Table of Contents

In an autogenous grinding circuit in which feed at approximately nine inches top size is reduced to a size suitable for subsequent processing, the build-up of a “critical size” fraction in the media causes problems. A “critical size” fraction has been defined as, “media too small to effect reduction by impact grinding of ore coarser than a quarter of an inch and too large to be broken by the largest size of media in the charge.

Crushing of the “critical size” fraction effectively coarsens the size distribution of the remaining media. By controlling the amount of crusher feed, it appears possible to control the size distribution of the grinding media and, consequently, the size distribution of the mill discharge.

This control could allow the grind produced by the autogenous mill to be changed at will over a certain limited range, or conversely allow for close control of the grind at a predetermined fineness.

Description of Pilot Plant

These investigations were carried out at the pilot plant facilities of the Institute of Mineral Research, Michigan Technological University, Houghton, Michigan.

The autogenous grinding unit was a six foot diameter by two foot length Hardinge Cascade mill with 3/8 inch slotted steel grates. Pebble ports cut into the grates allowed passage of pebbles having a top size of approximately 2½ inches.

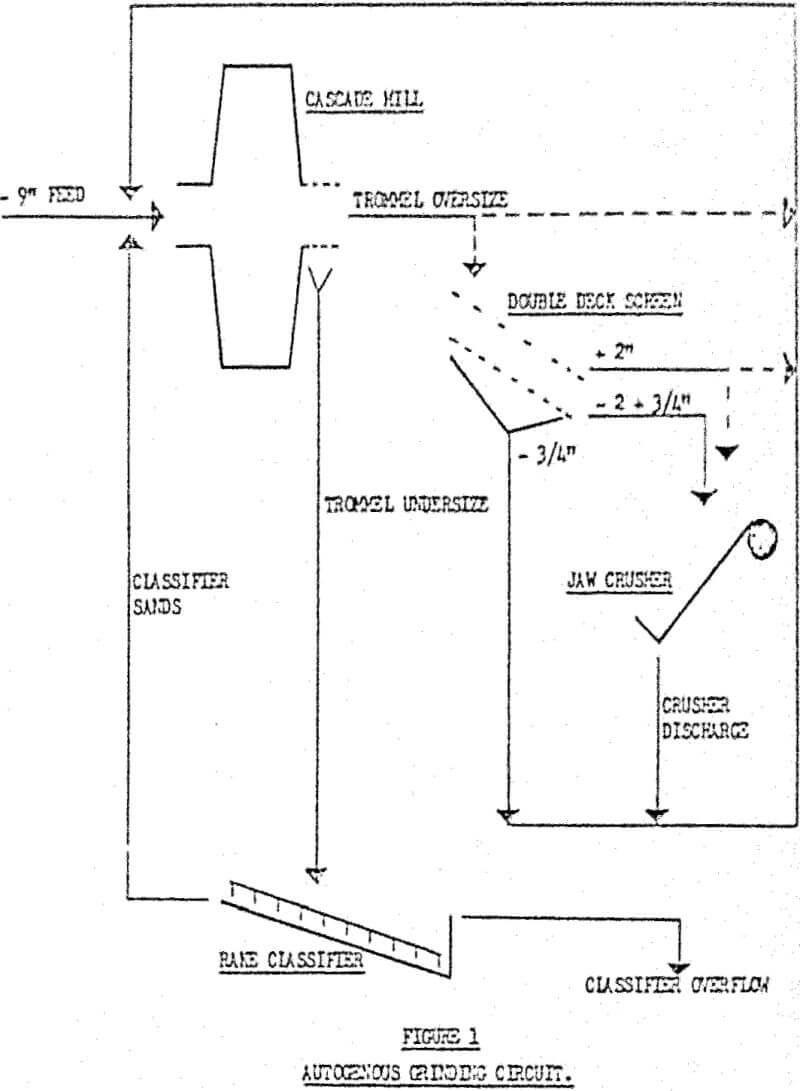

The grate and pebble port discharge material passed over a 3/16 inch trommel screen with the trommel undersize being pumped to the classification device. D.S.M. screens were employed for classification in the early investigations, but were replaced later by a small Dorr rake classifier. The trommel oversize material returned to the mill via scissor conveyors.

When the crusher was incorporated into the circuit, the trommel oversize material passed to a double deck vibrating screen fitted with 2 inch and ¾ inch square mesh screen cloths. The plus 2 inch and the minus 2 plus ¾ inch size fractions were combined and crushed to a nominal one inch in a 4 x 6 inch jaw-crusher. The crusher discharge and the minus ¾ inch screen undersize returned to the mill.

