Table of Contents

For a number of years the cyclone, familiar to Americans as a dust collector, has been used as a thickener of suspensions at one of the coal-preparation plants of the Netherland State Mines in Limburg. The plant treats nut-size coal at 120 tons an hour in a heavy-medium washer. The diluted medium from the rinsing screens is thickened in cyclones. More recently the cyclone has been adapted to act as a coal cleaner.

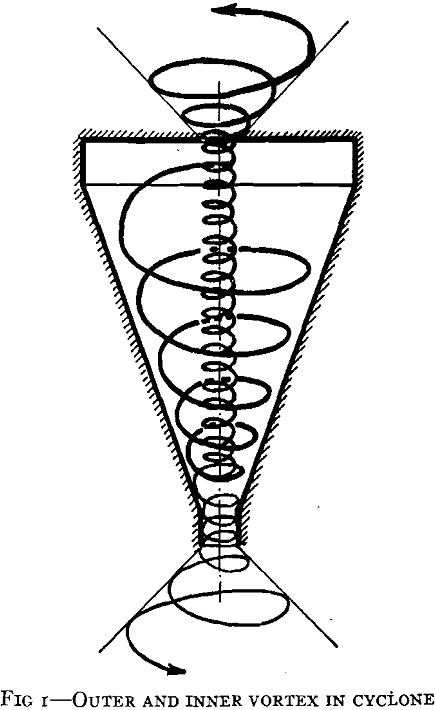

Method of Judging Performance of Coal Washer

Geologists, rather than mechanical engineers, would be able to describe the separating or stratifying effect in nature, but even a bather on the shore lying on the soft sand near the sea wonders why all the small sand grains have approximately the same size. A child playing on the border of the river could easily collect a hundred pebbles of practically the same diameter. When a mine shaft is sunk the overburden is often divided into horizontal strata of sands of different colors and particle sizes. In our country (The Netherlands, Limburg) and in China thick layers of so-called loess cover the earth; its main characteristic is that the sizes of the particles, although considerably smaller than those of sand, are limited within very small boundaries.1 The theory generally adopted for loess is that it is an air-borne material, which has been deposited on quiet places.

