Reducing the inorganic sulfur in coal to tolerable limits by physical beneficiation, including flotation, as now practiced, still is relatively inefficient and has not kept pace with the more sophisticated physical beneficiation approaches employed by the nonfuel minerals industry in general.

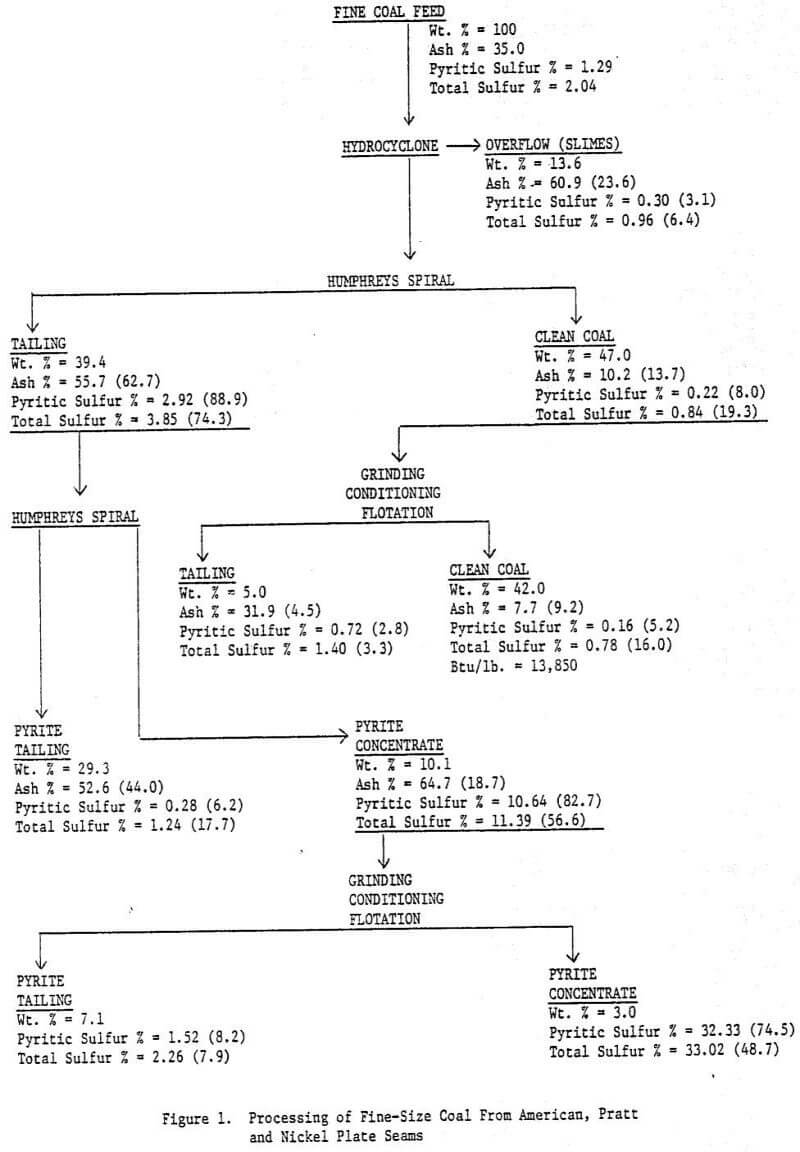

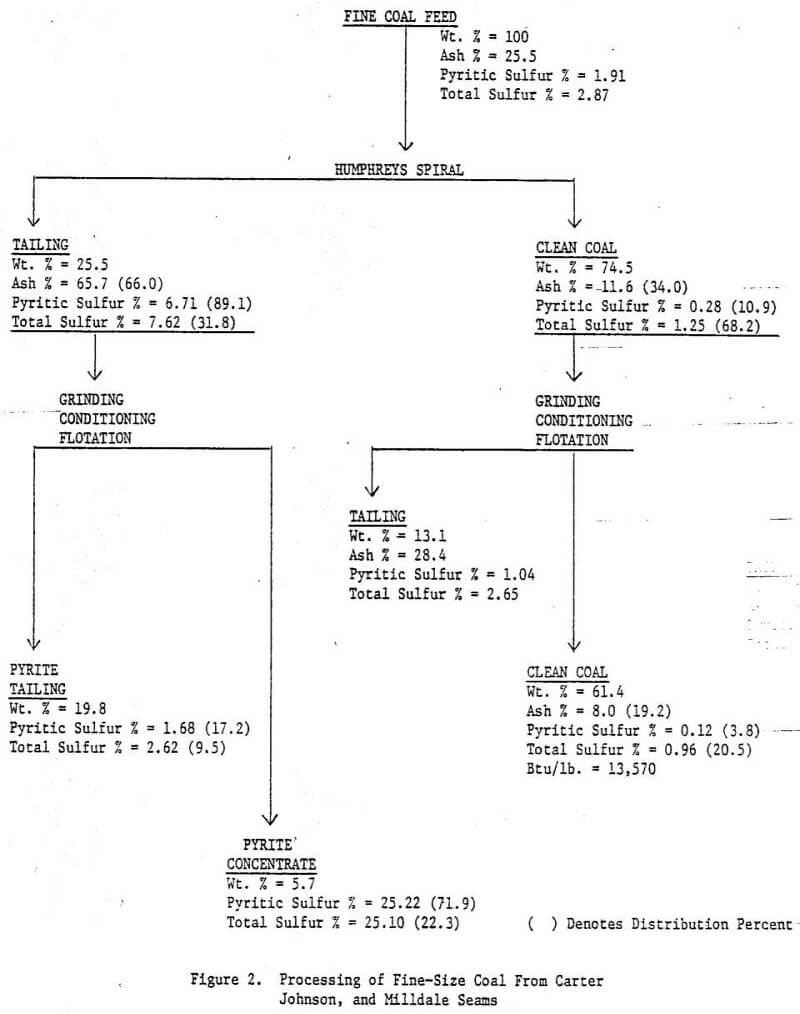

As one phase of a broad program conducted by the Mineral Resources Institute on the sampling and evaluation of impounded fine size waste coal, this Investigation included tests made of samples from two impoundments to determine the quality of coal recoverable by a combination of Humphreys spiral concentration and flotation.

Particular attention was given to the deportment and distribution of the organic and inorganic sulfur in the various products. Another objective of the investigation was to determine if the pyrite in the waste could be recovered for possible marketing.

