investor, decisions can be made as to the area to be explored. The first holes are usually placed at the upper end across the river/stream or apparent flow of the deposit. If the results are low to nil this may terminate the evaluation. But if promising, random holes may be set at intervals down stream from one side to another to search for the limits of the deposit.

Exploration Drilling Assuming positive results from the scout drilling, you proceed to set up a grid of holes on lines perpendicular to the flow starting at the up-stream point, spaced at fairly wide intervals from each side of the deposit to the other. Lines may be spaced 300 m or more apart depending upon the size of the prospect. Holes should be 50—100 m between centers.

The exploration phase is intended to either prove or disprove the concentration of gold in the deposit that will produce a reasonable level for economic exploitation. Once the drilling has been completed and the values achieve that level, the deposit can be classified as containing “Indicated Reserves”.

Development Drilling: The spacing between holes and lines needs to be closed in, the ultimate objective being to have about one hole per 3 acres or less, depending upon the nature of the deposit. In deposits with more erratic dispersion or lower tenors of gold, a higher saturation may be necessary such as one hole per acre. There are some deposits that have shown enough variation in values that a large bulk sample may be taken as a further verification of the gold quantity. When the sampling has been successfully completed, the deposit can be said to contain “Proven Reserves”.

Feasibility Study After completion of the exploratory drilling phase, a preliminary feasibility study can be conducted. This will include a tentative design decision of the appropriate mining equipment that would be used, its estimated cost of operation and the amount of investment required along with the expected return. At that point, the decision can be made whether to continue with development drilling or to drop the project. Assuming a positive result from the study, the next step is to conduct the final drilling phase.

When the drilling phases have been completed and the tenor of the deposit established, final decisions are made concerning equipment design for the mining and processing system. From these decisions, the final feasibility study is conducted to determine the potential return and risks. Some of the factors to be considered are discussed in subsequent sections and a basis for parametric analysis presented.

Reserve Criteria

How does the investor or mining company evaluate whether a new prospect is a viable mining opportunity? In the majority of cases that we see, the promoter alleges that the tenor of the deposit is “high”, using numbers that are usually associated with hard rock deposits. To the knowledgeable placer mining engineer, when figures like $10. to $50./m³ are stated for a placer gold prospect, he knows that there is only a slim chance of it being valid.

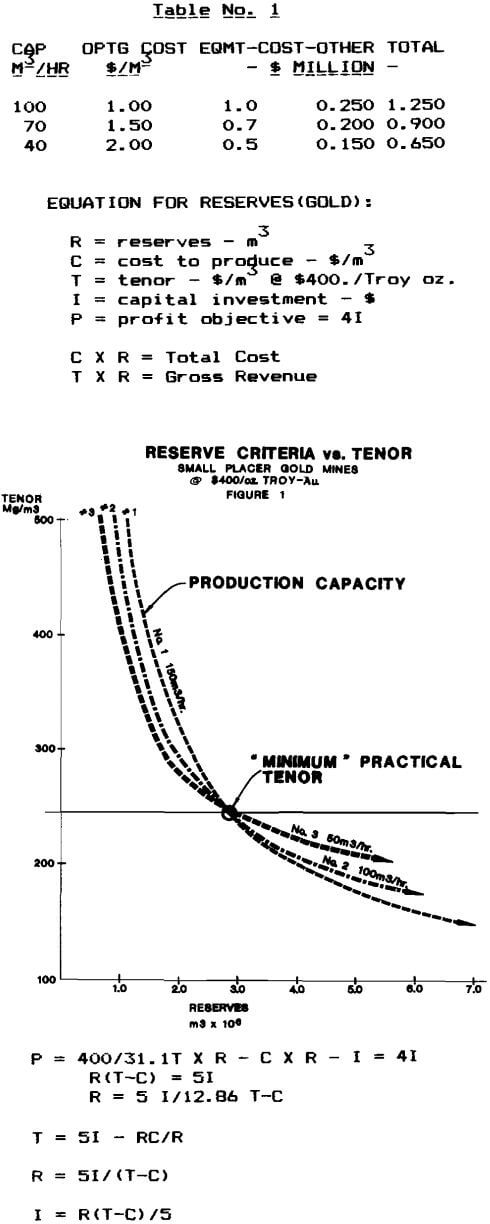

Competent sampling of a prospect is essential to making investment decisions, if the investor decides to pursue it. When such a decision is made, how do you assess the prospect when tenor figures begin to emerge from a sampling program? To provide an answer to that question, we have developed a set of curves shown in Figure 1.

