Cone Crushing, Rod Milling and Ball Milling Laboratory Testing

The two largest cost components in comminution circuits are energy consumption and metal wear which, for cone crushing, rod milling and ball milling, can be established by conducting laboratory bench scale tests. Pilot plant testing for these comminution methods is not normally required. Laborary testwork performed by Allis-Chalmers to identify these parameters are covered by: […]

Chromite Flotation

Careful studies of the fundamentals of chromite flotation have been made recently in the United States and in Poland. Palmer (1972), Palmer, Fuerstenau and Aplan (1975) and Fuerstenau and Palmer (1976) have demonstrated the importance of the presence or absence of charged metal hydroxy species in such flotation. These species appear particularly to influence anionic […]

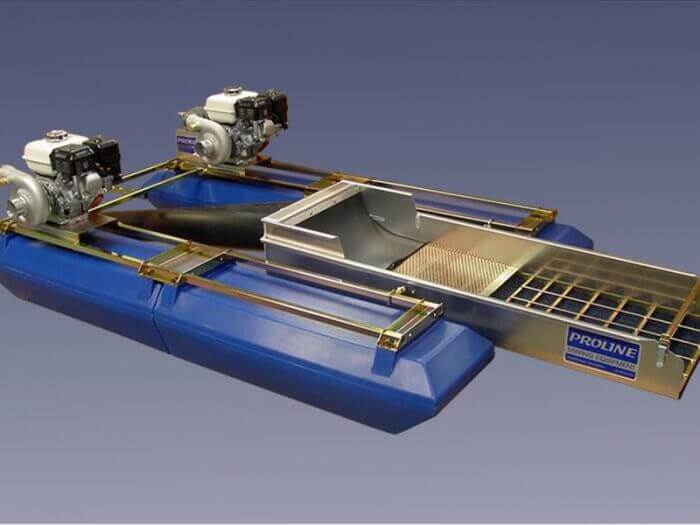

Diamond Dredge

With regards to diamond dredges and dredging, the kings of the 1970s were Consolidated Diamond Mines and Marine Diamond Corp. both parts of the famous DeBeers company, control the coast of the Namib Desert and the waters and more important, the ocean floor and beaches of this treasure cheat of gems. So rich were the original […]

Ceramic Mold Inserts

For many years, the diecasting process has been employed by the nonferrous foundry industry. In this process, castings are produced by forcing molten metal under high pressure into reusable permanent metal molds commonly called dies. Figure 1 shows the sequence of steps normally used in diecasting. Although zinc-base and aluminum alloys account for the bulk […]

How Ball Mill Ore Feed Size Affects Tonnage & Capacity

The important of crushing your ore and rock fine and properly is often forgotten. The finer you crush, the higher your ball mill tonnage and capacity will be. The effect of ball mill feed size and how it affects circuit throughput can be hard to estimate. Here we described a method of designing a crushing […]

Induction Heating in Fire Refining of Silver & Gold

The use of induction heating as an alternative to gas or oil fired heating for the fire, refining of precious metals is attractive for several reasons: (1) compactness, (2) less waste heat, therefore cooler room temperatures, (3) cleaner operation, (4) no off-gas discharge, (5) energy efficient as less material heated and (6) less time to […]

Carbon in Pulp Plant

Sslurry at a rate of approximately 3.785 cu. m. per minute (1,000 GPM) is placed in contact with activated carbon. A simplified flow-sheet of the CIP Plant is shown in Figure 2. For years it has been known of the affinity of activated carbon to adsorb preferentially the gold and silver in cyanide complex form. […]

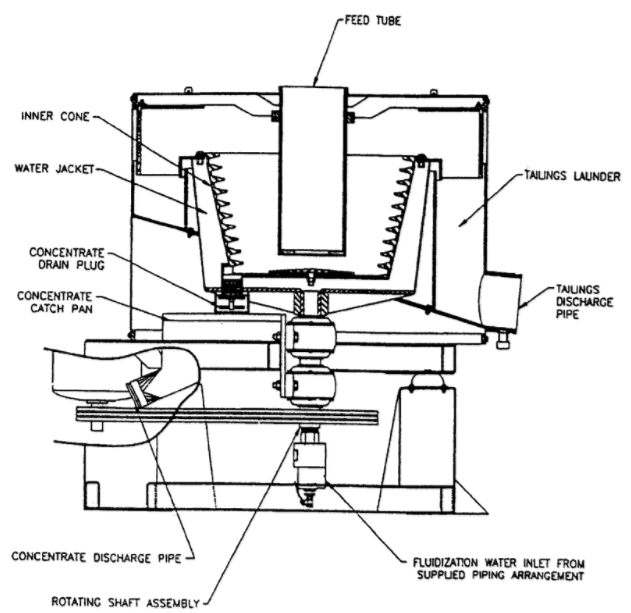

Knelson Concentrator

The Knelson Concentrator relies on an enhanced gravitational force together with fluidization process to recover even very micron sized particles. First water is injected into the rotating concentrating cone through series of fluidization holes. Then feed slurry is introduced through a stationary feed tube. Once the slurry is filled in each cone, create a concentrating bed […]

Recovery of Cadmium from Scrap Batteries

The manufacture and use of nickel-cadmium alkaline batteries began to grow in the late 1950’s. During the period from 1966 to 1971, approximately 3 pct of the U.S. primary cadmium demand was consumed by battery manufacturers. From 1971 to 1975, the demand grew from 3 pct to 13 pct. It was estimated by the battery […]

Rock Splitting

Rock splitting utilizes a tensional force to crack the rock. This is achieved by inserting a split steel shank in a drillhole and driving a steel wedge between the center of the split shank thereby producing the tensile forces. The advantages of the rock splitting technique over blockholing are the absence of explosives and the […]