Table of Contents

Underground in situ leaching is a method of in situ leaching which takes advantage of existing underground mine workings to gain preferential access to a deeply buried ore deposit. With this method of leaching, injection and recovery wells are collared in existing underground mine drifts and drilled into an undisturbed portion of the deposit. The method is currently being used to leach a copper oxide ore at the Casa Grande mine in Casa Grande, Arizona.

While there are significant operational advantages associated with underground in situ leaching, there are also some important hydrologic concerns. Maintaining acceptable rates of solution injection and recovery in wells, and distributing the injected leach solution effectively within the oxide ore zone are the primary concerns at the Casa Grande mine site.

The objective of an ongoing cooperative investigation between the Cyprus Casa Grande Corporation and the U.S. Bureau of Mines is to better understand the hydrologic conditions underlying the efficient distribution and control of leach solutions during underground in situ leaching. Cooperative activities at the Casa Grande mine involve hydrologic data acquisition, modeling studies, and on-site testing of new injection and recovery techniques. Developments thus far in this investigation are the subject of this initial paper.

Hydrologic Data Acquisition

Acquisition of pressure and flow data from injection and recovery wells is an important part of the hydrologic investigation of leaching operations. A hydrologic data acquisition system, capable of continuous monitoring of pressure and flow conditions in up to 64 wells, has been installed at the “tool crib” site. Pressure and flow sensors are installed, generally in pairs, on injection wells. Recovery well flow rates are manually recorded once or twice a day. Currently, 27 flow sensors and 18 pressure transducers have been installed at the site. Flow sensors are installed on 22 injection wells, 4 header injection lines (each header supplies three or four well fans) and the main “tool crib” injection line. Pressure transducers have been installed on 13 wells, 4 header injection lines, and the main “tool crib” injection line. Injection well flow sensors operate in the range of .2 to 10 gpm. Pressure transducers have a maximum capacity of 2500 psig. Analog signals from sensors and transducers are transmitted to a multiplexing unit located 200 ft from the wells, in an adjacent drift. Digital output from the multiplexor is transmitted to a data recorder also located in the mine. The recorder is linked by phone lines and a modem to a microcomputer located on the surface, which receives the data and stores it.

A logging program developed by the Bureau serves as an interface for remote digital recording of well flow rate and pressure readings. The scanning interval and configuration for each well sensor and transducer is set remotely using this program.

A database manipulation program permits real-time graphical display of the flow and pressure histories for each monitored well.

Extrinsic Permeability

Hydraulic conductivity is the constant of proportionality which relates piezometric head to flow rate in a porous media flow setting. It is also sometimes referred to as extrinsic permeability since it takes into account properties of the fluid as well as those of the medium. Extrinsic permeability conditions during leaching, arc influenced by stratigraphic heterogeneities in the ore body, by moisture controlled anisotropy, and by fracture openings.

Fracture openings have a dominant influence on permeability, since they account for a large part of the void space in a crystalline rock mass such as a monzonite copper ore body. While fractures vary in orientation, aperture, and spacing, they are generally more efficient fluid conductors than the intergranular pore network. High pressure injection of leach solution causes a more rapid response in the fractures than in the matrix, and this pressure imbalance initiates flow of solution between the fracture and matrix continui. Hence, the continuity and interconnectivity of fractures in an ore body contributes significantly to the flow behavior of leach solution.

Only stratigraphic heterogeneities can be considered to exert a static influence on permeability. Fracture openings and moisture conditions exert a dynamic, or time-dependent influence. The dynamics of fracture permeability are related to Terzaghi’s concept of effective stress, which asserts that fluid pressure must be compatible with the state of stress in the rock mass (Terzaghi, 1943). The transient redistribution of stress, due to high pressure injection of leach solution results in opening and closing of fractures, which in turn exert a temporal influence on ore zone permeability. The temporal influence of moisture conditions on permeability is fundamentally related to the non linearity of unsaturated flow. Specifically, the extrinsic permeability of variably saturated rock is dependent on the level to which it is saturated. (The geochemical effects of leaching on permeability conditions are also important, but are not dealt with here.)

