Table of Contents

The Bureau of Mines conducted research on techniques for recovering potash values from high-insoluble-slimes-bearing domestic carnallite ores. In the first phase of the study, two techniques were devised: (1) a method where the insoluble slimes were depressed during potash flotation and (2) a method where insoluble slimes were removed by flotation prior to potash flotation. Reports of the first phase of the research described batch- and locked-cycle, bench-scale testing of the two techniques. This report describes results of the second phase of the research: (1) operation of a continuous 100-lb/h flotation unit designed to technically evaluate the two methods and (2) an economic evaluation of the two methods.

Potassium is one of three basic chemical ingredients used for promoting plant growth. Refined potash salts, obtained from either ores or brines, are the only economically significant sources of potassium used in fertilizers. Current domestic demand for potash is 6.0 million tons of K2O. However, only approximately 1.8 million tons of K2O are produced in this country. The balance of the domestic demand is supplied by Canadian exports. About 84 pct of the domestic production is from bedded deposits in the Carlsbad, NM, area. This area has been a source of high-grade sylvinite (a mixture of KCl and NaCl) ores during the last 40 years. Depletion of high-grade ores makes low-grade sylvinite and carnallite ores major potash sources. Insoluble slimes in these ores create processing difficulties. Discarded insoluble slimes occlude valuable potash minerals and adsorb significant amounts of amine collectors used in flotation. Methods compatible with existing commercial potash processes must be devised to remove or treat these insoluble slimes before potash flotation to improve potash recoveries and reduce processing costs.

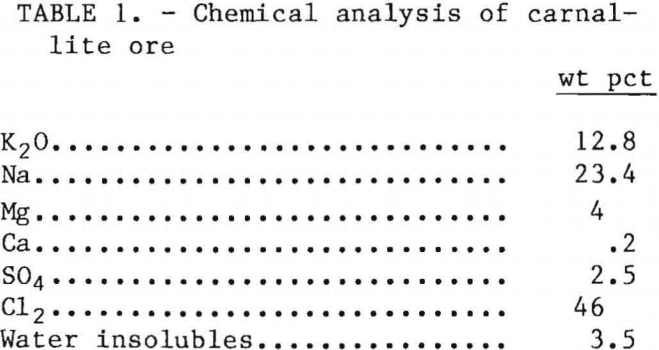

Sample Description

Over 25 tons of minus 4-in, run-of-mine ore was received for testing in the continuous flotation unit. A partial chemical analysis of the ore is given in table 1. Petrographic and X-ray diffraction analysis of the carnallite ore indicated that halite (NaCl) carnallite (KCl·MgCl2·6H2O), and sylvite (KCl) were the most abundant minerals. Minor amounts of kainite (KCl·MgSO4·3H2O), leonite (MgSO4·K2SO4·4H2O), and polyhalite (MgSO4·K2SO4·2CaSO4·2H2O) were also present. The

water-insoluble fraction of the ore contained abundant magnesite, chlorite, and illite. Some carnallite and sylvite contained minor amounts of occluded hematite, which gave the minerals a distinct red color.

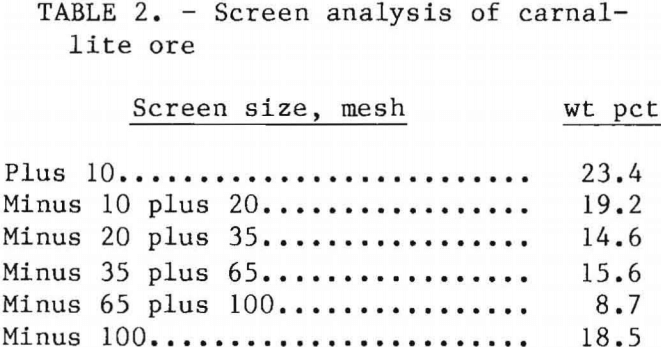

Carnallite ore was prepared for feed to the continuous flotation unit by crushing through 3/4-in size using a hammer mill. The ore was screened at 10 mesh, the liberation size for the sylvite and carnallite minerals. The oversize was processed in a rod mill. Dry screen analysis of the crushed ore, given in table 2, indicated that 23.4 pct of the total weight was coarser than 10 mesh.

Continuous Flotation Unit Design and Operation

Design For Insoluble-Slimes Flotation

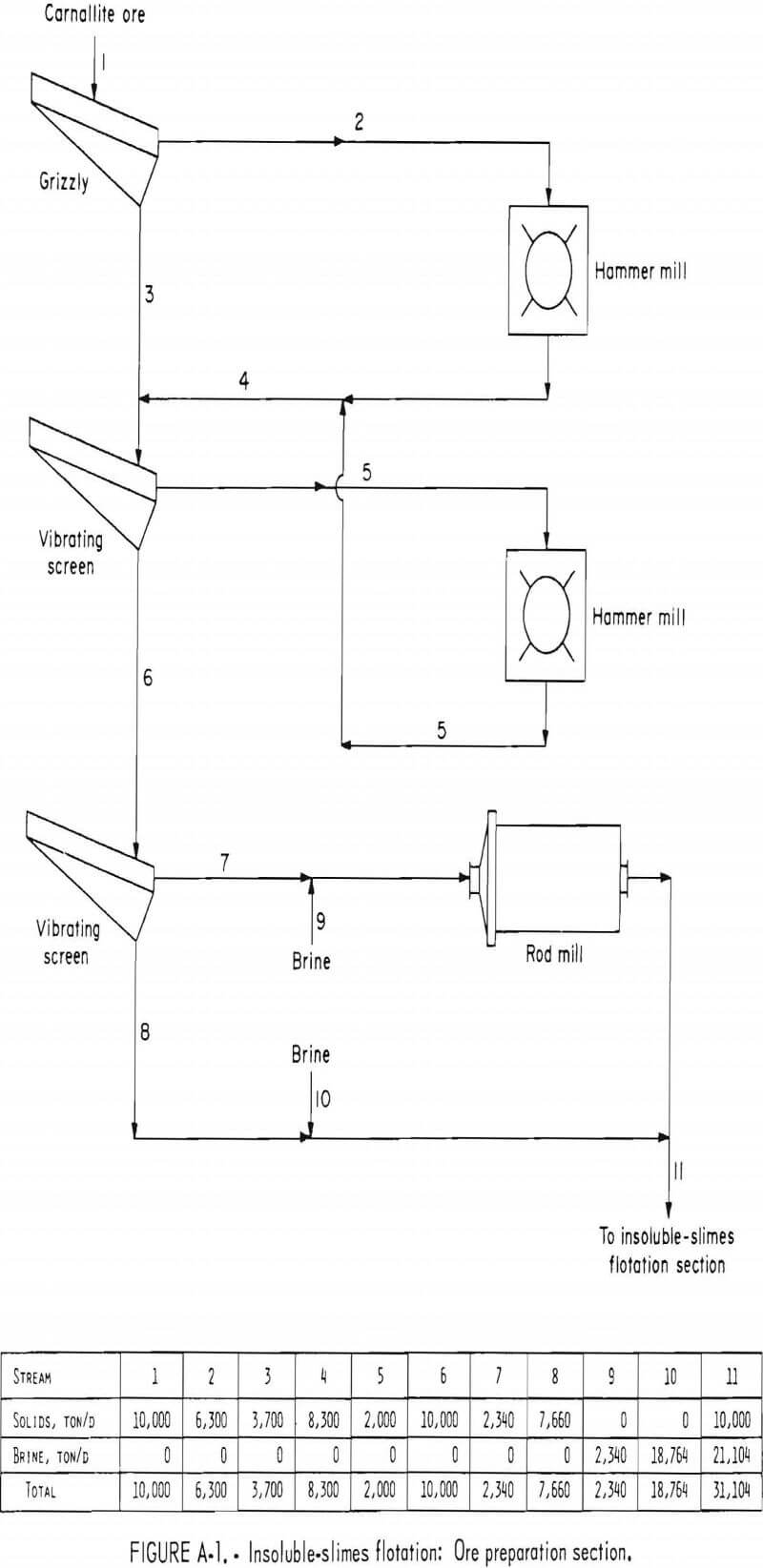

Circuit design was based on data obtained from bench-scale, locked-cycle testing. The flow diagram presented in appendix figures A-1 through A-5 was adopted for the method using insoluble-slimes flotation. Minus ¾-in material was fed to a 10-mesh vibrating screen. Screen oversize was processed in a rod mill operating at 50-pct-solids pulp density. The screen undersize was slurried with saturated brine and mixed with rod mill discharge. The combined slurry flowed to a carnallite decomposition tank. Because carnallite must be decomposed to KCl to produce a feed material for potash flotation, approximately 400 lb of fresh water per ton of the carnallite ore was added to dissolve the MgCl2, leaving a solid KCl product. Approximately 9 pct of the potassium in the carnallite was dissolved in the brine during the 5-min decomposition leach. (A portion of this potash could be recovered by solar evaporation of the excess plant brine.)

