Table of Contents

The USBM conducted laboratory research including operating a nominal 100 lb/h pilot plant to demonstrate the recovery and concentration of chromite by gravity and flotation operations. Gravity beneficiation test results show that concentrates contained as much as 52 pct chromic oxide (Cr2O3) with recoveries of about 80 pct. Results from the bench-scale unit operations of mineral liberation, tabling, vanning, spiraling, pinch sluice, work index, and thickener area determination tests are presented in this report.

The United States is highly dependent on imported materials for many mineral products that are critical to its economy and defense capabilities. Chromium is an important example. Apparent annual consumption of chromium-containing materials is on the order of 400,000 mt of contained chromium metal. However, domestic production has occurred only sporadically, mostly in times of national emergency, and none has been produced since 1962. The U.S. Bureau of Mines is investigating the potential for processing domestic ores as part of a program to develop technology for increasing production of mineral products from U.S. sources.

Resources of chromium in the conterminous 48 States are currently estimated to consist of 450 million mt of ore with Cr2O3 grades ranging from 0.7 to 42.9 pct and averaging 1.7 pct. Alaskan resources are estimated to contain from 3.1 to 3.9 million mt of Cr2O3, usually, in deposits containing from 5 to 10 pct Cr2O3.

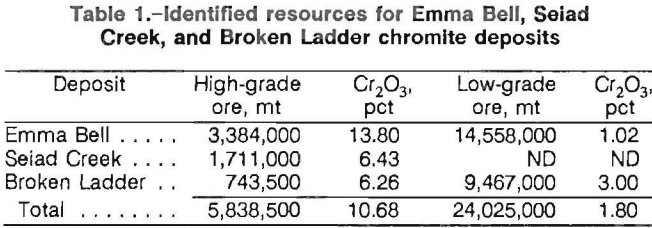

Three important deposits located in Siskiyou and Del Norte Counties in northern California are typical of many U.S. deposits in that they are fine-grained, low-grade ores with less than 15 pct Cr2O3. Resource estimates are given in table 1. These estimates are those of the Bureau and are based on surface and subsurface data from Bureau and private company explorations. Estimates for the Broken Ladder, Del Norte county deposit are conservative because no resources are inferred downdip more than 50 ft due to a lack of subsurface data.

Mining of northern California chromites was conducted as early as the 1880’s, and more than 40,000 st of concentrate were produced through the 1940’s, mostly during World Wars I and II. The Bureau performed exploratory resource definition and physical concentration investigations beginning in the 1940’s as part of the Federal Government’s war programs. A campaign of ore sampling by trenching, diamond drilling, and under ground development identified a minimum of 190,000 st of ore that contained 11 to 22 pct Cr2O3 from which production of a commercial or near-commercial grade concentrate seemed technologically feasible. Most deposits in northern California were found in random pods conducive to short-term operations. The Bureau later conducted metallurgical tests on ere samples containing from 5.2 to 20.0 pct Cr2O3, with the goal of establishing methods for economical treatment of marginal ores. The objective of the investigations was to produce market grade concentrate containing 48 pct or more Cr2O3 with a minimum Cr-Fe ratio of 2.8 using simple procedures suitable for small-scale operations. Methods included concentration by wet gravity, air-table, magnetic and electrostatic separation, and froth flotation.

Recoveries from tabling procedures were low because of fine liberation sizes of the chromite and ranged from 34 to 76 pect, with products containing from 49 to 53 pct Cr2O3. When tests were run with coarsely ground samples (minus 20 or minus 28 mesh), most losses were in the middling fraction. When the middling fractions were reground and retabled, or when the feed was ground to minus 65 mesh, recoveries were improved somewhat, but losses to the slimes were still excessive.

Flotation was generally less effective than tabling, even though recoveries of 80 to 92 pct at grades of 45 to 47 pct Cr2O3 were obtained for some samples. Most losses were in the slimes. Sometimes the most effective procedure was to float ore without desliming. For ores with Cr2O3 content less than 15 pct, high recoveries along with high grade were generally not achieved.

Magnetic and electrostatic separation methods were less effective than tabling or flotation as primary beneficiation procedures. Losses in the minus 325-mesh fines were approximately 20 pct. Also, the Cr-Fe ratio in the concentrate was not increased by use of these techniques. Recoveries were from 54 to 75 pct, with concentrate grades of 41 to 54 pct Cr2O3; when magnetic or electrostatic procedures were used alone or in combination with tabling or flotation.

In summary, research efforts have shown that chromites from northern California and other regions in the United States could be concentrated to a degree by physical separation techniques. However, no attempt was made to develop a scheme for systematically studying these materials. The Bureau, therefore, initiated a program to investigate chromite recovery from a comprehensive series of deposits using a complex scheme consisting of a combination of procedures. A pilot plant with a capacity of 100 lb/h was designed, constructed, and tested using stage grinding, classification, tabling, vanning, and flotation techniques to concentrate chromite from fine-grained ores. The samples from northern California were the first materials tested in this plant.

