Table of Contents

We have been conducting research on methods for beneficiating platinum-palladium ores from the Stillwater Complex, Montana. The Stillwater Complex contains the only known major deposits of platinum-palladium ores in the 48 contiguous States. Exploration by Johns-Manville Corp. (Manville Corp.) has resulted in the delineation of an approximately stratigraphic zone (J-M Reef) rich in platinum- and palladium-bearing sulfide minerals. The zone is 1 to 3 m thick, is composed of anorthositic rocks, and has been traced for 40 km. Anaconda Minerals Co. has been exploring a platinum-palladium deposit which is the strike extension of the J-M Reef developed farther to the west. The extension, called the Howland Reef, is sheared and serpentinized, and there are significant differences in primary stratigraphy between the Howland Reef and the J-M Reef.

The Bureau has conducted flotation studies on the anorthositic ore from the complex but not on serpentinized ores. This report presents the results of a pilot mill study using xanthate-normal dodecyl mercaptan suites in the flotation of serpentinized ore from Anaconda’s Minneapolis Adit on the Rowland Reef.

Sample Description

A 20-ton bulk sample of minus 2-in ore from the Minneapolis Adit was obtained for pilot mill testing. Analysis of the sample showed 0.10 oz/ton Pt, 0.32 oz/ton Pd, 0.006 oz/ton Au, 0.03 pct Cu, and 0.06 pct Ni.

The material was serpentinized and sericitized rocks with some anorthositic gabbro. The altered material contained serpentine, calcite, kaolinite, chlorite, and sericite. Accessory minerals included pyrrhotite, pentlandite, pyrite, and magnetite. The platinum-palladium mineralization was associated with the sulfides which made up about 1 pct of the rock. Microscopic examination of screened fractions of crushed ore showed that most of the sulfides could be liberated at 200 mesh. The Bond Index value for grinding the ore to minus 200 mesh was 16 kW·h/ton. Specific gravity of the ore was 2.8.

Bench-Scale Flotation Tests

Rougher Flotation

Bench-scale tests were made to determine the amenability of serpentinized ore to flotation using conventional anionic collectors for sulfide minerals. During preliminary tests, no significant difference in rougher flotation results was obtained between ores that were dry-ground and those that were wet-ground. For convenience, dry grinding of ore for bench-scale studies was chosen. Rougher flotation tests using batches of 1,600 g of ore which was dry-ground in stages to minus 200 mesh (65 pct minus 325 mesh) were made to screen collectors. Tests were conducted in a Denver No. 12 laboratory flotation cell with a stainless steel impeller, stator, and tank. Because of the presence of acid-consuming minerals in the ore, the flotation scheme devised for the anorthositic platinum-palladium ore was not satisfactory for the serpentinized ore. To obtain the desired pulp pH of 3.7 for acid circuit flotation, an excessive amount of sulfuric acid (92.5 lb per ton of ore) was required.

Several xanthate and nonxanthate collectors were tested at the natural pH of 8.2. Since lime was reported to act as a depressant in floating iron sulfide minerals and a high sulfide recovery in the concentrate is necessary for the recovery of platinum-palladium values, tests employing lime were not made.

The following experimental conditions were used:

Amount of collector per ton of ore lb……………………………………………………………………….0.2

Polypropylene glycol methyl ether frother (Dowfroth 250) per ton of ore lb………………0.014

