Table of Contents

Ball Sizes

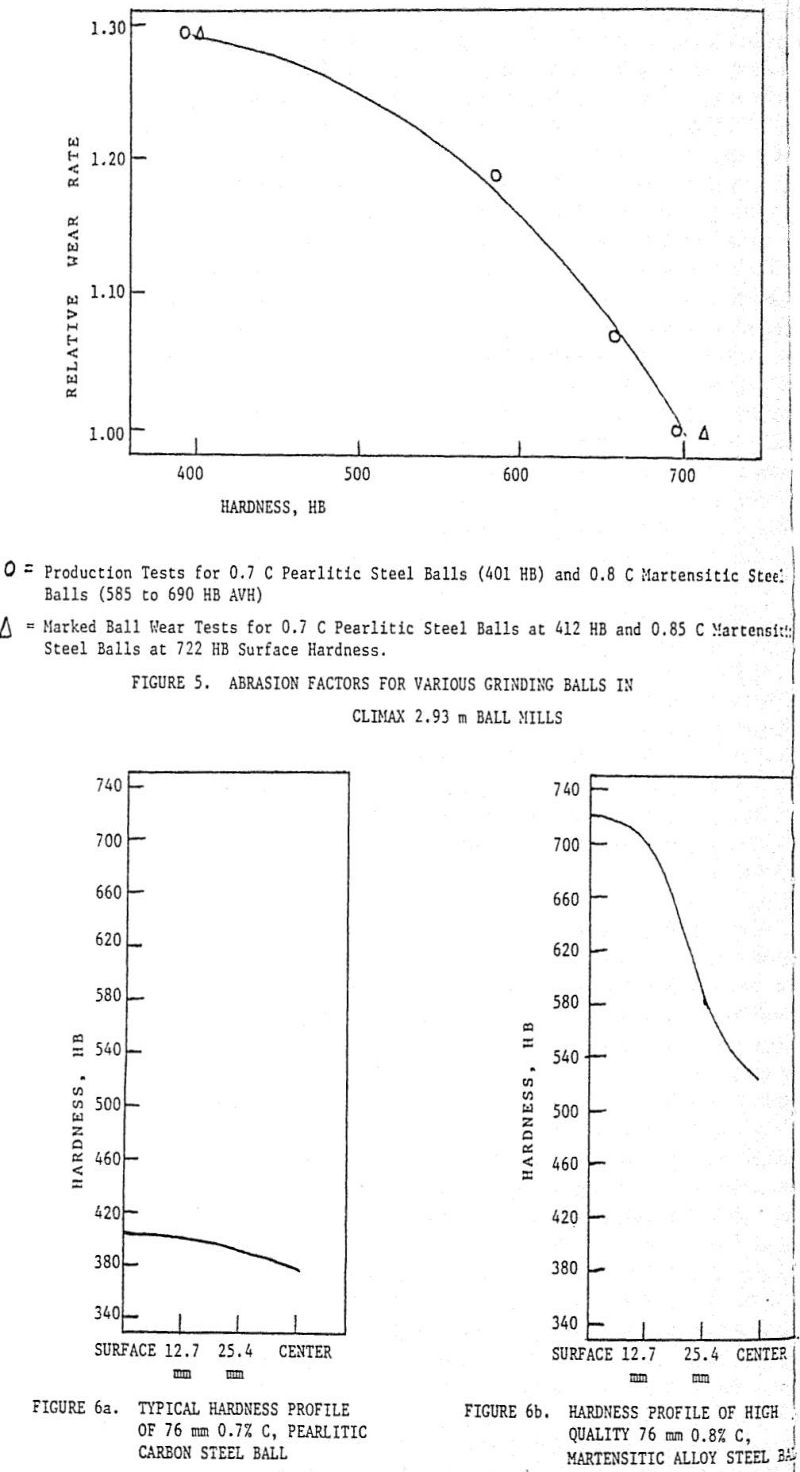

As mentioned earlier, years of operating experience indicated that the maximum ball size for the 2.93 m Climax mills was 76 mm. Application of Azzaroni’s equation confirmed that 76 mm was the correct maximum size.