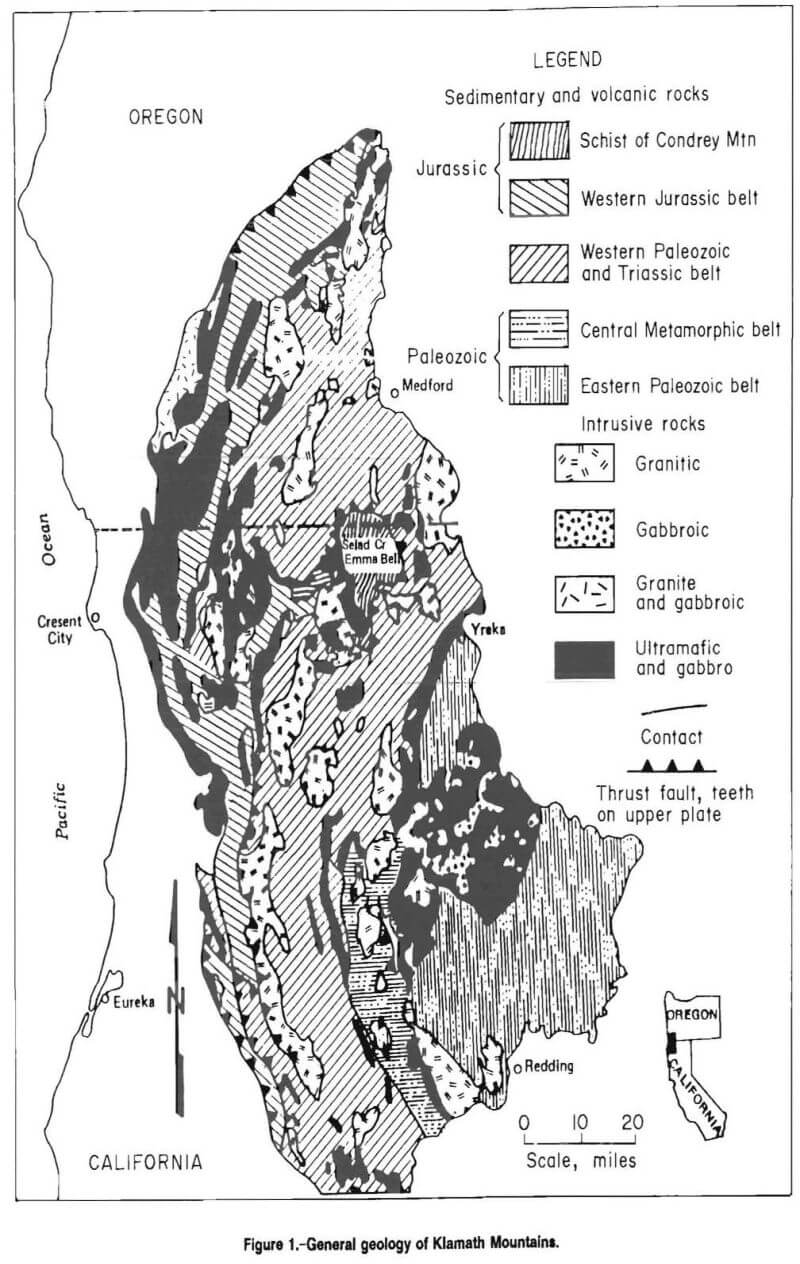

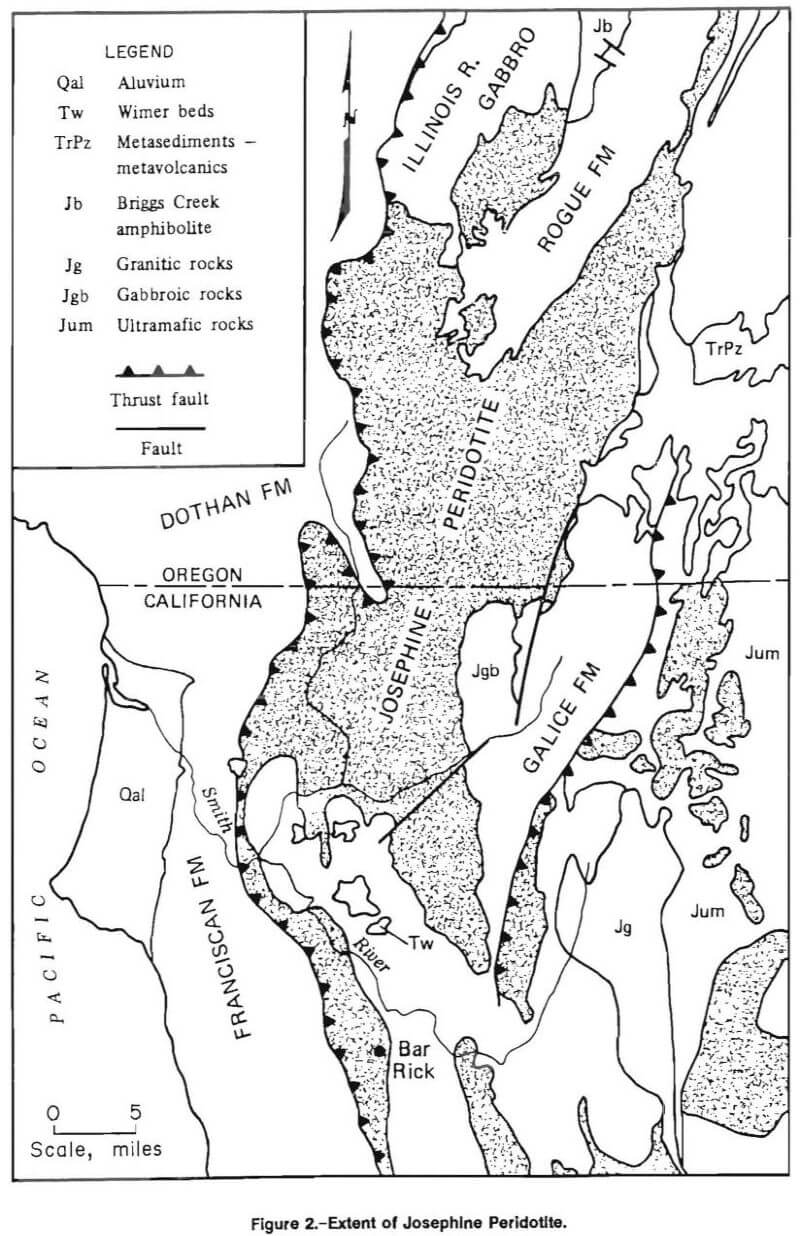

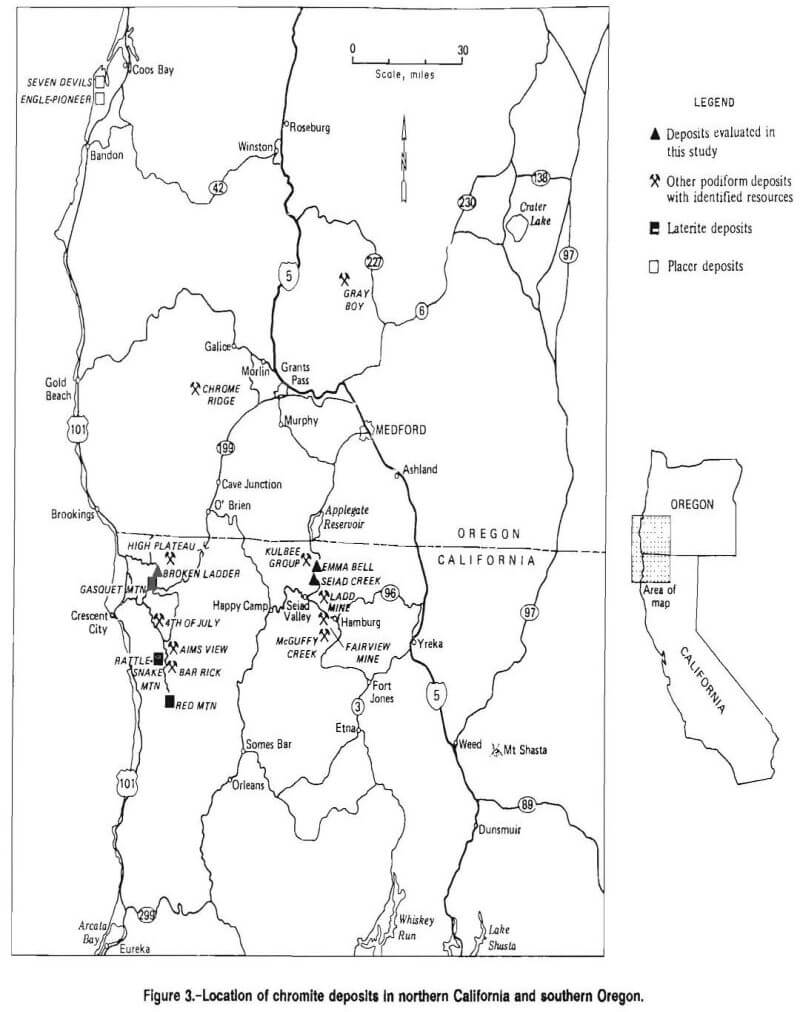

The mountains along the west coast of northern California and southern Oregon were formed by the accretion of oceanic crust onto the continental margin (fig. 1). This accretionary process produced lithotectonic belts dating from the Ordovician to the Jurassic geological periods. The westernmost belt, called the Western Jurassic Belt, is composed of northeast-trending and southeast dipping sedimentary and intrusive rocks. The sedimentary rocks represent an island are environment that formed subsequent to emplacement of the Josephine Complex, which they overlie. The complex is composed of peridotites, gabbros, and sheeted basalt dikes (fig. 2). It has undergone several periods of deformation during which time it has been flattened, folded, and subjected to various degrees of metamorphism, and accreted onto the continental margin. The peridotite member of the complex is composed primarily of harzburgite, with smaller amounts of dunite, orthopyroxenite, and lherzolite. Typically, the harzburgite weathers into lateritic deposits containing anomalous amounts of nickel, cobalt, chromite, magnesium oxide, manganese, copper, and zinc. The dunite typically is the host rock of the area’s chromite resources.

Another lithotectonic belt, the Western Paleozoic and Triassic Belt, is adjacent to the Western Jurassic Belt. This belt also consists of ultramafic and sedimentary rocks that have been accreted onto the continental margin.

In both the Josephine Complex and the ultramafic rocks of the Western Paleozoic and Triassic Belt, dunite, in crude alignment with the regional foliation, occurs as patches, tabular bodies, and podiform masses. Locally, weathered outcrops of dunite, characterized by a yellowish-brown color and fine-grained smooth texture, predominate. Freshly broken dunite has a grayish-green color with a glassy luster; where serpentinized, it is dark green in color with a waxy luster. Dunite also displays fracturing, granulation, kinkbanding, and a preferred orientation to the regional structure.

Deposit Descriptions

Emma Bell And Seiad Creek, Siskiyou County

Principal chromite deposits in the Western Paleozoic and Triassic Belt of Siskiyou County are the Emma Bell and Seiad Creek properties in the Seiaa Creek Mining District (fig. 3). Workings at the Seiad Creek Mine straddle the steep ridge just above the confluence of the East and West Forks of Seiad Creek, approximately 8 miles north from the community of Seiad Valley. The Emma Bell Mine lies on the south slope of the ridge approximately 2.5 miles northwest from Seiad Valley. The Emma Bell workings are accessible by a 19-mile road from Seiad Valley.

These deposits have produced only 3,200 st of lump ore and concentrates with an average Cr-Fe ratio of 3.0. However, exploration, which began in 1941 and is ongoing today, has delineated some of the largest disseminated domestic resources discovered to date. From April to October of 1941, the Bureau completed 6,500 ft of diamond drilling, 420 ft of underground workings, and 3,140 ft of trenching in an attempt to delineate the Seiad Creek deposit. In 1978, U.S. Chrome located in Grants Pass, OR, initiated a diamond drilling program on the Seiad Creek properties to expand the Bureau’s resource estimates. By the end of 1978, the company had drilled seven holes totaling 1,670 ft at the Seiad Creek Mine and three holes at the Emma Bell; the company drilled 14 more holes on the upper Emma Bell in 1979. Drilling between 1980 and 1982 totaled 1,620 ft on three new target areas southeast of the Emma Bell; however, no significant chromite intercepts were encountered. In 1983, Asamera Minerals located in Reno, NV, leased the Seiad Creek and Emma Bell deposits and other regional deposits. During the 2-year lease, Asamera and U.S. Chrome each drilled two additional holes at the Emma Bell.

Chromite in the Seiad Creek-Emma Bell area is found in schlieren, disseminated, and small massive occurrences. Schlieren deposits constitute the most readily identified occurrences, and the spatial extent of schlieren zones is used to delineate individual deposits.

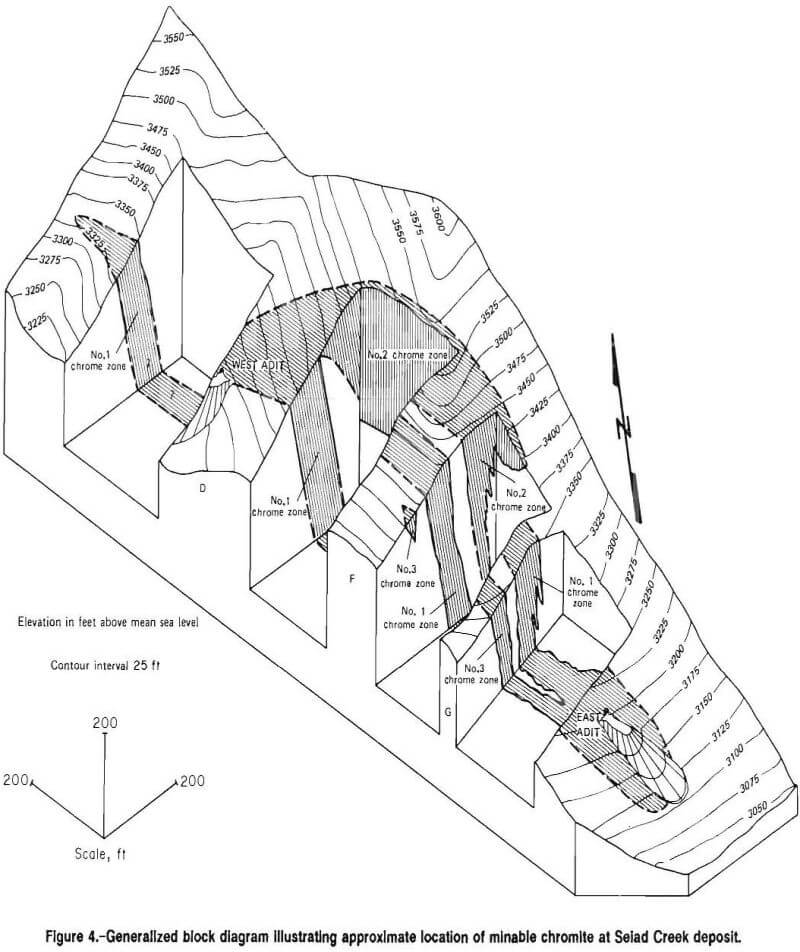

The main body at the Seiad Creek Mine has a strike length of nearly 1,600 ft, an average thickness of 148 ft, and has been intersected by drill holes approximately 300 ft downdip. The first, zone 1 strikes N 40° W and dips from 45° to 80° NE (fig. 4). A second, zone 2 with the same strike and dip occurs near the middle of the first about 65 ft up the hillside. Only 460 ft long, zone 2 aver-ages 130 ft wide and 230 ft deep.

Two smaller zones, referred to as Mountain View Claim No. 8 and Mountain View Claim No. 11, are located several hundred feet north of the principal Seiad Creek Mine workings. A surface exposure at the Claim No. 8 deposit consists of massive chromite 6 to 10 ft wide with a strike length of 490 ft. Two drill holes encountered disseminated and schlieren bands of chromite approximately 10 ft downdip. The Claim No. 11 deposit contains a schlieren chromite zone that is exposed 150 ft along strike and averages 28 ft wide. A single drill hole intersected the zone 49 ft below the surface.

The Emma Bell deposits are divided into the Upper Emma Bell, the Lower Emma Bell, and the Tail zones. The Upper and Lower Emma Bell deposits consist of schlieren and disseminated chromite striking N 10° to 40° W and dipping 45° to 75° SW. The Tail zone continues along strike from the Lower Emma Bell; however, it is overturned and appears to dip from 55° to 80° NE.