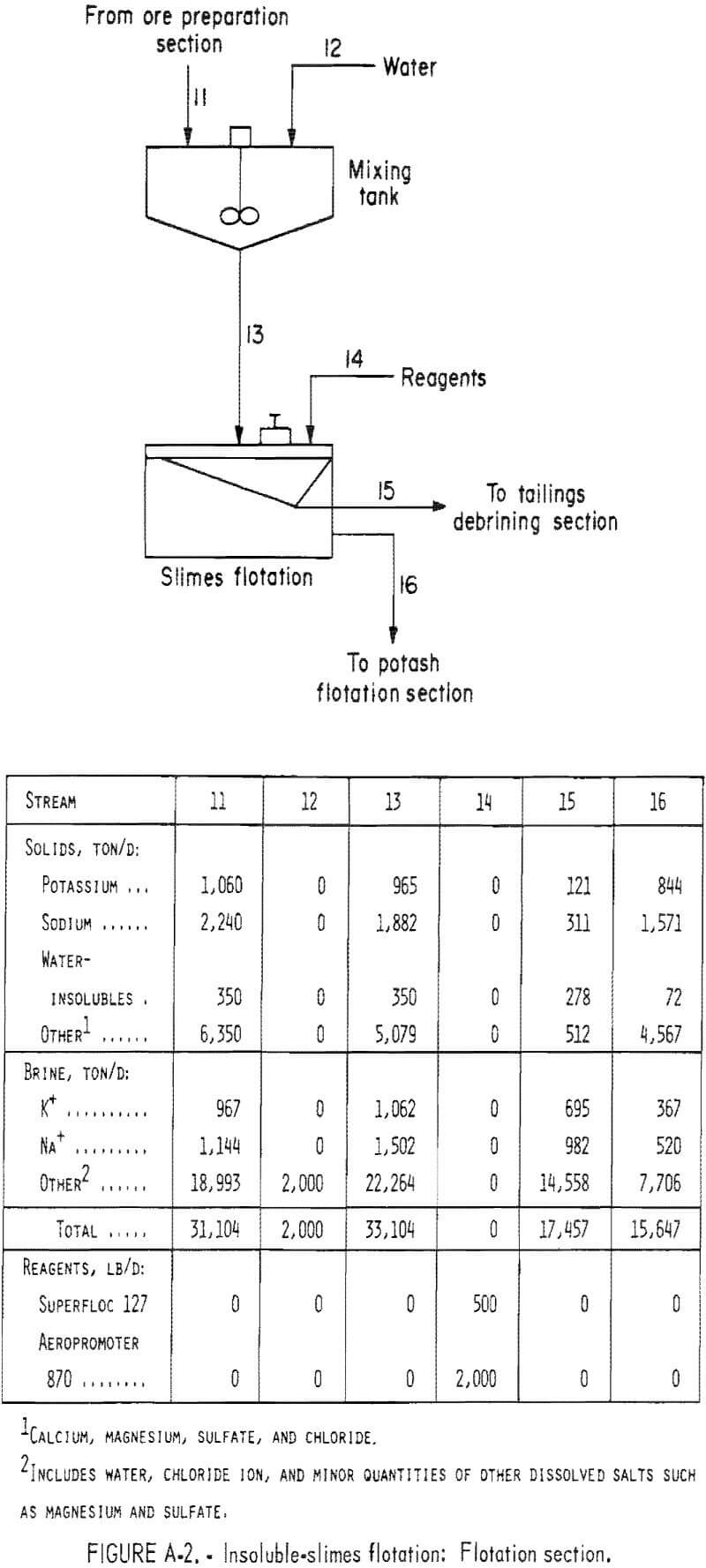

Slurry from the carnallite leach decomposition step was diluted to 27 pct solids for the insoluble-slimes flotation

circuit. Insoluble-slimes flotation reagents (Superfloc 127 and Aeropromoter 870) were added ahead of flotation in a Denver No. 7 Sub-A flotation machine. No conditioning was required. Total insoluble-slimes flotation time was approximately 10.5 min.