The selection of the second, smaller ball size was made by analyzing historical screen analyses representing composite ball mill feed and ball mill discharge. Analysis consisted of calculating the percentage of the available material at each mesh size which was actually ground in passing through the mill. These data were compared to determine the mesh size at which additional grinding ball surface area was needed to improve grinding. Once this critical mesh size was established, a second ball size was selected. Analysis of the Climax screen data indicated that additional grinding was required at 35 mesh and smaller. Armco has accumulated several years experience relating ball size to ore particle size. This experience indicated that a 51 mm ball was the appropriate size for grinding ore particles in this size range. Therefore, 51 mm balls were selected for the smaller size of the rationed charge.

Weight Percent of Each Size

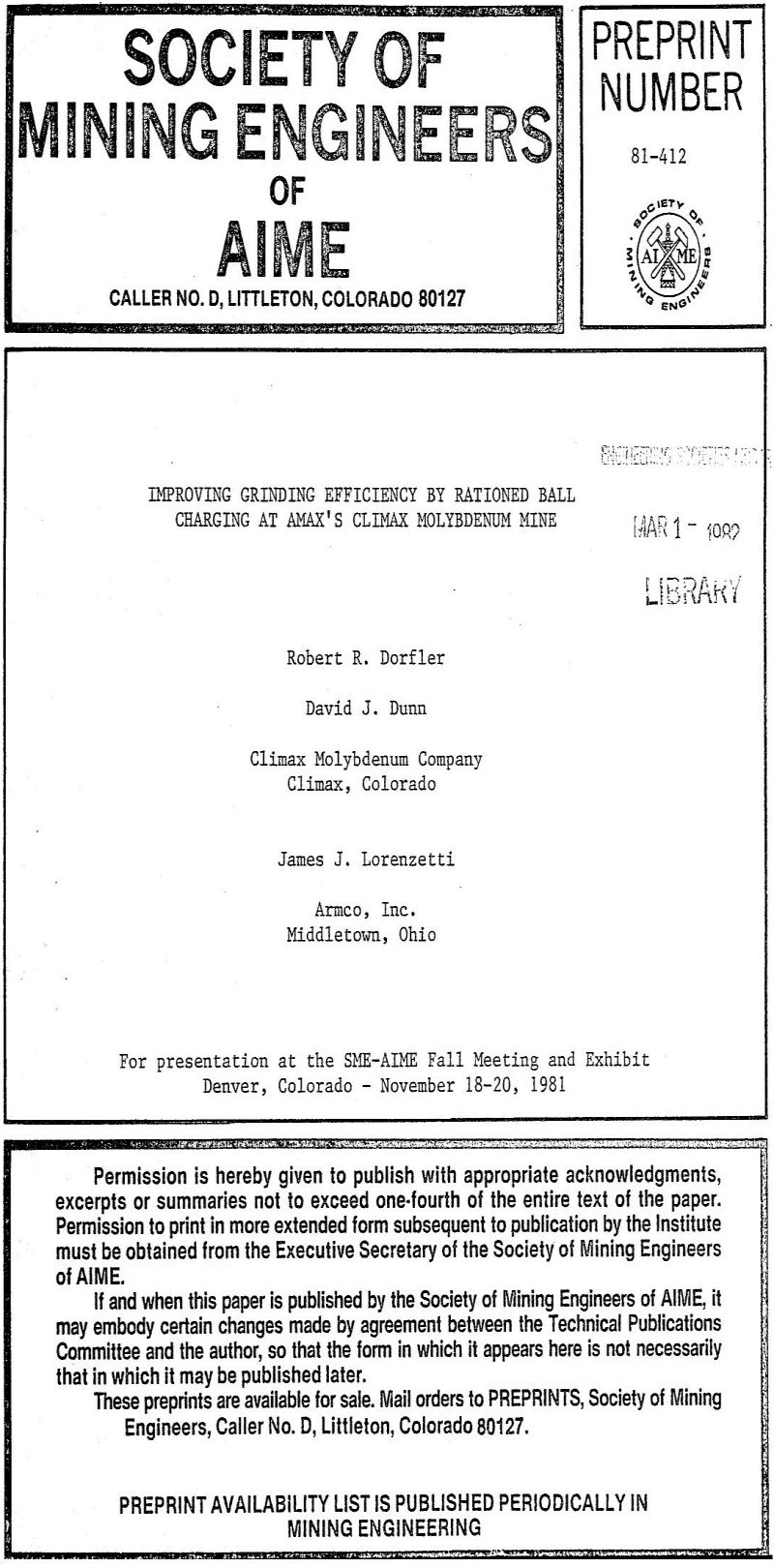

The weight percent of each size was established by balancing ball charge surface area versus the necessity to have a sufficient number of 76 mm balls to grind the coarse particles entering the ball mill. Computer analysis showed that a 50% 76 mm plus 50% 51 mm ration increased the surface area of the charge 21% compared to a seasoned charge of 76 mm pearlitic carbon steel balls. It was felt that further reduction of 76 mm balls would jeopardize the ability to grind coarse particles. Therefore, a 50% 76 mm plus 50% 51 mm ration was selected.