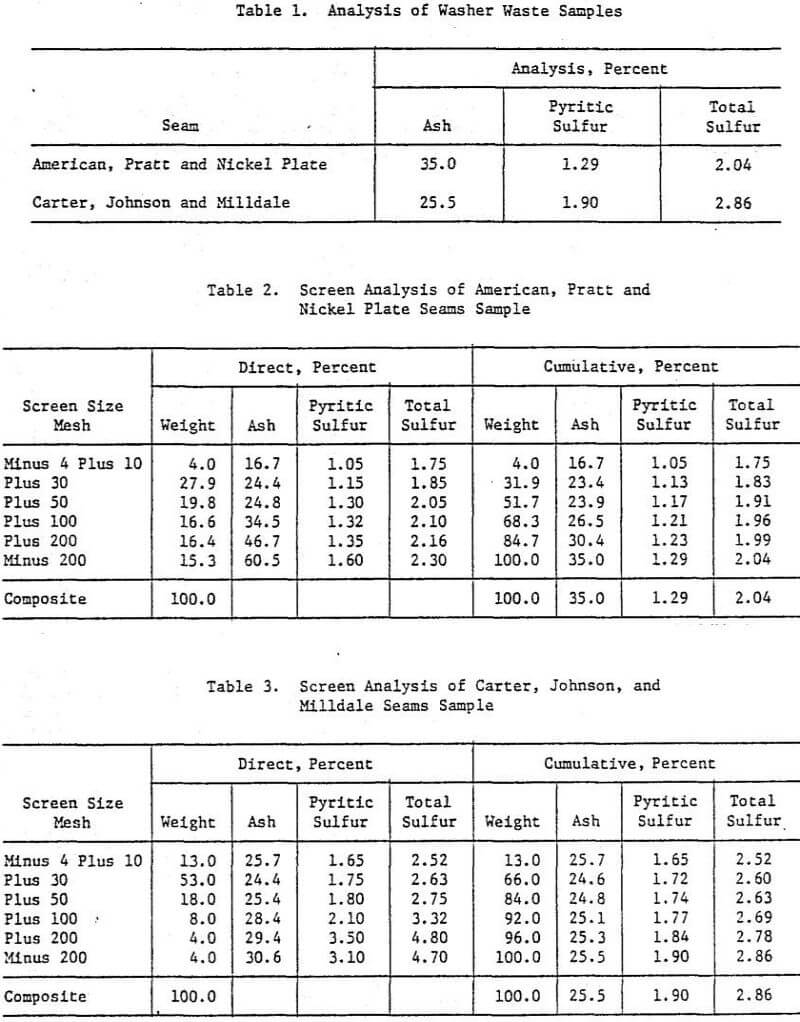

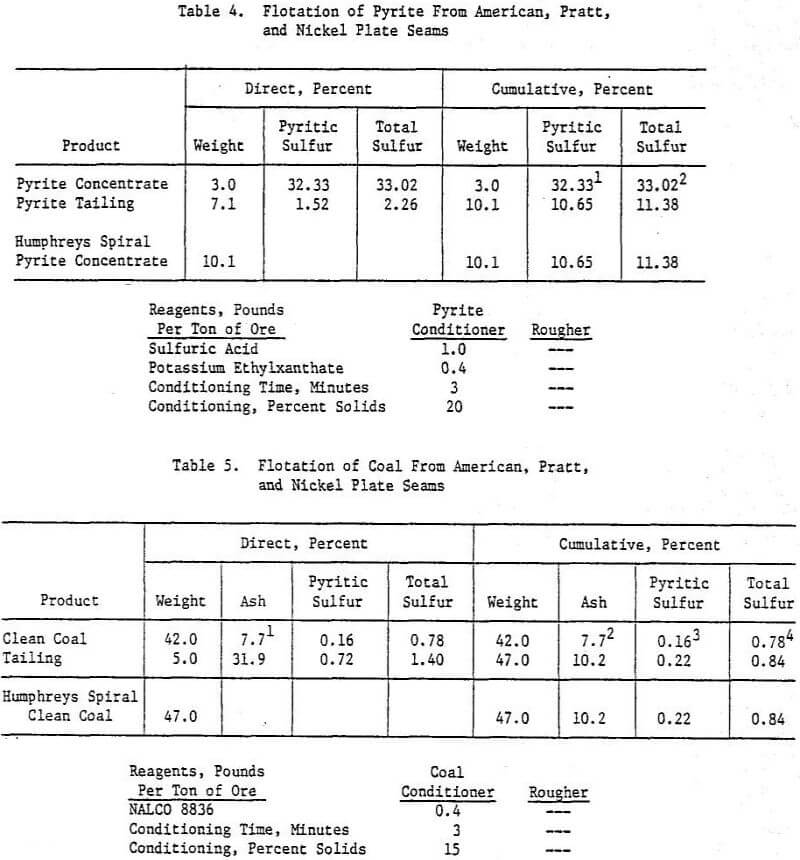

Samples of washer waste were obtained from two impoundments. One sample was representative of waste generated during the washing of steam coal from the American, Pratt and Nickel plate seams in Alabama. The other sample represented metallurgical coal washer waste from the processing of coal from the Carter, Johnson and Milldale seams. Partial analyses of the samples are shown in Table 1, and screen analyses of the samples are given in Tables 2 and 3. The screen analyses showed that one sample contained about 4 percent of material coarser than 10 mesh and the other contained about 13 percent of plus 10 mesh material. Also, the analyses indicated that the ash and sulfur increased as the particle size of the material decreased.