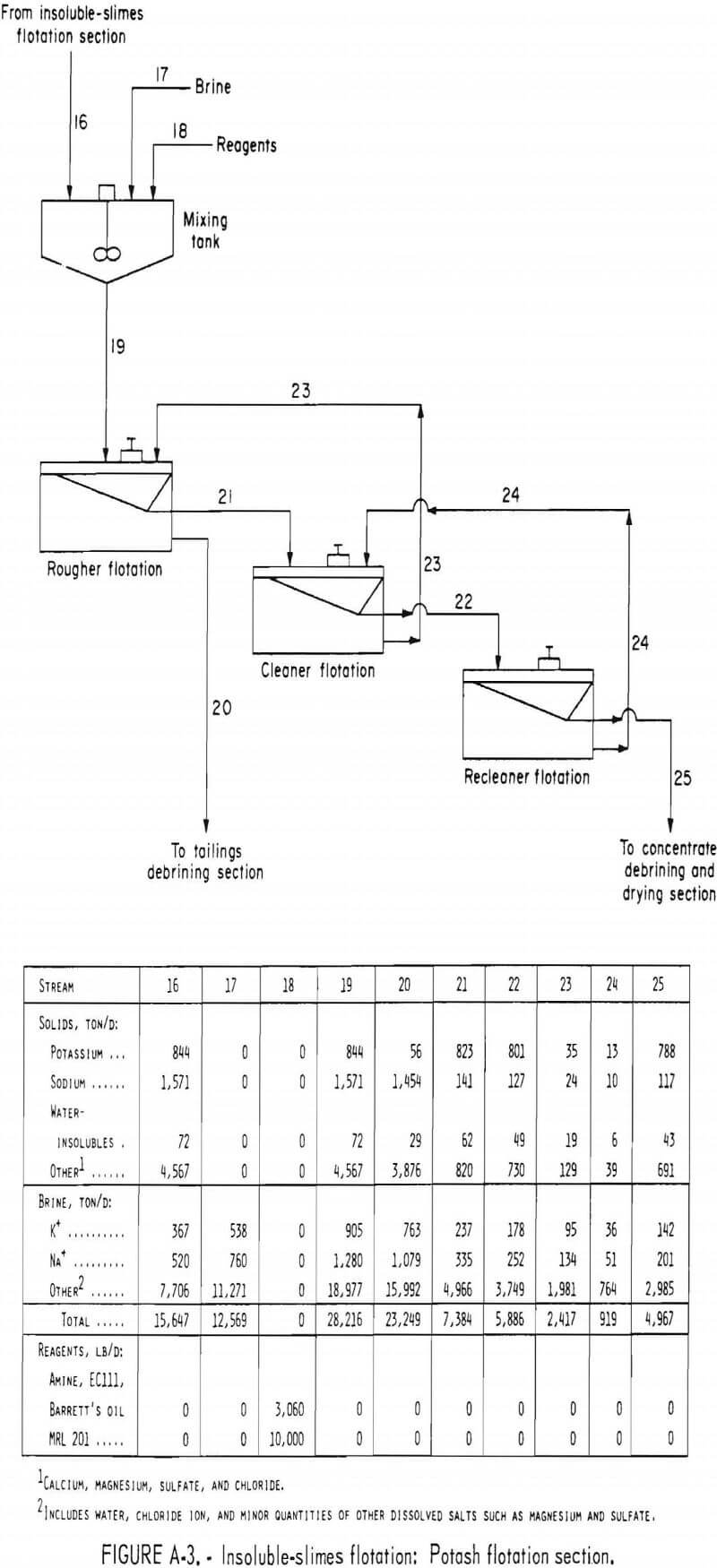

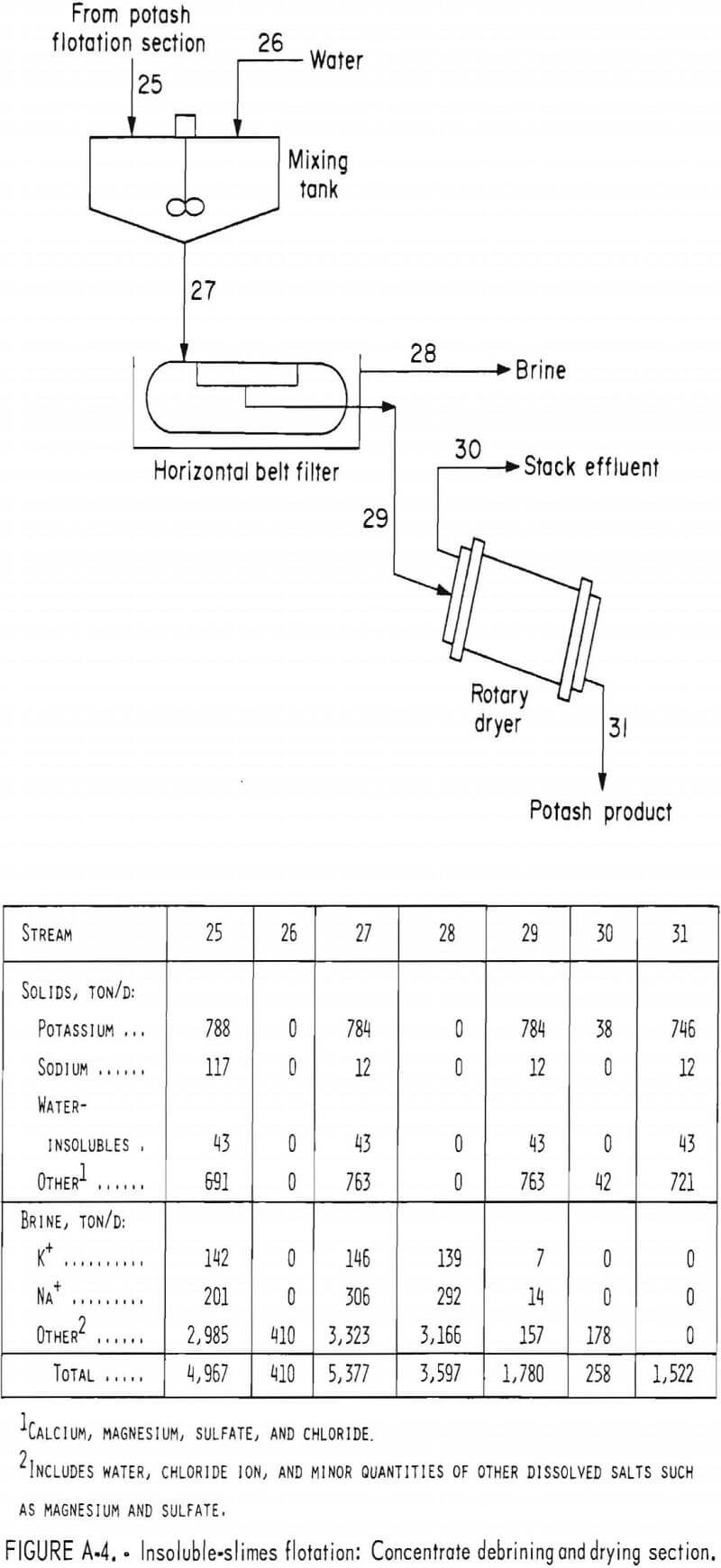

Deslimed pulp was conditioned for 2 min with MRL-201 insoluble-slimes blinder and an emulsion of Armeen TD and Barrett’s oil. Conditioned pulp was fed to a bank of three Denver No. 5 Sub-A flotation machines. Potash rougher flotation time was 10.5 min. The potash rougher concentrate was upgraded further by a 3.5-min single-stage cleaner flotation and 3.5- min recleaner flotation without additional reagents. The recleaner concentrate was water-washed to remove fine NaCl and filtered to recover the en¬trained brine. Less than 0.5 pct potash was lost during final product leaching. Pan filters were used for final debrining of all products in the flotation unit. Potash cleaner and recleaner tailings were recycled to rougher and cleaner flotation circuits, respectively.

Insoluble-slimes concentrate and salt tailings from potash rougher flotation were combined and thickened in a spiral classifier. The clear brine was recycled, while the thickened solids were filtered to recover additional brine. New equilibrium brine, made from the ore, was used in the flotation unit for initial startup only. Brine was recycled as completely as possible during operation.

The recycled brine from classifier and filtered products was pumped to a recycle brine tank. This tank served as a surge tank for process brine, which was metered to various points in the flotation unit.