Recharge Schedule

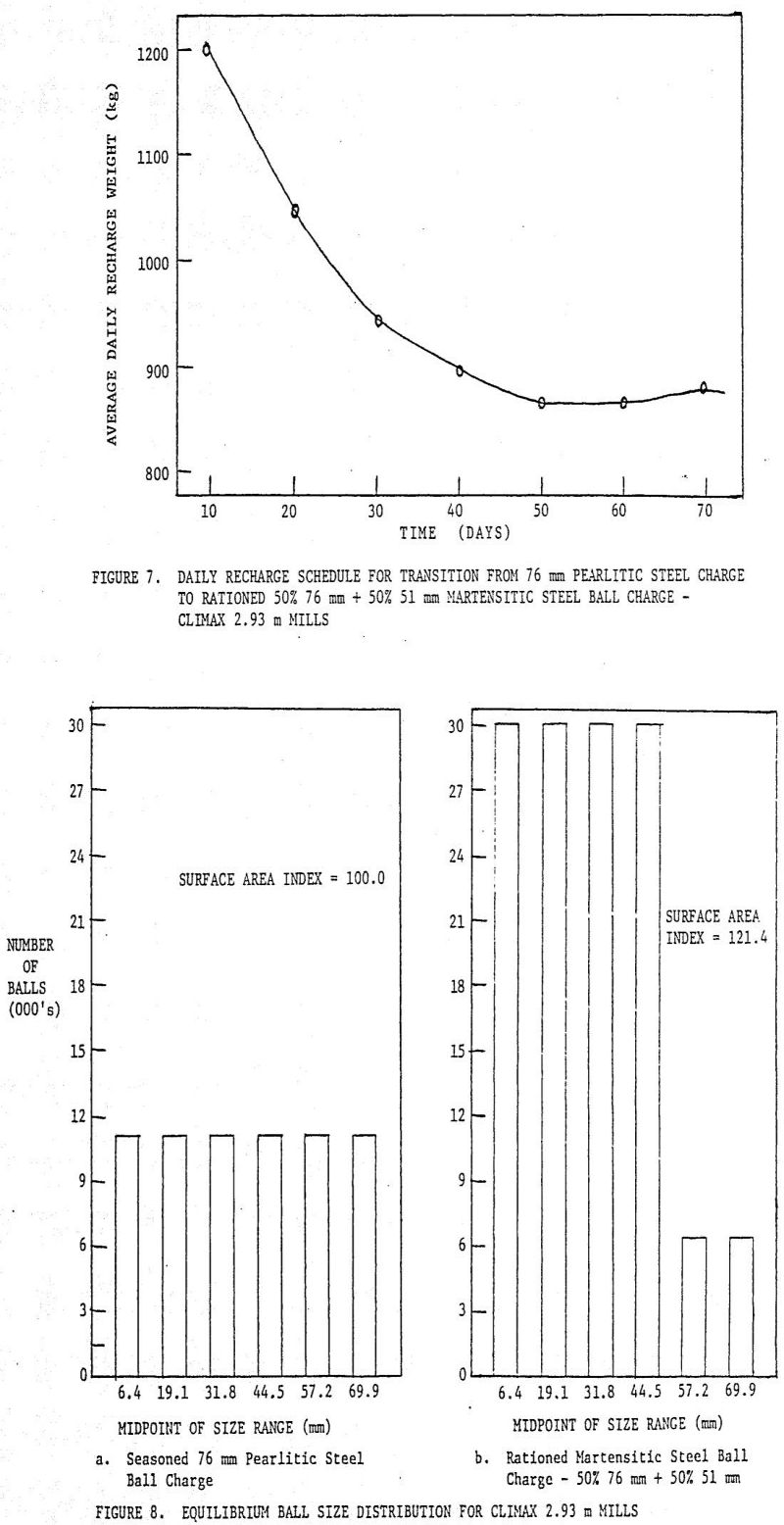

The specification of a recharge schedule during the transition from a carbon steel charge to an alloy steel charge was complicated by several factors. First, the wear rate of the martensitic alloy steel ball would be about 30% lower than the wear rate of the pearlitic carbon steel ball. This difference would cause the consumption rate to decrease continuously as the 0.7% C pearlitic carbon balls were purged from the mill.

