Table of Contents

The Bureau of Mines and the Nevada Bureau of Mines have investigated hydrometallurgical methods for recovering mercury metal from sulfide concentrates. Most recently, Atkinson investigated the recovery of mercury from sulfide concentrates by a CuCl2 leaching- electrolysis technique. The concentrate used in the investigation was obtained from the McDermitt Mine, the major mercury producer in the United States. The impetus for developing a hydrometallurgical method for recovering mercury from concentrates was to eliminate from the workplace mercury vapors that are difficult to control in a conventional furnacing operation.

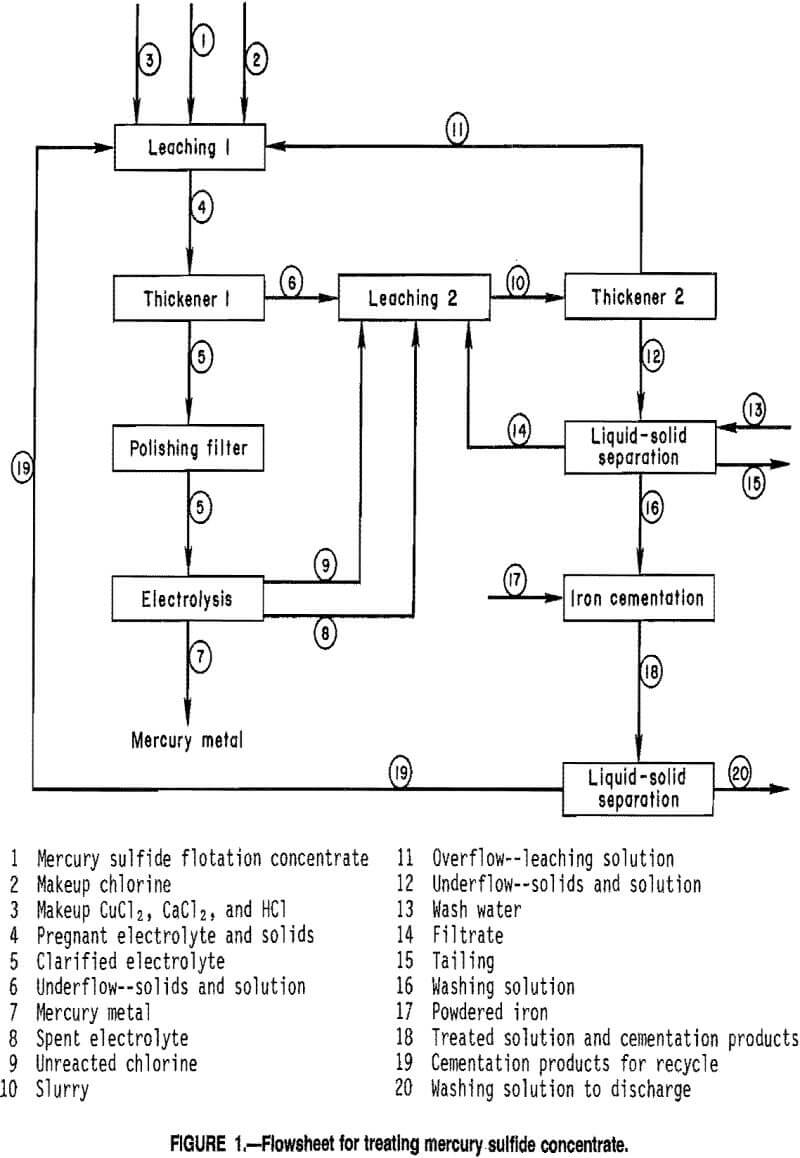

The flow diagram for the previously developed leaching-electrolysis method is shown in figure 1. Mercury concentrates were leached in a CuCl2-FeCl3-CaCl2-HCl- Cl2 solution. Following solid-liquid separation, mercury metal was electrowon from the pregnant chloride solution, and spent electrolyte was recycled to leaching. The electrolytic cell employed a mercury pool cathode and a graphite anode. The technique was demonstrated on a continuous basis for 11 days with a bench-scale apparatus. Mercury extractions averaged more than 99 pct. Electrowinning mercury from the pregnant solution yielded a current efficiency of only 30 pct, and sludge formed on the mercury cathode surface during electrolysis. The sludge, which contained mercurous chloride and finely divided mercury metal, increased the cell voltage and eventually had to be removed.

