Table of Contents

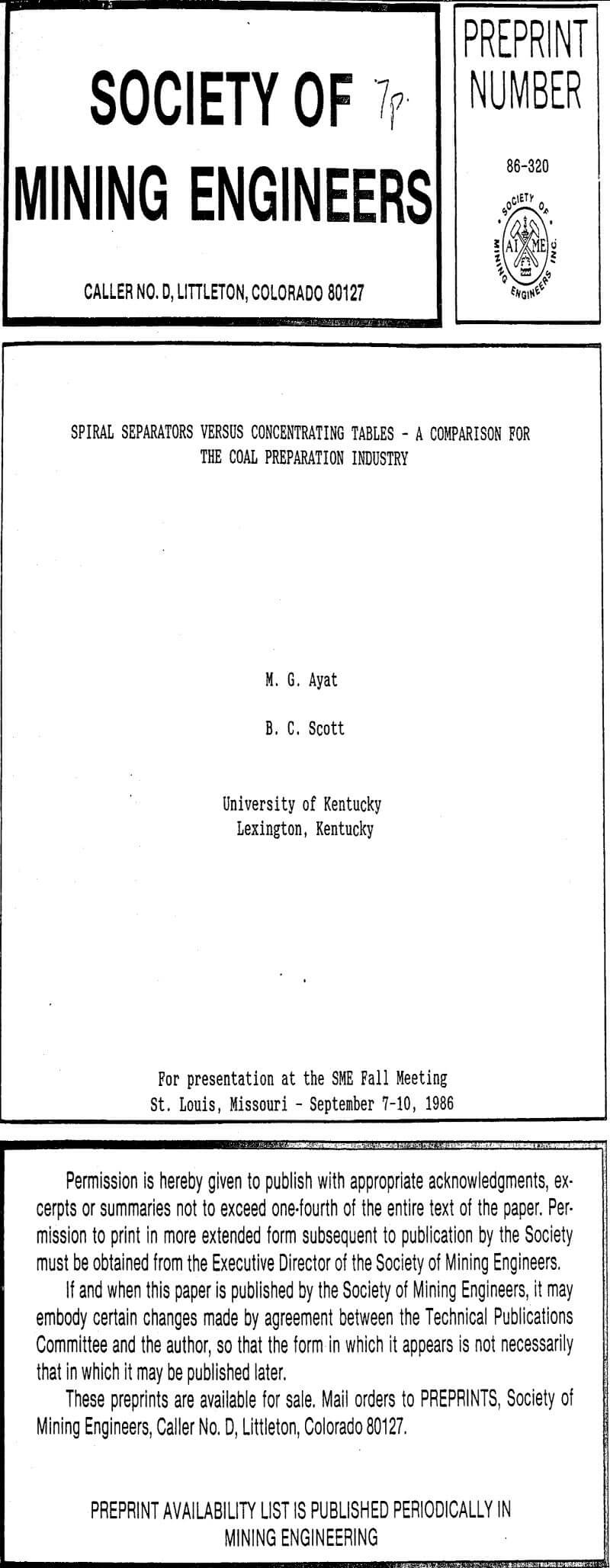

Concentrating Table

As far as the efficiency of the concentrating table is concerned, it has been established that a table can clean coals of 9.5mm x 0.075mm(3/8″ x 200mesh) with high efficiencies and low probable errors. It is, however, important to notice that the particle size of coal treated on a table has a significant influence on the separation characteristics as stated below:

- As particle size decreases the specific gravity of separation will increase.

- As particle size decreases the efficiency of separation on the table will decrease.

- The removal of ash from coal is most successfully achieved for the size fraction 9.5mm x 0.30mm (3/8″ x 50mesh).