Description of Samples Employed

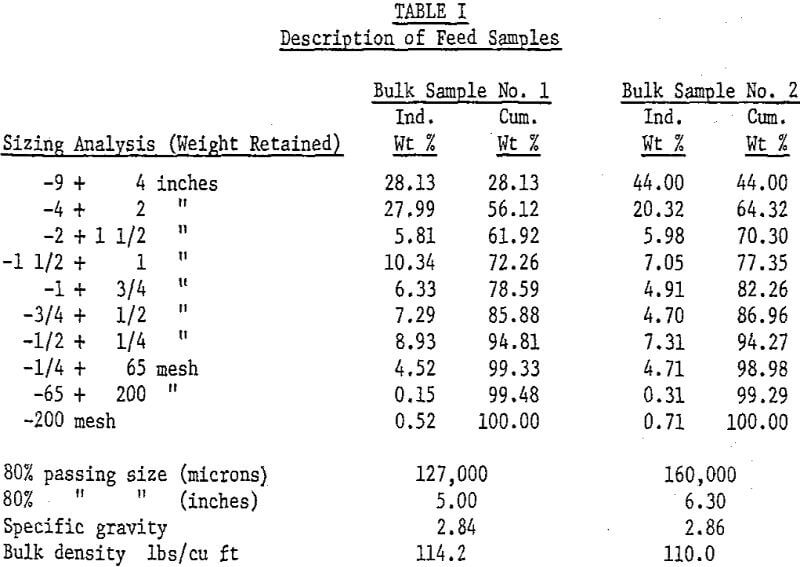

Two samples of ore were employed in these investigations. Bulk Sample 1 was employed in the investigations having the objective of determining the most suitable autogenous grinding flowsheet for this ore deposit. Bulk Sample No. 2 was employed in the final investigation which attempted to demonstrate the degree of control of the grind made possible by the use of a crusher. This sample was a composite of four bulk samples taken from different sections of the ore body.

The host rocks exhibit a wide variety of primary lithologic features, including volcanic agglomerates, wackies, tuffs, tuffaceous siltstones, interbedded lavas of porphyritic andesite and pre-ore intrusions of diorite, monzonite and syenite. Subsequent extensive metamorphic alteration resulted in rocks of exceptional hardness and toughness. Copper mineralization occurs predominantly as chalcopyrite with minor amounts of bornite. Pyrite is the most common sulphide mineral but seldom exceeds 5% by weight of the ore.

Results of Investigations

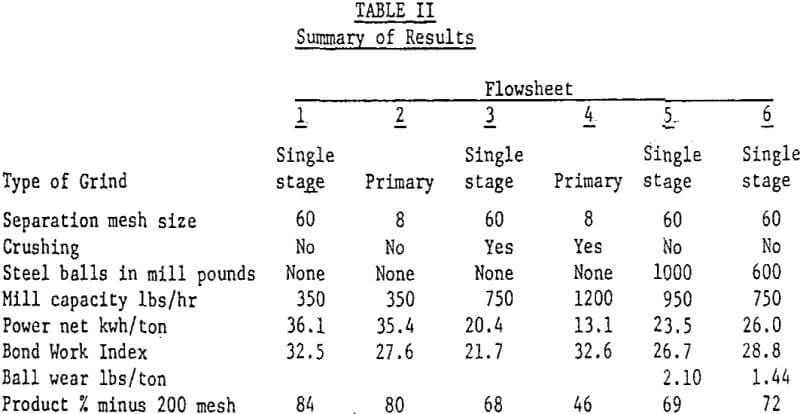

Six autogenous grinding flowsheets were investigated, including:

- Single stage autogenous grinding to produce a minus 60 mesh finished product.

- Primary autogenous grinding to produce a product suitable for second stage pebble milling.

- Single stage autogenous grinding to produce a minus 60 mesh finished product, with a crusher in the circuit to crush the minus 2½ inch pebbles to minus 1 inch.

- Primary autogenous grinding to produce a product suitable for second stage pebble milling, with a crusher in the circuit to crush the minus 2½ inch pebbles to minus 1 inch.

- Single stage autogenous grinding with 1000 pounds of minus 5 plus 3 inch steel balls in the mill to produce a minus 60 mesh finished product.

- Single stage autogenous grinding with 600 pounds of minus 5 plus 3 inch steel balls in the mill to produce a minus 60 mesh finished product.

Effect of the Crusher on the Size Distribution of the Grinding Media

When a selected size fraction of the media in an autogenous mill is removed and crushed down to a size at which it is no longer effective as grinding media, the size distribution of the remaining grinding media is changed appreciably. The minus one inch material in the mill charge has been arbitrarily assumed to provide no useful grinding function and has been omitted from the calculations.

Without the crusher in the circuit the grinding media contained 30.3% by weight of plus 3 inch material; with partial crushing of the minus 2½ inch pebbles the plus 3 inch material increased to 60.5% by weight, and with crushing of all the minus 2½ inch pebbles it is calculated that the plus 3 inch material would amount to 78.8% by weight of the charge.

To determine whether the products produced by the autogenous mill circuit incorporating a crusher could be closely controlled at the required 65% minus 200 mesh, the pilot plant was operated continuously on a 24 hour per day basis.

This investigation was carried out on Bulk Sample No. 2. The Cascade mill was completely relined before the start of the run and the number of pebble ports increased from five to seven. Relining the mill affected the operating characteristics and the new sample was found to have somewhat different grinding characteristics to Bulk Sample No. 1. Several days’ operation were required to bring the circuit in reasonable balance.

The mill pulp density averaged 58.3% solids with swings from 54.0% to 60.8% solids. The classifier overflow density ranged from 24.4% to 27.6% with a median of 26.6%. The average circulating loads of intermediate products were 73% of plus 2 inch pebbles, 45% of crusher discharge, and 123% of minus ¾ inch screen undersize.