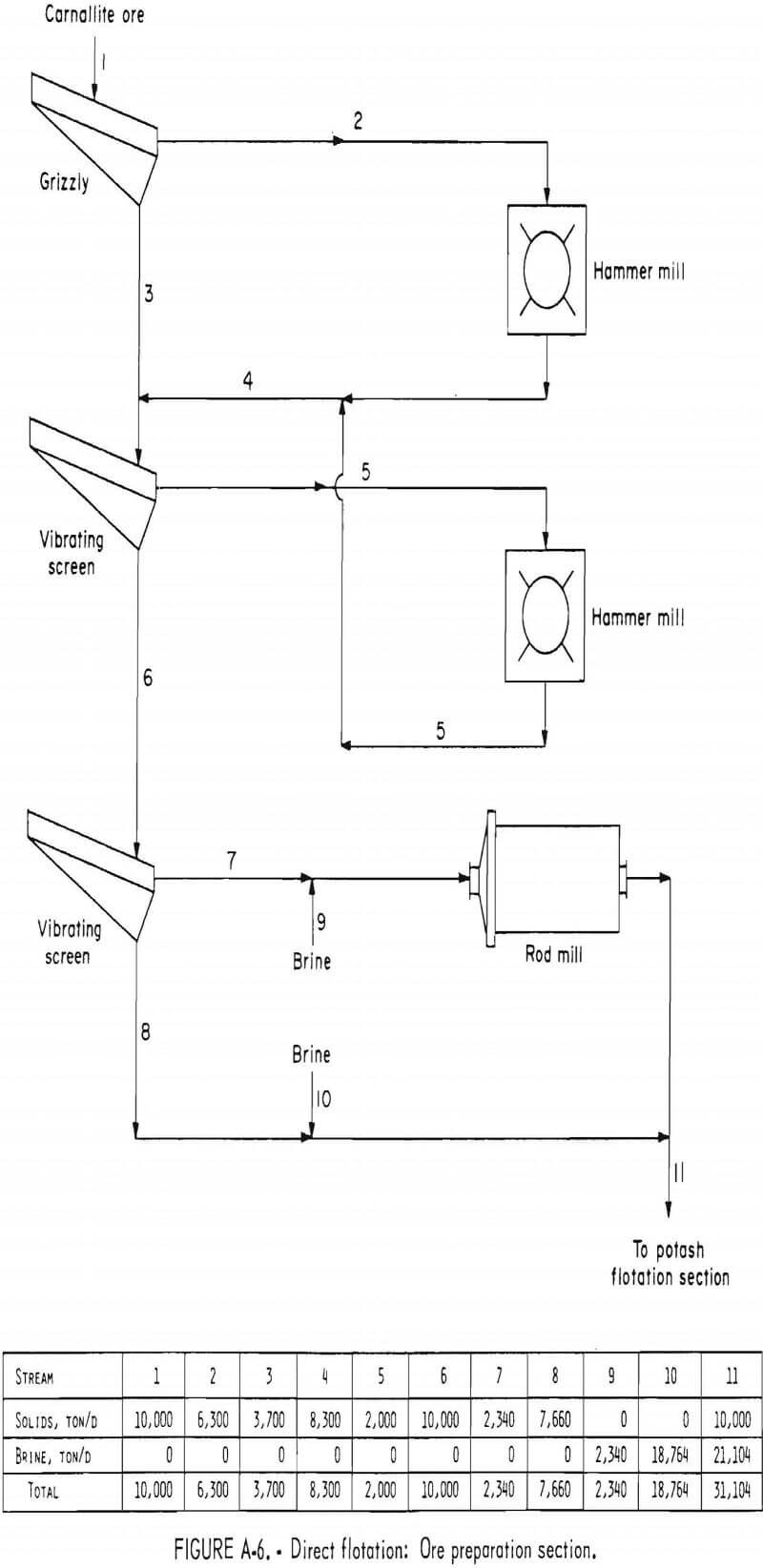

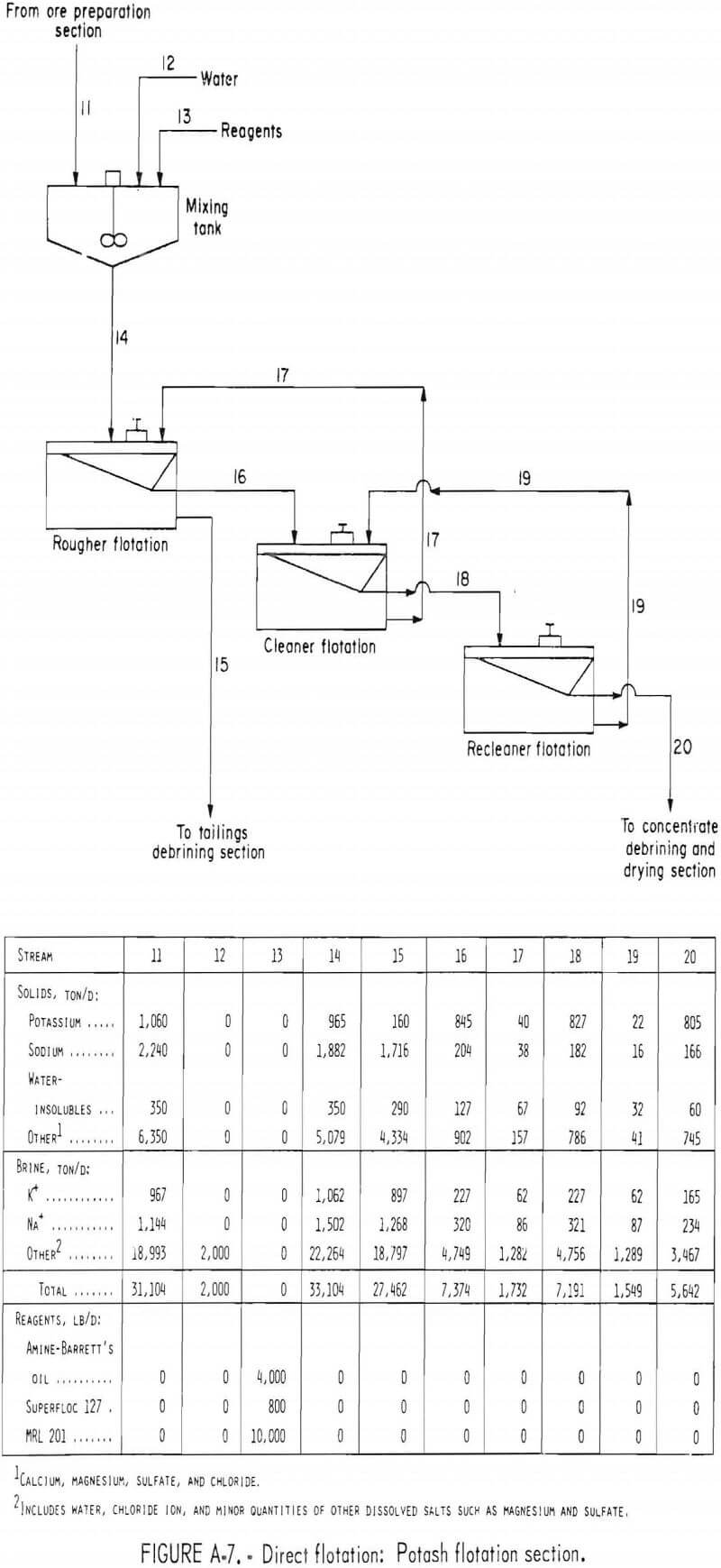

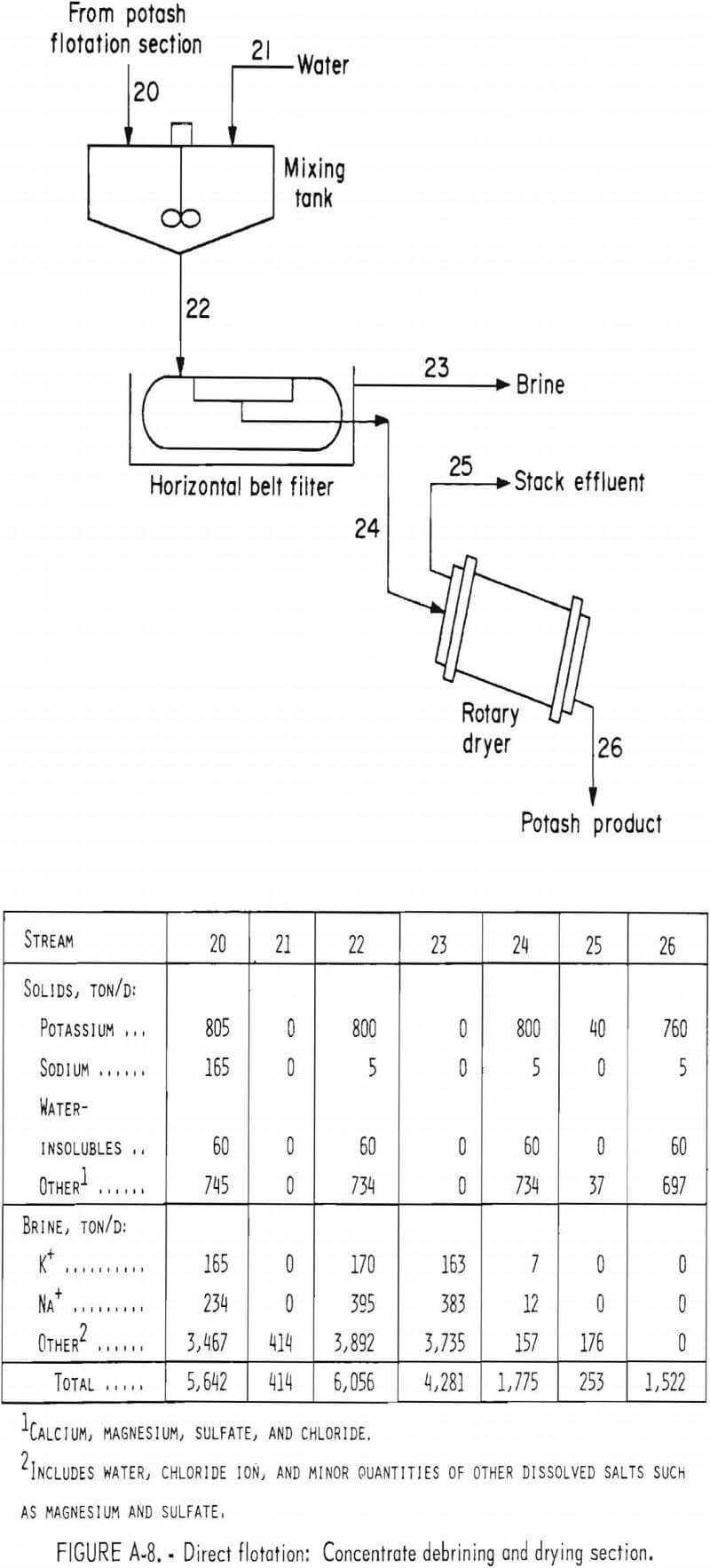

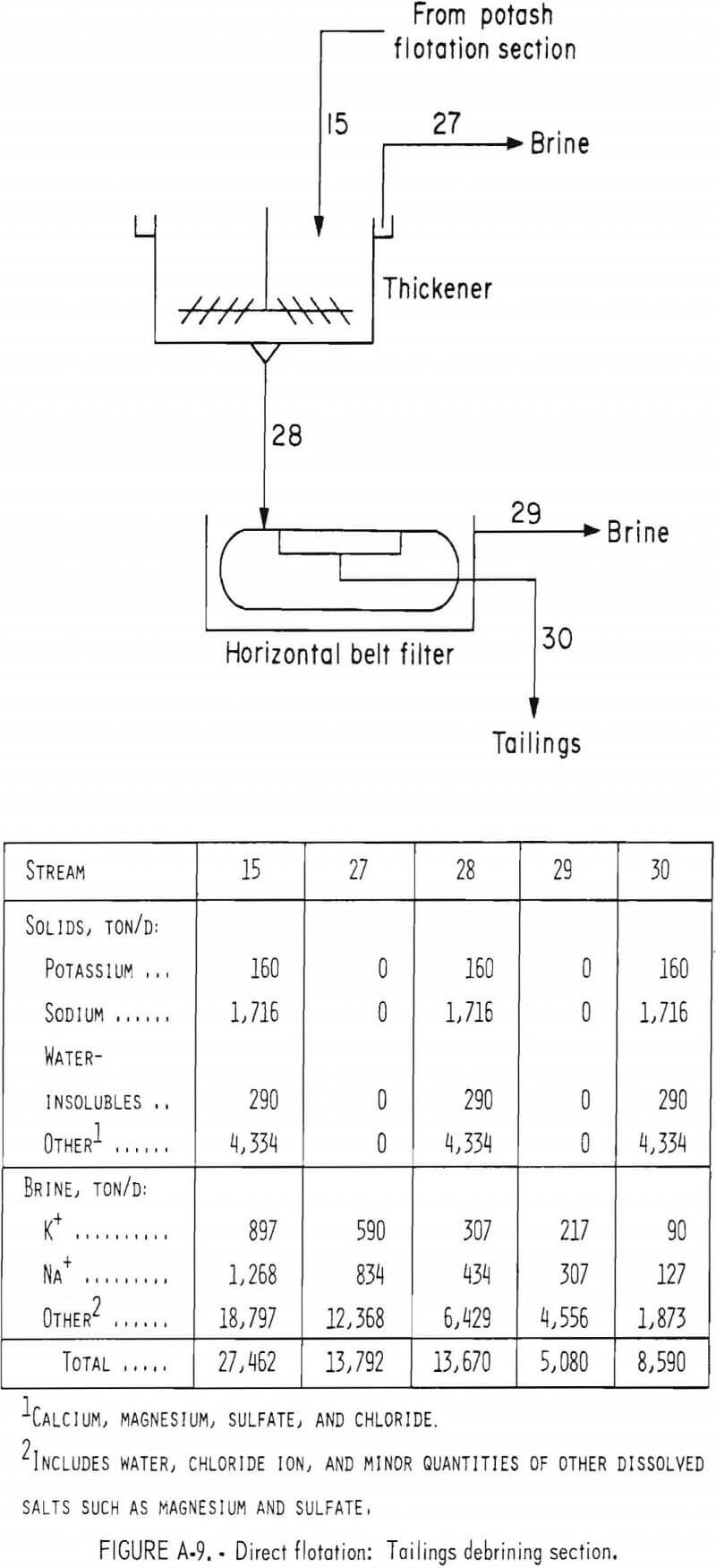

Design For Direct Flotation

This circuit, shown in appendix figures A-6 through A-9, was similar to the insoluble-slimes flotation circuit except (1) the insoluble-slimes flotation circuit was eliminated, (2) slurry from the carnallite decomposition was pumped directly to the potash flotation circuit, and (3) the slimes were flocculated with Superfloc 127 and depressed with MRL-201 in the potash flotation circuit. Figure 1 shows an overall view of the continuous flotation unit.

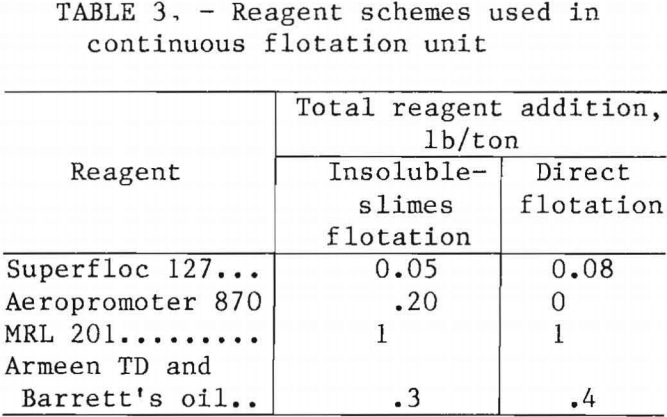

Operation

The reagent schemes described in table 3 were used in the operation of the insoluble-slimes flotation and direct flotation units. These represent optimum dosages determined during operation. Most of the data were obtained during 12-h runs; however, 48- and 96-h runs were also conducted. The major problems encountered were (1) production of minus 100-mesh fines in the rod mill and (2) generation of excessive froth during potash flotation.

During insoluble-slimes flotation, fine sylvite reported to the insoluble-slimes concentrate, thus increasing potash losses. When operating either flotation unit, fine halite reported to the potash concentrate, thus lowering the grade and requiring a final water wash to raise the grade to a marketable 60 pct K2O. The water wash was performed at an optimum 4-to-1 ore-to-water ratio.