The present investigation was undertaken to improve the electrolysis step of the process by eliminating sludge formation on the cathode and increasing current efficiency. The investigation showed that copper and iron had to be removed from the electrolyte to improve the electrolysis. As a result, the leaching procedure was modified to produce a copper- and iron-free pregnant solution suitable for electrolysis. A modified process flowsheet was developed.

Equipment and Materials

Mercury sulfide flotation concentrate was provided by the McDermitt Mine. Analysis of the concentrate is shown in table 1. Approximately 70 pct of the mercury was present as cinnabar and 30 pct as corderoite (Hg3S2Cl2).

The leaching solution used in the previous study contained copper, iron, and calcium as chlorides, and HCl. Calcium chloride was added to increase the chloride concentration, which would increase the solubility of cuprous chloride and would control the sulfate produced during leaching by precipitation of CaSO4·2H2O. Iron was added to the leaching solution because the iron concentration would slowly increase as the leaching solution was recycled. HCl was added to prevent precipitation of copper. In the present study, the leaching solution normally contained 50 g/L Cu and 100 g/L Ca as chlorides, and 3.8 g/L HCl. The leaching solution differed from the solution in the previous study in that iron was eliminated and the HCl concentration was decreased from 42 to 3.8 g/L. Iron was eliminated because the flowsheet was

revised and the buildup of iron appeared to be less likely. The HCl concentration was decreased to avoid unnecessary HCl consumption, which will be discussed in the text under Leaching.

Leaching was performed in a 2-L glass beaker. All chemicals used in the experiments were reagent grade. A hotplate, thermocouple, and temperature controller were used to control the leaching temperature. A Teflon paddle-type stirrer was used to keep the concentrate suspended in the solution. Chlorine was sparged into the slurry through a capillary glass tube with a 1.5-mm-diam bore. Filtering operations were done with Whatman No. 5 filter paper on a Buchner funnel with a slight vacuum applied.

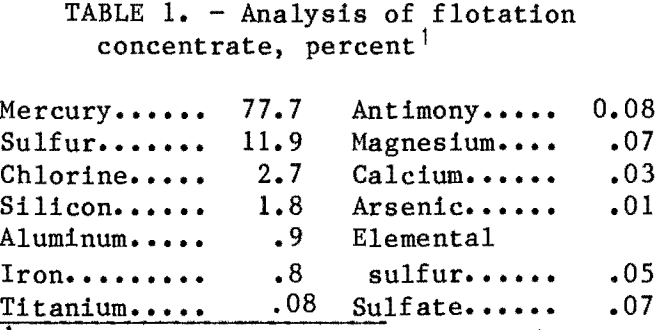

The bench-scale electrolytic cell shown in figure 2 consisted of a 1-L glass beaker with a 3.5-in-diam, ½-in-thick graphite plate for the anode and a ½ in-deep mercury pool as the cathode. A 3/16-in-diam iron rod, which was protected from the electrolyte by a glass sleeve, served as electrical contact to the cathode. A ½-in-diam graphite rod threaded into the anode plate served as the anode connection. The cell was operated at 7 A except when the current density was varied. Cell temperature, typically 50° C, was maintained by a hot-plate that was controlled by a glass- encased thermocouple in the electrolyte. A paddle-type polyethylene stirrer was

used for electrolyte agitation during electrolysis.

