Cost of Stoping for Underground Mining

Stoping cost is one of the largest of the items comprising the total cost of producing ore. The cost per ton of ore mined is important but may be overemphasized if the more important cost, that per unit of metal recovered, is thereby overlooked. A given stoping method may give a low cost per ton […]

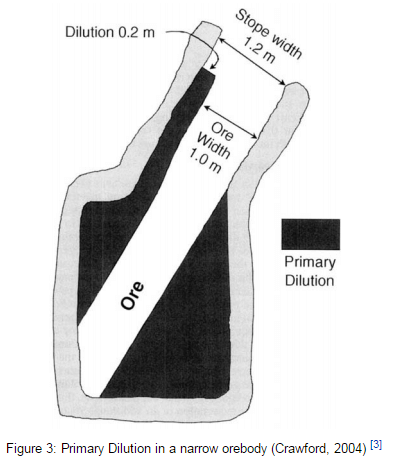

Ore Dilution & Recovery in Mining

Recovery and dilution usually are interrelated; with some methods of stoping a high recovery involves contamination of the ore from the walls or capping, and often clean ore can be obtained only by leaving some ore in the mine. In open-stope mines the greatest loss of ore is that tied up in pillars left for […]

Compare Stoping Methods of Mining

The foregoing descriptions and discussion of the different stoping methods and practices and the accompanying tabulated data indicate the conditions under which they may be applied and serve as a basis for comparing them. Stoping costs will be presented later. Direct comparisons of the different methods are difficult because these methods and variations thereof are […]

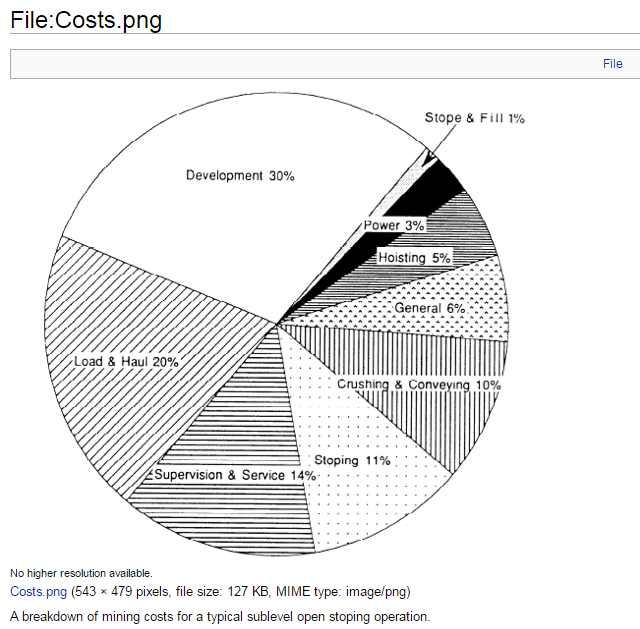

Costs of Mining Methods

To compare properly two different methods of mining, it is not wise to attempt to calculate the total cost of each, but rather to compare the costs of those operations that are differently executed in the two methods under consideration. When any method is in operation the proper way to reduce the total cost is […]

Backfilling Mining Stopes

Stope filling has been discussed by Jackson in an earlier paper. Filling long has been recognized as the most effective method of permanently supporting the walls of mine workings and minimizing movement and subsidence. It is used alone in cut-and-fill stoping and in conjunction with framed timbers in square-set stoping for support of weak walls […]

Drilling & Blasting of Underground Stopes

Drilling in stopes is done with pneumatic-feed stopers, light handheld hammer drills of the jackhammer type and heavier plugger machines, drifters of the Leyner type mounted on crossbars or on columns, and drifters (and, now, only occasionally, piston drills) mounted on tripods; more recently, with the more extensive use of bort instead of carbon for […]

Timbering Mining Stopes

Timbering in stopes ranges from occasional light props or stubs to temporarily support patches of unsafe ground to regular timbering with square sets and large bulkheads or “cribs” of solid timbers. Regular stull timbering has been mentioned. Figure 94 shows this type of timbering in a narrow, steep-dipping vein. Figure 116 shows regular stub timbering […]

Underground Stoping Practice & Methods

The general conditions to which each of the principal stoping methods is applicable have been stated briefly in the preceding pages. Variations of the principal methods, differences in methods of drilling and blasting, handling ore and waste in the stopes, transferring broken ore from the stopes to the haulageways, and filling and timbering operations, and […]

Determination Method of Gold & Silver in Cyanide Solution

Many assay methods for the determination of gold or silver, or both, in cyanide solutions have been published, which with care in manipulation, and modification in some cases, will give results that are satisfactory. It is possible to classify or group these methods as follows: Evaporating the solution in a porcelain or agate-ware dish containing […]

Melting Copper Cathode in Electric Furnace

The electric furnace has always been found to be especially adapted to melting, refining, and finishing processes throughout its gradual acceptance by metallurgists as a practical apparatus for conducting metallurgical operations. In the steel industry, the electric furnace is firmly established in the manufacture of steel of the highest grade, equal to crucible steel. For […]