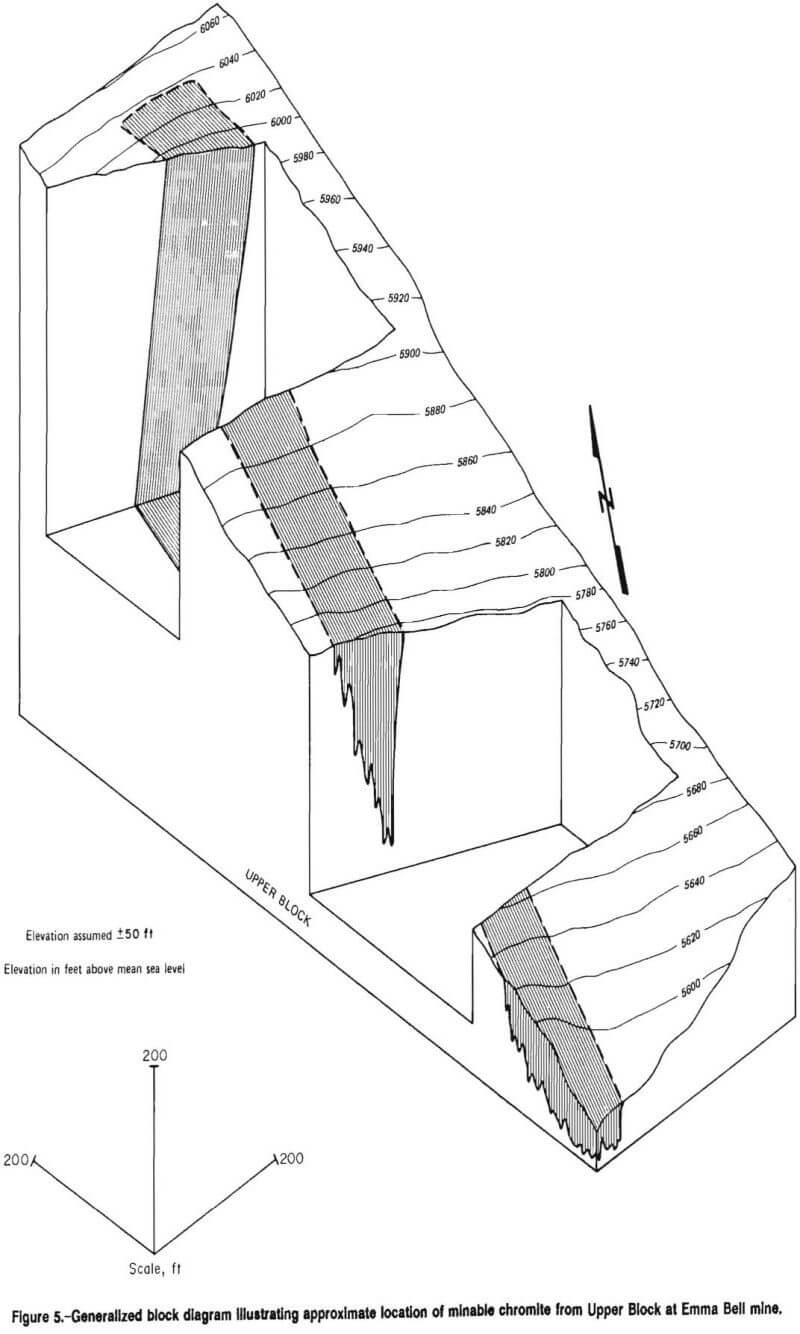

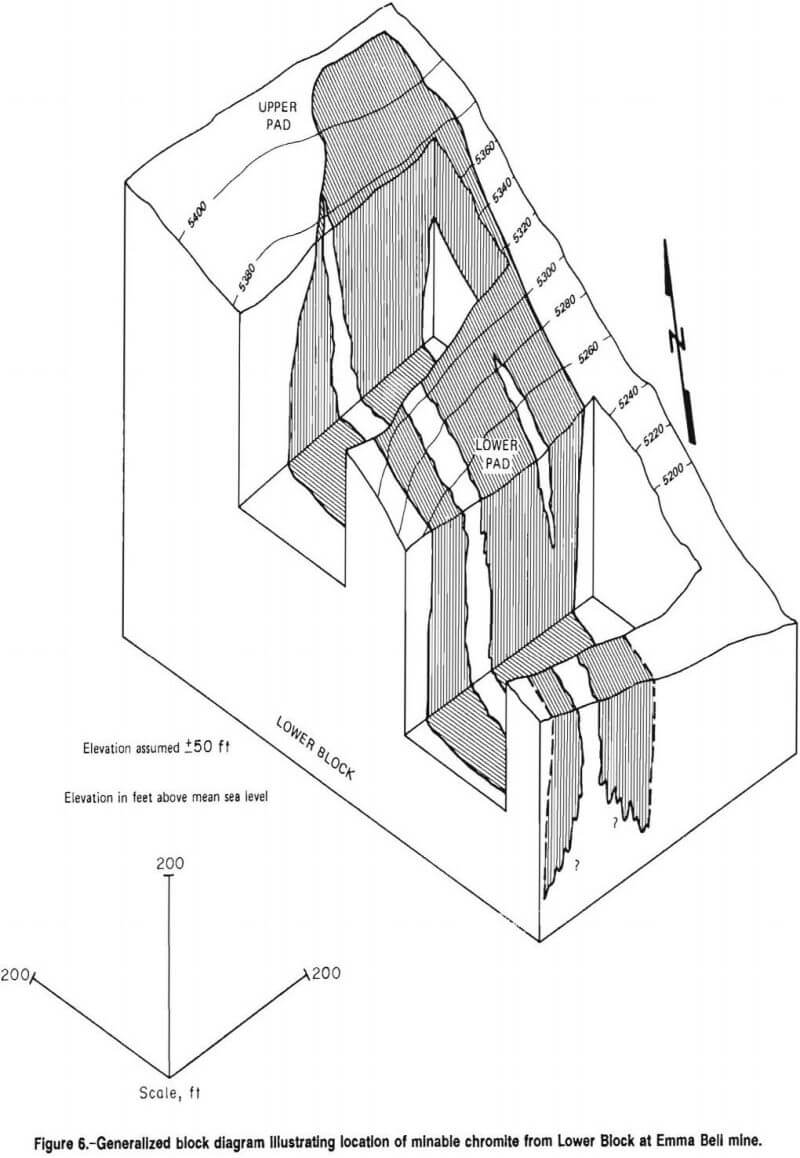

Schlieren in the Upper Emma Bell has a strike length of 980 ft, an average width of 85 ft, and a known depth of 330 ft (fig. 5). The Lower Emma Bell has a strike length of 590 ft, an average width of 175 ft, and a known depth of 330 ft (fig. 6). Chromite within both the Upper and Lower zones averages less than 5 pct Cr2O3 across the total width; however, most of the chromite is concentrated in the discrete layers and schlieren. These schlieren consist of subparallel high-grade bands of chromite (45 to 50 pct Cr2O3) bounded by nearly barren dunite (1 to 2 pct Cr2O3). High-grade layers are generally well defined and vary in thickness from 1 to 4 in (6).

The Tail zone is by far the most significant discovery on the Emma Bell property. Schlieren chromite with unusually high dissemination (10 pct Cr2O3) of accessory chromite is concentrated in a zone averaging nearly 13 ft wide for more than 1,950 ft along strike. Surface samples indicate that a high degree of consistency exists from one end of the zone to the other (fig. 6). To date, only two drill holes have tested the zone to depth, with intersections of approximately 80 ft and 160 ft downdip.

Broken Ladder, Del Norte County

Del Norte County is second only to San Luis Obispo County for total mine production of chromite in California. Through the end of the government buying program in 1958, more than 80 mines had produced a total of 86,600 mt of lump ore and concentrate. The majority of the known remaining resources in Del Norte County are contained in two deposits, the Bar Rick and the Broken Ladder. The Bar Rick Mine road is impassable, and thus prevented collection of bulk samples for metallurgical work.

The Broken Ladder chromite deposits are in the High Divide mining district. The date of discovery for the Broken Ladder deposit is unknown. Six unpatented lode claims covering most of the area were staked in 1979 by Ruess and Suitt. They allowed the claims to lapse in 1985, and in the fall of that year, Del Norte Chrome Ltd., Crescent City, CA, restaked the deposits. There is no recorded production for the Broken Ladder deposits. Existing workings consist of three small pits, none of which exceeds 100 ft across, and several trenches. Probably no more than a few hundred metric tons of shipping grade ore have been removed. These deposits, being situated only ½ mile east of the Mountain View Mine, were probably developed in conjunction with Mountain View and other regional deposits.

Rocks in the vicinity of the Broken Ladder Mine are predominately peridotites composed primarily of harzburgite and dunite. The contact between the two rock types is

usually gradational, but in places appears to be abrupt. The dunite is composed of approximately 95 pct olivine and 5 pct pyroxene. The predominant pyroxene is enstatite. Disseminated grains of chromite and magnetite are present throughout the dunite. The chromite and magnetite have been remobilized and concentrated as stringers, pods, and masses along shear planes and as fracture fillings within the metamorphosed dunite. A major north-south fault is located in the Hardscrabble Creek Valley, east of the Broken Ladder deposits; other faults appear to have dissected the deposit in an east-west manner. This faulting has divided the Broken Ladder deposits into three blocks. The southern block contains an altered dunite body that averages 690 ft wide and has a strike length of 1,220 ft. The dunite averages 3.2 pct Cr2O3 with assays ranging from 0.5 to 15.5 pct Cr2O3. Although isolated areas of heavy dissemination, stringers, and fracture fillings exist, none are of sufficient size to constitute a minable resource. The general trend of the dunite is approximately N 30° W.

Dunite in the central block also averages about 690 ft wide and 1,400 ft long; it trends more northerly at about N 10° W. The average grade of the dunite (excluding higher grade zones described below) across the 690 ft width is 2.5 pct Cr2O3. Four distinct higher grade zones occur within the central block of the Broken Ladder deposit. Zone 1 consists of massive concentrations of chromite filling fractures in intensely sheared, altered, and serpentinized dunite. The average grade of zone 1 across a 70 ft width is 11.4 pct Cr2O3 and its estimated strike length is 200 ft. Zone 2 consists of stringers and concentrations of heavily disseminated chromite in sheared, serpentinized dunite. The average grade of zone 2 is 7.2 pct Cr2O3 across a 40 ft width; its strike length is 300 ft. Zone 3 consists primarily of stringers with some bands up to several centimeters wide of massive chromite in fractured serpentinized dunite. The average grade across one 26 ft width is 6.6 pct Cr2O3; surface strike length is 400 ft. Zone 4 consists of sheared and altered dunite with heavily disseminated chromite along fractures and in shears. Stringers and bands of massive chromite are relatively rare. The average grade of the zone across a 75 ft width is 6.4 pct Cr2O3, with a strike length of 600 ft.

The northern block consists of altered dunite averaging 200 ft wide and 1,200 ft long. Within this area the dunite contains approximately 4.0 pct Cr2O3; assays range from 0.5 to 43.5 pct Cr2O3. The outcrop trend of the dunite is north-south. Three distinct higher grade zones occur within the northern third of the Broken Ladder deposit. Zone 5 consists of massive chromite up to 1.3 ft wide in a shear associated with serpentine minerals and serpentinized dunite. Along the 1,200 ft strike of the zone, high-grade material, averaging 43 pct Cr2O3, occurs intermittently. Zone 6 consists of stringers and concentrations of heavily disseminated chromite in sheared, serpentinized dunite; its average grade is estimated at 16.4 pct Cr2O3 across a 2.3 ft width and a strike length of 525 ft. Zone 7 consists of stringers and heavy disseminations of chromite-filled fractures in highly altered dunite. The average grade across a 100 ft width is 5.7 pct Cr2O3; the surface strike length is 600 ft.

Sample Description and Mineral Liberation Analysis

Emma Bell

Two samples were collected for the test series conducted in this campaign. The first sample was collected by chipping rock samples from the portal of the mine. The second sample was provided by Asamera Minerals. They blasted three rounds at the end of the existing adit and collected approximately 5 st of rock, which they shipped to a Bureau facility. The resulting samples represent medium to high grade ore that accounts for about one-fourth of the ore body.

The Emma Bell ore, as represented by the samples received, was characterized as a friable aplitic peridotite, consisting mostly of the olivine forsterite with a small amount of accessory chromite. The amount of iron in the forsterite is quite variable (forsterite forms a solid solution series with fayalite, the iron-bearing form of olivine); FeO assays varied from 9.3 to 29.6 pct. The chromite mineral assayed at an estimated 60.4 pct Cr2O3 and 39.6 pct FeO.

The ratio of MgO to SiO2 was 1:1; the sample was estimated at 40 pct for each. Minor oxides that assayed less than 0.6 pct were TiO2, NiO, CuO, CaO, K2O, and ZnO.

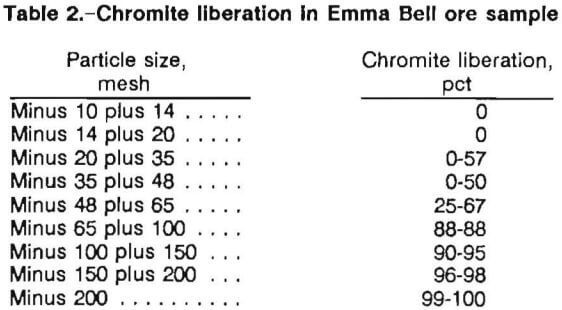

Liberation was determined by grain counting and was performed on polished sections of all the size fractions. Liberation begins at 20 mesh and is near completion at 100 mesh (table 2).

Seiad Creek

The sample collected for the test series conducted in this campaign was taken from veins and adjoining wall rock on the surface in an unmined area of the prospect. The resulting sample represents medium-grade ore that accounts for about one-half of the ore body.

The sample of Seiad Creek ore, as represented by the sample received, was a weathered peridotite, consisting mainly of olivine that was intermediate in composition between forsterite and fayalite. Most of the olivine grains showed signs of weathering to a serpentine-like mineral, which was probably hydrated and depleted in both iron and magnesium. Also the gangue had minor amounts of calcium, iron, and magnesium pyroxenes, augite, and orthopyroxene enstatite.

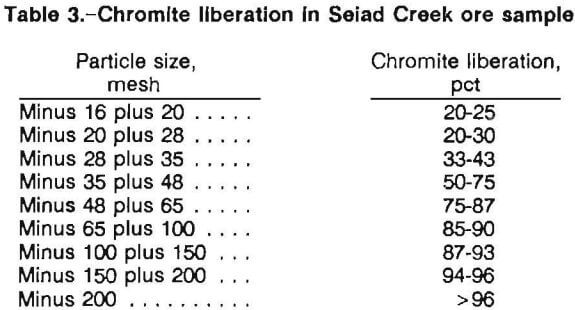

The chromite content varied in the different size fractions. A typical analysis of chromite grains ranged from 60 to 70 pct Cr2O3. The chromite began to liberate around 28 mesh and was mostly liberated at 65 mesh (table 3). Liberation was measured by grain counting on all of the size fractions.