A larger 200-A cell, shown in figure 3, was constructed. The container was a Pyrex glass vessel 11½ in in ID by 12 in high. A 2-in-diam graphite rod that was connected to the anode bus was threaded into a 1-in-thick by 9-in-diam graphite plate. A 1/2-in-deep mercury pool was electrically connected to the cathode bus by a 1-in-diam iron rod encased in glass tubing. Mercury metal was removed from the cell by siphoning through a ½-in-ID Pyrex glass tube. The cell operated at a cathode and anode current density of 407 and 453 A/ft², respectively, and required cooling to maintain the temperature at 60° C. The electrolyte was circulated between the cell and a 25-gal reservoir tank that was equipped with a water cooling coil. Chlorine generated during electrolysis was scrubbed by passing the cell offgas through a Na2CO3 solution.

Procedures and Results

Electrolysis Tests in 7-A Cell

The initial objective was to eliminate sludge formation during electrodeposltion of mercury from the pregnant solution. The first approach was to manually skim the sludge from the mercury cathode and return the sludge product to the leaching operation. However, the sludge leached very slowly in the cupric chloride solution. After 48 h of leaching at 80° C, less than half of the sludge dissolved.

Electrolytic cell parameters were investigated to determine their importance in sludge formation. Normally, the electrolytic cell was operated at 50° C with a cathode and anode current density of 80 and 105 A/ft², respectively, and electrode spacing of ½ in. The electrolyte contained 50 g/L Cu, 100 g/L Ca, 100 g/L Hg, and 35 g/L HCl, Cell parameters that were investigated included electrolyte composition, temperature, agitation, and electrode current density.

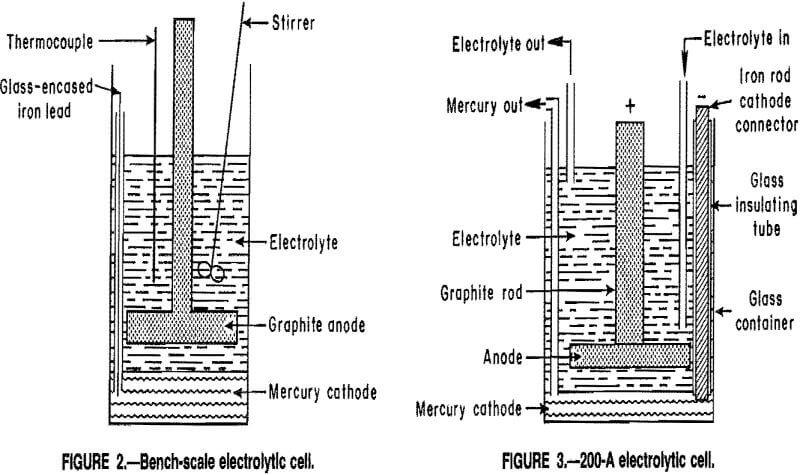

The experiments showed that copper concentration of the electrolyte was the most important factor in sludge formation and current efficiency. Decreasing the copper concentration in the electrolyte dramatically decreased sludge production and increased current efficiency. Below 1 g/L Cu, the mercury cathode remained clean and bright during electrolysis and current efficiency was more than 99 pct. The effect of copper concentration on current efficiency is shown in figure 4. The decrease in current efficiency with increasing copper concentration resulted from the reduction of cupric ion at the cathode and oxidation of cuprous ion at the anode. Sludge formed on the cathode was mostly mercurous chloride and finely divided mercury metal and contained only a few percent copper. Apparently,

cuprous chloride reacted with the mercuric chloride to produce cupric chloride and insoluble mercurous chloride. The effect of iron chloride in the electrolyte on current efficiency and sludge formation was similar to that of copper chloride.