Solids content pct…………………………………………………………………………………………………..36

Conditioning and flotation time, min……………………………………………………………………….10

Natural pH…………………………………………………………………………………………………………..8.2

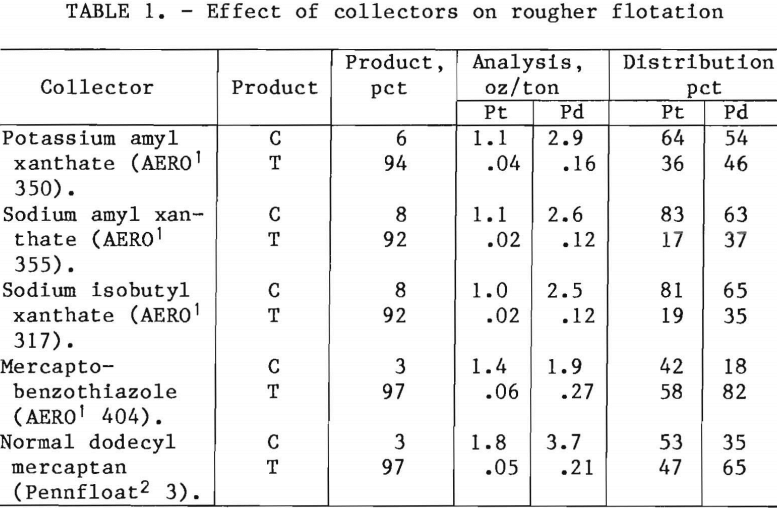

The collectors tested were potassium amyl, sodium amyl, and sodium isobutyl xanthates. The nonxanthate collectors tested were mercaptobenzothiazole and normal dodecyl mercaptan. Results are shown in table 1.

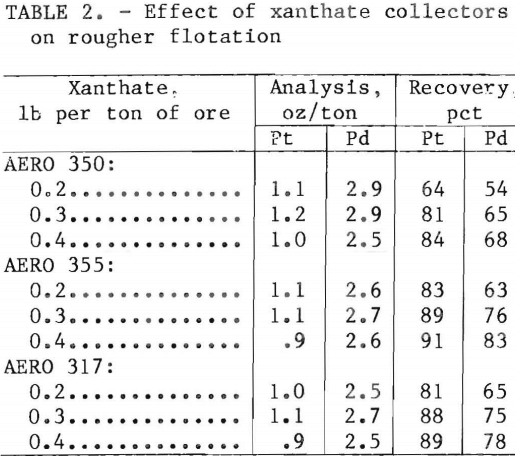

Pennfloat 3 produced higher grade concentrates than AERO 350, 355, 404, or 317, but the 355 and 317 reagents produced considerably higher recoveries. These collectors were also evaluated to determine the effect of the amount of xanthate added on flotation. Except for the amount of collector added, experimental conditions were the same as previously described. Results are shown in table 2. AERO 350, 355, and 317 in the amounts of 0.3 lb per ton of ore gave the best platinum-palladium grade. Grade was lower and recovery only slightly higher when 0.4 lb xanthate per ton of ore was used.

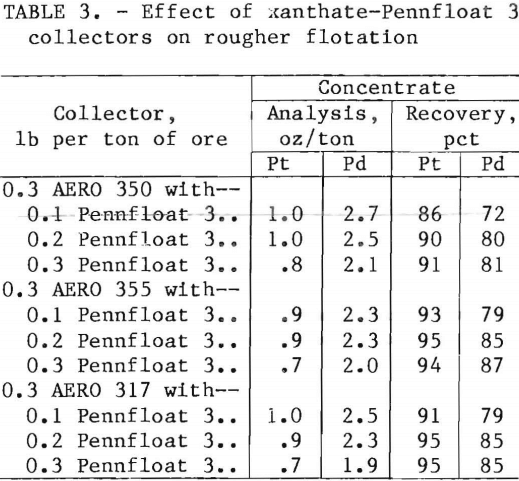

Efforts were made to improve recovery and grade. Data reported by Shaw on floating a platinum-bearing sulfide ore indicated that a combination collector consisting of sodium isobutyl xanthate and Pennfloat 3 was more effective than the individual xanthate. Tests using 0.3 lb of AERO 350, 355, and 317 per ton of ore in combination with different amounts of Pennfloat 3 were made on the serpentinized ore. Results are given in table 3. Best results for each

xanthate-Pennfloat suite were obtained with 0.3 lb xanthate and 0.2 lb Pennfloat 3 per ton of ore. Dowfroth 250 used at 0.015 lb per ton of ore gave acceptable froths and was not investigated as a variable.