The sample of Seiad Creek ore also contained minor amounts of feldspar, hornblende, magnetite, and ilmenite and trace amounts of manganese, nickel, and zinc.

Broken Ladder

The sample collected for the test series conducted in this campaign was taken from veins and adjoining wall rock on the surface in an unmined area of the prospect. The resulting sample represents medium to high grade ore that accounts for about one-fourth of the ore body.

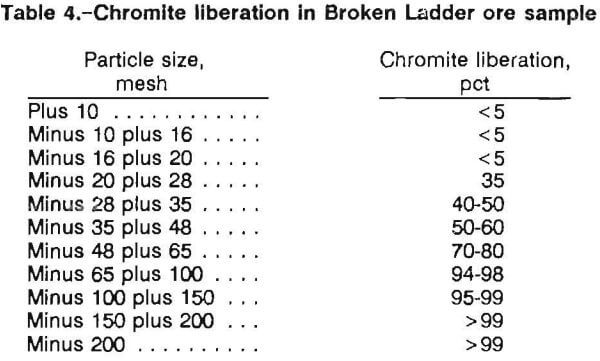

The Broken Ladder ore was dunite, which consisted mostly of chromite and olivine and contained a very small amount of pyroxene. The olivine grains were partially weathered to a mineral, probably serpentine, that was depleted in iron and magnesium and probably hydrated. The chromite content varied in the different size fractions and is listed in table 4. Chromite gram analyses ranged from 60 to 70 pct Cr2O3.

Liberation was measured by grain counting and was performed on all the size fractions. This ore began to show chromite liberation around 20 mesh and was nearly liberated at 65 mesh.

The Broken Ladder ore sample also contained minor amounts of magnetite, ilmenite, and feldspar and trace amounts of manganese, nickel, and zinc.

Laboratory Beneficiation Studies

Laboratory beneficiation studies were conducted to examine unit operations that can be used to determine the design parameters for a process that will produce a high-grade concentrate at a high rate of recovery from ores similar to the northern California chromites. The unit operations tested were tabling, vanning, spiraling, Reichert tray concentration, and froth flotation.

Tabling

Tabling is a concentration process where two or more minerals can be separated mainly because of a difference in their specific gravities and to a lesser degree because of differences in sizes and shapes. The tabling process consists of flowing a slurry of the minerals to be separated across a plane riffled deck that is usually covered with neoprene or other suitable material. The deck is shaken in the direction of the long axis of the deck, and the shaking motion can be varied both in the frequency and intensity of motion. The head motion is such that the return stroke velocity is faster than the forward stroke. It is the quickness of the return that causes the material to migrate forward toward the discharge end. Wash water flows evenly at right angles to the shaking motion. The deck can be inclined in the direction of the waterflow up to 8° from a horizontal plane. The highest density minerals are least affected by the current of the wash water and so they are collected and moved to the leading edge of the riffles. The lower density particles tend to be washed over the riffles to the lower edge of the deck. Tabling was tested as a method of primary concentration for each of the chromite ore samples.

Separations were made using a one-eighth scale Deister shaking table with a sand deck (fig. 7). Separations were made at two particle sizes, minus 28 mesh and minus 65 mesh, to determine the grades of concentrates that could be produced. Each sample was screened at 28 mesh, and the oversize was stage ground in a laboratory 1,000-g ball mill at 50 pct solids until all of the oversize material passed the 28-mesh screen. Results of these tests showed that table concentrates from the Seiad Creek deposit will range from 45 to 56 pct Cr2O3, Emma Bell concentrates from 35 to 52 pct, and Broken Ladder concentrates from 37 to 50 pct.

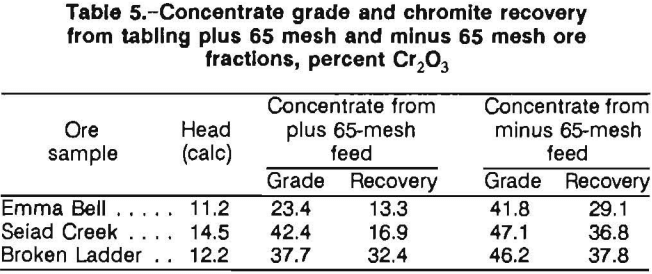

A minus ¼-in sample of each ore was screened into plus 65-mesh and minus 65-mesh size fractions and then tabled. The results (table 5), show that the plus 65-mesh concentrate has a lower Cr2O3 content than the minus 65- mesh concentrate because of mineral locking. The locked chromite in the tailing fractions from the table was the cause of high losses and indicated that further size reduction was required for higher recovery. The Seiad Creek table tailings from both passes were combined, reground to minus 100 mesh, and retabled using a slime deck. A 41.0-pct Cr2O3 concentrate was produced; however, the scavenger tail contained a high concentration of Cr2O3, 6.1 pct.

Results of these tests show that if tabling is used as the primary concentration step, further treatment of the tailings will be necessary to achieve acceptable chromite recovery.

Vanning

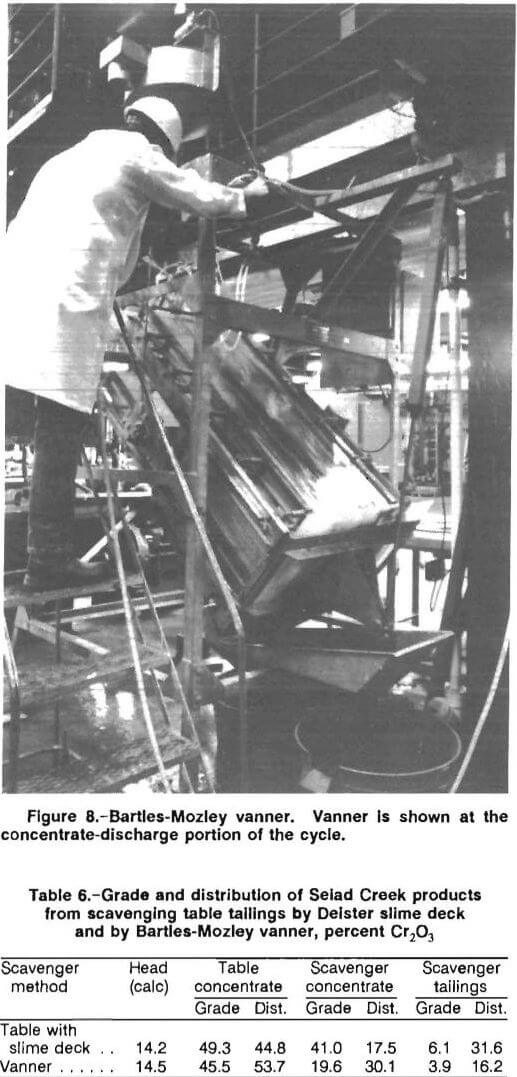

The Bartles-Mozley vanner is a high-capacity concentrator designed to recover fine particles that would otherwise be lost to the tailing. The vanner consists of fiber-glass decks mounted in rigid frames that are suspended by two wire ropes. The discharge end of the frames is attached to a hydraulic piston. The decks slope toward the discharge end. A rotating eccentric weight mounted between the decks transmits an orbital or vanning motion to the whole assembly in a horizontal plane. A batch of slurry of the minerals to be separated is charged to the elevated end of the sloped decks. Shear forces, generated in a plane parallel to the deck, have the effect of allowing the higher density and finer particles to settle. Wash water is then introduced at the upper end. The fluid motion is

more rapid at some distance above the deck than at its surface, and the lighter particles are washed away. The heavier particles are closer to the deck where the fluid motion is slower; thus, an accumulation of high density minerals occurs. After a predetermined period the deck automatically tilts and the higher density minerals are washed off into a separate launder. The deck is then returned to the feed position and the cycle recommences. Important parameters that can be optimized for each application are: orbital speed, eccentric weight and amplitude, deck slope, pulp feed rate, wash water feed rate, and process cycle times for feeding, washing, and dumping.

Vanning was investigated to scavenge chromite from the table tailings. The Bartles-Mozley vanner used is shown in figure 8. When samples of Seiad Creek table tailings were reground to minus 100 mesh and concentrated with the vanner, Cr2O3 concentration in the vanner tailings was as low as 1.2 pct. Unfortunately, the grades produced in the concentrates were below the target grade of 44 pct, ranging from 15 to 20 pct Cr2O3. Table 6 compares the chromite recoveries from table tail samples of Seiad Creek ore that were scavenged with the Deister slime deck and with the vanner. As the results show, the vanner produces a lower chromite grade concentrate, but with much higher recovery than the table with the slime deck. The vanner also produces the desired low grade tailing.

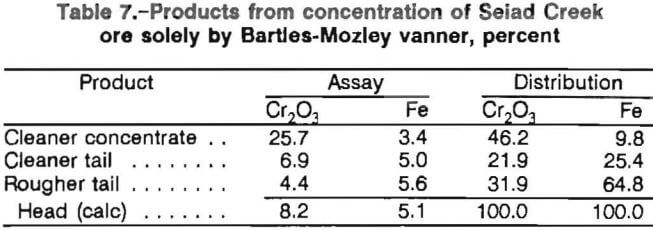

In addition, concentration was attempted solely by use of the vanner. A sample of Seiad Creek ore was ground to minus 200 mesh and concentrated on the vanner, with results shown in table 7. The cleaner concentrate contained 25.7 pct Cr2O3, and the rougher tail was reduced to 4.4 pct Cr2O3. A high concentrate grade was not achieved; therefore, the vanner cannot be used as the sole concentrator for the California chromite ores.

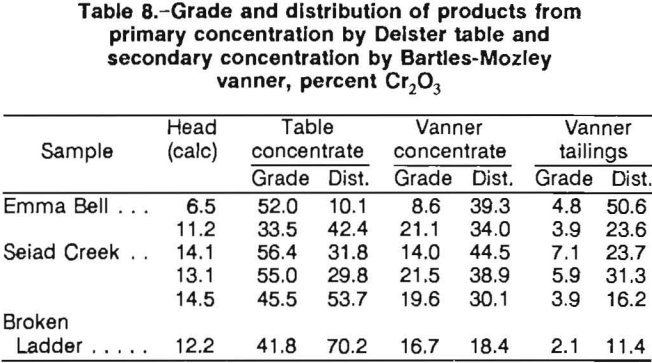

Overall results indicated that high recoveries and high-grade chromite concentrates (but lower than the targets) could be achieved with a combination of the Deister table and the vanner by using rougher, cleaner, and scavenger steps. A series of tests was made on the three ore samples to determine the recoveries that could be expected from gravity concentration using the Deister sand deck as a rougher and the vanner as a scavenger. These results (table 8) indicate that gravity concentrates with chromite grades of about 50 pct Cr2O3 can be expected. Tailings from the vanner may be as low as 2 pct.

Spiraling

Spiral concentration of ores and industrial minerals is based primarily on the specific gravity differentials of the minerals to be separated. A series of tests was conducted using a Humphrey’s spiral concentrator, a spiral-shaped channel of launder with a modified semicircular cross section. The spiral contained the standard five complete turns with a drop of 13.5 in per turn.

The flowing pulp progresses from the top to the bottom of the spiral. As the feed slurry flows down the spiral channel, the particles with the highest specific gravity sink to the bottom and move inward toward the inside of the channel. The lighter weight particles move to the outside and are carried away in a faster, more dilute part of the stream. At 120° intervals circular concentrate ports, or openings, appear in the bottom of the channel near its inside edge. There are 15 ports in a five-turn spiral, but usually more than half of these are blocked off with smooth stainless steel disks to allow proper configuration of the concentrate stream and good washing of the concentrate. Concentrate ports are fitted with very simple stainless steel belt-disk splitters, which can split out the desired portion of the concentrate stream. Wash water is available along the entire inside edge of the spiral, where it flows at the rate of 3 to 10 gpm in a separate wash-water channel. As the gradually impoverished pulp flows down the spiral, wash water is proportioned from the wash-water channel by a series of notches and directed to wash repeatedly across the concentrate band and sweep out unwanted gangue particles. Thus, the spiral provides repeated washing stages as the pulp flows down the channel. Generally the richest concentrate is withdrawn from the concentrate ports near the top end of the spiral. The concentrate withdrawn from ports near the bottom of the spiral is usually low grade and, if liberated, may be recirculated to obtain additional recovery of values and a higher grade of concentrate.

