The Quarto Mine and preparation plant of Quarto Mining Company is based on the production of coal from the Pittsburgh seam. At this location the raw coal contains a substantial amount of refuse with some troublesome characteristics. The refuse at the mine face (about 50% of the mine output) contains only a very small amount of very fine particles. As the raw coal ages in the storage pile, however, the refuse swells and oxidizes to a slurry of 400 mesh clay. After 30 days, a major portion of the refuse (nearly 25%) will measure – 200 mesh. The deterioration in particle size is accompanied by the formation of a charge layer which has been measured in excess of -27 millivolts.

Historically, Quarto Mining has used two methods to attempt to cope with these unexpectedly large volumes of troublesome clays. For many months after startup they added sulfuric acid to drop the pH of the water from 8.0 to 5.0-6.0 to neutralize the double layer. However, inaccurate use of manual controls for the acid addition resulted in plant corrosion. After halting the pH adjustment it was necessary to add very large quantities of cationic and anionic polyelectrolytes in order to effectively operate the thickener. With polyelectrolyte cost of $45 per operating hour, the clays built up to such an extent that the plant could not operate. When cleaning coal on a one shift basis for 5 days per week, the thickener was operated on a round-the-clock basis. Studies with advanced types of polymers indicated that using combinations of cationic and anionic polyacrylamides costing $65 to $85 per hour would provide the necessary solids removal to allow the plant to operate on a 10 shifts per week basis without special shifts to clear the thickener.

Preliminary tests with a bench scale, laboratory device indicated that the Quarto refuse responded very well to electrocoagulation with alternating current. Although no economic projections were possible it was demonstrated that substantial savings of polyelectrolytes could be achieved.

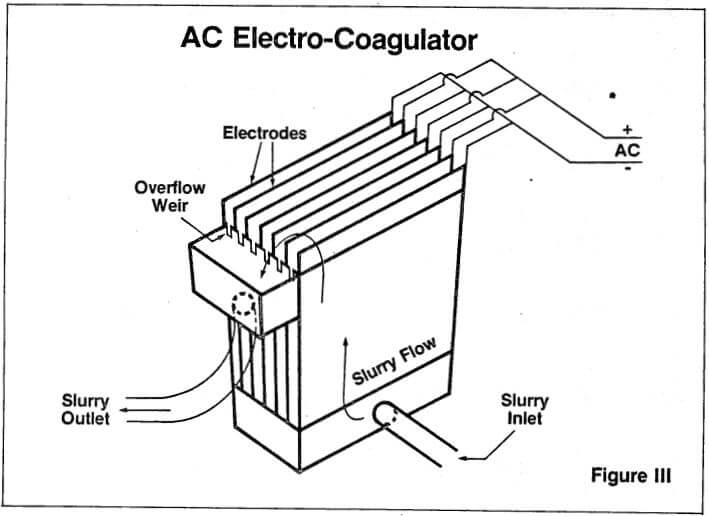

A pilot scale electrocoagulator with a nominal capacity of 4.53 cubic meters per hour (20 gallons per minute) was moved to Powhatan Point, Ohio, for testing. This unit featured upward flow through 6 channels, each with its own control valve. The unit was built to use a fluidized bed of conductive particles as a means of increasing the apparent conductivity of the thickener feedwater.

The unit was operated in a configuration whereby the feedwater entered the bottom of one or more cells and overflowed a weir at the top of the cells. Electrical connections to the cell walls, which also acted as electrodes, were made above the liquid levels in the cells. The simplest description of the unit geometry would be that it looked like an oversized automobile battery. (See Figure III).

Our testing procedure consisted of setting a flow rate through the unit, coagulating the solids at various power settings, collecting samples of the untreated and treated slurry and measuring settling times at various polyelectrolyte addition rates. In addition, the samples were judged visually for adequate clarity of the supernatent. There were a number of factors which influenced these tests.

First, the thickener feedwater experienced very rapid fluctuations in solids contents due to operating anomalies in the prep plant. Samples were checked frequently but there were still numerous instances in which the power settings were not correct for the solids contents of the slurry.

Second, the small passages in the electrocoagulator frequently plugged whenever the thickener feedwater contained excessive solids. At solids contents up to 7% we were able to operate consistently. At 9% and 11% we operated with intermittent backflushing and with purges of fresh water. At 15% solids we had to backflush and purge after every test run. At 18% solids the unit was inoperable. Despite these problems we were able to keep the unit running. New designs for subsequent test programs are constructed to tolerate the high solids concentrations and to operate under typical coal preparation plant conditions.

Third, the tests were performed during a period of labor and transportation problems in that area of Ohio. It was not unusual for the mine to produce coal, then have it sit in the raw coal stockpile for several weeks, allowing the refuse to oxidize and deteriorate into very troublesome material. Tests which could have been completed in two weeks stretched out over two months.

Nevertheless, the tests demonstrated that electrocoagulation could eliminate the need for massive amounts of cationic polyelectrolytes and reduce the amounts of anionic polyelectrolytes required to operate the thickener.

