Zinc Hydrometallurgy Solvent Extraction

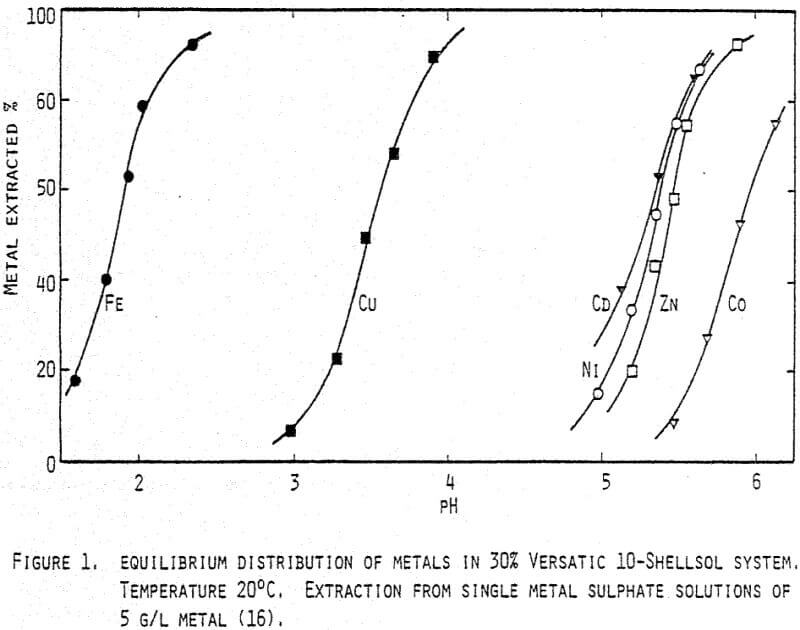

Part of Zinc Hydrometallurgy and Zinc Solvent Extraction includes the zinc and iron sulphate solution from the hot acid leach will typically contain 80-100 g/l Zn, 20-30 g/l Fe, mostly in the ferric state, and 40-60 g/l free sulphuric acid. The sulphuric acid concentrations will depend upon the leaching techniques used, and the composition of […]

Alunite Crystal Chemistry

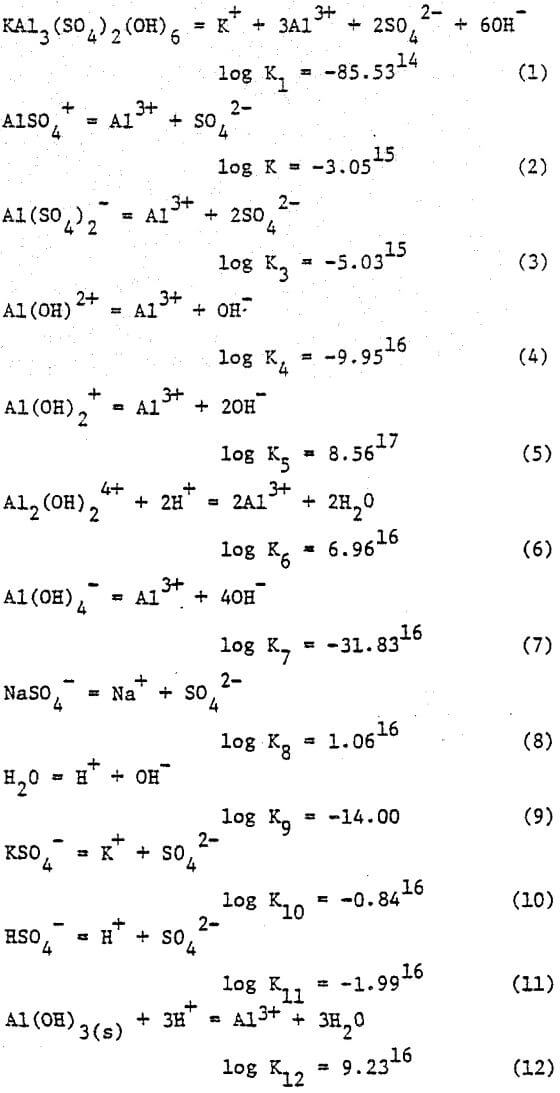

Alunite has been described both by the chemical formula [KAl3(SO4)2(OH)6] and by the chemical formula [K2SO4·Al2(SO4)3·2Al2O3·6H2O]. The latter gives an erroneous impression that water is structurally associated with the mineral. The former representation is therefore, to be preferred. It is more in conformity with the crystal structure of alunite. The structure of alunite is similar […]

Calculating Stockpile Capacity

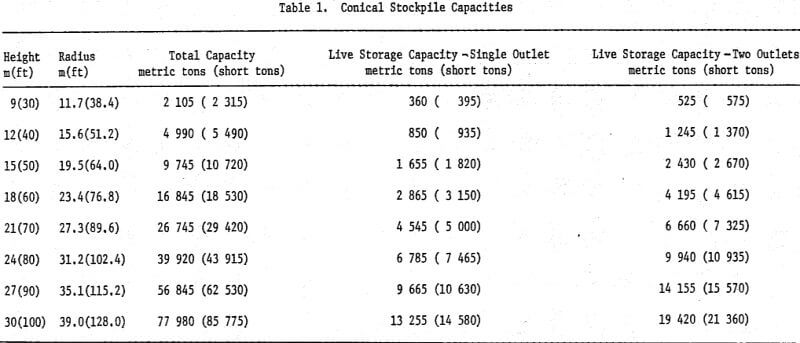

Calculating Stockpile Capacity: Once the minimum storage capacities which will assure maximum mill output are known, the appropriate stockpile configuration must be determined. Stockpiles fall into two general categories: conical and elongated. Conical Stockpiles The conical stockpile is the simplest and easiest to analyze. The total stockpile capacity is given by: 3.14 (Tan A)R³ D/3000 = […]