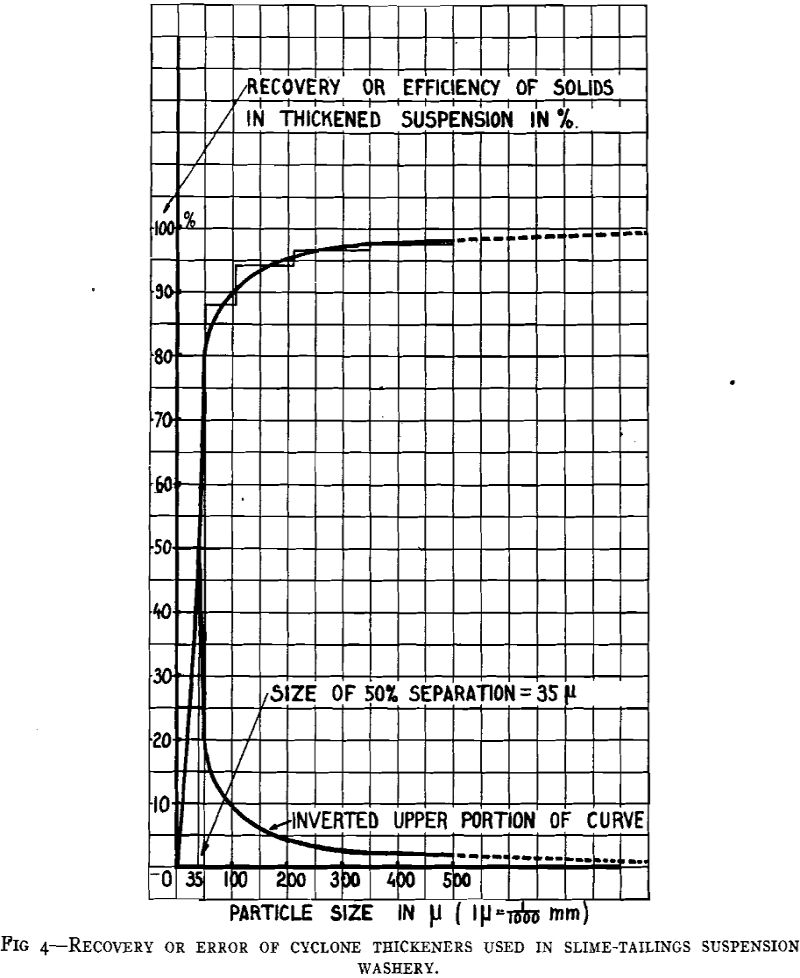

Efficiency or Recovery Curves of Cyclones

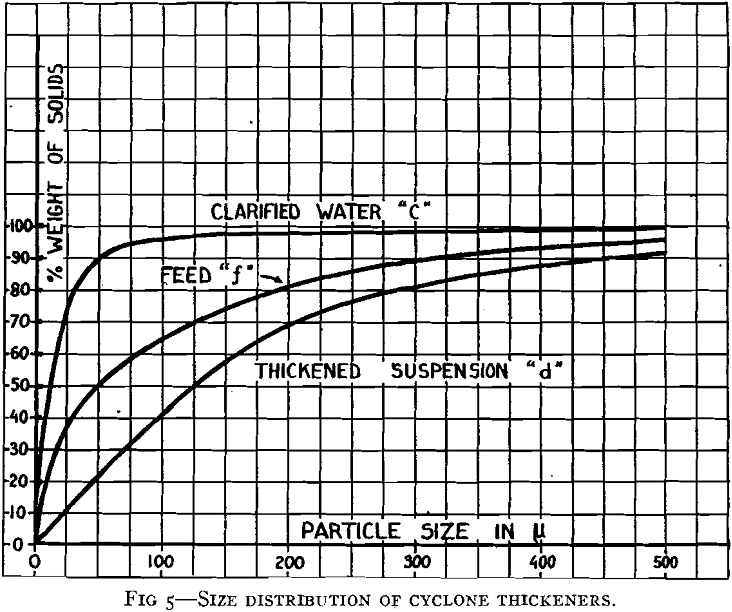

A cyclone used in washery practice can be looked at from different viewpoints. The particle size of the suspension or the specific gravity of the particle

introduced into the cyclone, or both, may be the physical property for which a separation is required. In the first case we have a cyclone thickener, where a suspension in water or other liquid is

introduced into the cyclone, and where a separation takes place between the coarser and the finer suspension particles. In the cyclone washer we are interested in the separation of particles according to their specific gravity, but as we introduce these particles together with a suspension, a separation of the suspension particles according to size takes place at the same time. It may be described also in this way: Superposed on the thickening effect of the suspension particles is the washing effect of the coal and shale particles, which are introduced together with the suspension.