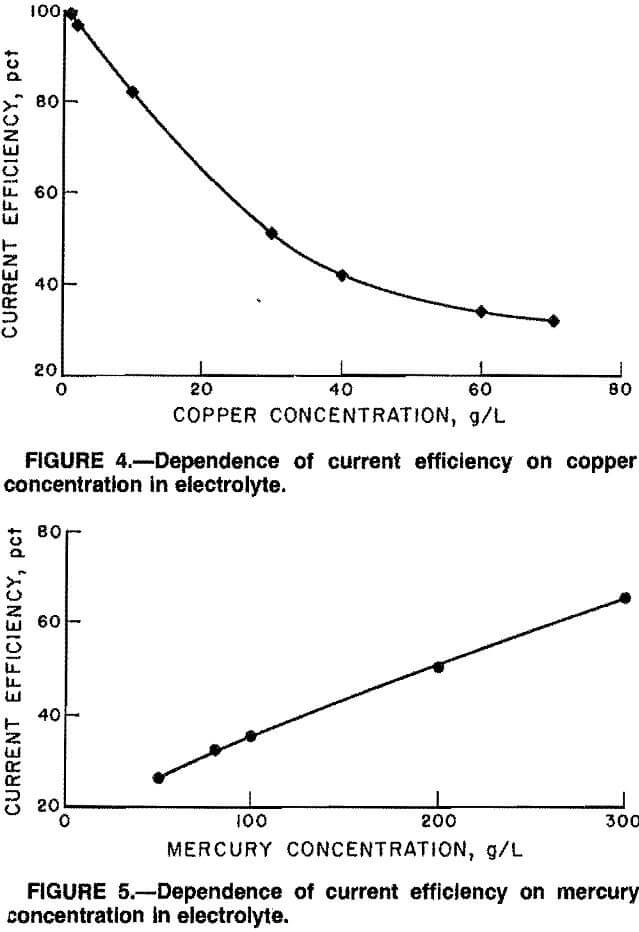

Besides copper concentration, the only cell parameter that significantly influenced current efficiency was mercury concentration of the electrolyte. The effect of varying mercury concentration on current efficiency in a copper-containing electrolyte is shown in figure 5. Increasing the mercury concentration increased sludge formation. At 300 g/L Hg, sludge formed on the cathode at a rate of ½ in/h. Also, slight disintegration of the graphite anode was noted at 300 g/L Hg.

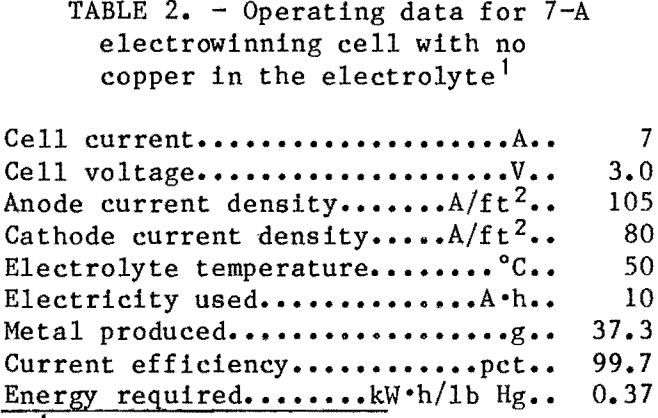

Several experiments were made with a copper-free electrolyte containing 100 g/L Hg, 100 g/L Ca, and 3.8 g/L HCl. Data from a typical experiment are shown in table 2. Without copper present, current efficiency was more than 99 pct and the energy requirement was 0.37 kW’h/lb. No sludge formed on the mercury metal cathode, which remained bright and shiny until electrolysis was stopped.

In a series of experiments, electrolysis was continued to determine the effect of low mercury concentration in the electrolyte. At 5 g/L Hg the cell voltage started to gradually increase, and at 2 g/L Hg hydrogen production was apparent on the cathode.