Second, after the carbon steel balls were purged, an additional period of time would be required to establish a complete size distribution of martensitic steel balls. Consumption would increase slightly during this time period.

Third, during the entire transition period, it would be necessary to charge 51 mm as well as 76 mm martensitic balls to minimize the development of size gaps in ball size distribution. Charging of both ball sizes would cause the surface area of the ball charge to increase continuously during the transition period. Consumption would increase slightly as surface area increased.

A decision was made to estimate the recharge schedule using the computer simulation program. The following information was required for input to the program: ball charge weight, average hourly recharge weight for the pearlitic carbon steel balls, wear rate of the specific quality of martensitic alloy steel ball to be charged to the mill, and the inherent wear law for the 2.93 m Climax mills.

Ball charge weight and average daily recharge weight for the pearlitic carbon steel balls were readily available. The remaining information was developed by conducting a marked ball wear test.

Production Test Procedure

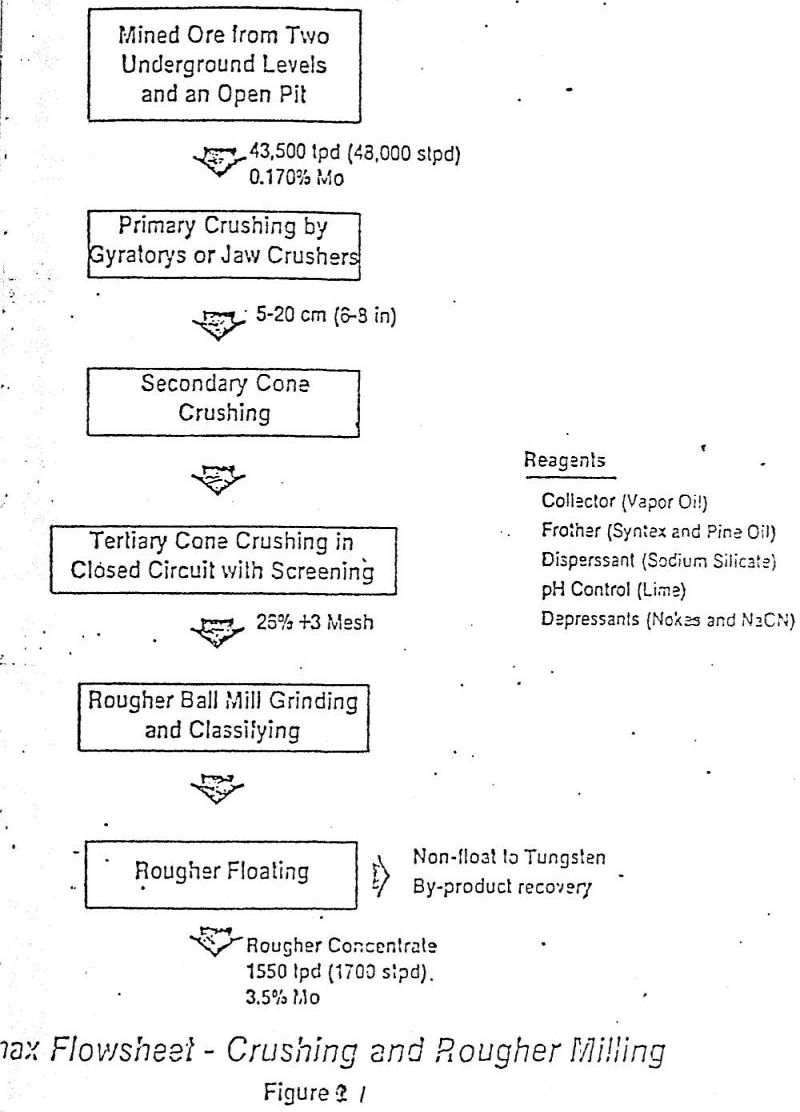

A rationed grinding ball test using 50% 76 mm plus 50% 51 mm martensitic alloy steel balls was initiated in January, 1980. The rationed charge was allowed to reach equilibrium in Unit 14 over a 100-day period, and the test was then conducted through May, 1980.

