Dewatering refuse tailings with a belt filter press has not been widely accepted by the Coal Industry. Part of the problem lies with the highly variable characteristics of the refuse solids themselves. The belt filter press, like other dewatering devices, is highly dependent on these dewatering characteristics. The purpose of this study was to examine the feasibility of using a belt filter press to dewater refuse tailings from a broad spectrum of coal washing operations and not to define all the specific variables which affect dewaterability. It was not intended to ignore these variables; only that most are uncontrolled.

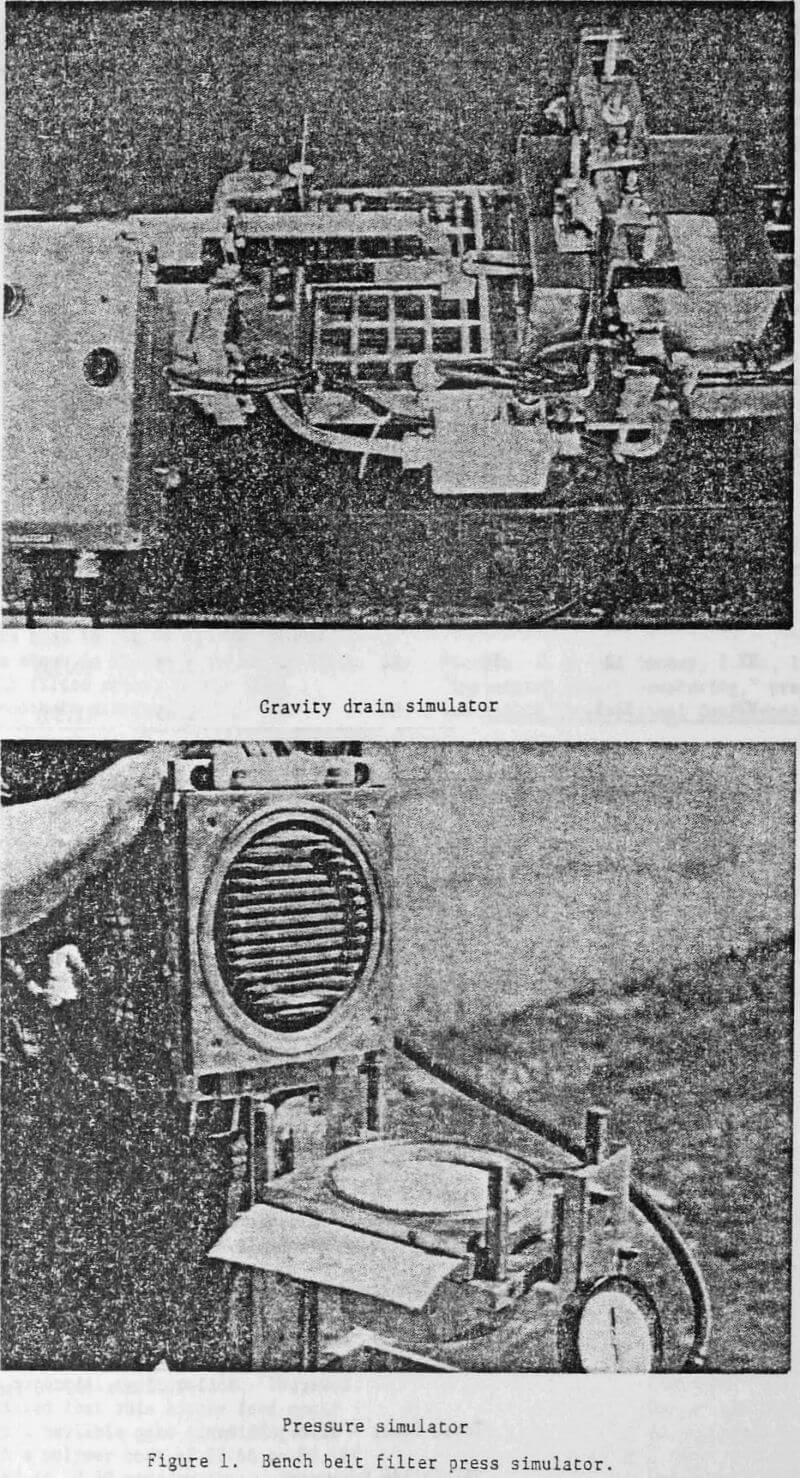

The gravity drainage cake is then placed in the pressure simulator. This device requires a pressurized gas source (generally a nitrogen cylinder) to apply step-up pressure simulating the action as the material passes through the rolls in the belt filter press. The direct pressure applied can be correlated to belt tension. The number of rolls and the pressure required can be determined with this device. Proper selection of belt material for optimum belt filter press performance is also evaluated.