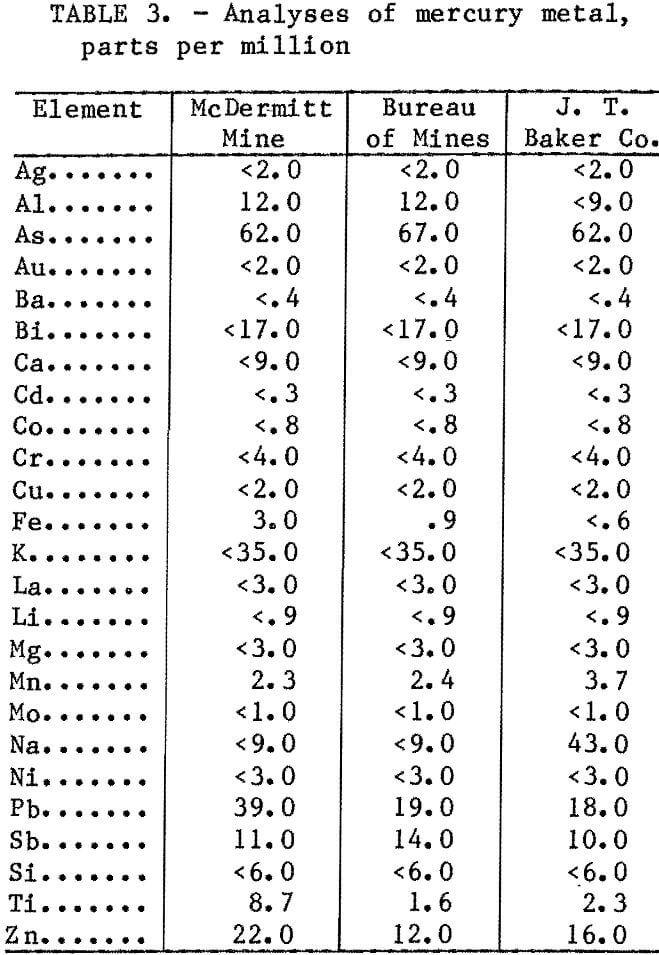

Mercury metal electrowon from solutions in which there was no copper was very pure. In table 3, analyses of the electrowon mercury are compared with analyses of mercury produced at the McDermitt Mine and triple-distilled mercury from the J. T. Baker Company.

Electrolysis in 200-A Cell

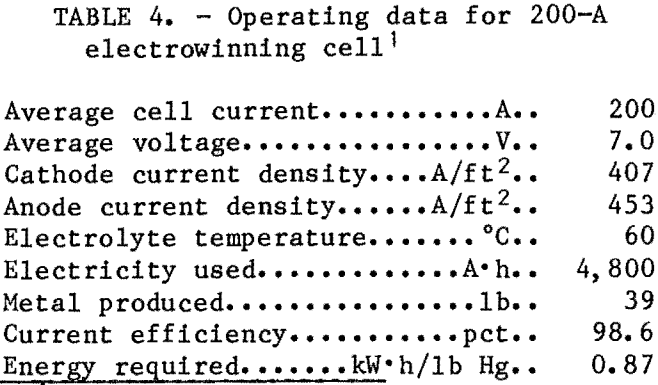

The larger cell was operated continuously for 24 h to determine if sludge on the cathode or other problems would be encountered in a larger scale operation. Feed electrolyte composition was

150 g/L Hg, 100 g/L Ca, 0.5 g/L Cu, and 1 g/L HCl. Electrolyte was continuously pumped from the reservoir tank to the 10-L cell at a rate of 1 L/min. Total volume of electrolyte was 95 L. Spent electrolyte was replaced with fresh electrolyte after 12 h of electrolysis. At the end of the 12 h, the spent electrolyte contained about 50 g/L Hg. Anode- cathode spacing was maintained at about 1 in by siphoning 10 lb of mercury from the cell every 6 h. Operating data for the cell are given in table 4. The mercury cathode remained sludge-free during the test, and current efficiency was 98.6 pct. Anode and cathode current densities exceeding 400 A/ft² and 1-in electrode spacing were responsible for the high energy requirement of 0.9 kW·h/lb; however, this was less than the 1.4 kW·h/lb reported when anode and cathode current densities of 100 A/ft² and an electrode spacing of ½ in were used.

Leaching

Cupric chloride leaching followed by copper removal from the solution before electrolysis is a good approach to hydrometallurgical treatment of mercury concentrates.