Hydrodilation of Fractures

Hydrodilation refers to a hydraulic technique in which existing rock fractures are intentionally opened and/or propagated by high pressure injection of leach solution. Hydrodilation is aimed at exploiting the existing fractures in the ore body, in order to maximize solution injection and recovery rates. No propping agents are used to hold the fractures open so it is necessary to understand the conditions under which open fractures can exist in the ore body.

No matrix stress can exist across an open fracture. Thus, it is mandatory that (at least) the smallest of the principle matrix stresses in the rock matrix be zero. A zero principle matrix stress can be achieved by; 1) active release and redistribution of the stress in a zone of extension, such as around an existing mine drift, or 2) an increase in the fluid pressure to the point where (at least) the minimum total stress (sum of effective stress and fluid pressure) is completely carried by the fluid pressure. If injection pressures are sufficient to overcome the effective stress, the fractures intercepting the well open, resulting in an increased (low capacity. A general rule-of-thumb is approximately 1 psi per foot of depth (Driscoll, 1986). Since the top of the Lakeshore deposit is located 700 to 1000 ft below the surface, one could expect that the injection pressure required to open and/or propagate existing fractures (referred to here as the hydrodilation pressure) must exceed 700 psig. However in actuality, the hydrodilation pressure of “tool crib” wells, ranges from 50 to 1350 psig.

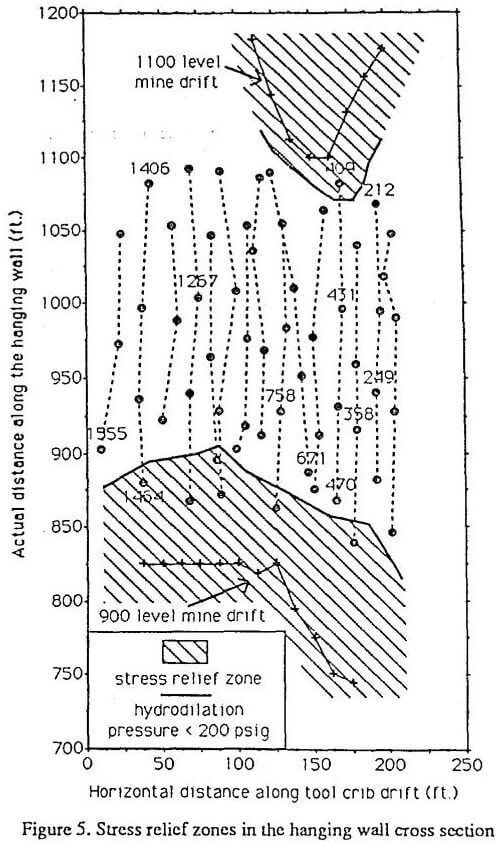

The actual hydrodilation pressure depends on whether a well is completed in competent rock in the middle of the well pattern, or in one of the stress relief zones surrounding the 900 or 1100 level drifts. The hydrodilation pressure of a well completed in the middle of the pattern reflects the hydraulic pressure needed to overcome overburden pressure, which is generally greater than 1000 psig. The hydrodilation pressure of a well completed in the vicinity of the 900 or 1100 level drifts ranges from 50 to 700 psig, reflecting the lower effective stress in this portion of the ore zone. The boundaries of stress relief zones surrounding the 900 and 1100 level drifts can be described in terms of well hydrodilation pressures. In figure 5 for instance, stress relief zones arc defined so that they include only those wells in which the hydrodilation pressure is less than 200 psig.

Changes in the extrinsic permeability and storage properties of the ore deposit as a result of hydrodilation are reflected in

changes in the proportional relationship between well injection pressure and well flow rate. As demonstration of this, short segments from the flow and pressure histories for three injection wells; 409, 431, and 212, are presented here. The flow and pressure histories were generated using the graphical data base manipulation program developed by the Bureau. The hanging wall and foot wall locations of these three wells are shown in figures 2 and 3.