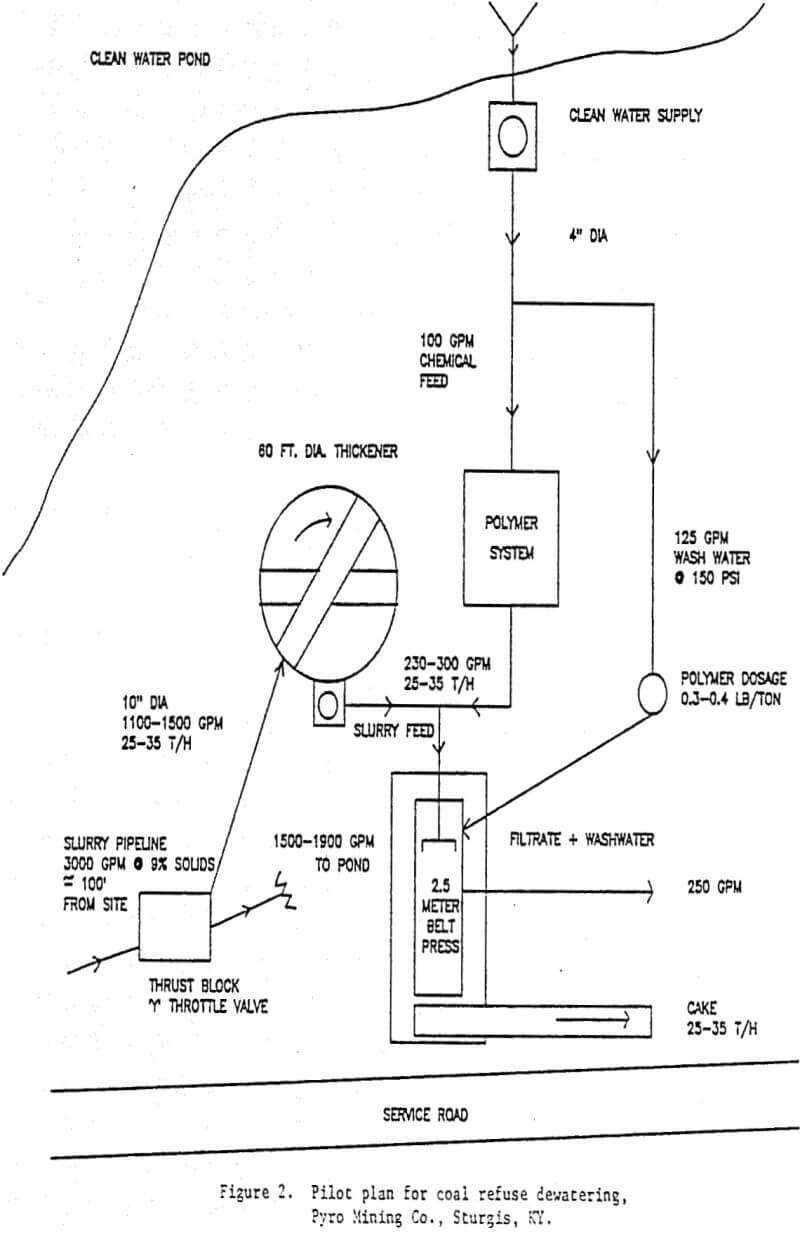

Bench scale testing was conducted prior to the full scale operation to predict both thickener and belt filter press performance. The results of these bench tests proved to correlate very well to full scale performance. Polymer selection, polymer dosages, and concentrations reported in the preliminary testing is what was used during the 6 month full scale study for the thickener and belt filter press. Bench scale cake moisture content varied from 26 to 29%; very close to full scale cake of 25 to 30% moisture. The predicted polymer consumption also correlated very well to the full scale results.

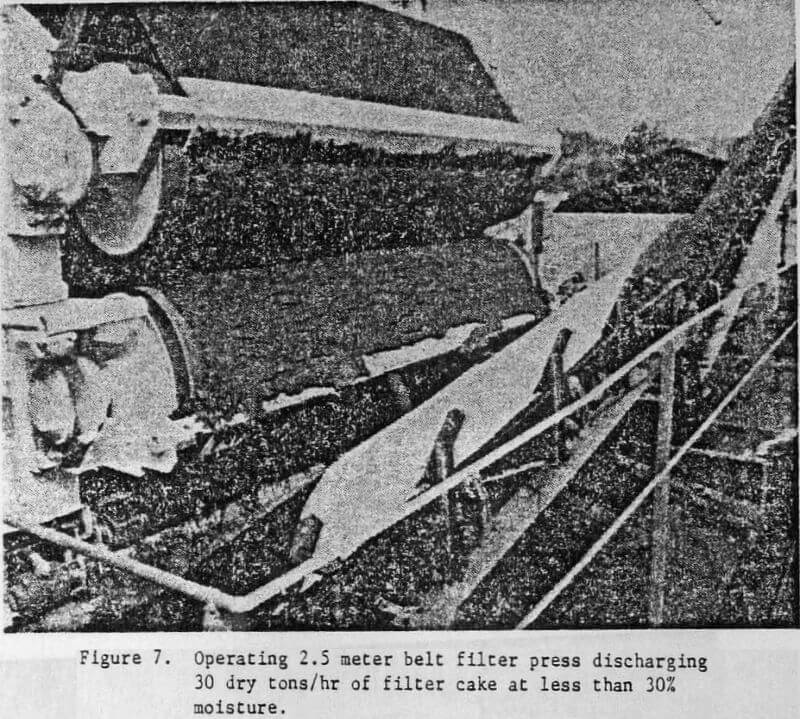

The belt filter press was able to handle extreme variations in feed solids concentrations as well as variations in slurry particle size or any other process changes which may occur in the preparation plant. Feed solids concentration introduced to the belt filter press varied from 24 to 61% solids. The press consistently produced a cake with 30% total moisture or lower (as low as 23% moisture).