Hydrostatic Bearing Type Center Mechanism

Development of the Hydrostatic Bearing Mechanism evolved from the caisson thickener design. Conventional thickener mechanisms are driven by gearing which rides on ball or roller type anti-friction bearings. It would not be feasible to use this method of support with a very large diameter bearing, especially with high torque, vertical and unbalanced loads. Additional stresses […]

Dewatering Clay

Phosphatic clay waste is one of the principal waste products resulting from the mining and benefication of Florida phosphate ore. This waste material, which is comprised of ultrafine particles (70 pct less than 1 µm), responds poorly to conventional solid-liquid separation techniques and is currently disposed of by impoundment behind earthen dams. The overall natural […]

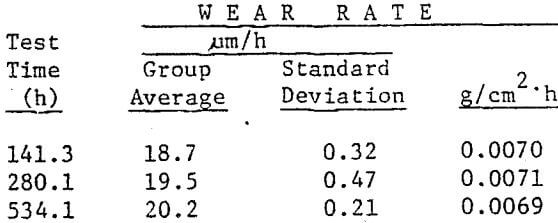

Marked Ball Wear Test

Marked ball wear testing described in a 1948 paper by Norman is an invaluable test method to measure relative and/or absolute wear rates of balls under identical mill operating conditions. Preparation of balls at Armco consists of drilling a 6.4 mm diameter hole in each ball with an electrical discharge machine (EDM), cleaning, weighing, placing […]

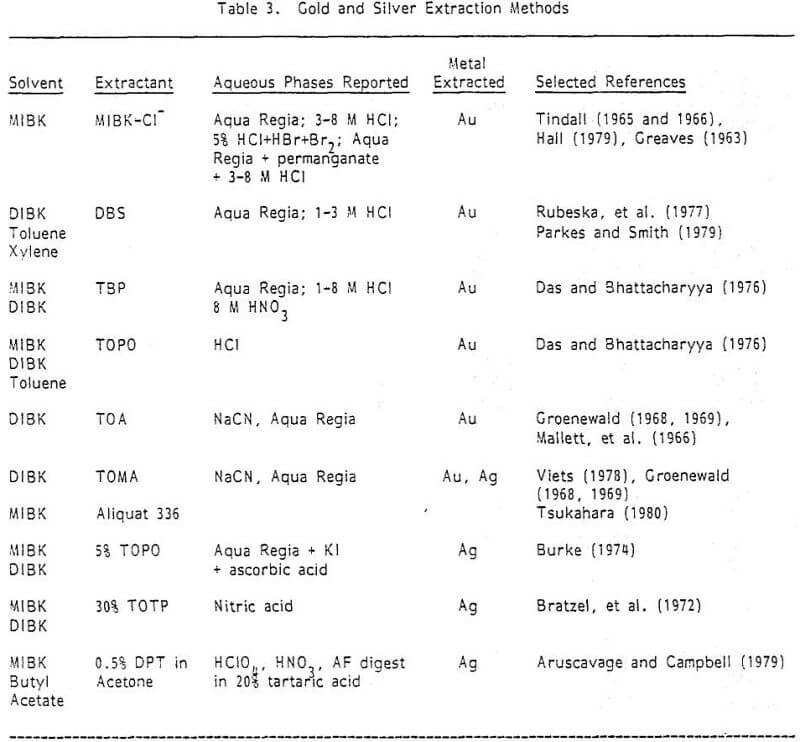

Flameless AAS Atomic Absorption Spectroscopy

Flameless AAS provides a means to increase flame AAS sensitivity, by up to 200 times. Interferences from aqueous leachates and digestates are so great, however, that flameless AAS has found application mainly after organic extraction. Thereby, the analytical sensitivity is increased far beyond that of the SX/flame- AAS methods. Interferences Interferences from other elements have […]

Neutron Activation Analysis for Silver

Gold values in the surveyed sulfide-poor rock units proved to be generally even lower than those in sulfidic sandstone. As a further check on this survey of mineralization, silver values began to be measured by NAA on the silver-gold beads. Radioactivity induced in silver by neutron bombardment is long-lived. The half-life of 110mAg is 253 […]