Experimental Laboratory Tests

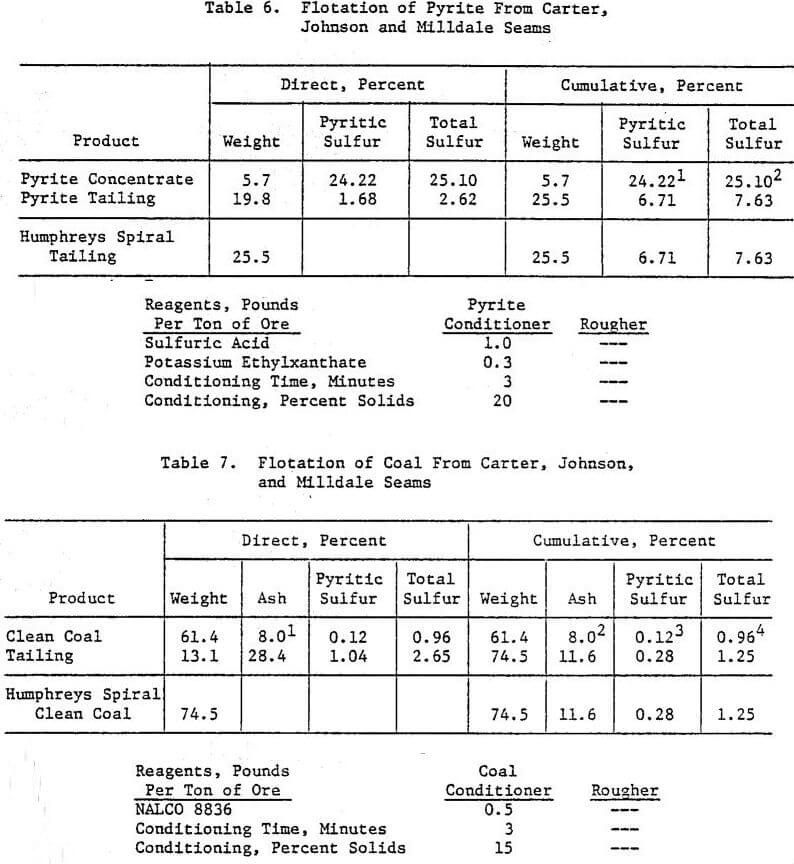

Sink and float tests using a heavy liquid of 1.4 specific gravity were made on the different screen sizes shown in Tables 2 and 3 to determine the effectiveness of gravity concentration for separating the coal from the pyrite and other gangue constituents. The tests indicated that gravity separation, under optimum conditions, could be expected to yield coal products containing 10 to 12 percent ash, and 0.20 to 0.30 percent pyritic sulfur. Good recoveries of coal also could be expected.

Using the sink-float tests as a guide, tests were made in a Humphreys spiral by a procedure in which a 90 to 135 kg (200-300 lb) portion of the sample was recycled over the spiral until equilibrium conditions were reached, after which a clean coal and tailing product were obtained.

The tests of the two samples indicated that under simulated continuous operating conditions it would be possible to recover coal products containing about 10 to 12 percent ash while rejecting about 90 percent of the pyritic sulfur. Operation of the Humphreys spiral has been described in previous publications.

The combination gravity and flotation methods demonstrate the technical feasibility of processing fine size coal to effectively remove sulfur and ash to recover high quality clean coal products which meet or exceed specifications for commercial grade coal as regards to Btu value, and ash and sulfur content. The process effectively removed over 95 percent of the pyritic sulfur in the coal. Reclamation of pyritic sulfur would eliminate stream pollution by acid water drainage and other environmental problems.