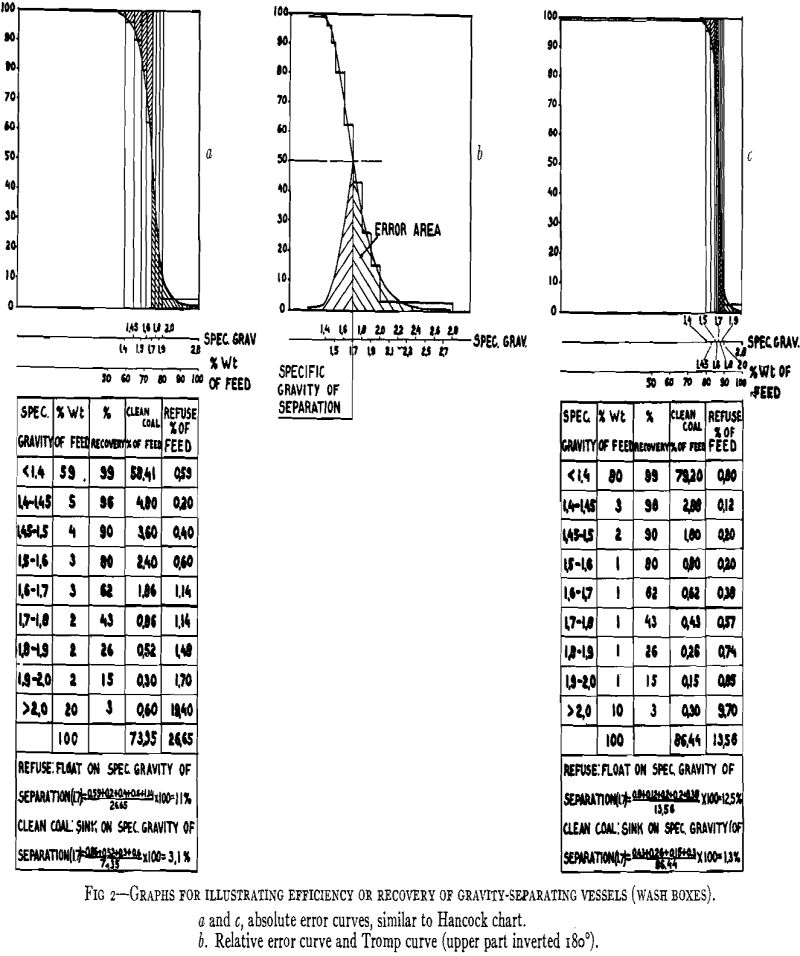

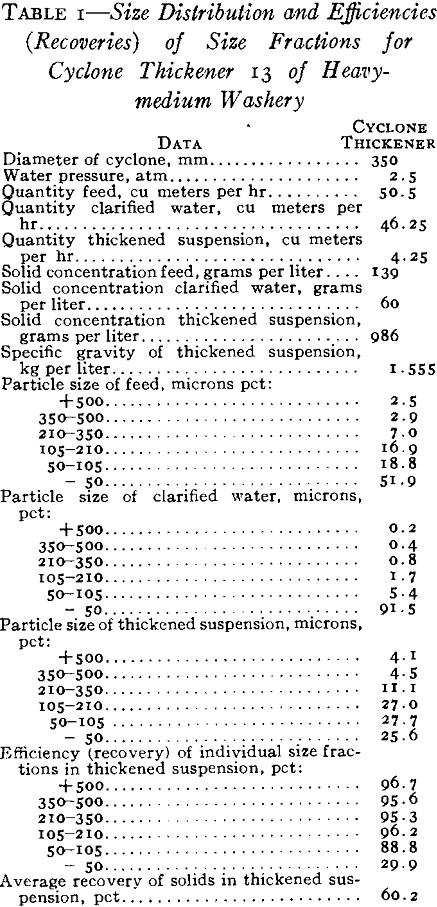

Example of Cyclone Thickeners

Fig 3 shows a flowsheet of a suspension washery working at the rate of 120-ton per hour on slime tailings from the froth-flotation plant at the Netherland State mine, Maurits, in which a cyclone thickener is used. Raw 8 to 90-mm coal (5/16 to 3¼ in.) is fed to the plant by a belt conveyor 1 and screened to remove the undersize by vibrating screens 2 and 3.

The rinsing water, enriched with the heavy suspension from the coal, middlings and shale, flows to a vibrating screen 11, where the coarser coal and shale particles are screened. From there the water flows to the frother 10, where the fine coal particles are eliminated. The regenerated tailing water flows to the pump tank 12. From there the suspension is pumped to the cyclone thickeners 13, and is thickened to the required specific gravity of the wash box. The clarified water of the cyclones 13 flows to the rinsing-water tank 14, from which it is distributed to the screens 5, 9 and 9a. Part of the rinsing water flows to a smaller and more efficient cyclone 15, the overflow of which is better clarified than that of the main cyclones 13, so that it may flow to waste as an effluent of the system. The thickened material of the small cyclone 15 is returned to the circulating flow system. Clear water is admitted to screens 5, 9, and 9a for final rinsing of the washed products.