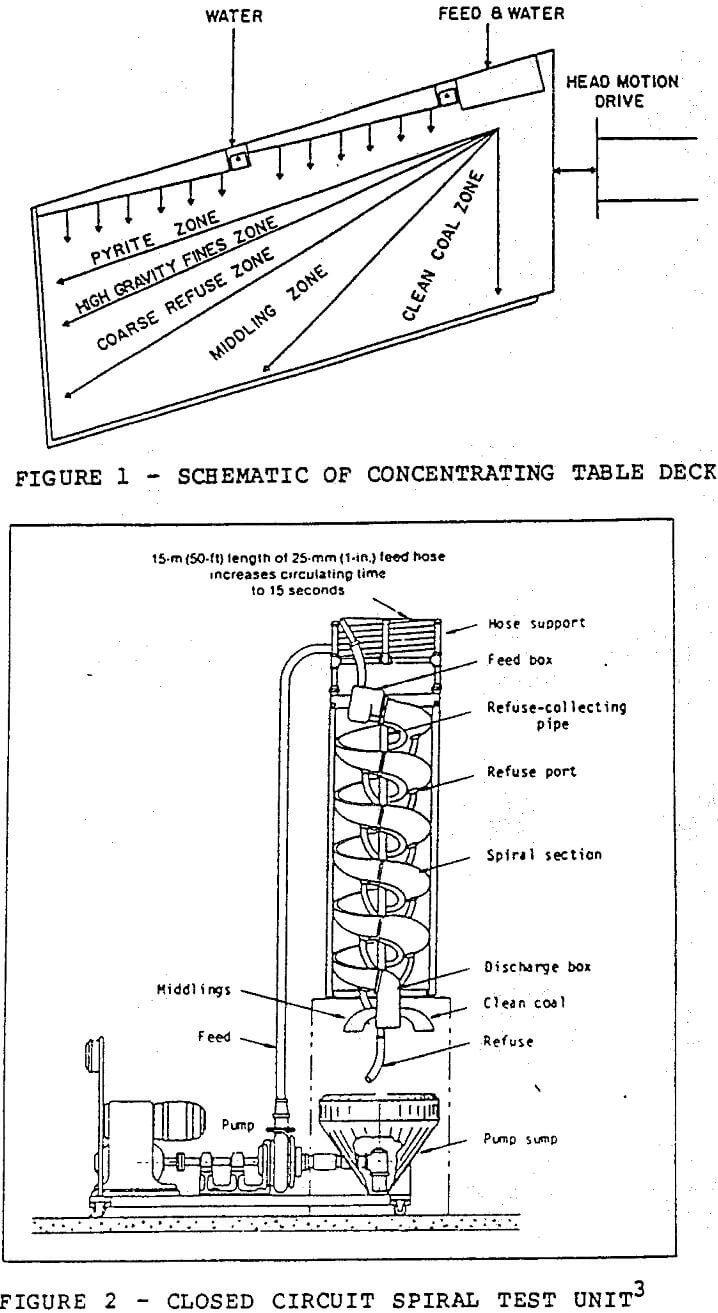

Spirals

Spiral concentrators designed for applications in coal preparation operations have a shallower pitch than those used in heavy mineral separation. The typical spiral unit consists of a spiral conduit with a modified semi-circular cross section. As the slurry flows down the spiral, those minerals with highest specific gravity move to the inner edge of the spiral while the light material moves upward to the outer edge of the spiral. A full size spiral concentrator is shown in Figure 2.

The effectiveness of spiral separation for the removal of clean coal from pyrite and other contaminants varies according to the type of coal feed and the feed rate. For coals containing 19.0% to 41.9% ash the spiral separator can produce products containing less than 9% ash and containing up to 98.7% of the coal. As the feedrate ranges from 1.1tph to 3.9tph per spiral start, coal recovery is maintained at levels of 90% over the full range of particle sizes.

The shallow pitch spirals used for the beneficiation of coal have capacities in the range of 1 to 3 tph per spiral start. A very recent study has suggested that while spirals will accept up to 3.5 tph per spiral start, optimum performance is achieved at a feedrate of 2 tph per spiral start. However, ash displaced to the product increases with increasing feedrate and particle sizes below 0.10mm. It has also been stated that feedrate is in fact the most significant independent variable governing spiral performance.

Comparison

Although the concentrating table and the spiral separator are presently used for different purposes, the fact remains that there is a common ground between the two in coal beneficiation operations. Figure 3 represents the variation of particle size and reduced probable error for both systems. The reduced probable error is defined as the probable error(Ep) divided by the specific gravity of separation (SG50). This figure indicates that for the size fraction, 1.40mm x 0.5mm, the efficiency of both devices is virtually the same. However, it should be noted that the use of Ep values for the purpose of comparing two devices is limited due to the fact that they are designed to determine how accurately the equipment can cut at a predetermined and set specific gravity. This is particularly so in the case of the spiral since the Ep values depend on flowrate, splitter positioning, feed size distribution and other variables.

As far as unit capacities are concerned, both are affected by feedrate and particle size. While the capacity of a single deck concentrating table is several times that of a single spiral start, the feedrate for both devices must be decreased as the percentage of fine material in the feed increases. However, this effect is less critical for the spiral separator due to the fact that it is designed to treat finer size fractions.

The concentrating table is in no danger of being replaced by the spiral separator.