Extensive measurements were made during the test. Three composite samples were prepared daily from each of the following five sampling points—new feed, mill discharge, classifier overflow (flotation feed), flotation concentrate, and tailing.

Four days’ operation at constant grind conditions of 32, 36, and 40% plus 100 mesh constituted the base data. Critical data of tons per hour, percent solids and operating comments were collected. Ore grindability determinations (Work Index) were run on the new ore feed samples and screen analysis ranging from 0.95 cm through + 400 mesh were determined on all samples. Armco furnished a calculated mixed charge of 0.75 kg of balls per tonne of new feed that was to be added over a five-day period each week. The ball charge level was checked bi-monthly by a complete grind out and visual inspection. Charging was reduced to 0.50 kg/t in February and 0.43 kg/t in March but was revised to 0.55 kg/t in April for an overall average of 0.57 kg/t to maintain a charge loading of 45% of the total mill volume.

Results

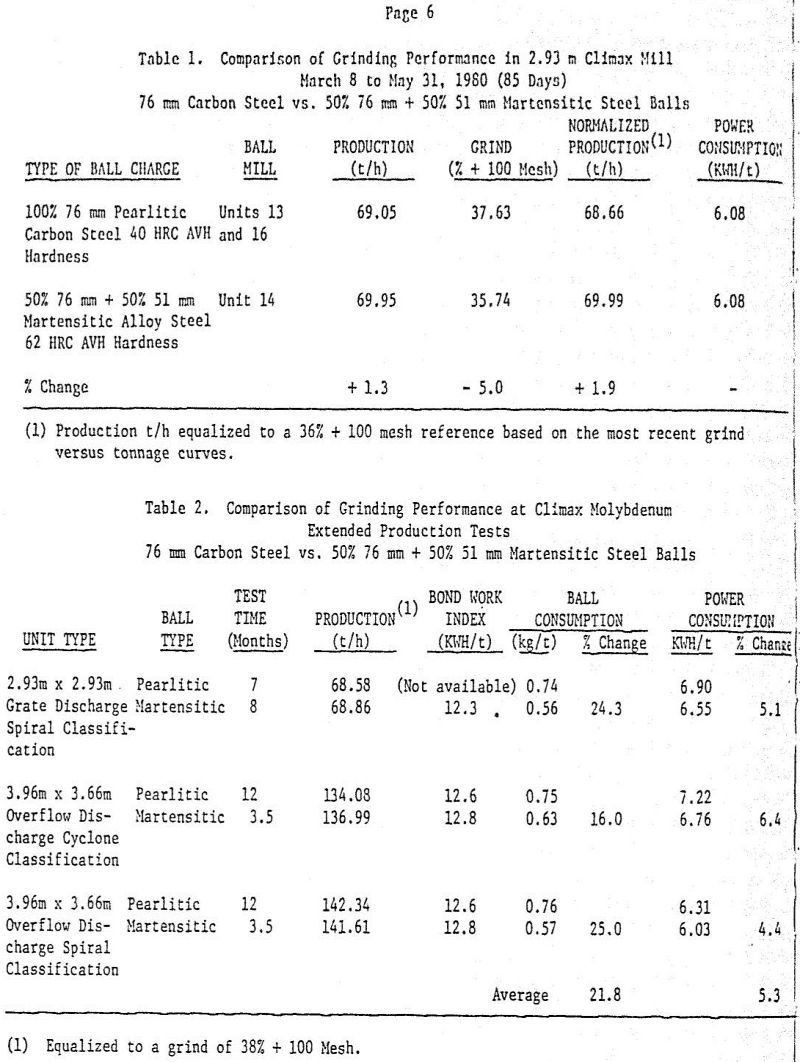

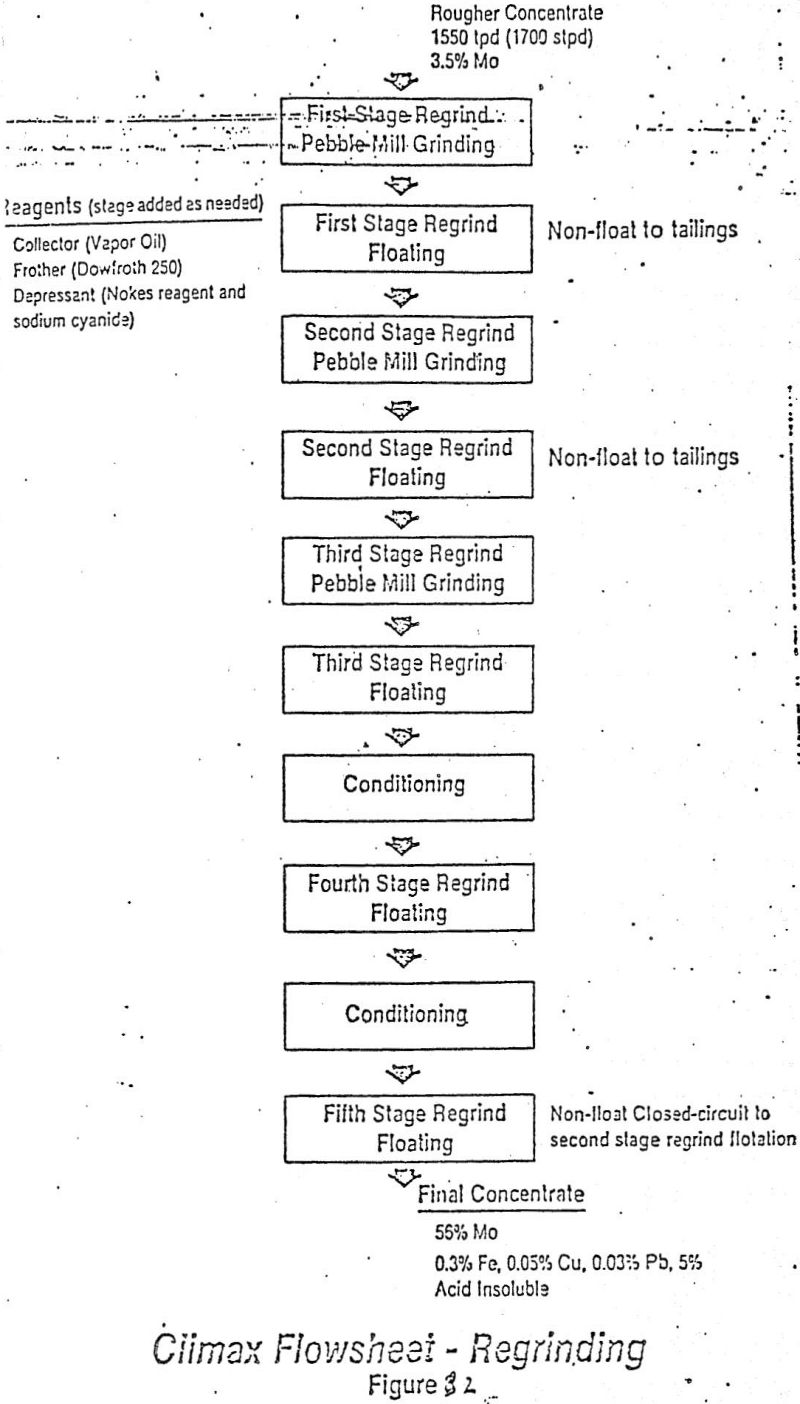

The results from the Unit 14 Ball Mill test were compared over the same period to the performance of two similar adjacent mills, Unit 13 and Unit 16. Table 1 summarizes the results. Tonnes per hour increased 1.3% while the grind decreased 5.0%. Climax has a mathematical, method of normalizing data to a common base of reference of 36% + 100 mesh grind. The data indicated that Unit 14 ran 1.9% greater tonnes per hour than the average of Unit 13 and Unit 16, or if the data were compared to a common tonnage throughput, a reduction of 5.0% + 100 mesh was observed which could then be correlated to an increase in molybdenum recovery. Ball consumption decreased 24% and power remained the same although power data was somewhat questionable because of power metering problems.

The test results of Unit 14 Ball Mill were sufficiently convincing to immediately convert the grate discharge mills in the newer mill building to mixed balls. The eight grate discharge mills in the older building could not be charged with two different sized balls because of storage and charging problems related to the older facility. At the same time that conversion of grate mills started in the new building a test was initiated on Unit 17, one of eight Climax 3.96 m x 3.66 m overflow discharge mills. By August, 1980, 20% of the rougher milling circuit was being charged with a mix of 76 mm and 51 mm martensitic balls. Sufficient confidence was gained with Unit 17 to move on to Unit 10, a discharge overflow mill that receives coarser segregated ore from the crusher because of the feed conveyor arrangements. There were no serious problems experienced when Unit 10 was placed on test in December, 1980.