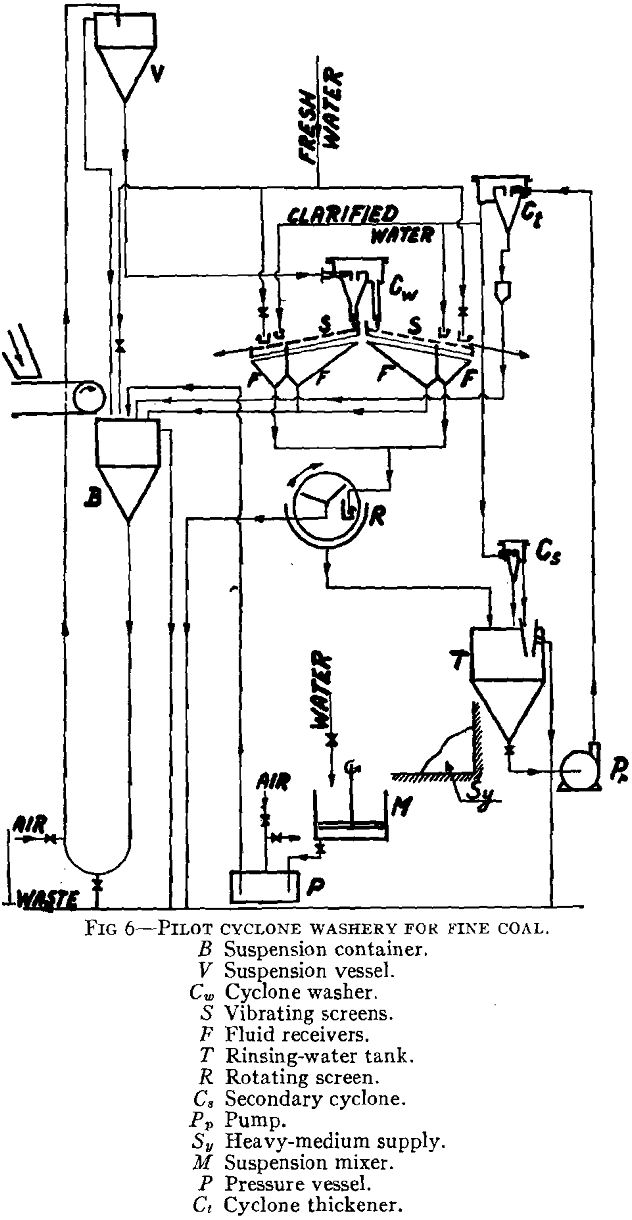

Example of Cyclone Washer

Raw fine coal is admitted from a coal hopper by means of a belt conveyor into container B, filled with the suspension of the desired specific gravity. An air lift pumps the mixture to a vessel V, placed about 13 m (43 ft) above the cyclone washer. This height is sufficient to furnish the necessary inlet pressure for cyclone CW. The air lift is installed to take care of local conditions at the laboratory. An actual plant would provide for a bucket elevator to bring the fine coal directly to vessel V.

The separated products, coal and shale, leaving the cyclone are discharged on two

vibrating screens 5. Under each screen two fluid receivers F are placed; the first takes the undiluted suspension and returns it to container B and the second takes the rinsing water, enriched with the suspension washed off over the second part of the screen. The rinsing water then passes to a rotating screen R to remove the coarser coal and shale particles and arrives in a tank T, from which the pump Pp, delivers the rinsing water to the cyclone thickener Ct.

Ideal Two-Dimensional Flow of Nonviscous Fluid

The motion of the liquid in a cyclone can be described comparatively easily if an ideal nonviscous fluid is assumed.

In this case the motion can be thought of as a superposition of a vortex and a sink, each of which is a potential motion, so that the potential functions can be added together.