Sampling and Data Analysis

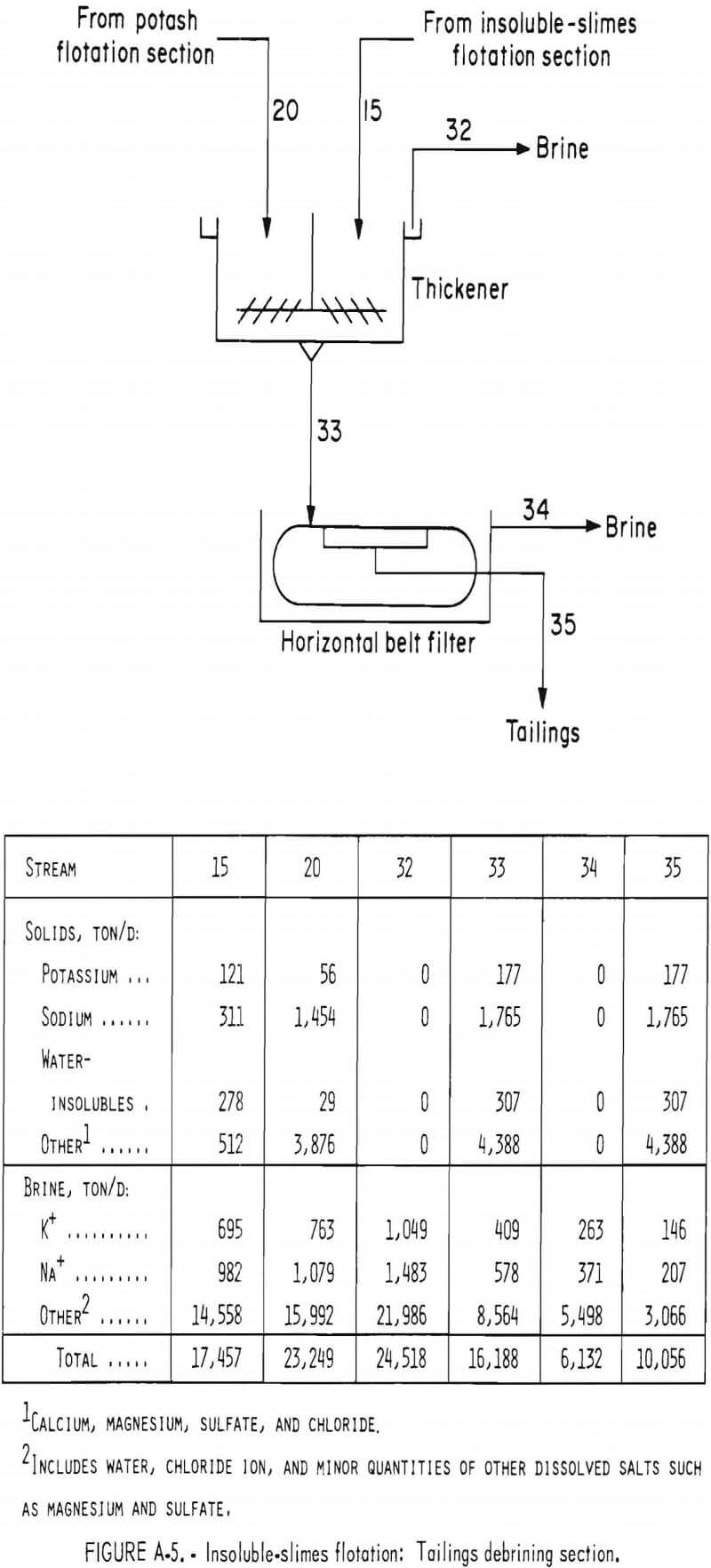

During operation of the insoluble-slimes flotation unit, samples of the plant feed, rod mill overflow, insoluble-slimes concentrate, potash recleaner concentrate, insoluble-slimes tailings, salt tailings, and recycle brine were taken every 4 h for a complete material balance. The samples were filtered, dried, and assayed for potassium, sodium, and water insolubles. During operation of the direct flotation unit, the same samples were taken except for the insoluble-slimes concentrate. Complete mass balances of potassium, sodium, and water in¬solubles are shown in figures A-1 through A-9.

Experimental Results

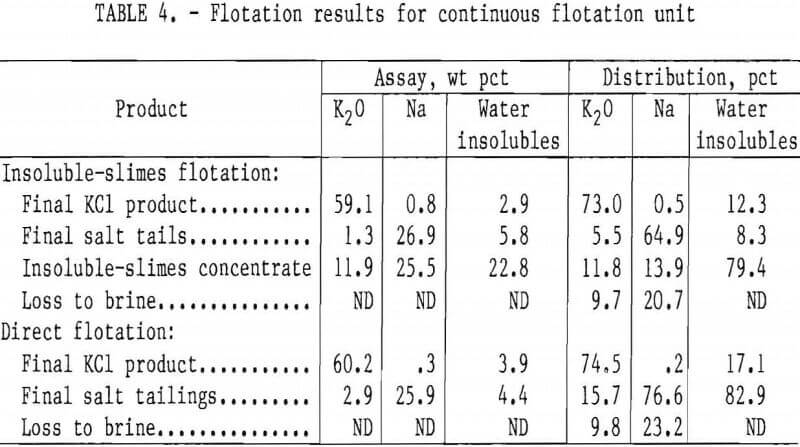

Results of the flotation operations for both procedures are shown in table 4. These are results under the optimum conditions listed in table 3.

When treating the carnallite ore by the insoluble-slimes flotation method, 73 pct of the potash in the plant feed was recovered in a leached final KCl concentrate containing 59.1 pct K2O. Almost 80 pct of the insoluble slimes and 12 pct of the potash in the feed reported to the insoluble-slimes concentrate. Decomposition leaching of the carnallite and water washing of the potash recleaner concentrate dissolved 9.7 pct of the potash.

When treating the ore with the direct flotation method, 74.5 pct of the potash in the feed was recovered in a leached recleaner concentrate containing 60.2 pct K2O. The final salt tailings contained nearly 77 pct of the insoluble slimes and 16 pct of the potash. Decomposition- leaching of the carnallite and water washing of the potash recleaner concentrate dissolved 9.8 pct of the potash.

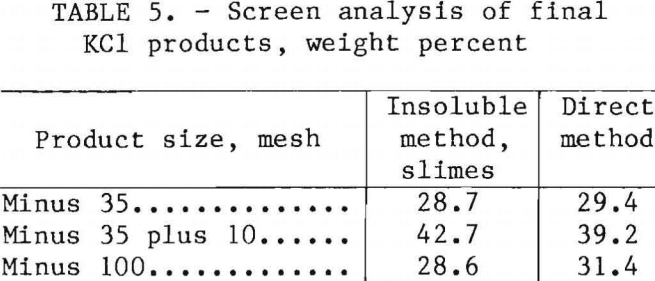

Screen analysis of the concentrates obtained under optimum conditions are shown in table 5. Over 28 pct of the weight was in the minus 100-mesh fraction. Limited testing indicated that the material could be pelletized readily to increase particle size and thus improve market value.

Potash lost to the insoluble-slimes concentrate was predominately minus 100-mesh material, while potash lost to the final salt tails was predominately plus 35-mesh material. Both plus 35-mesh and minus 100-mesh material were lost to the final tailings when using the direct

flotation method. Halite contamination of the potash recleaner flotation concentrates was almost entirely minus 100-mesh material. This fine material was entrained in the froth.