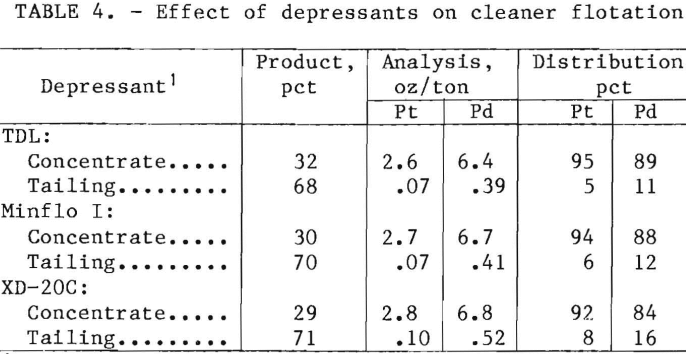

Cleaning of Rougher Concentrates

It is desirable to produce a concentrate high in platinum and palladium values and sulfur content for feed to a matte smelter. The rougher concentrate from serpentinized ore flotation contained approximately 1 pct S. Because of the success in cleaning rougher concentrates from anorthositic ore with water-soluble polymers as gangue depressants these reagents were tested on rougher concentrates from the serpentinized ore. The rougher concentrates were prepared by using the xanthate-Pennfloat 3 collectors. Flotation was conducted at 16 pct solids and a natural pH of 8.2. The amount of depressant added was 0.3 lb per ton of rougher concentrate. Conditioning and flotation times were 10 and 5 min, respectively. Results obtained with a concentrate from flotation using AERO 317-Pennfloat 3 are shown in table 4. The amount of gangue minerals depressed was about 70 pct of the weight of the rougher concentrate. The platinum-palladium recoveries and concentrate grades were comparable for tests using TDL and Minflo I depressants. Platinum-palladium recovery was lower with XD-20C.