Although the spiral concentrator is mechanically a very simple piece of equipment, the separating action taking place is complex. It involves centrifugal force, friction against the spiral surface, gravity, and the drag of the water.

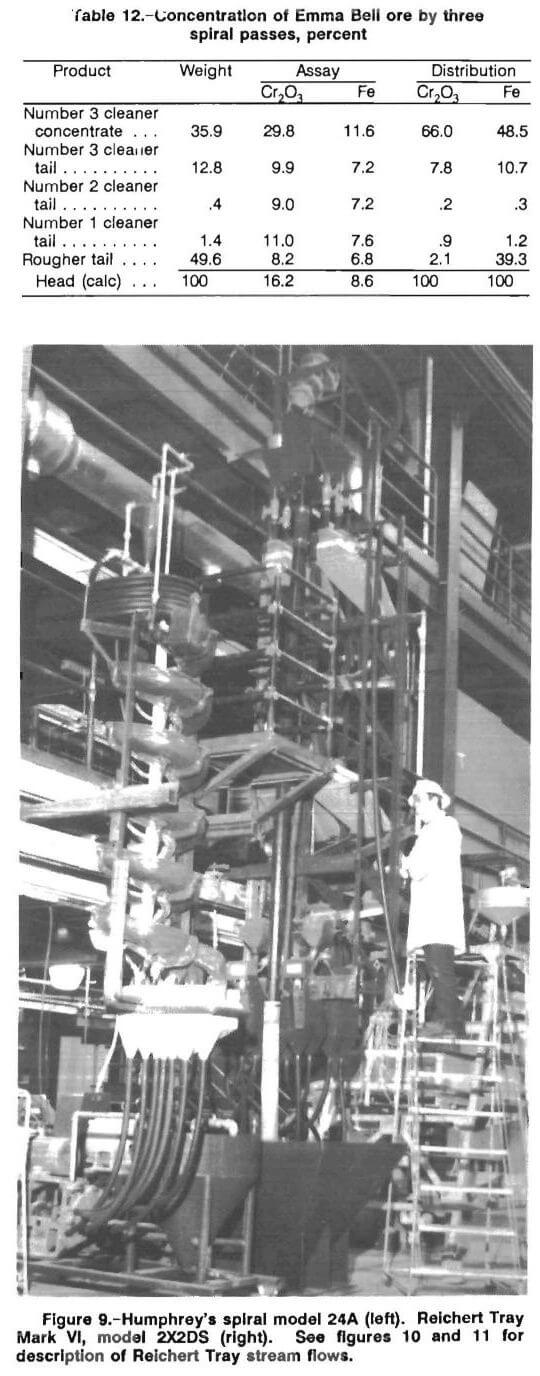

The Humphrey’s spiral Model 24A (fig. 9) was designed for primary or rougher concentration of ores. With a closed circuit arrangement, a batch test can be made on as little as 20 lb of solids. The sample is added to 12 gal of water (17 pct solids), and the flow from the pump is adjusted to 20 gpm. Adjustments of the flow, wash water, and splitters are used to optimize the chromite separation prior to sampling. Samples are taken by dividing the stream in the spiral into seven splits. Sample 2 is the main concentrate removed by the disk splitters. Samples 3 through 7 progressively change from concentrate to tailings. To insure the integrity of the feed during the 8-s sampling period, the spiral is fitted with a 50-ft length of 1-in-diam feed hose to set the circulating time at 15 s.

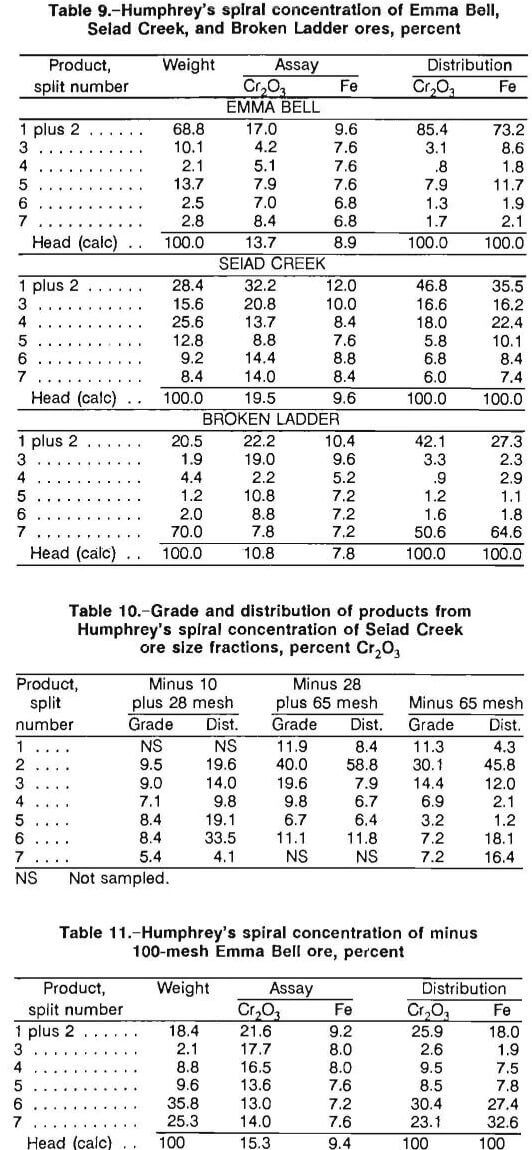

Samples of the three ores were ground to minus 28 mesh and processed by the spiral (table 9). The concentrates contained 17 to 32 pct chromite; the lowest grade tailing fraction contained 2.2 pct chromite and accounted for only 4.4 pct of the weight.

Three different size fractions of Seiad Creek ore were processed with the spiral (table 10). No products were made that did not require additional treatment. If the spiral was to be used, the concentrates would have to be cleaned and the tailings would need to be scavenged to meet target grades: 44 pct Cr2O3 or higher for the concentrate, less than 4 pct for the tailings.

To improve chromite recovery with the Humphrey’s spiral, a sample of Emma Bell ore was ball mill ground to minus 100 mesh and then processed with the spiral (table 11). This procedure improved the concentrate grade (splits 1 and 2) to 21.6 pct Cr2O3 from 17 pct for the minus 28-mesh test (see table 9), but did not decrease the grade in the tailings (splits 5, 6, and 7) below 13 pct.

A large sample of Emma Bell ore was concentrated on the spiral to determine if several spirals in series could be used to clean the minus 28-mesh feed to produce a commercial grade concentrate. The results of this test (table 12) show that after three stages of cleaning, the concentrate had a grade of 29.8 pct Cr2O3 with 66 pct recovery.

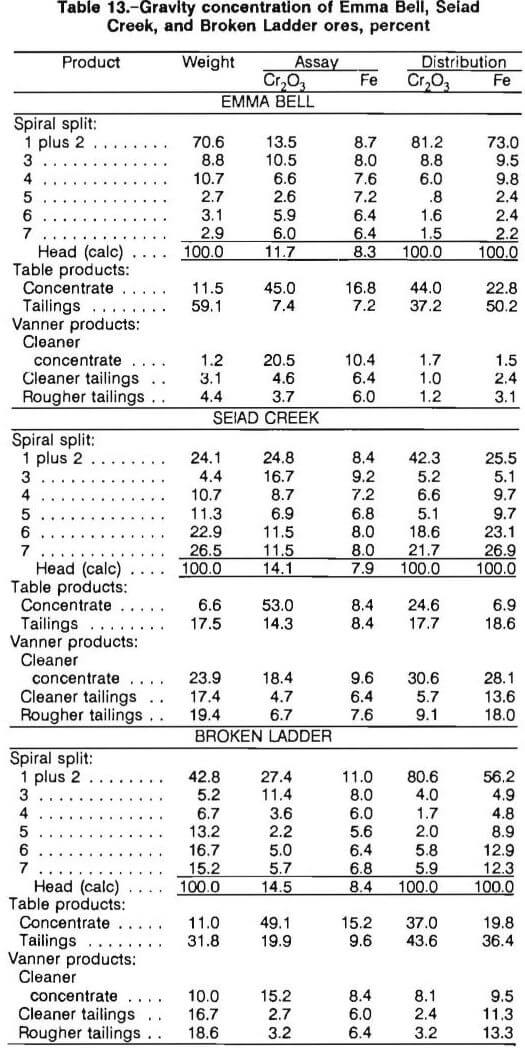

This test showed that the Humphrey’s spiral alone could not produce a satisfactory concentrate or tailing. Therefore, treatment of the spiral products was investigated. The spiral concentrate (splits 1 and 2) was tabled and the spiral tailings (splits 5, 6, and 7) was scavenged with the vanner to improve the grade and recovery. Retreatment of the spiral concentrates of the three California ore samples by tabling produced concentrates that contained from 45 to 53 pct Cr2O3. Retreatment of the spiral tailings by regrinding to minus 200 mesh and vanning reduced the Cr2O3 content of the tailings to as low as 2.7 pct. Spiral middlings (splits 3 and 4) were not retreated. Table 13 summarizes the results of these tests.

As these results demonstrate, there is no advantage in using the Humphrey’s spiral, since all the products required further treatment. The middlings would require further concentration as well.

Reichert Tray Concentration

The Reichert Tray Mark VI test rig has been developed as a relatively inexpensive concentrator that can be used to provide performance data for Reichert cone concentrator applications. The Reichert tray assembly (fig. 9) is a high capacity flowing film type concentrator related to the pinched sluice and represents a one-twentieth segment of a cone. For batch tests, water is circulated through the test rig until the flows are properly adjusted, then ground ore is added to the primary sump until the pulp density reaches steady state at 15 to 20 pct solids. The feed is dewatered by a classifying cyclone situated on top of the unit so the pulp density of the feed to the trays is 60 to 65 pct solids. Cyclone overflow is used as dilution water or is recirculated to the sump to maintain a water balance. Concentration occurs as the flowing pulp changes depth and velocity with the narrowing of the sluice. A concentrate is removed from the flow by splitting the stream horizontally with the bottom portion as the concentrate. The Reichert tray consists of four stages of three sluices each: two parallel roughers and one cleaner. In operation the concentrate from the two roughers is fed to the cleaner sluice. The concentrate from the cleaner is removed and the tail is combined with the rougher tail to be fed to the next stage. Once the flow in the rig is in steady state, a 12-s timed sample is taken.