Material Balance and Economic Evaluation

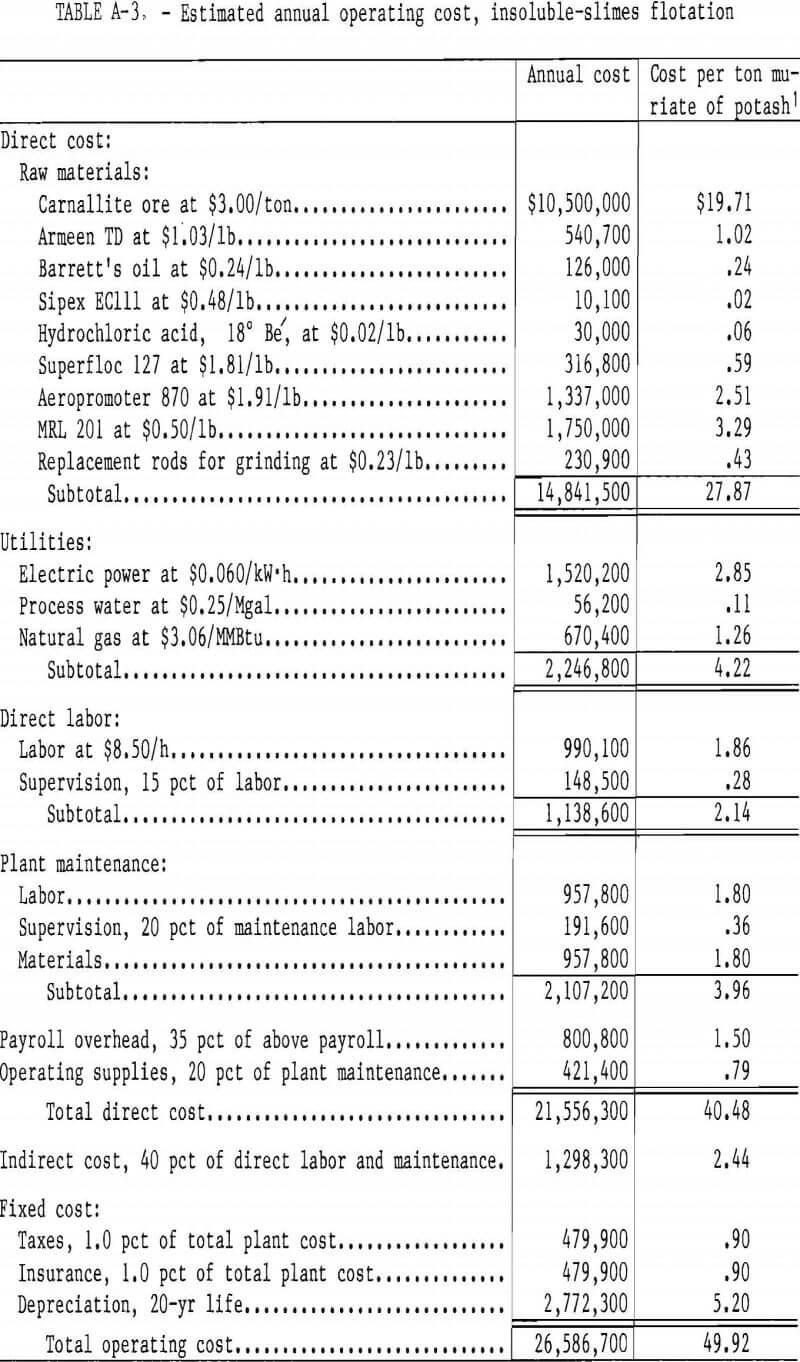

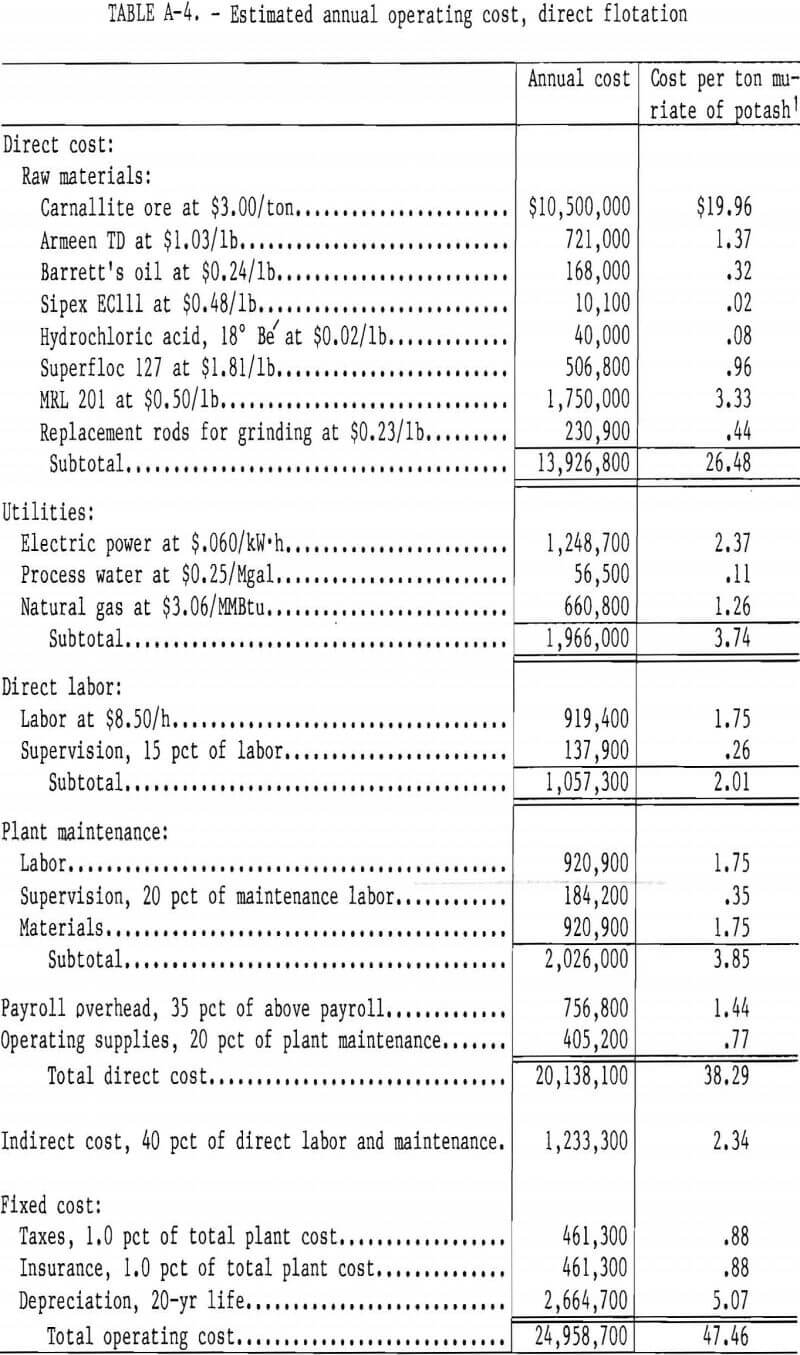

Flow diagrams and complete material balances for the insoluble-slimes flotation and direct flotation procedures are shown in figures A-1 through A-5 and A-6 through A-9, respectively. The material balances are for a plant designed to process 10,000 ton/d of carnallite ore of the grade described in table 1. Economic evaluations of the methods are described in tables A-1 through A-4.

Estimated operating cost for the insoluble-slimes flotation process is $49.92/per ton of potash product, or $0.85 per unit of K2O; the cost for the direct flotation process is $47.46 per ton of potash product, or $0.78 per unit of K2O. Based on a selling price of muriate of potash of $1.26 per unit of K2O, the insoluble-slimes flotation procedure yields an estimated rate of return on investment of 43 pct after taxes. Direct flotation yields an estimated 15-pct after-tax rate of return on investment.

Summary and Conclusions

Operation of a 100-lb/h continuous flotation unit demonstrated the technical and economic feasibility of recovering potash from insoluble-slimes bearing carnallite ore. Using the insoluble-slimes flotation process, where the slimes are removed by flotation prior to potash flotation, 73 pct of the potash in the feed was recovered in a leached recleaner flotation concentrate contiaining 59.1 pct K2O. Nearly 80 pct of the insoluble slimes was recovered in the insoluble-slimes flotation concentrate.

Using a direct flotation method, where the potash is floated directly while depressing the insoluble slimes, 74.5 pct of the potash in the feed was recovered in a leached recleaner concentrate containing 60.2 pct K2O. The final salt tailings contained nearly 83 pct of the insoluble slimes.

The processes are economically feasible, yielding, after taxes, estimated rates of return on investment of 13 pct for the insoluble-slimes flotation method and 15 pct for the direct flotation method.