Pilot Mill Operation

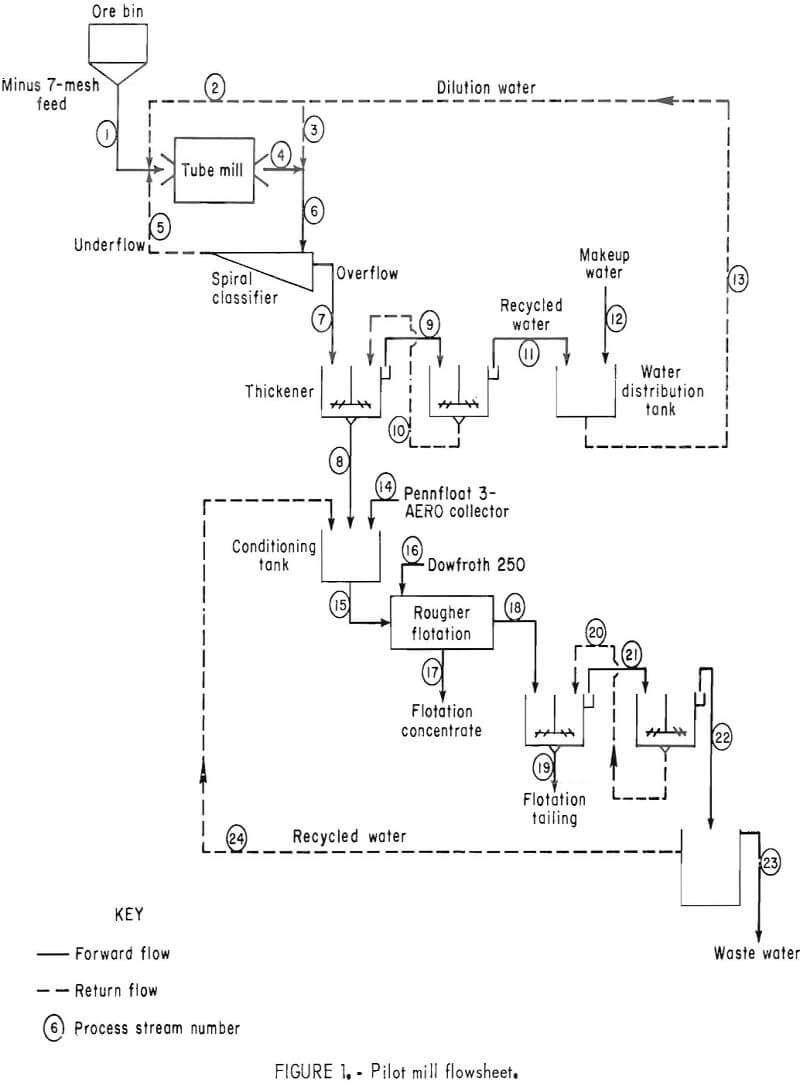

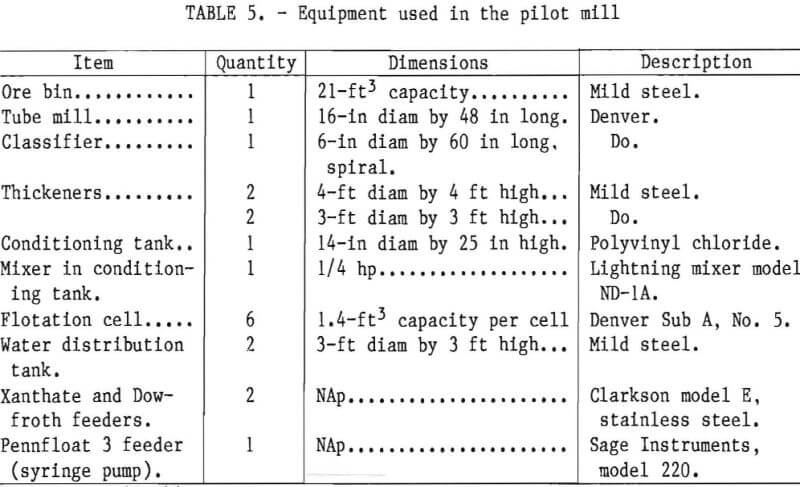

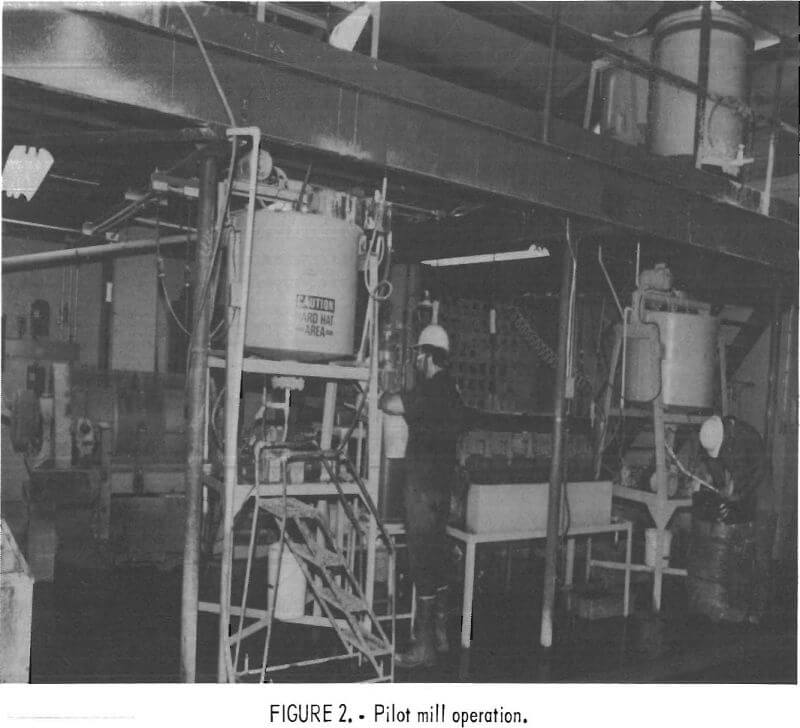

Three 32-h campaigns in the pilot mill setup shown in figure 1 were run to determine the effect of AERO 350-Pennfloat 3, AERO 355-Pennfloat 3, and AERO 317- Pennfloat 3 collector combinations on rougher flotation. These collector combinations had given comparable results in the bench-scale tests. The pilot mill was described in a previous report on flotation of anorthositic platinum-palladium ore from the Stillwater Complex. A description of the equipment used is given in table 5. In the present investigation, the mill feed. fineness of grind, and solids content of the grinding circuit products were the same in all three campaigns.