The best method for removing copper from the pregnant solutions was precipitation of a basic salt by pH adjustment. Sulfide precipitation with addition of H2S or Na2S to the solution was also investigated but was not practical because at pH 1 almost 30 pct of the mercury precipitated with the copper. Increasing the pH of the pregnant solution with calcium or sodium carbonate or hydroxide precipitated a copper oxychloride, which was identified by X-ray diffraction as atacamite [Cu2Cl(OH)3]. The neutralizing agent was added slowly to the solution over a 15-min period with constant stirring. All of the neutralizing agents worked, but the carbonates entrained less mercury in the copper precipitate.

Disadvantages of increasing the pH to remove copper were that HCl was removed from the pregnant solution as calcium chloride and an H2SO4 addition was required to dissolve the copper precipitate. Although the copper precipitate was readily soluble in HCl, the use of H2SO4 was preferred because H2SO4 adds sulfate to the leaching solution, which controls the calcium concentration in the spent electrolyte by precipitating CaSO4·2H2O. Acid consumption could be minimized by decreasing the concentration of HCl in the leaching solution and by increasing the ratio of mercury to copper concentration. A series of experiments was made to determine the effect of HCl concentration on leaching and to determine if the mercury concentration in the leaching solution could be increased to 200 g/L. In addition to HCl, the solution contained 50 g/L Cu, 100 g/L Ca, and 300 g/L Hg concentrate. Leaching was carried on for 3 h at 80° C with the redox potential maintained at 850 mV (Eh) by chlorine sparging.

Concentrations of HCl between 2 and 38 g/L had no effect on leaching. In all tests, mercury extractions were more than 99 pct. The mercury concentration of the pregnant solution was more than 200 g/L. Analysis of the residue showed that 5 to 10 pct of the sulfur in the concentrate was converted into sulfate. All solutions filtered easily.

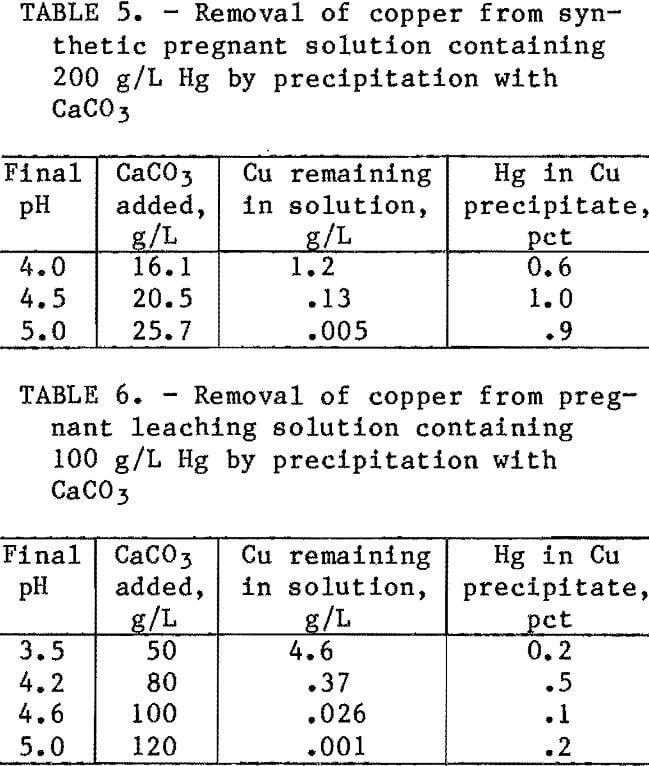

Since the mercury concentration of the pregnant solution could be increased easily, tests were made to determine if copper removal would be adversely affected by a high mercury concentration. A synthetic pregnant solution was made containing 50 g/L Cu, 200 g/L Hg, and 10 g/L HCl. Calcium carbonate was added very slowly to the stirred slurry until the pH was raised to a selected level. The slurry became very thick after the CaCO3 was added, but filtered easily. Results of the tests are presented in table 5 and demonstrate that excellent separation of the copper was possible with CaCO3. The precipitate redissolved easily in HCl and could be returned to the leaching step. Adding 10 g/L Fe as FeCl3 to the pregnant solution and increasing the pH with CaCO3 showed that iron precipitated with the copper.

