Table of Contents

Objective: Use water-jet-assisted cutting technology to reduce the exposure of mine workers’ to respirable dust.

Approach: Install water-jet-assist on mining machines and evaluate its impact on respirable dust.

How it Works

Water-jet-assisted cutting involves a mechanical cutting bit working in combination with a moderate pressure (generally up to 10,000 psi) water jet directed just in front of, or through, the bit tip. One of its advantages is reduced dust generation because the jet wets the face of the material being cut more efficiently than a conventional low-pressure water spray, thus capturing much of the dust before it ever becomes airborne. It also removes loose cuttings ahead of the bit before they are pulverized by the bit into respirable dust. Total water consumption is about the same as for conventional low pressure dust control water spray systems. However, there is some increase in power consumption because of the energy needed to provide the high pressure water.

Test Results

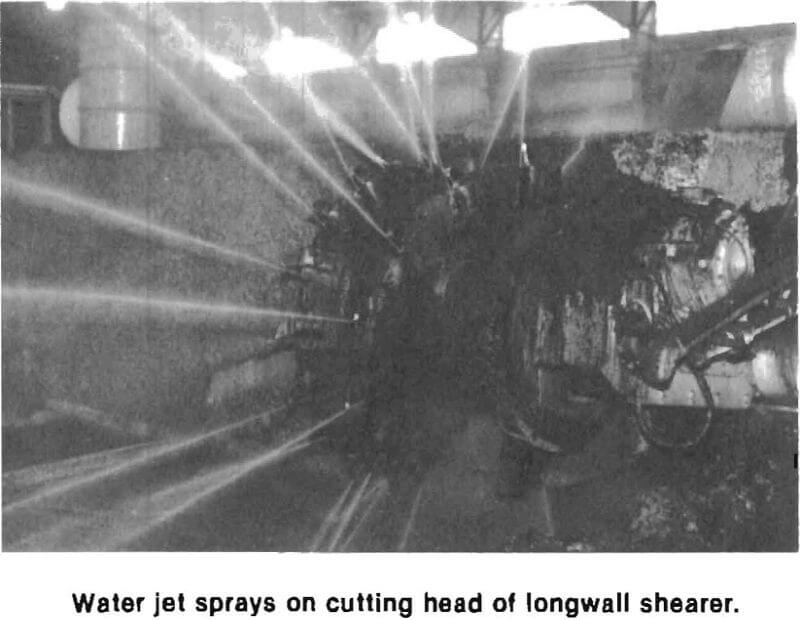

Longwall shearer

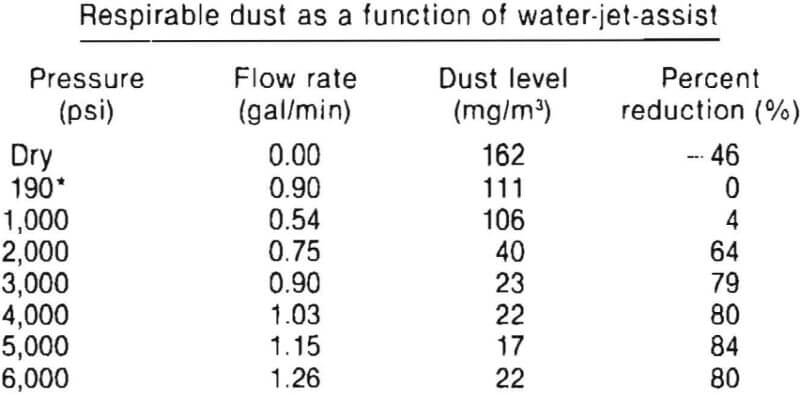

A water-jet-assisted longwall shearer was used in cutting trials on a simulated coal block consisting of 85 percent coal and 15 percent flyash and cement. The water jet pressure was varied from 0 to 6,000 psi. Each of the 32 cutting bits on the cutting drum had a 0.024-in orifice water jet nozzle, located in the bit block approximately 4 inches from the bit tip. These delivered a solid stream of water to within 3 mm of the bit tip. The 54-in diameter cutting drum trammed at 5 ft/min and had a rotational speed of 46 rpm, which translates to a bit tip speed of 650 ft/min. Dorr-Oliver 10-mm nylon cyclones, located near the cutting drum and at the operator location, were attached by plastic tubing to continuous recording dust monitors. The average dust levels measured at the different water pressures and flows are given in the follow

ing table along with the percent reduction versus a conventional spray pressure of 190 psi.

As the pressure was increased to 3,000 psi, significant dust reductions occurred; further increases in water pressure had no dust reduction effect. The same flow rate was used at 3,000 psi as was used at 190 psi. The effect of water-jet-assist on dust levels appears to be a combination of both pressure and flow rate.

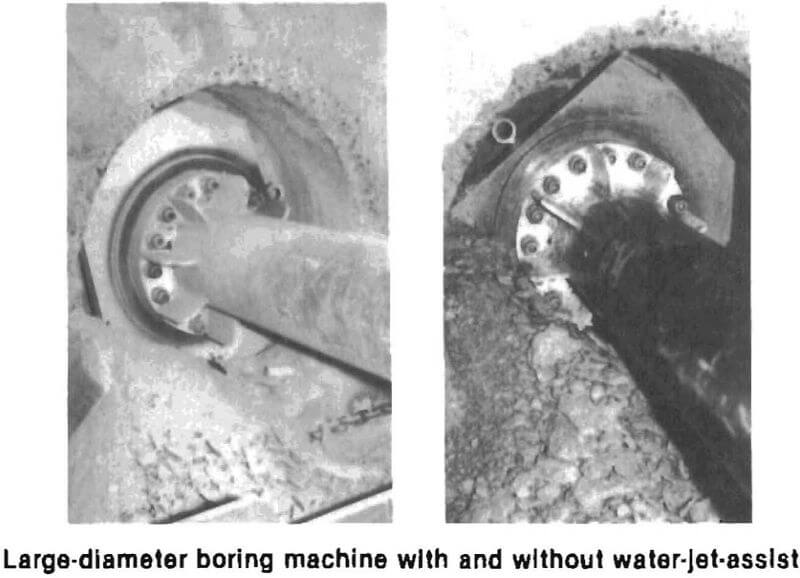

Large-diameter boring machine

Tests using a water-jet- assisted large-diameter boring machine gave both visual and measured evidence of dust reductions while cutting a variety of rock types. Regardless of the type of rock cut, 3,000 psi water-jet-assist resulted in dust reductions of more than 70 percent over dry cutting. The photo¬graph demonstrates the difference between cutting with and without high pressure water on this machine.

Roadheader

Respirable dust measurements by the Canada Centre for Mineral and Energy Technology on a water-jet-assisted roadheader cutting both coal and rock in a Canadian coal mine and measurements made by the Bureau on a roadheader operating in a U.S. copper mine showed dust results similar to those for the longwall shearer. In both cases, major dust reductions occurred as the water

pressure was raised to about 3,000 psi; no significant reductions occurred above that pressure. Research on water-jet-assisted road- headers by the National Coal Board of Great Britain, under a Bureau contract, also showed that water-jet-assist can provide significant respirable dust control benefits.