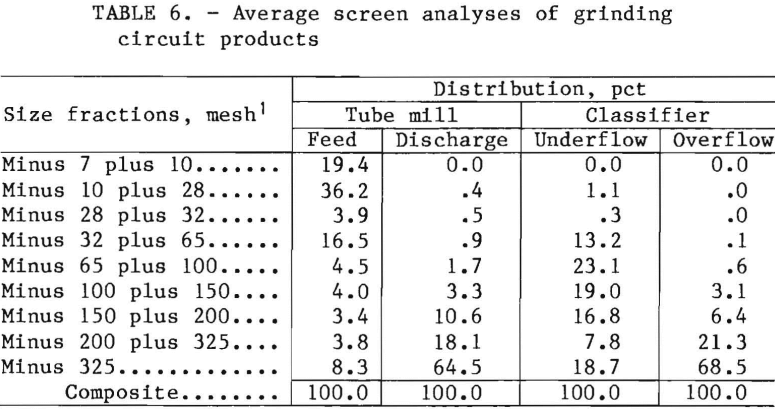

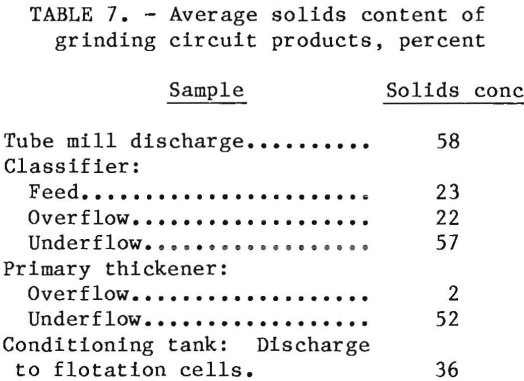

The 20-ton sample was minus 2 in as received and was dry-crushed to minus 7 mesh through a jaw crusher, cone crusher, and rolls. The rolls were operated in closed circuit with a vibrating screen. The minus 7-mesh ore was stored in 55-gal steel drums until needed. Each drum of ore was sampled with a pipe sampler and analyzed for Pt, Pd, and Au before being dumped into the ore bin. During the three campaigns, an average of 86 lb of ore per hour was fed by a short-belt conveyor from the ore bin into the tube mill. The tube mill contained a 700-lb charge of steel balls ranging from 1 to 1-7/8 in and was operated at 82 pct of critical speed. Screen analyses of the feed, mill discharge, and classifier underflow and overflow are shown in table 6. The solids contents of the grinding circuit products are given in table 7.

The xanthate and Pennfloat 3 for each campaign were separately metered to the conditioning tank. Reagent dosages, 0.3 lb xanthate, 0.2 lb Pennfloat 3, and 0.015 lb Dowfroth 250 per ton of ore, were the same as determined in the bench-scale tests, and flotation was performed at a natural slurry pH of 8.2. Dowfroth 250 was added to the first flotation cell. During each 8-h shift in the three

32-h campaigns, the concentrate and tailing streams were sampled and analyzed for Pt, Pd, and Au.

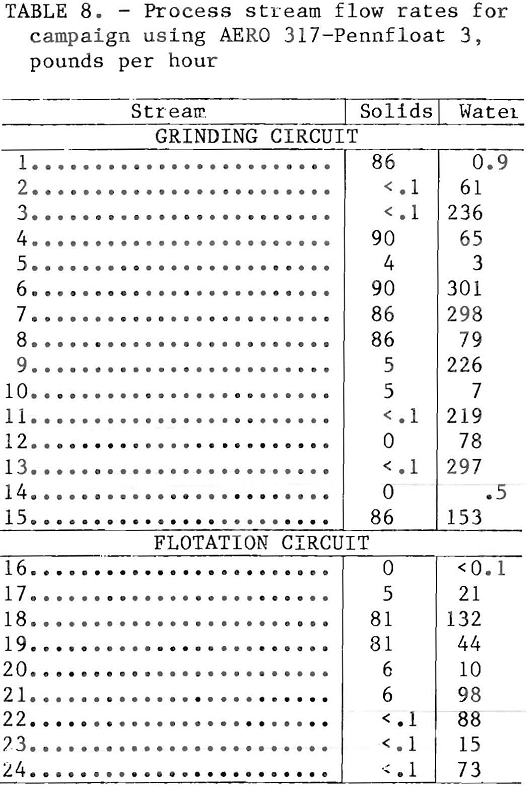

Figure 1 is a flowsheet of the unit operations used in the pilot mill. A mass balance showing solids and water contents of process streams during the campaign using AERO 317-Pennfloat 3 collectors is given in table 8. Streams are identified by numbers in figure 1. The flow rates of the pilot mill streams were measured once during every 8-h shift. Figure 2 shows the pilot mill during operation.