Conclusions

The primary hydrologic concerns of underground in situ copper leaching are; 1) maintaining adequate solution injection and recovery rates, and 2) insuring effective distribution of leach solution within the ore zone. Insight into these concerns can be gained by investigating underlying hydrologic considerations, including, the degree of saturation of the ore zone prior to leaching, the underground mine setting, and permeability conditions.

The unsaturated condition that exists prior to leaching, has a lesser impact on solution control in the ore body than originally anticipated, since saturated conditions are shown to exist in the vicinity of tool crib injection and recovery wells soon after leaching operations begin, and since the rate at which solution goes into storage on the phreatic boundary of the plume is restricted by the low extrinsic permeability and low specific storage of the unfractured rock mass.

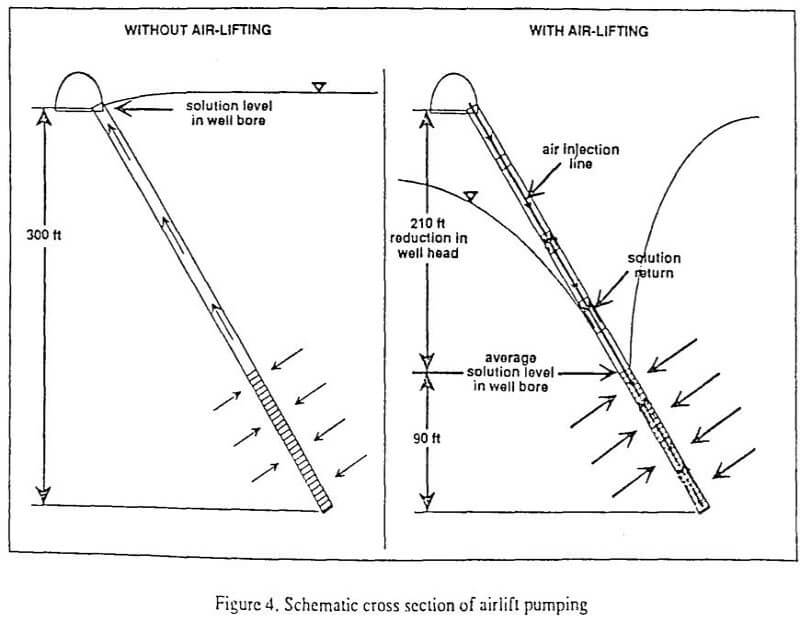

Two notable hydrologic considerations associated with the underground mine setting are, the use of small diameter wells for injection and recovery of leach solution, and the proximity of underground mine drifts to the leaching operation. Higher injection pressures are required to induce acceptable flow rates in small diameter wells. Underground drifts act as distributed sinks for injected leach solution. Airlift pumping is necessary to recover leach solution from wells that are completed within the stress relief zones surrounding underground drifts.

Permeability exerts a dominant influence on solution control and distribution concerns. In fractured crystalline rock, such as a monzonite copper ore body, permeability conditions arc largely determined by the distribution and development of fracture openings. Transient permeability conditions are demonstrated to occur al the study site as a result of coupled fluid flow and fracture deformation. Elastic/plastic deformation of fractures occurs in response to the propagation of a fluid pressure front within the fractured rock matrix. Hydrodilation pressures which exceed the overburden stress are generally required to affect a fracture volume expansion and increase the flow capacity of wells A reduced hydrodilation pressure is sufficient to affect an increased flow capacity in wells that are completed in stress relief zones.

The characterization of permeability conditions through time is necessary for maintenance of optimum pressure conditions in injection and recovery well s during leaching. Individual well pressure and flow histories reflect the changes in permeability that occur. A statistical modeling procedure can be used to generate estimates of permeability, and to verify these estimates statistically. Operational flexibility which permits easy conversion of wells from injection to recovery mode, or visa versa, is an essential in situ design requirement for accommodating changes in permeability conditions.