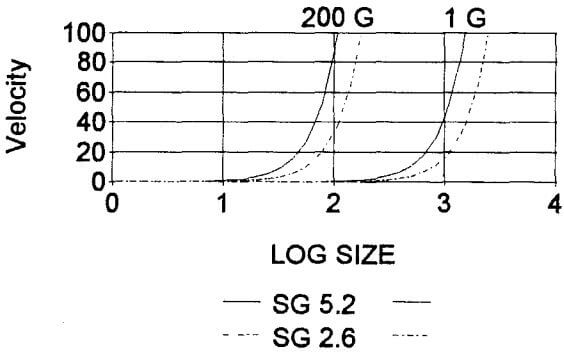

Falcon Enhanced Gravity Separator

Enhanced gravity separation devices (centrifuges) have been patented for over a century but were impractical until recently. The physical laws behind the concept were well understood but engineering had to catch up with the science. This included the development of abrasion resistant materials, the improved design of rotating equipment that allowed higher RPM, and a […]

Compression Tests Iron Pellets

A number of compressive tests were conducted on iron ore pellets obtained from the Samarco pelletizing plant located at Ponta Ubu, Brazil. These pellets are formed by disk pelletizing of a mixture consisting of hematite iron ore, (particle size less than 50 µm) water, and lime; they are hardened in a traveling-grate furnace and the […]

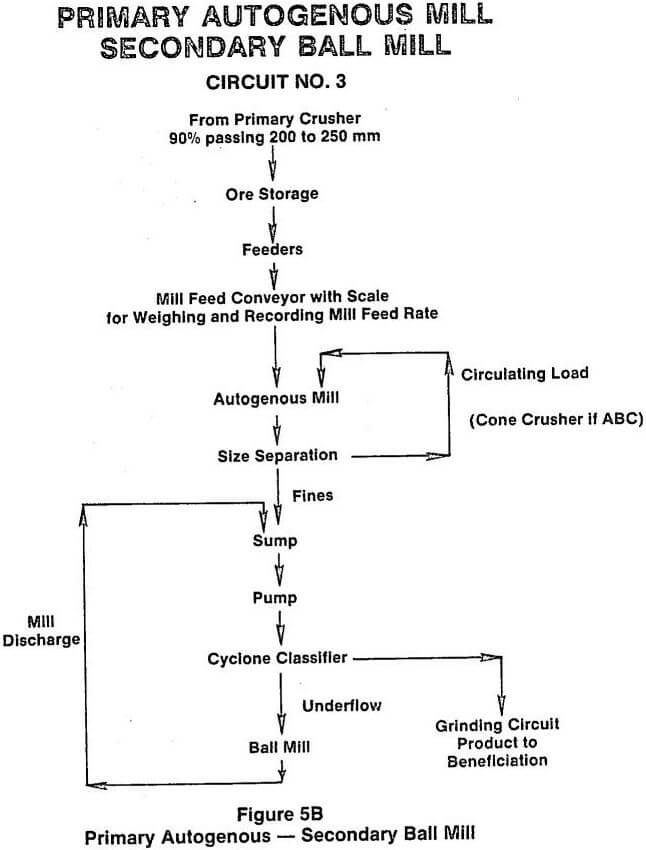

Autogenous and Semi-Autogenous Grinding Mill Testing

Ff the drill cores indicate that the ore could contain sufficient lumps in the sizes needed for ore media in autogenous and semi-autogenous grinding, then bulk samples (750 kg) of mine run or primary crushed ore, with an even distribution by quantity in the size fractions between 100 mm and 200 mm, should be obtained […]

Grinding Media Corrosion Rate

While grinding is unavoidable in nearly all mineral processing, it is an inefficient and costly step. As an example, the National Academy of Sciences (NAS) estimates that the copper industry consumed 205,000 tons of grinding media in 1978. A typical copper producer processing 100,000 tons of ore per day may spend approximately $25,000 daily to […]

DSM Wood Chip Removal Screen

One of the minor but occasionally troublesome problems in the Creede plant is related to the clayey nature of some of the ore from the mine. At times the thickener underflow is so clayey that it forms a rope which can almost be carried around without a bucket. As described in the previous report: ” […]