Metallurgical Results

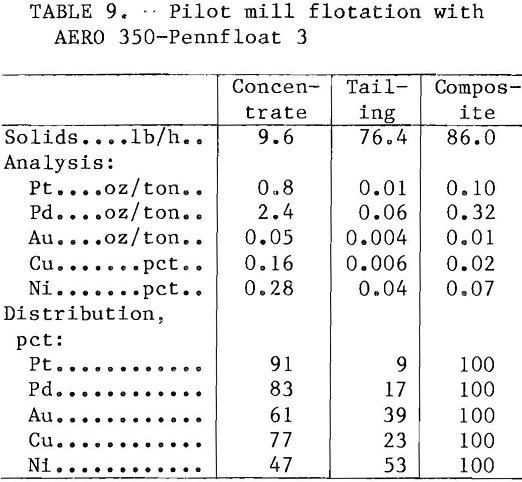

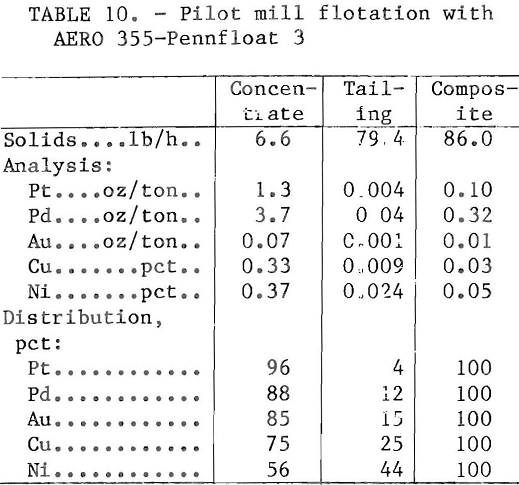

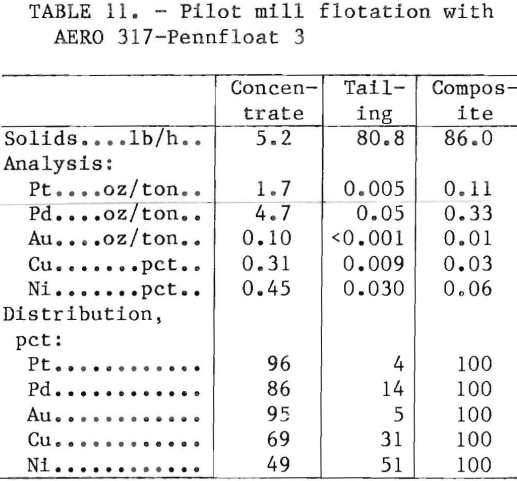

Averaged metallurgical results from each campaign are shown in tables 9, 10, and 11. Platinum and palladium recoveries were approximately the same with AERO 355 and AERO 317 collectors in combination with Pennfloat 3. Concentrate grade was highest with the AERO 317-Pennfloat 3 combination. Concentrate grade and recovery were significantly lower with AERO 350-Pennfloat 3. Because of the higher grade concentrate, AERO 317-Pennfloat 3 was chosen over AERO 355- Pennfloat 3 for further investigation.

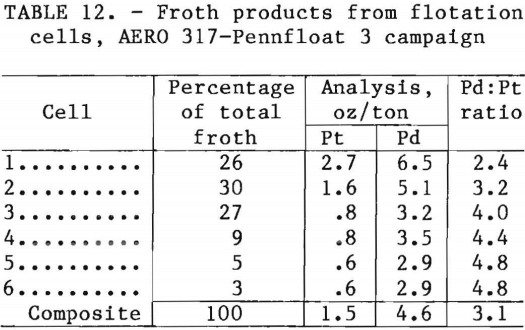

At the end of each shift, 15-min samples of flotation froths were taken

simultaneously from each of the six cells. Analytical results of the campaign using AERO 317-Pennfloat 3 are shown in table 12. The Pd:Pt ratio increased in the froths from successive cells, indicating that the paltinum-bearing minerals floated more easily than the palladium-bearing minerals.,

