Objective

To produce industrial-grade titanium castings by processes that are nonpolluting and lower cost than the currently used rammed-graphite process.

Approach

Foundry-grade zircon and olivine sands, bonded by waterglass or bentonite, are used to make shell or rammed molds which require relatively low-drying temperatures and do not generate noxious fumes during drying or casting.

Procedures

Three separate processes have been developed which meet the stated pollution and cost goals.

These are:

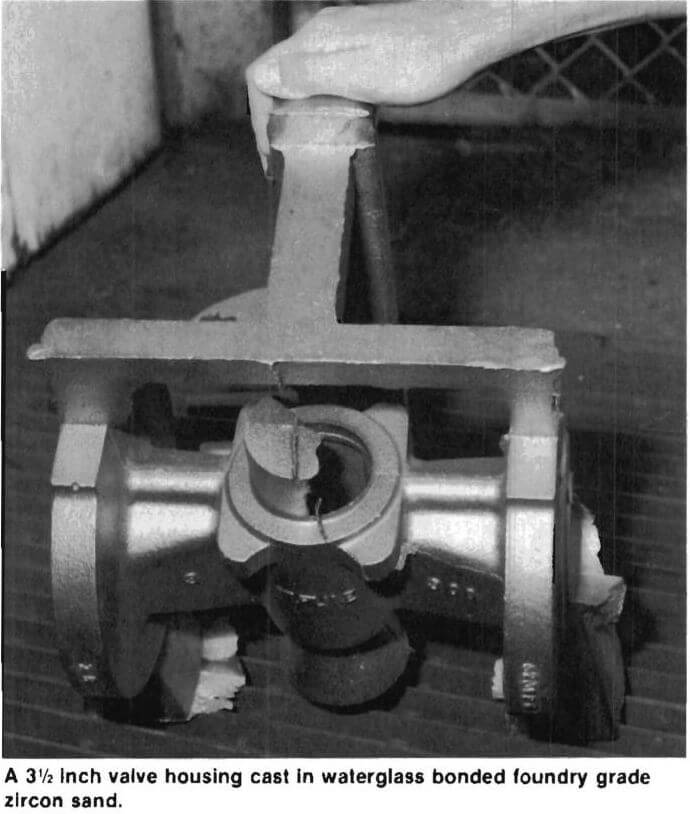

- Waterglass-bonded rammed zircon or olivine sand molds are dried at 480° F, zirconia washed, redried, and used in an inductoslag or skull-casting furnace.

- Waterglass-bonded zircon or olivine sand shell molds arc formed at 560° F, cured at 620° F, zirconia washed, dried at 480° F, and used in an inductoslag furnace.

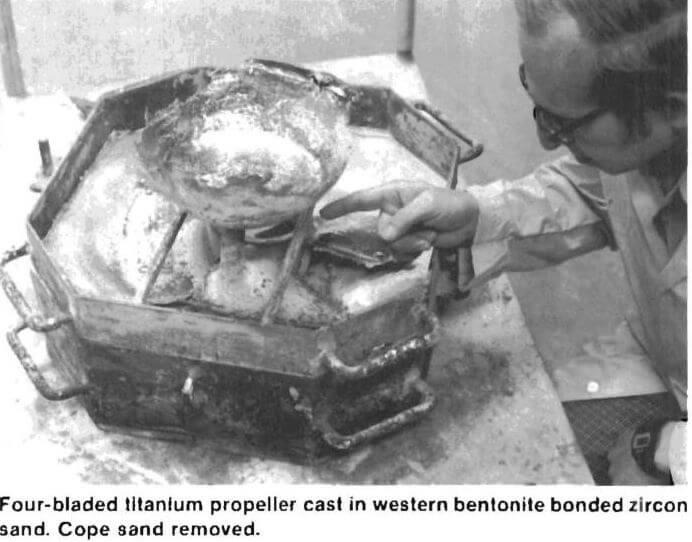

- Rammed zircon and olivine sand molds are bonded with western bentonite, zirconia washed, dried at 980° F, and used in an inductoslag or skull¬casting furnace.

Test Results

Industrial-grade castings were made by all three processes. However, process 1 molds have very little green strength and must be handled carefully until dried. Process 2 molds have good initial strength and are formed on heated patterns. However, shell mixes have only been tested on a simple dump-box molding machine. Process 3 molds have excellent green strength, adequate dry strength, and are compatible with automatic, green-sand molding machines. A typical dry-sand iron or steel foundry would have all the equipment needed for the process except for the inductoslag or skull-casting furnace.

A titanium casting poured in western bentonite-bonded rammed sand is shown above. Larger gates and more-intensive sand mulling are required for titanium casting than are normally used in ferrous foundries. However, commercial equipment is adequate if the mulling cycle is extended. Patterns used for iron and steel casting can be used for titanium casting if the gate cross-sectional areas are increased.

Patent Status

The U.S. Department of the Interior is applying for a patent on this development.