Four experiments in which leaching was followed by copper removal were performed. Three hundred grams of mercury concentrate was added to 1 L of solution containing 50 g Cu and 100 g Ca as chlorides and 3.8 g HCl. Leaching was conducted for 3 h at 80° C with the redox potential maintained at 850 mV (Eh) by Cl2 sparging. Mercury extraction averaged 99.4 pct, and between 7 and 11 pct of the sulfur was converted to sulfate.

After filtering, water was added to the filtrate to bring the volume to 2 L. In practice, spent electrolyte would be used to dilute the filtrate. Dilution of the filtrate made the copper precipitate easier to filter and decreased the mercury concentration to about 100 g/L, which was a good electrolyte concentration.

Filtrates from the leaching experiments were treated with CaCO3 to remove copper. The CaCO3 was added slowly, and the solution was stirred for 1 h. The copper precipitate was filtered from the solution and washed with 200 mL of water. Analyses of the pregnant solutions and the copper precipitates are given in table 6. Adding 100 g CaCO3 per liter of solution decreased the copper level to less than 0.1 g/L, which is lower than necessary for electrowinning. Mercury concentration in the precipitates averaged less than 0.3 pct. Even this small amount of mercury would not be lost, but would be redissolved in H2SO4 along with the copper and returned to leaching.

As an alternative for producing a copper-free electrolyte, a few leaching experiments were made with chlorine alone as the lixiviant. Leaching was successful, with 99 pct extraction in 3 h.

However, chlorine losses to the atmosphere were high and 40 pct of the sulfur was converted to sulfate, both of which were considered to be serious drawbacks. As a result, chlorine leaching was not pursued.

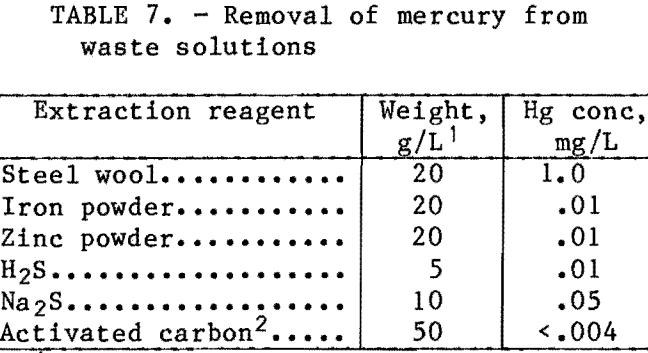

Mercury Removal from Wastewater

Three methods evaluated for mercury removal from wastewater were cementation with iron powder, steel wool, or zinc; precipitation with H2S or Na2S; and adsorption on activated carbon. A solution containing 10 g/L Hg, 50 g/L Ca, and 1 g/L HCl was used in the experiments. When solid reagents were used, 1 L of solution was stirred with the reagent for 2 h at ambient temperature. With H2S, the gas was slowly sparged into the solution for 2 h. The results of the experiments are shown in table 7. Iron and zinc powder, H2S, and activated carbon decreased the Hg concentration to below the Environmental Protection Agency (EPA) discharge level of 0.02 mg/L. Probably the best alternative is precipitation of HgS by H2S sparging because the HgS can be returned to leaching and no additional process steps are necessary. Mercury level in solution after treatment with steel wool was higher than the EPA limit, but extending the treatment time to 4 h or doubling the quantity of steel wool decreased the mercury concentration to 0.01 mg/L. Steel wool has the advantages of low cost and simplicity of treatment.