Portland Cement Kiln Dust Reprocessing

From 10 to 12 million tons of cement kiln dust accumulate annually at domestic cement plants. This finely divided dust is emitted from cement kilns to prevent the buildup of excessive salts in the cement product. The alkali salts in the dust are derived from the clay raw materials, which include potassium and sodium feldspars. […]

Ferric Chloride Thiourea and Brine Leaching to Extract Ag-Au

Independent mine operators have difficulty marketing complex gold-silver concentrates and ores. Generally, complex sulfide concentrates and ores cannot be handled by existing smelters. Even when handling them is technically possible, smelter charges and transportation costs become limiting factors. Hydrometallurgical methods are seriously being considered to provide a simple, inexpensive, low-pollution process to treat complex gold-silver […]

Sulfation Leaching Treatment ilmenite Concentrate Titanium Slags

The United States depends upon imports to supply most of the rutile and up to 70 pct of the ilmenite and titanium slag requirements for the manufacture of TiO2 pigments, titanium metal, and welding rod coatings. To help assure an adequate supply of titanium raw materials to meet national economic and strategic needs, the Bureau […]

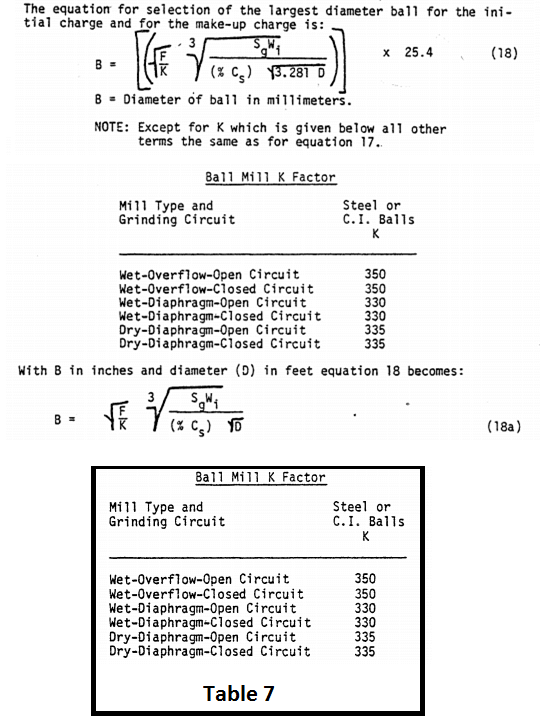

Grinding Ball Diameter Calculation

How to Size a Rod Mill Grinding Rod Diameter

How to Size & Design a Regrind Ball Mill

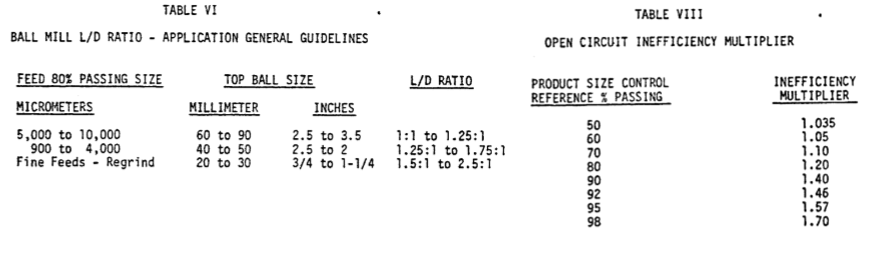

Regrind Ball Mill F = 210 micrometers. P = 45 micrometers. Wi = 14.0 W = 10 x 14.0/√45 – 10 x 14.0/√210 = 11.21 kwh/s. ton Efficiency Factors: EF1 does not apply. EF2 Many regrind operations are closed circuit, but assume this one is open circuit and 80 percent passing grind will be […]

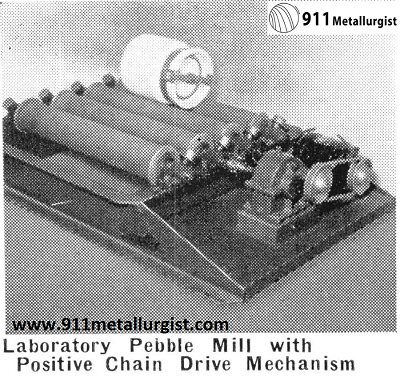

Pebble Mill Design Calculations – HOW TO

Pebble Mill: Rod Mill Pebble Mill Circuit The calculation for determining grinding power for Pebble milling (secondary autogenous) can be the same as for ball milling from rod mill product size to the desired specified size, neglecting the diameter efficiency factor if less than 1.0. 5.47 x 1.102 x 1.341 x 500 = 4039 […]