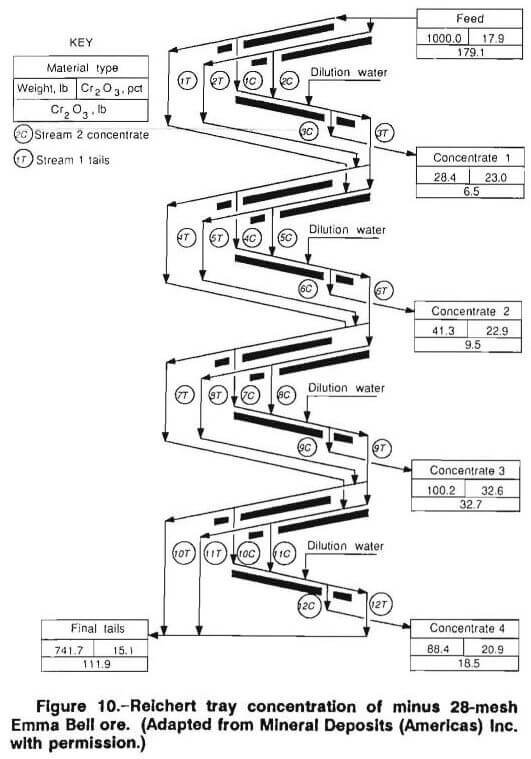

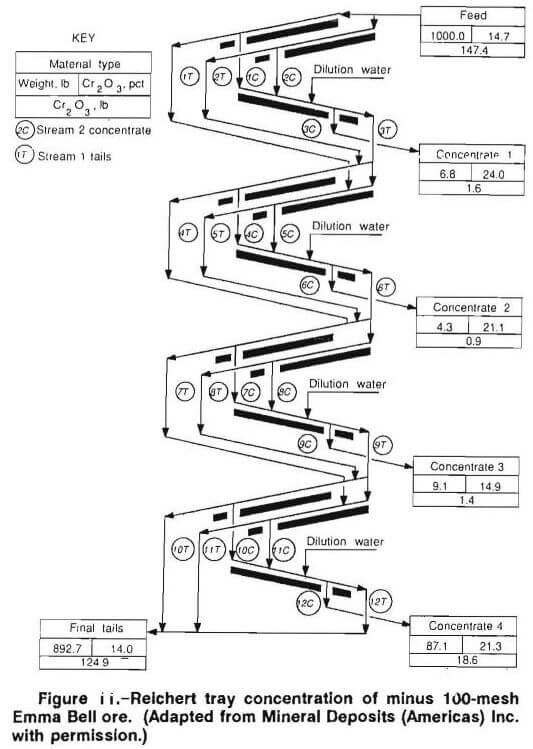

The Emma Bell ore was the only material tested with the Reichert tray because proper operation for each test more than 900 lb of sample; there was ample supply of the Emma Bell ore, but only limited amounts of the others. Samples were crushed to minus 10 mesh and ball mill ground to minus 28 mesh or minus 100 mesh for testing. The results showed that as the slurry flowed down the assembly, the chromite was collected in the concentrate in each successive stage; however, only low recoveries and concentrate grades were achieved. The minus 28-mesh test did produce one concentrate at 32.6 pct Cr2O3, but the final tail was 15.1 pct Cr2O3 from a 17.9-pct feed; results are given in figure 10. The highest grade concentrate for the minus 100-mesh test contained 24.0 pct Cr2O3 and the final tail contained 14.0 pct Cr2O3 from a 14.7-pct feed (fig. 11). Like the Humphrey’s spiral, the Reichert tray was unable to produce a product that did not require further treatment.

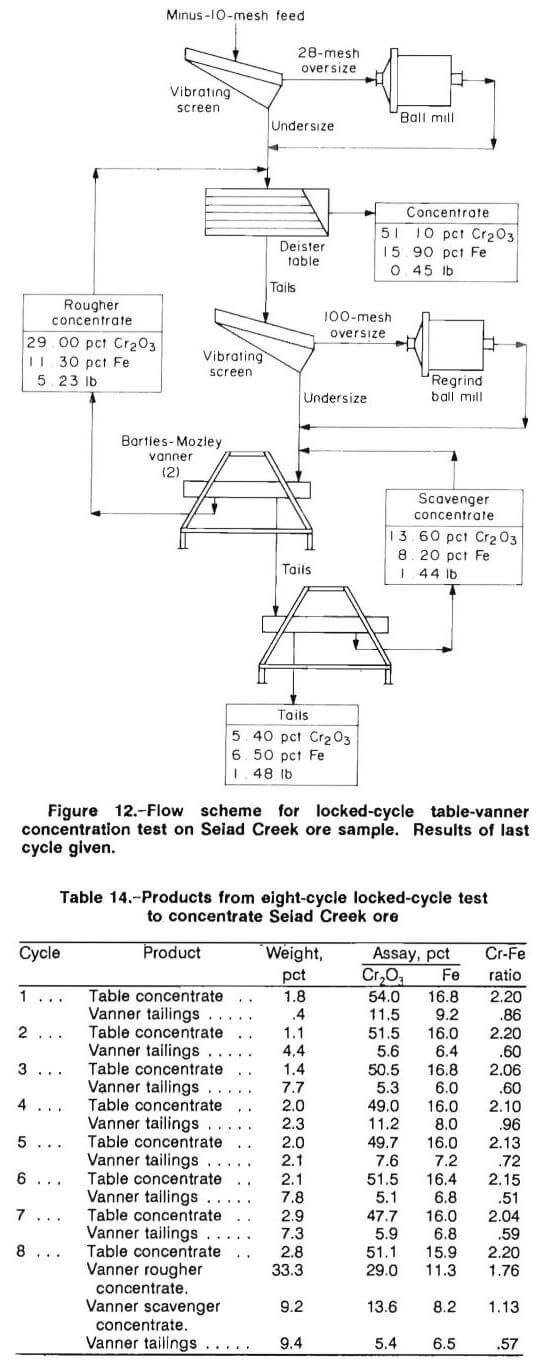

Locked-Cycle Table-Vanner Procedure

A locked-cycle test was performed on the Seiad Creek ore to obtain material balance data for designing a continuous gravity circuit. The flow scheme used in this test is shown in figure 12. Ore samples were crushed to minus 10 mesh, and 2.2-lb samples were weighed out for each cycle. Each 2.2-lb sample was dry screened on 28 mesh, then the oversize was ball mill ground at 50 pct solids to minus 28 mesh and combined with the undersize fraction. Each sample was fed in turn to the Deister table. Table concentrates were dried, weighed, and assayed. Table tails were wet screened on 100 mesh. The oversize was ball mill ground at 50 pct solids to minus 100 mesh and combined with the original minus 100-mesh fraction; this product was concentrated on the Bartles-Mozley vanner. The vanner concentrate was combined with the minus 28- mesh feed to the next cycle table feed. The tailings were concentrated, as a scavenger stage, on the vanner. The scavenger concentrate was combined with the minus-100- mesh feed to the vanner rougher for the next cycle. The vanner scavenger tail was dried, weighed, and assayed. The process was repeated for eight cycles. At the end of the eighth cycle, all products, including the intermediate products from the vanner rougher and scavenger, were dried, weighed, and assayed.

Results of the eight-cycle locked-cycle test on Seiad Creek ore are given in table 14. Based on these results and the mass balance shown in figure 12, the following conclusions were reached:

- Table concentrates containing more that 47.7 pct Cr2O3 can be made.

- Recoveries of approximately 74 pct calculated using the table concentrate and the vanner tailings, disregarding slime losses, can be achieved.

- When the combined slimes and table tailings from each of the ores were treated on the Bartles-Mozley vanner, the tailings for each of the ores contained approximately 5 pct Cr2O3.

- The recirculating load from the vanner rougher stage to the table will be about 240 pct at a grade of 29 pct Cr2O3.

- The recirculating load from the vanner scavenger stage to the vanner rougher stage will be approximately 65 pct at a grade of 13.6 pct Cr2O3.

- Unaccounted weight may have been due to slimes lost while handling; this loss was as high as 11 pct of the total feed weight and contained approximately 17 pct Cr2O3.

Flotation

The objective of flotation studies was to improve the overall chromite recovery by flotation of chromite in the slimes from the gravity concentration circuit.

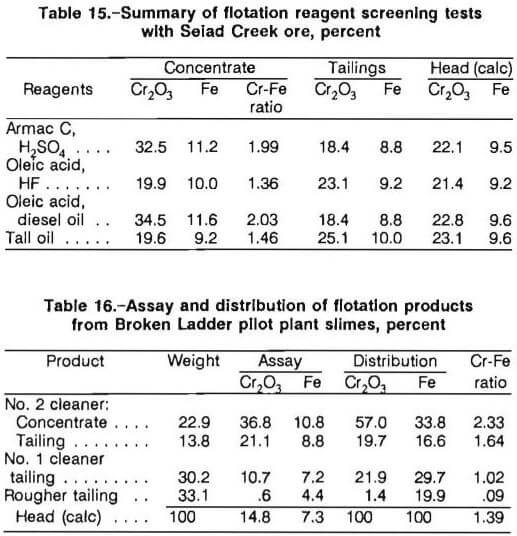

Smith showed that an ore containing serpentine as the primary gangue mineral was amenable to concentration by flotation using a cationic collector with the pH modified to below 2.5 with sulfuric acid (H2SO4). Reagent screening tests were conducted on deslimed Seiad Creek ore with the objective of producing tailings with the lowest grade chromite. Results are shown in table 15. Armac C, a primary coco amine acetate, used as a collector and H2SO4 as a modifier yielded tailings with the lowest grade, 2.7 pct Cr2O3. Rougher concentrate grades were as high as 30 pct.

Flotation tests to concentrate chromite in the slimes from the pilot plant gravity circuit were successful on the Seiad Creek and Broken Ladder samples. Table 16 gives typical test results on the Broken Ladder slimes. As much as 98 pct of the chromite was recovered in the rougher concentrate, and cleaner concentrate grades as high as 37 pct were achieved.

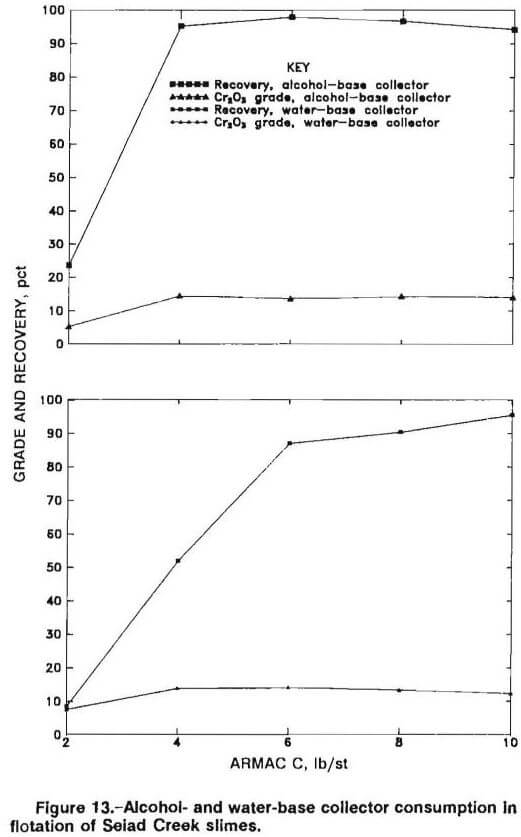

The vehicle with which Armac C was prepared affected the consumption of the collector. Test results (fig. 13), revealed that 4 lb/st of Armac C was required for the highest chromite recovery from the slime fraction of Seiad Creek samples when prepared with ethyl alcohol, while 10 lb/st was required when Armac C was prepared with water.

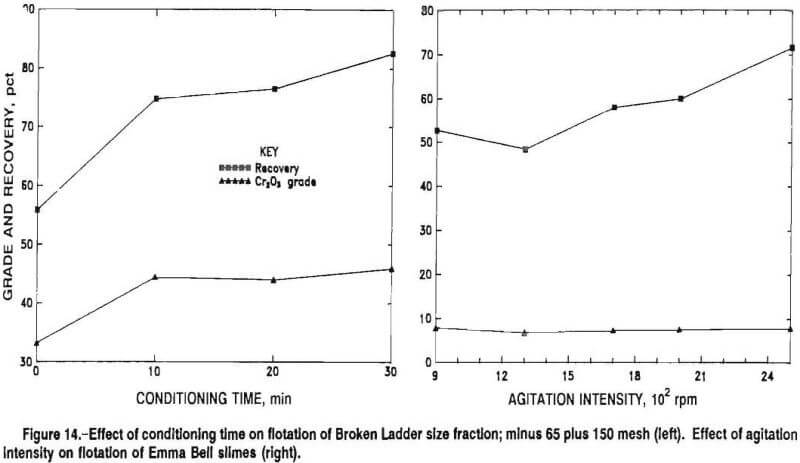

Results similar to Smith’s showed that use of a preconditioning acid scrub increased chromite recovery. Results from tests with preconditioning periods of 0 to 30 min prior to flotation of the Broken Ladder size fraction minus 65 mesh plus 150 mesh (fig. 14) showed that recovery was optimized as conditioning time was increased to 30 min with addition of 10 lb/st of Armac C. The chromite recovery from a Broken Ladder sample was increased from 55.8 pct with 0 min of preconditioning acid scrub to 82.7 pct with a 30 min scrub.

The results of tests to determine the effect of agitation intensity during preconditioning on an Emma Bell sample (fig. 14) show that during a 20-min preconditioning acid scrub, increased agitation intensity yielded increased chromite recovery.