Appendix—Economic Evaluation

Capital Costs

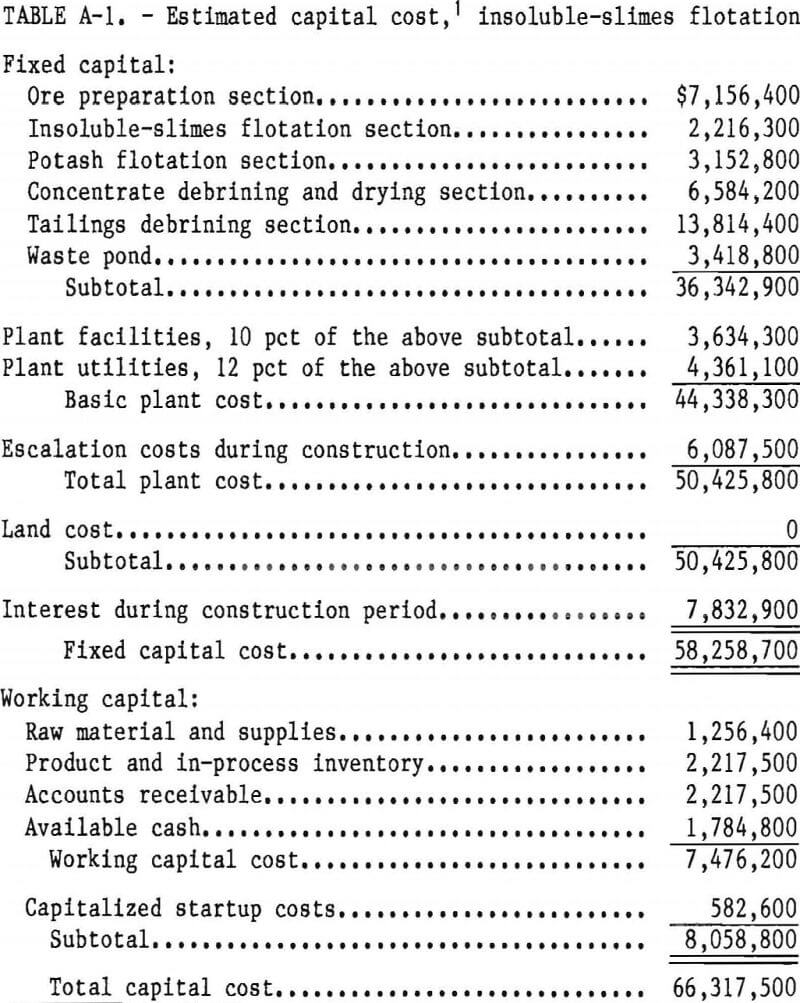

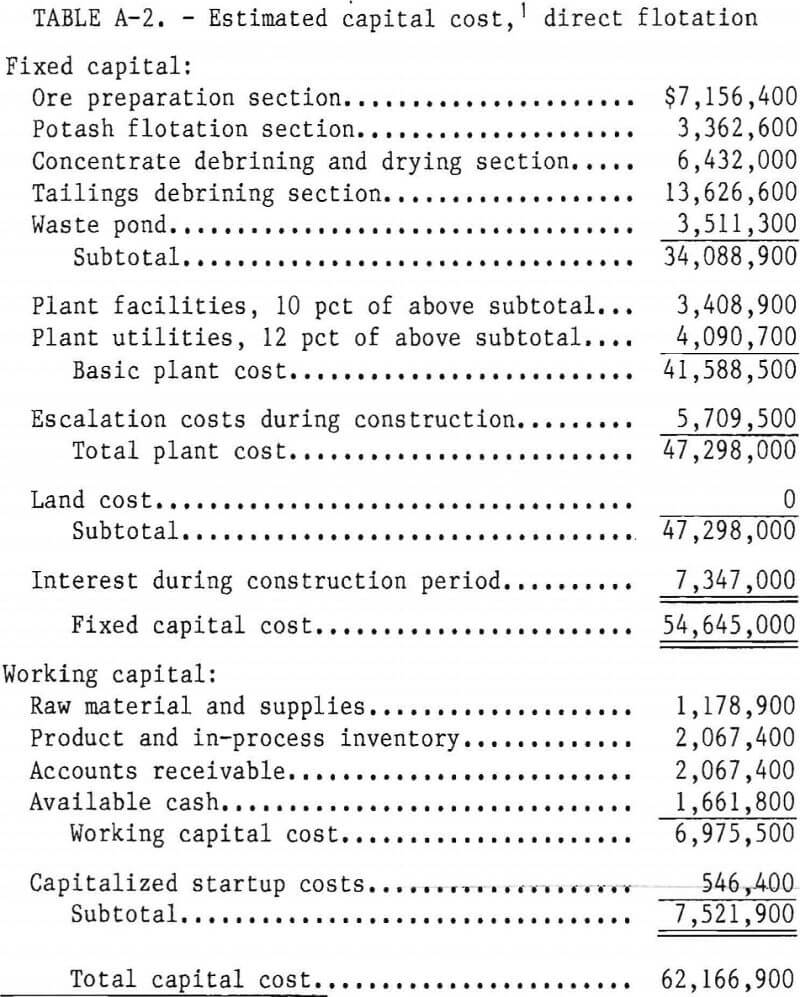

The capital cost estimate is of the general type called a study estimate by Weaver and Bauman. This type of estimate, prepared from a flowsheet and minimum of equipment data, can be expected to be within 30 pct of the costs for the processing plants previously described.

Estimated capital costs on a first quarter 1982 basis (Marshall and Swift (M and S) index of 739.0) for plants processing 10,000 ton/d of carnallite ore are $66,317,500 and $62,166,900 for insoluble-slimes flotation and direct flotation, respectively, as shown in tables A-1 and A-2. The plants are designed to operate 3 shifts per day, 7 d/wk, 350 d/yr, except for some of the reagent preparation facilities which operate 1 shift per day, 7 d/wk. The remainder of the time is for scheduled and unscheduled downtime.

Equipment costs used in this estimate are based on informal cost quotations from equipment manufacturers and on capacity-cost data. In developing the plant capital costs, corrosion-resistant materials of construction are used where appropriate. The tanks and flotation

cells are constructed of mild steel, but the rod mill is rubber lined to withstand corrosive properties of the chloride brine.

Working capital is defined as the funds in addition to fixed capital, land investment, and startup costs that must be provided to operate the plant. Working capital is estimated from the following items: (1) raw material and supplies inventory (cost of raw material and operating supplies for 30 days), (2) product and in-process inventory (total operating cost for 30 days), (3) accounts receivable (total operating costs for 30 days), and (4) available cash (direct expenses for 30 days).

Startup costs are estimated as 10 pct of the fixed capital costs, of which 1 pct is shown in tables A-1 and A-2. The remaining 9 pct are assumed to be first year operating costs; however, they are not shown in the operating cost table. These startup costs are used in calculating the required return on investment. Land investment is not included in this estimate.

Operating Costs

The estimated operating costs are based on an average of 350 d/yr of operation over the life of the plant. The operating costs are divided into direct, indirect, and fixed costs.

Direct costs include raw materials, utilities, direct labor, plant maintenance, payroll overhead, and operating supplies. Raw materials and utility costs are shown tables A-3 and A-4. The direct labor cost is estimated on the

basis of assigning 4.2 employees for each position that operates 24 h/d, 7 d/wk, and 1.4 employees for each position that operates 8 h/d, 7 d/wk.

Payroll overhead includes vacation, sick leave, social security, and fringe benefits.

Indirect costs include the expenses of control laboratories, accounting, plant protection and safety, plant administration, marketing, and company overhead. Research and overall company administrative costs outside the plant are not included.

Fixed costs include the cost of taxes (excluding income taxes), insurance, and depreciation. Depreciation is based on a straight-line, 20-yr period.

The estimated annual operating costs for a plant processing 10,000 ton/d of carnallite ore are $26,586,700 for the insoluble-slimes flotation circuit and $24,958,700 for the direct flotation circuit, as shown in tables A-3 and A-4. For the insoluble-slimes flotation circuit which produces a product of approximately 59 pct K2O, this corresponds to $49.92 per ton of product, or $0.85 per unit of K2O. The direct flotation circuit produces a product of approximately 61 pct K2O, and the above operating cost corresponds to $47.46 per ton of product, or $0.78 per unit of K2O. (One unit is equivalent to 1/100 of a ton, or 20 lb.)