Climax converted 70% of primary mill grinding capacity to mixed size, rationed charges of 50% 76 mm + 50% 51 mm martensitic alloy steel balls in January, 1981, and plans to complete the conversion to rationed charging of martensitic steel balls when ball handling and charging modifications in the older part of the plant are complete.

The most dramatic advantage of rationed charging of martensitic alloy steel balls as compared to use of 76 mm pearlitic carbon steel balls has been a 16.6% to 25.0% reduction in grinding ball consumption (Table 2).

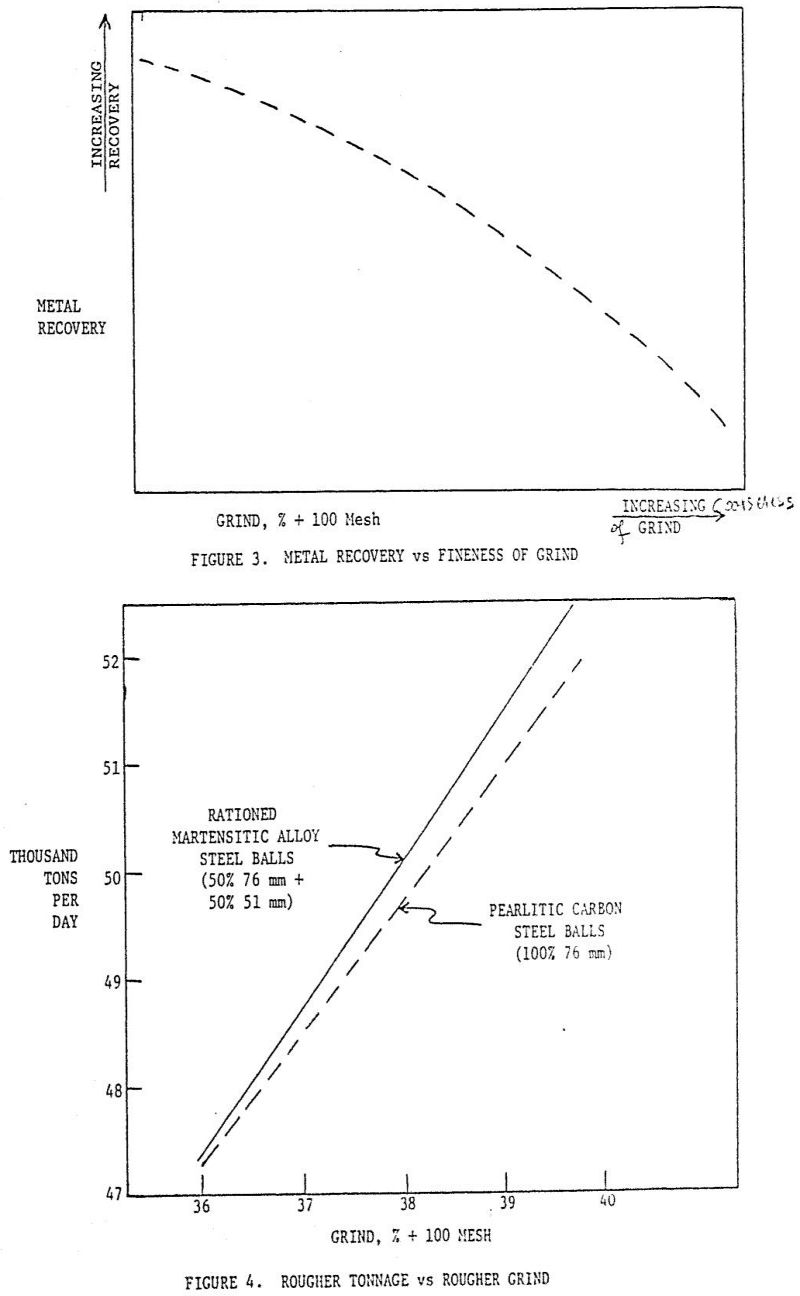

Further, the rationed charge test showed a small improvement in throughput at a given fineness of grind or, conversely, if tonnage is held constant, a finer grind and improved recovery can be expected (comparing Figures 3 and 4). Total plant operating data tend to support this observation, although insufficient operating experience has been accumulated to confirm the findings.

There is a definite indication that power consumption is less with rationed charging because of grinding efficiency improvements. Note that the Work Index of Climax ore remain essentially constant during the test and implementation period.