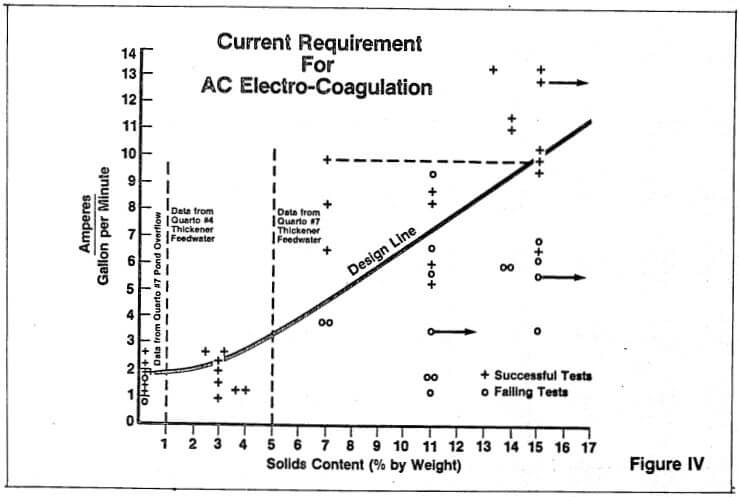

The results of the tests are shown on Figures IV and V. Figure IV is a graphic illustration of the current density requirement for the electrocoagulation of the clays at Quarto Mining as a function of the solids content of the thickener feedwater. In this presentation, the current density is divided by the slurry flow rate to produce a single curve which will be used as the design basis for any larger units to be supplied for the Quarto 7 preparation plant. Of 31 data points taken at the Quarto 7 thickener, only one unsuccessful data point lies above the line and only three successful data points lie below the line. In the interval of the Quarto 7 data the design line is linear, indicating a direct relationship between the current density and the amount of colloidal material passing through the current field (the electrocoagulator flow passages).

Several data points are marked by arrows in Figure IV. These arrows are used to indicate that the data were obtained during a period of preparation plant upset in which the solids contents were changing rapidly. Most of these data points were marked because the amount of settled sludge in the test graduates was noticeably inconsistent with the last previous density measurement.

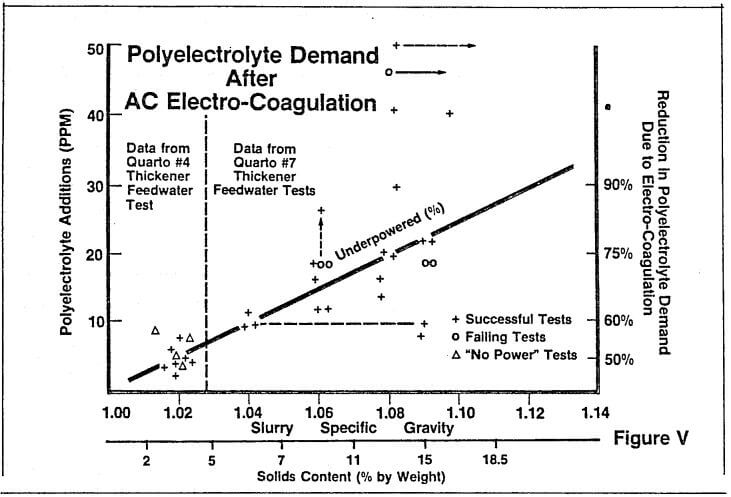

Figure V Indicates on the left scale the amount of polyelectrolytes additions needed to achieve satisfactory settling of the slurry solids -<100 mm/minute <4″/minute) and satisfactory clarity of the supernatent – visually transparent.

On the right scale, we have indicated the reduction in total polyelectrolyte demand which can be attributed to the effects of electrocoagulation.

This parameter is measured by comparing the polyelectrolyte required for satisfactory settling and supernatent clarity for treated slurry against the demands for untreated slurry collected at the beginning and/or end of a test setting.

Polyelectrolyte savings at Quarto 7 range from 50% to 80% within the operating range of the coal preparation plant during our tests.

As a basis of comparison, we also moved the electrocoagulator to the Quarto 4 plant. The coal for this facility is also mined from the Pittsburgh 8 seam but 12 miles north of Quarto 7. Refuse volume at 4 plant is smaller and the colloidal characteristics of the clays are far less troublesome. An indication of this statement can be seen on Figure IV where the maximum current density for Quarto 4 was 13 amperes per cubic meter per hour (3 amps/gpm). The slurry was also coagulated at substantially lower current densities. By comparison, the lowest effective current density at Quarto 7 was 22.1 amperes per cubic meter per hour (5 amps/gpm).

Similarly, although the saving in polyelectrolyte at Quarto 4 was shown on Figure V to be 50%, the total usage of polyelectrolyte was so small that no practical benefit could be shown from electrocoagulation.

The tests showed that electrocoagulation of thickener feedwater can be an effective process whose economic benefits will depend upon its application to preparation plant waters containing large amounts of stable, colloidal clays.