Batch Mill Grinding VS Continuous Grinding Compared

When the amount of ore in the mills was the same, no appreciable difference between batch and continuous open-circuit ball-mill grinding was found. This should be so, because the progression in particle size for the duration of a batch run would be expected to be the same as the progression from the feed to the […]

Chloride Leaching of Silver and Precipitation Recovery of Ag

As part of the U.S. Department of the Interior, Bureau of Mines, mission to assure a viable domestic minerals and materials economy, research is being conducted to investigate methods for recovering accessory elements from solutions resulting from hydrometallurgical processing of base-metal sulfide concentrates. These types of sulfide concentrates have traditionally been treated by smelting procedures […]

How to Determine Power Input in Laboratory Ball Mill

In the study of ball mill grinding at the International Experiment Station of the United States Bureau of Mines at Salt Lake City, Utah, it was desirable to measure the work input to a ball mill at the mill itself so that consideration of motor efficiency and transmission losses would be eliminated. The device adopted […]

Gold Hydrometallurgy – Refining to High Purity

We investigated chemical methods for producing high-purity gold from precious-metal-bearing zinc precipitates and steel wool cathodes. Precious-metal-bearing zinc precipitates and steel wool cathodes are unrefined products from conventional cyanidation and heap leaching-cyanidation operations. The zinc precipitates contained 14.40 pct Au and 0.35 pct Ag. The precious-metal-bearing steel wool cathodes contained 20.65 pct Au and 4.84 […]

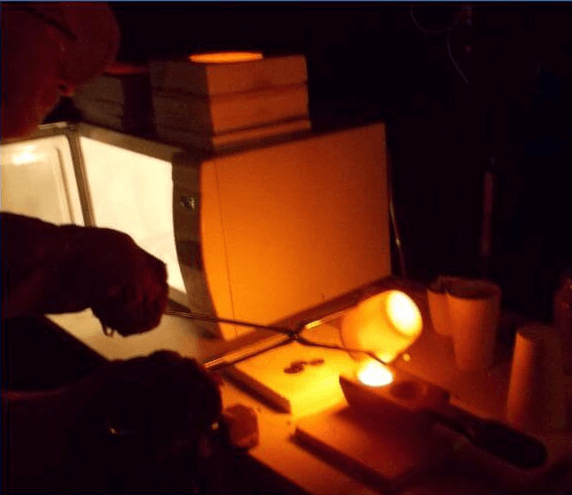

DIY Fire Assay Home Laboratory Microwave

I have always been amazed at the amount of knowledge the Alchemists in the Middle Ages possessed regarding chemistry, metallurgy and the precious metals. Yet they did not realise that the fleas of rats were transmitting the plague that killed literally millions of people in Europe during the 1300’s, nor that the earth was round. […]

Recovery of Rutile Titanium Dioxide

The increasing demand for titanium minerals, especially rutile, has sparked interest in the abundant domestic titanium resources of the United States. Although 93 percent of the rutile used in this country is imported, there are porphyry copper deposits in the Western United States that constitute a very large potential rutile resource. Rutile is used to […]

Ball Impact Spalling Wear Test

Many types of ore crushing and grinding equipment, such as hammer mills, rod mills, and ball mills, subject wear parts to repetitive impacts. The wear that results from fatigue, spalling, chipping, and fracturing can be more severe than abrasive wear. This is especially true of very hard alloys such as martensitic steels and alloyed white cast […]

High Speed Impact Gouging Test

A new and promising method for transporting raw materials from a mine is by pneumatic pipeline. This method uses a flow of air to transport solid particles of rock or ore through a pipeline. Lifting ore from underground to the surface pneumatically has great economic potential but is limited by severe wear problems. Pneumatic conveying […]

Pin-on-Drum Abrasive Wear Test

The pin-on-drum abrasive wear test involves high-stress, two-body abrasive wear. One end of a cylindrical pin specimen is moved over an abrasive paper, abrading material from the specimen and crushing the fixed abrasive grains. The wear is believed to simulate wear that occurs during crushing and grinding of ore-processes in which the abrasive particles are […]

Ball Mill Wear Test

When a lump of ore is crushed by the impact between two balls in a ball mill, it is considered high-stress, three-body abrasive wear. The abrasive wear of balls that results from the milling of ore is the major wear loss in most minerals processing plants. During the wet milling of ores, abrasive wear is […]