Fig 9a shows the streamlines and the velocities of a vortex with circulation K and increasing tangential velocities v toward the center but without vorticity, in areas that exclude the center of rotation.

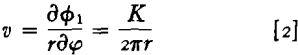

The potential function, written in cylindrical polar coordination r and φ is:

and the tangential velocities can be found as follows:

Fig 9b shows the streamlines and the velocities of a sink with a constant capacity —e and increasing radial velocities toward the center. The potential function is:

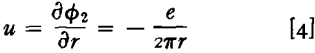

![]()

and the radial velocities can be found as follows:

Fig 9c shows the superposition of Figs 9a and 9b. The potential function is:

![]()

The velocities c in the direction of the streamlines are:

![]()

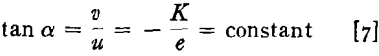

and the direction of the streamlines with reference to radius R is given by:

from which it follows that the streamlines are logarithmical spirals.

Summary

The principle and behavior of cyclone thickeners and washers are described and flowsheets showing the position of the cyclones in heavy-medium washeries are included.

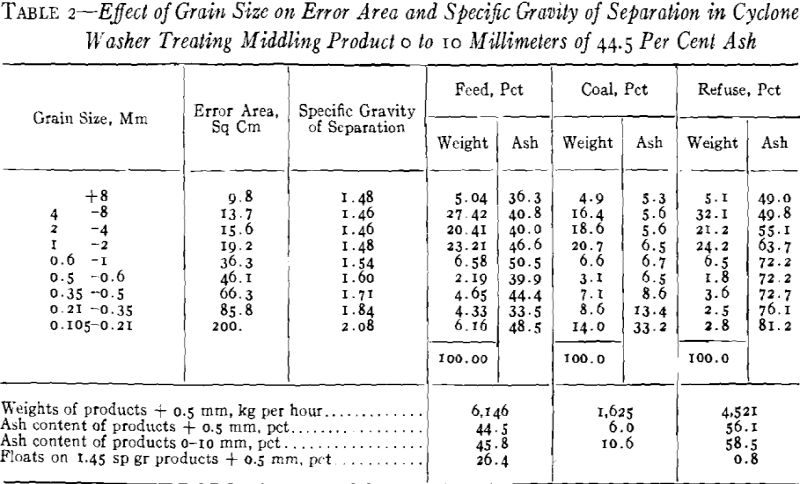

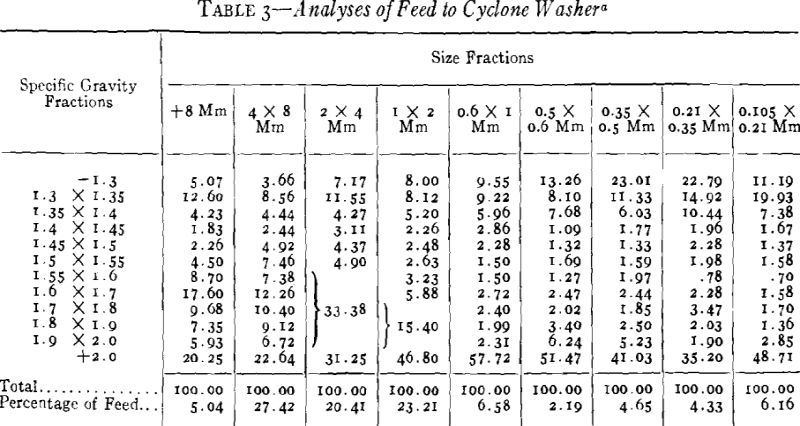

A method of error curves, to judge the effect of separating apparatus, is developed and specialized as well for the cyclone thickeners separating small particles into coarser and finer fractions as for cyclone washers separating particles of various specific gravities into heavier and lighter fractions.

An example for the cyclone thickener is given, showing that the “separating size” where 50 pct of a certain fraction is caught is situated at a grain size of about 35µ.