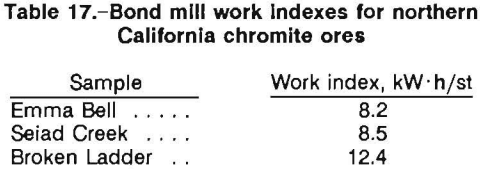

Grinding

Laboratory Bond mill tests were made to determine the grinding properties of samples of each of the ores. The results of these tests should be used to calculate the mill size for any scale-up process. The Bond ball mill grind work index was determined by the standard Bond procedure. The mill used was manufactured by Bond and is 12 by 12 in. The mill revolves at 70 rpm and contains 285 balls ranging in size from 1.5 to 0.6 in. in diameter with a total weight of 20,125 g. The ore charge in the mill was 700 cm³. The original sample was split out of a representative ore sample. Sample additions were taken from a blended sample of the candidate ore being tested. Product sizes were chosen at minus 65 mesh and minus 200 mesh. Results for the three ores are summarized in table 17.

Thickening

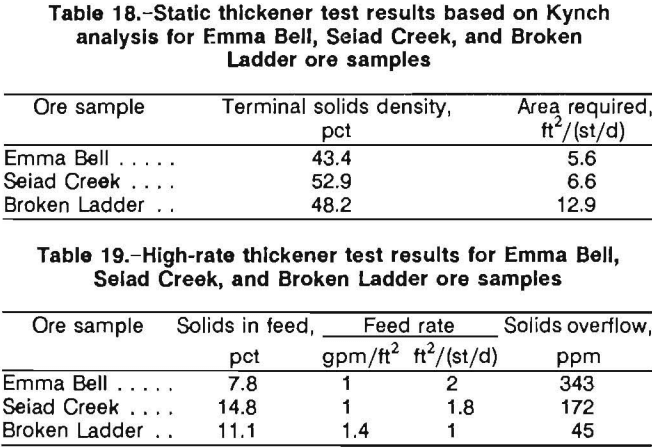

The thickener area requirements for the minus 325- mesh fractions of each ore were determined by both static and dynamic tests. Static tests were made in 1,000-mL graduated cylinders, and the settling results were analyzed by the Kynch method of thickener area determination.

Dynamic tests were made using an Enviro-Clear high-rate thickener test kit. Even though the addition of chemicals to aid flocculation greatly improved the settling characteristics, they were not used because of their potential interference with chromite recovery by both gravity and flotation processes.

The thickener area test results for each of the candidate ores are listed in tables 18 and 19. Standard units for test results from the Kynch analysis are square foot per short ton per day. Typically, the units for the test results from the high-rate thickener tests are gallons per minute per square foot; for comparison the high-rate thickener tests are converted to square foot per short ton per day. High-rate thickener tests results are reported with the accompanying suspended solids in the overflow for each deposit. The underflow density from the high-rate thickener was not determined because the column used was too short to achieve maximum density; however, underflow densities can be estimated from the terminal density of the static tests.

Pilot Plant

Design and Operation

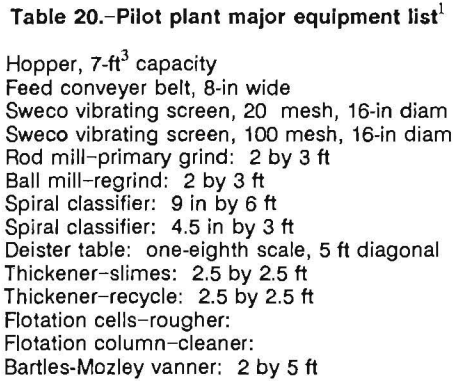

The results of the laboratory tests were used to design and operate a pilot plant with a nominal capacity of 100 lb/h. Major equipment (table 20) consisted of a belt feeder, rod mill, ball mill, two Sweco vibrating screens, two thickeners, two spiral classifiers, a Deister table, and a Bartles-Mozley separator. Equipment for the flotation section included a 1.5-ft³ Galigher flotation machine and a 2.5-in-diam by 12 ft flotation column.

The design capacities of the rod and ball mills were much greater than required for the application; therefore, they were used with reduced grinding media charges and at reduced rotation rates. The thickeners were too small when they were operated as conventional style thickeners; therefore, they were converted to Enviro-Clear-designed high-rate thickeners, which produced both clear overflow and underflow densities of near 50 pct solids.

Supporting equipment for the pilot plant included agitators, conditioner tanks, slurry and waterhoses, and pumps.

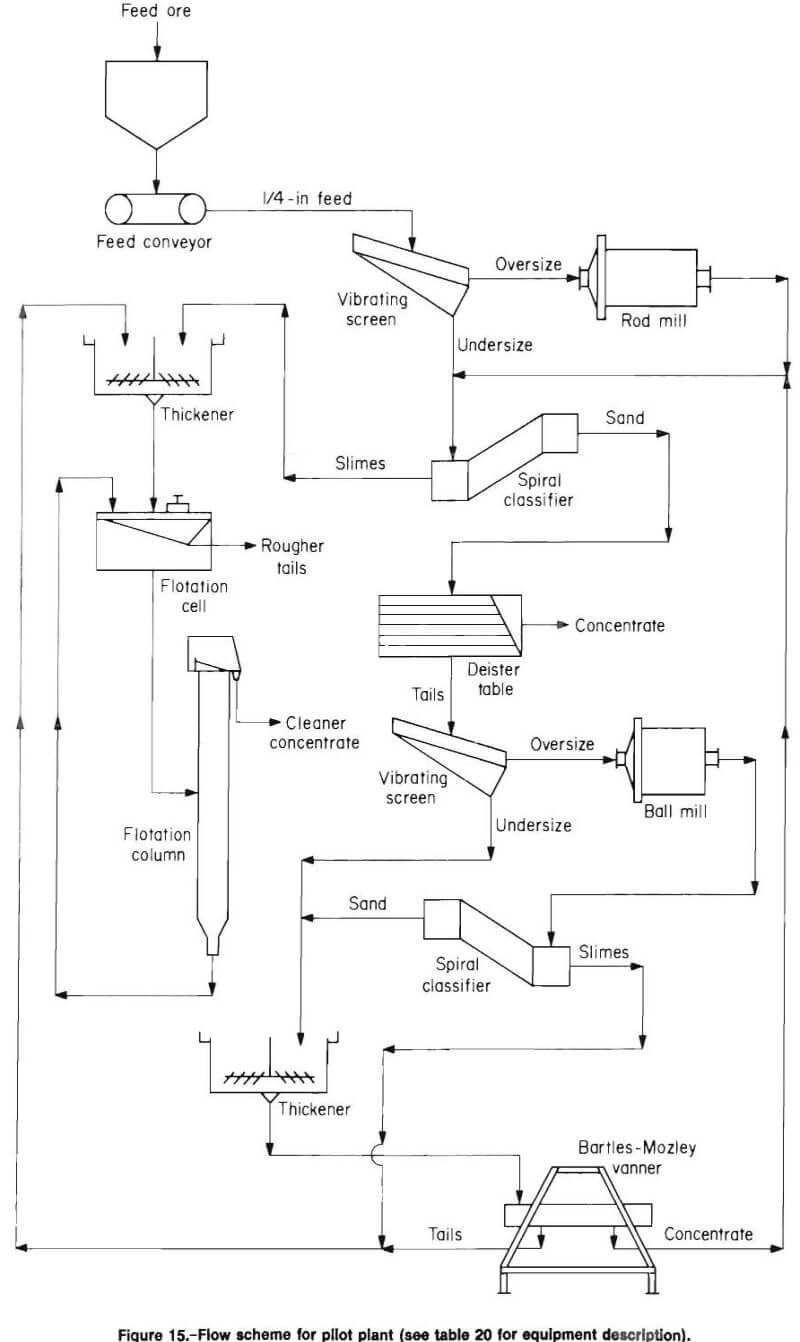

The flow scheme for the plant is shown in figure 15. The final chromite product was recovered as a concentrate from the Deister shaking table. Table tailings were reground and scavenged with a Bartles-Mozley vanner. The concentrate from the Bartles-Mozley vanner was recirculated to the table. The final tailing was taken from the Bartles-Mozley vanner in tests that used only gravity concentration; otherwise the final tailing was taken from the flotation circuit.

Ore was crushed to minus ¼ in and loaded into the hopper. A belt feeder on the hopper fed a 20-mesh vibrating Sweco screen at a nominal 100 lb/h rate. The screen oversize was fed open circuit to the rod mill where it was ground to minus 20 mesh. The rod mill discharge and the screen undersize were deslimed at 325 mesh in the spiral classifier. The slimes were thickened in the slimes thickener. The sand from the spiral classifier was fed to the Deister table. The final concentrates, ranging from 47 to 58 pct Cr2O3, were recovered on the table. All the table tailings were directed to a 100-mesh vibrating Sweco screen. The oversize was reground in the ball mill to minus 100 mesh and deslimed at 325 mesh in a second spiral classifier. The classifier slimes were thickened in the slimes thickener, and the sand was recombined with the 100-mesh Sweco undersize and dewatered to about 50 pct solids in the recycle circuit thickener. Because of its fine size, concentration of chromite was done at this stage by the Bartles-Mozley separator, and the conccntrate was recycled to the Deister table via the primary classifier.

In the plant operation, the tailings from the Bartles-Mozley separator were either collected as the final tailings or sent to the slimes thickener. The dewatered slimes were concentrated by flotation. A Galigher 1.5-ft³ flotation machine was used for the rougher stage, and a 12-ft flotation column was used for the cleaner stage.

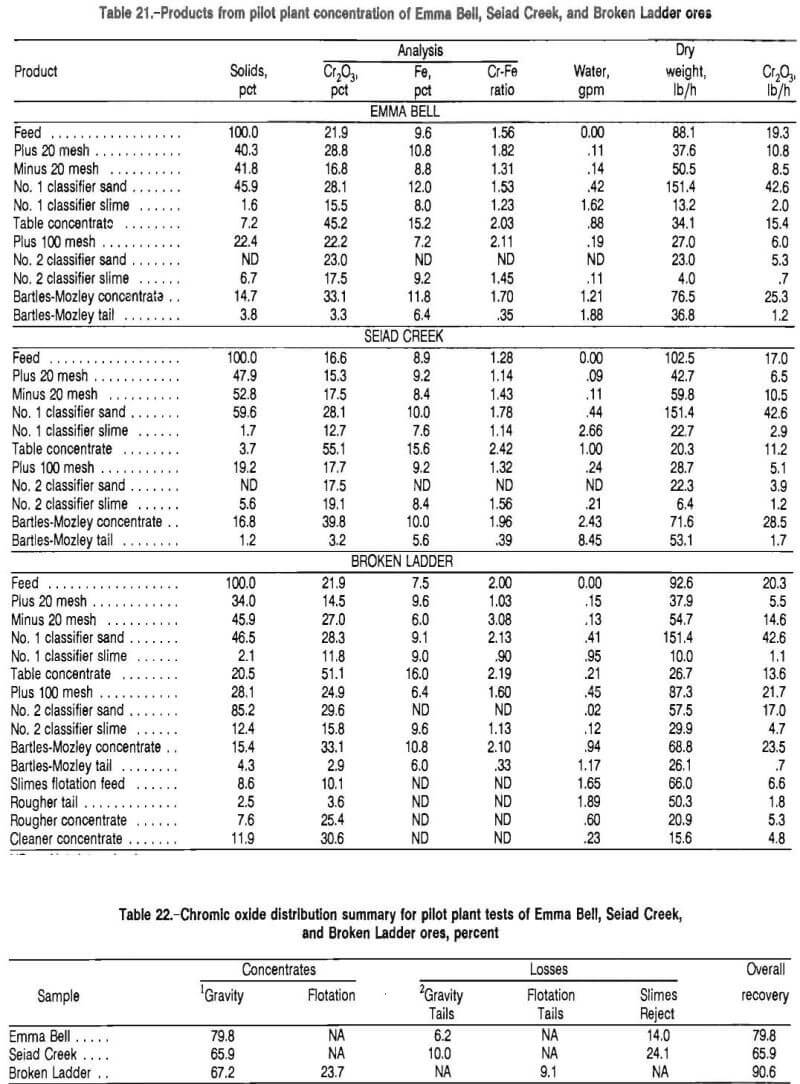

Results of Pilot Plant Tests

The pilot plant performed as well as or even better than predicted from the laboratory and unit operations tests. Chromite concentrates were as high as 55 pct Cr2O3 with a Cr-Fe ratio >2. Recirculating loads between the table and the Bartles-Mozley separator were 250 pct, which was predicted by the locked cycle test. Sand tailings from the Bartles-Mozley assayed between 2.9 and 3.3 pct Cr2O3, which was better than the bench tests. Tailings from the flotation circuit assayed over 4 pct Cr2O3.