Examination of Rougher Circuit Products

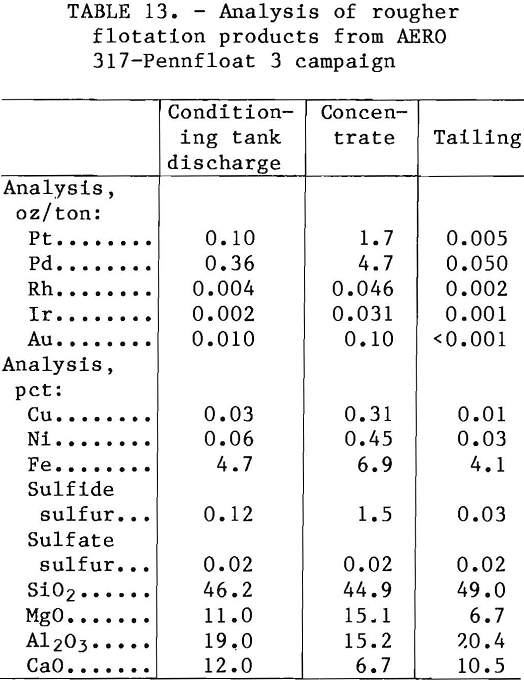

Conditioning tank discharge, concentrate, and tailing streams from the AERO 317-Pennfloat 3 campaign were sampled, and detailed analyses are given in table 13. The concentrate was 90 pct minus 325 mesh.

Note.– indicates value below detection limits.

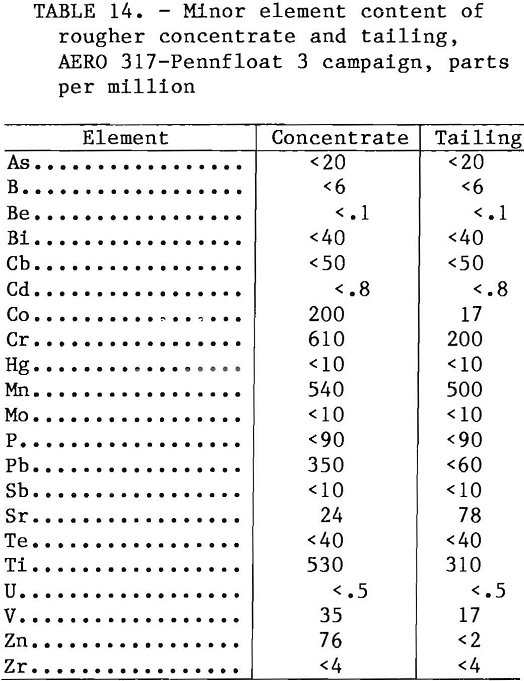

In table 14, minor element contents of concentrate from the AERO 317-Pennfloat 3 campaign are compared with those of the tailing. The data show that the minor element concentration levels are low—in most cases below the detection limits.

A sample of rougher tailing from the AERO 317-Pennfloat 3 campaign was screened and gave the following size distribution, in percent:

Plus 150 mesh………………………………………………………3

Minus 150 plus 200 mesh……………………………………..9

Minus 200 plus 325 mesh…………………………………….23

Minus 325 mesh………………………………………………….65

Platinum and palladium concentrations were uniform in all of the fractions.

Note.– indicates value below detection limits.