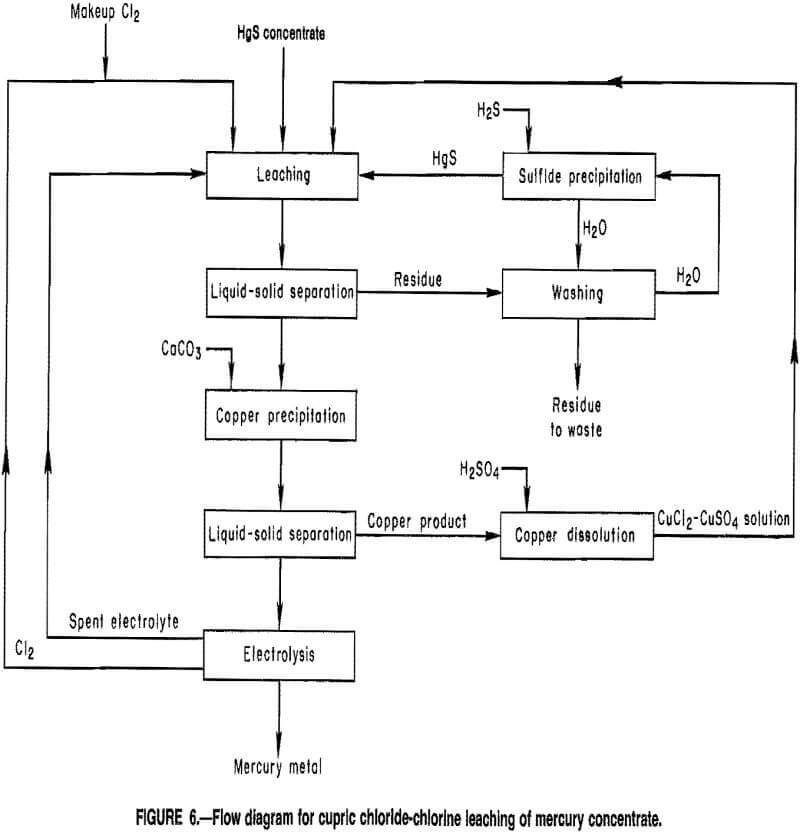

Improved Process for Mercury Extraction from Concentrates

The flowsheet for mercury extraction from concentrates developed previously (fig. 1) was modified as shown in figure 6. In the revised flowsheet, chlorine is sparged into a leaching slurry containing 300 g/L concentrate and 50 g/L Cu. After leaching, the slurry is filtered and the pregnant solution is diluted with spent electrolyte. Copper is precipitated from the pregnant solution by increasing the pH from 1 to 4.5 with CaCO3. Following copper removal, the pregnant solution is routed to electrowinning, which produces high-purity metal and chlorine for recycling to leaching. The copper precipitate is dissolved in H2SO4 and returned to leaching. Sulfate added to the solution is precipitated in the leaching step as CaSO4·2H2O.

The residue from leaching must be thoroughly washed to remove highly toxic mercuric chloride. Wash water could be treated with H2S to recover HgS for recycling to leaching. Alternatively, wash water could be treated by iron cementation to produce a relatively impure mercury product. Salable mercury metal could be obtained by filtering and acid washing.

Summary and Conclusions

Cupric chloride leaching has potential for treating mercury concentrates with minimal mercury vapor emissions. Leaching was rapid, and mercury extractions exceeded 99 pct. Chlorine was sparged into the slurry during leaching to decrease the copper required for leaching. Before mercury was recovered from the solution by electrolysis, copper was removed by increasing the solution pH to 4.5 with calcium or sodium carbonate. Iron present in the leaching solution was also precipitated at pH 4.5. Failure to remove copper caused sludges to build up on the mercury cathode and decreased current efficiency to 30 pct. After copper removal, current efficiency was 99 pct and the energy requirement was 0.37 kW·h/lb.

Wastewater was treated by cementation, sulfide precipitation, and carbon adsorption. Although all methods gave solutions that met EPA requirements for mercury contamination, sulfide precipitation was favored because the HgS product could be returned to leaching, which did not require additional process steps.