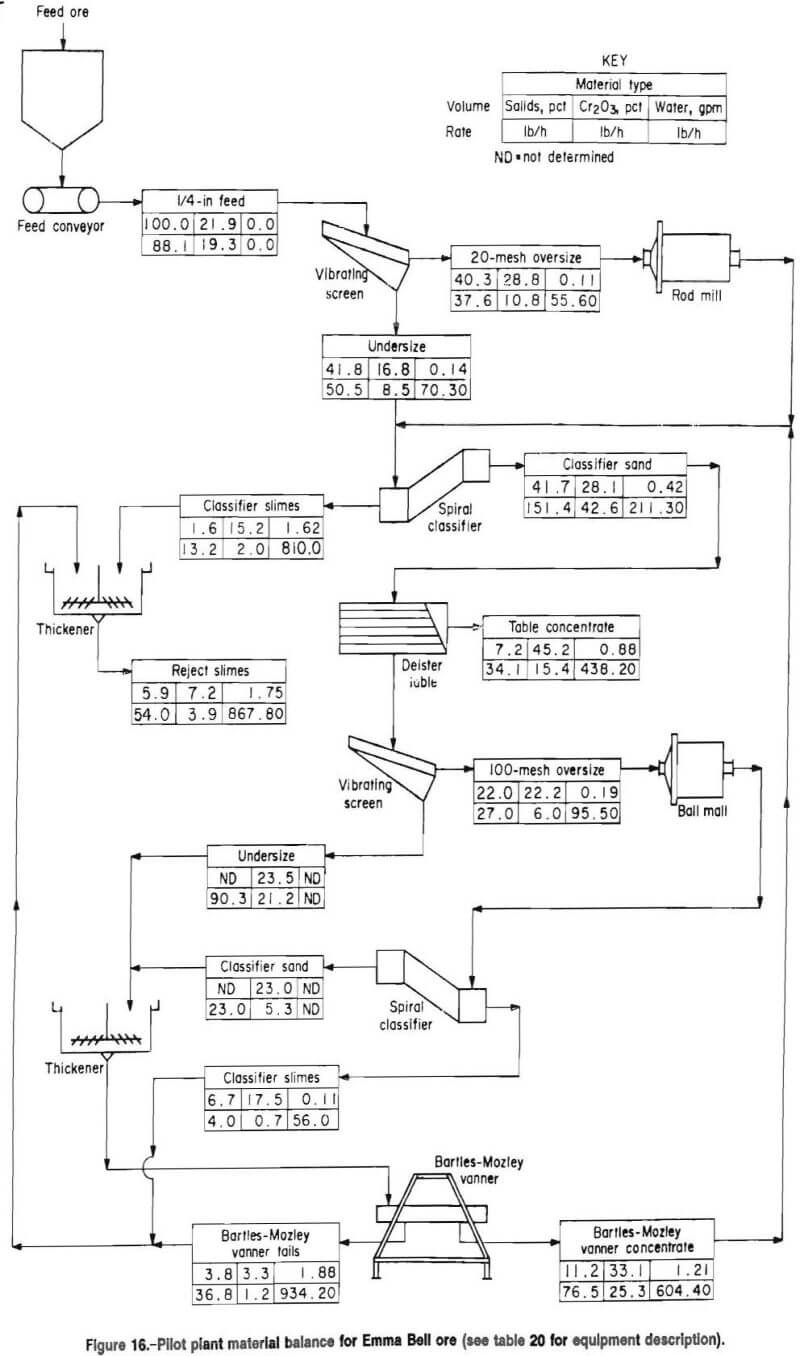

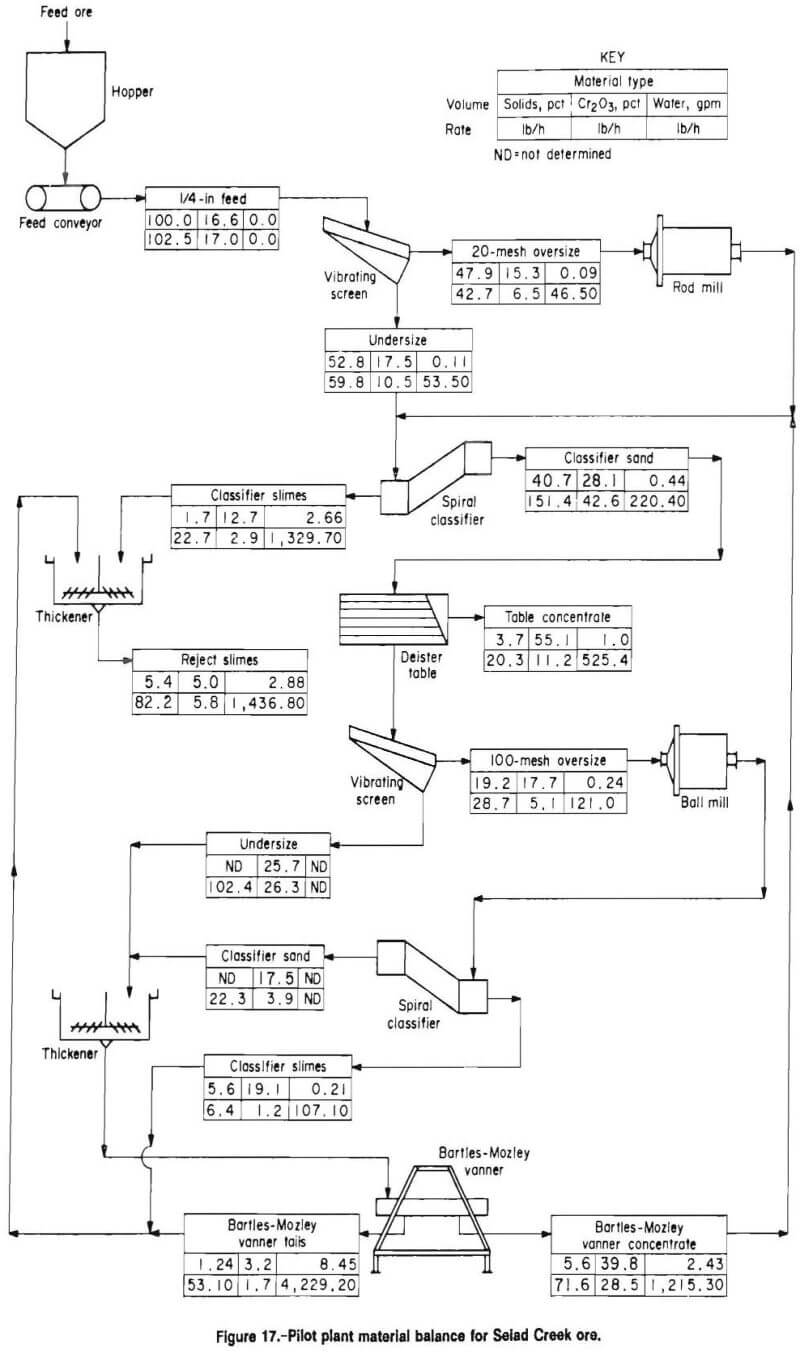

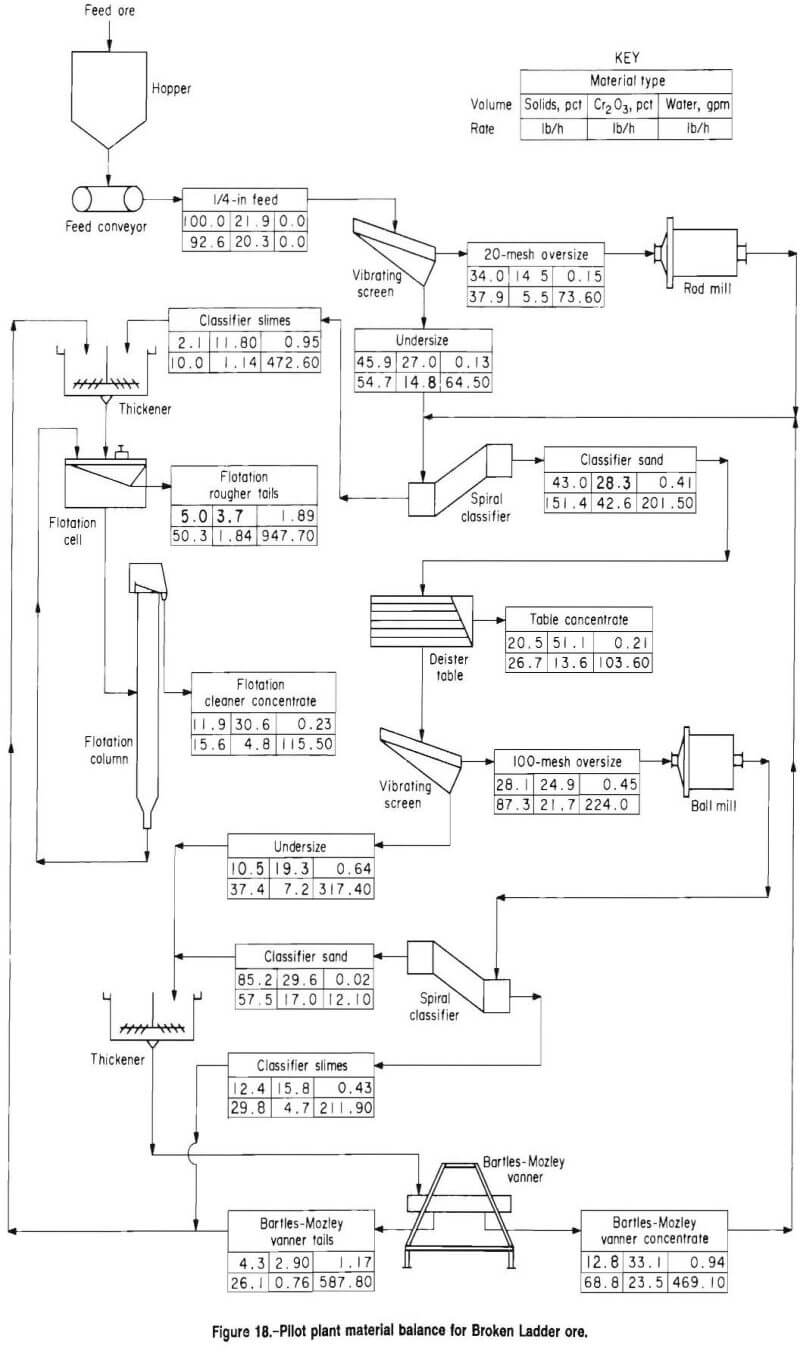

Summary results of the continuous tests are presented in table 21, and a chromite distribution is presented for final streams in table 22. Also, flowschemes that contain analytical results and material balances are presented in figures 16 to 18.

Summary and Conclusions

Mineral liberation analyses of the northern California ore samples suggested that chromite could be physically concentrated using methods that are generally effective for particle sizes of 65 mesh and smaller. Results of laboratory tests confirmed these expectations. Concentrates containing more that 50 pct Cr2O3 were produced for all three samples, which contained from 11.2 to 14.5 pct Cr2O3, using a shaking table as a primary concentrator. Overall recoveries ranging from 66 to 91 pct were achieved by regrinding table tailings to increase liberation, then using vanning for secondary separation and flotation for scavenging the gravity separation tailings.

Laboratory test results were used to design a pilot plant with a 100-lb/h capacity. Efficiency of the plant was equal to or greater than that achieved in bench and unit operations tests. The Bartles-Mozley vanner produced intermediate concentrates containing from 24 to 33 pct Cr2O3 and tailings containing from 2.9 to 3.3 pct Cr2O3, which was better than the unit operation tests. Flotation reduced slimes from 14.9 to 4.7 pct Cr2O3 in the ore sample tested using the flotation circuit.