Cleaning of Rougher Concentrates

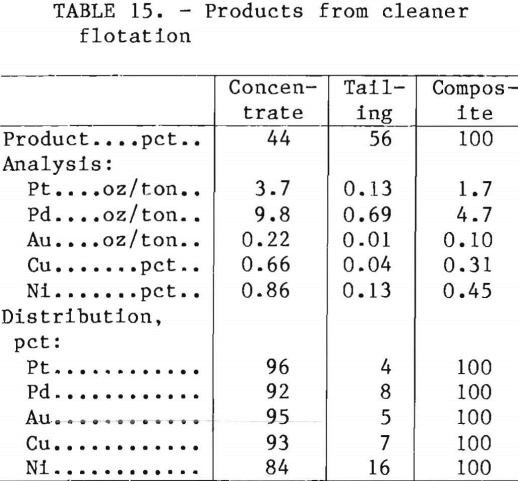

A 150-lb sample of the bulk rougher concentrate from the AERO 317-Pennfloat 3 campaign was cleaned in a bank of six pilot mill cells. The rougher concentrate slurry was pumped from a drum into the conditioning tank. Tapwater was added to obtain 16 pct solids, and TDL depressant was added in the amount of 0.3 lb per ton rougher concentrate. TDL was chosen instead of Minflo I because of its greater solubility in water. Conditions were the same as those used in the bench-scale cleaner flotation tests. After the 10-min conditioning time, the slurry was fed by gravity into the flotation cells. The results of the cleaner flotation test are given in table 15. The cleaner concentrate had approximately twice the platinum and palladium contents of the rougher concentrate. About 4 pct of the platinum and 8 pct of the palladium values in the rougher concentrate remained in the cleaner tailing.

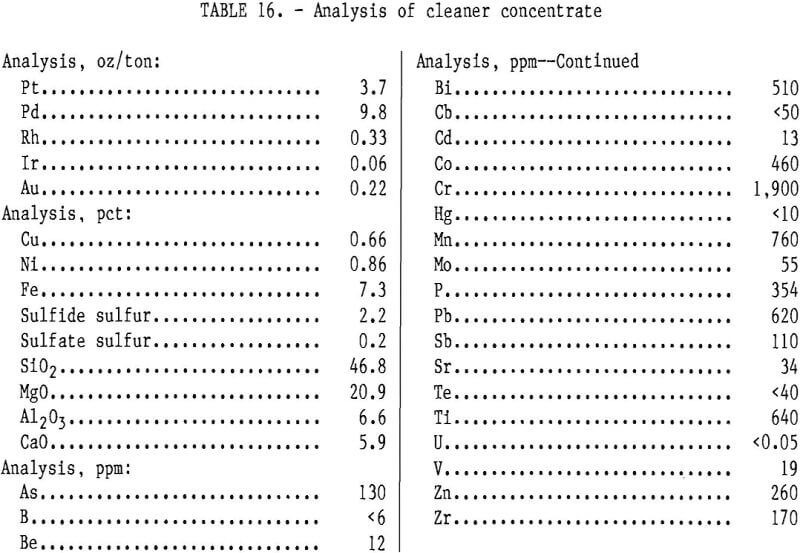

Examination of a polished section of cleaner concentrate showed that the sulfide minerals were pentlandite, chalcopyrite, pyrite, bornite, and galena, and that the gangue minerals were pyroxene, plagioclase, epidote, and chlorite. The platinum-palladium-bearing grains included braggite, merenskyite, vysotskite, and nickel-bearing vysotskite. All of the platinum-palladium mineral grains were <10 µm in diameter, and most were <4 to 5 µm across.

Because the cleaner concentrate would be subsequently treated to recover the PGM values, precious metal and minor element contents are important. Detailed analyses of the cleaner concentrate are given in table 16. The sulfur content was approximately 1.5 times that of the rougher concentrate. Although minor element content increased significantly, particularly with respect to Cr, Sb, As, Bi, and P, these amounts pose no problem for subsequent smelting.

Summary and Conclusions

Serpentinized platinum-palladium ore from the Stillwater Complex, Montana, was successfully floated on a pilot mill scale using a sodium isobutyl xanthate-normal dodecyl mercaptan combination at the natural pH of 8.2. Rougher flotation recovered 96 pct of the platinum and 86 pct of the palladium in a concentrate assaying 1.7 oz/ton Pt and 4.7 oz/ton Pd. Cleaning the rougher concentrate with a reagent suite containing a water-soluble polymer gangue depressant yielded a concentrate that had approximately twice the platinum and palladium content of the rougher concentrate. About 4 pct of the platinum and 8 pct of the palladium values remained in the cleaner tailing. These data indicate that a technically feasible process for producing a platinum-group-metal-bearing sulfide concentrate from serpentinized ore from the Stillwater Complex is available.