Ball Mill Grinding Theory – Crushing Motion/Action Inside

Testing Plant Equipment: In order to determine, among other things, the operating conditions of the ball-mill when working on this rock, a test mill of about 300 T. daily capacity was erected at Duluth, Minn. The fine-crushing plant contains a Hardinge 8-ft. by 22-in. (2.4-m. by 55.8-cm.) conical mill, a 6- by 27-ft. (1.8 by 8.2-m.) […]

SX EW Capital & Operating Cost of Solvent Extraction & Electrowinning

Solution mining followed by solvent extraction-electrowinning (SX-EW) is one possible way to economically extract copper from ore bodies which cannot otherwise be profitably exploited. Published costs for the unit processes of SX and EW are out of date especially in view of the newer reagents now available and the newer circuit configurations. This paper updates […]

Iron Ore Beneficiation Process

During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material. By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and […]

Antique Mining Equipment

The early mining of iron ore in Minnesota was carried on with the most primitive kind of tools. The pioneers used only such equipment as could be packed from Duluth through one hundred miles of forest to the first mines on the Vermilion Range and the operations were carried on with picks, shovels, hand drills […]

Types of Welding Process

The general object of the investigations has been to extend the use of welding in the construction of merchant ships and, specifically, to provide a definite basis for obtaining the best economy and efficiency in employing welding in place of riveting in the construction of the hulls of such ships. The extent of the field […]

Spectroscopic Determination of Lead in Copper

In a previous article preliminary experiments were described, indicating the possibilities of a quantitative spectroscopic method for the determination of small amounts of lead in copper, which would be accurate and rapid, and could be carried out in the refining plant by one not skilled in chemical analysis. The present paper deals with the development […]

Type of Melting Furnace

The following may be said to be essential characteristics of a furnace for determining the melting point of refractories: It should be capable of easily reaching a temperature of 1800° C., since most refractories melt below 1800° C.; for those materials melting over 1800° C., special procedure and technique are usually required. The atmosphere in […]

Melting Point of Refractory Materials

The object of this paper is to discuss the factors and conditions that affect the observed values of the melting points of refractory materials and to describe practical methods for the determination of these points. While it appeared to be necessary to discuss some of the general properties of silicates and refractories, these subjects have […]

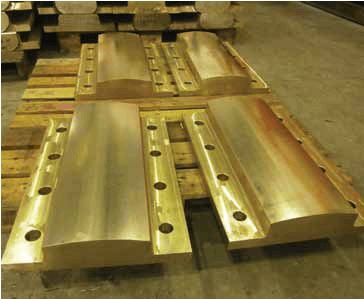

Manganese Bronze

Developments in engineering during the past decade, particularly as applied to marine construction, mining machinery and other purposes in which corrosion offers a serious problem, have created a large demand for a non-ferrous metal highly resistant to corrosion and at the same time useful in general construction work as a substitute for steel without materially […]

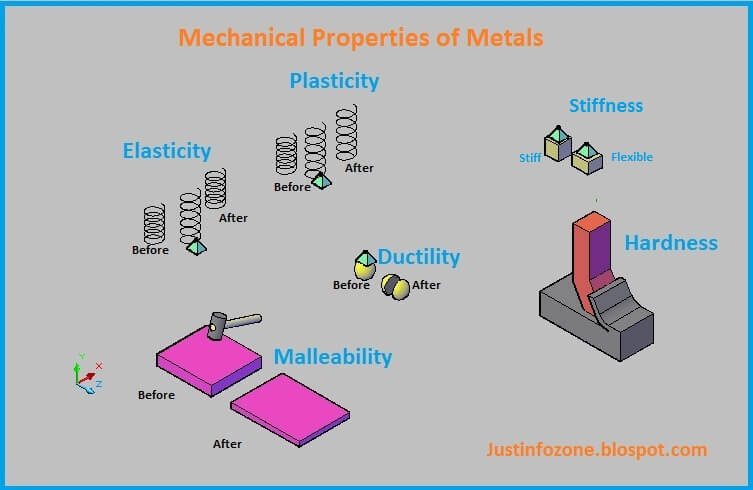

Mechanical Properties of Metals

In a recent discussion of Dr. Jeffries’ paper on tungsten, J. C. W. Humfrey, after taking exception to certain of the author’s ideas relative to the cohesion of A and C metal, expresses the opinion that future research is likely to develop a method of preparing tungsten possessing “mechanical properties in line with those of […]