“Reserve Criteria vs Tenor, Small Placer Gold Mines”, that are intended to provide a basis for decisions.

Criteria for Calculation of Reserves

In Table No. 1, we are assuming three levels of production that fall within the category of “small-scale placer gold mining”. The corresponding capital investment for each size is also specified. It is assumed further that the mining will be accomplished using that equipment configuration but with differing sizes of components, specified in a subsequent paragraph.

With the foregoing equation breakdown, the problem can be approached several ways. The curves resulting from this equation shown in Figure 1, are useful in establishing a rule—of—thumb for go—no—go decisions. The range of tenors shown up to 500 mg/m³, are typical of placer deposits in volumes up to 7.0 million m³. The three production ranges give logical dividing points for scaling the primary equipment sizes of trommel, jigs and backhoe; thus governing the amount of capital investment required. The “other” costs include exploration and development drilling; engineering design, feasibility and environmental investigations; obtaining permits and other associated costs.

The three production curves in figure 1- coincide at a tenor of 245 mg/m³ and reserve volume of 2.8 x 10 6 m³. The curves are influenced by our arbitrarily selected profit goal for the project of 4 x Investment which we consider to be the minimum necessary to absorb risks and provide a reasonable return. This can be set higher depending upon the tenor and price of gold; not unusual to have 10 I or higher. It can be seen that as the total volume of the reserves exceeds about 3.0 m³ x 10 6, the efficiency of return diminishes rapidly. This suggests that consideration should be given to installing higher production equipment such as a bucket ladder dredge.

Mining Plan

When approaching the problem of mining a property while in the evaluation stage and confining the activity to a relatively small deposit, the difficulties became apparent. This is mainly due to the limitation of reserves and tenor, the consequently low potential revenue which in turn reduces the investment capital that is justified for allocation to the project. The foregoing example of placer mining equipment, is the most common system used for small scale placer gold mining. The following discussions illustrate the basis for decisions that must be made to define the Mining Plan.

Equipment Selection

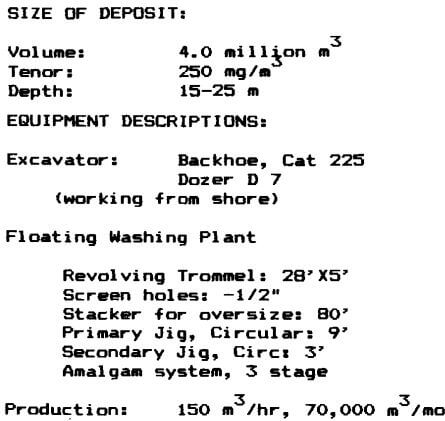

In a small-scale placer gold property in the range of reserves illustrated above, it appears that a maximum for equipment costs should $1.5 million. The example shows total investments ranging from $650,000. to $1,250,000. including evaluation and permit acquisition. One of the pitfalls to be avoided is devising a method of mining that involves double or triple handling of material. This includes using front end loaders, skip loaders, trucks and multiple stacker—conveyors. How then to move material in the excavation and processing stages without engulfing the operation in its own tailings and staying within tolerable costs of operation? The following is an equipment configuration that we selected for a prospect whose general characteristics are in the small placer category:

Excavation and Tailings Disposal

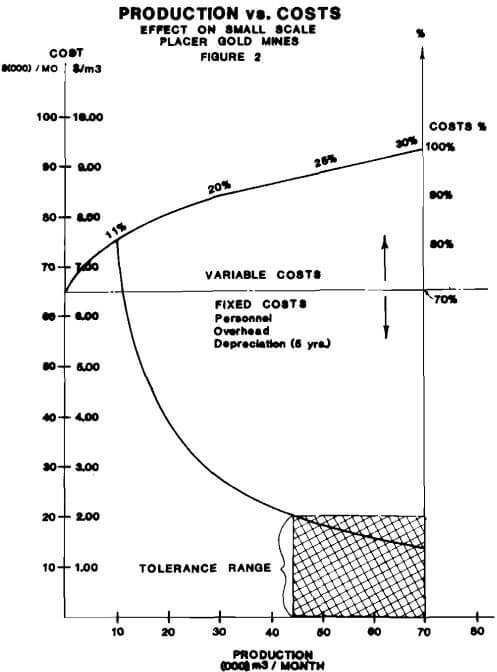

Given the foregoing configuration and other assumptions, we have developed a graph that demonstrates the consequences of a drop in production level that will degrade the cost of operation. This is shown in Figure 2, “Production vs Costs, Effect on Small-Scale Placer Gold Mines”. In Figure 1 we showed the effects of different equipment sizes on production levels. In Figure 2, with the choice made in size of equipment, it can be seen that there is a range of tolerance of production loss before the cost of operation renders the project uneconomic. The margin of tolerance will vary, depending upon the price of gold and tenor of the deposit. But to achieve the higher production level the excavation and disposal methods must be worked out on the most efficient basis.

The cost of operation is shown to vary between $1.30/m³ and $2.00/m³ when production decreases. This will extend the length of time to deplete the reserves and have other financial consequences. Figure 2 also dramatizes the effect of a small operation in terms of fixed vs variable costs that interplay with production levels.

Excavator During the 1930’s, California experienced a proliferation of what were then called “Doodle Bugs”. These were placer gold mining plants using a dragline for excavation and feed to the plant which was on a barge floating in a pond. They usually used revolving trommels and tables or riffles for both concentration and recovery. In some published reports it has been said that there were over 300 “Doodle Bugs” operating in California during the 1930’s.

The dragline was not an efficient tool for placer mining since it will not clean bedrock effectively. The backhoe had not yet been perfected but since WWII it has become the ideal tool for placer gold and tin mining on a small scale. In the latter case, a company in Brazil is reported to be operating up to 45 plants using in most cases a backhoe. In two plants they feed with a bucket wheel suction dredge but in those cases, the deposits are not considered “small-scale”. With jungle operations and shallow ground, the backhoe can work effectively with little concern for tailings disposal. In the typical North American placer however you must deal with greater depths and earth moving becomes more of a problem. Disposal also involves environmental issues. We therefore see that the backhoe has become the preferable small-scale, placer gold mining tool. Its greatest limitation however is its maintenance and repair cycle that makes it difficult to keep operating around the clock.

Tailings Disposal. How this problem is solved often spells the success or failure of a small project. The environmental requirements usually specify that the land contour must be restored and grasses and plants replaced. The operator should insist on the requirements not causing him to recreate more than the land had on it before mining takes place; and to only produce a contour that simulates what had previously existed and no more. In most cases that we have seen, a properly designed operation will in fact enhance the area.

Processing Plant

There has been a tendency to use lower cost equipment in small scale placer gold washing/processing plants with little regard for its ability to recover the majority of gold. This includes using flat shaking screens for classificaton and riffles for concentration. Few have knowledge of amalgamation and thus will not have a continuous system for recovery.

The history of placer gold recovery systems shows a slow development of technology until the bucket ladder mining dredge was combined with a processing plant as a single system, in the 1880’s in New Zealand. While mineral jigs were being actively developed for other minerals in the 1880’s, no application was made for placer gold on a dredge until about 1914, in California. Until that time and for some years after, only riffles were used and records have shown that as much as 40% of the gold was lost to tailings. Adding jigs to the circuit recovered more and by the mid 1930’s our company and a small dredge operator in Idaho, took the lead and replaced riffles with jigs on our dredges.

The solution to environmental problems with small scale placer gold mining, is to adopt more modern methods using jigs along with recirculation of processing water. The equipment described in this paper can offer a step forward in meeting those goals and to improved disposal reclamation methods.