Laboratory Flotation Cells

The 500, 1000, and 2000 gram Laboratory Flotation Cells have been proved by mining, chemical and government laboratories and schools all over the world, to produce reliable results which can be duplicated in actual milling installations because they incorporate all of the basic principles of the commercial size machines. The 50-gram unit is designed to complete this line of Batch Laboratory […]

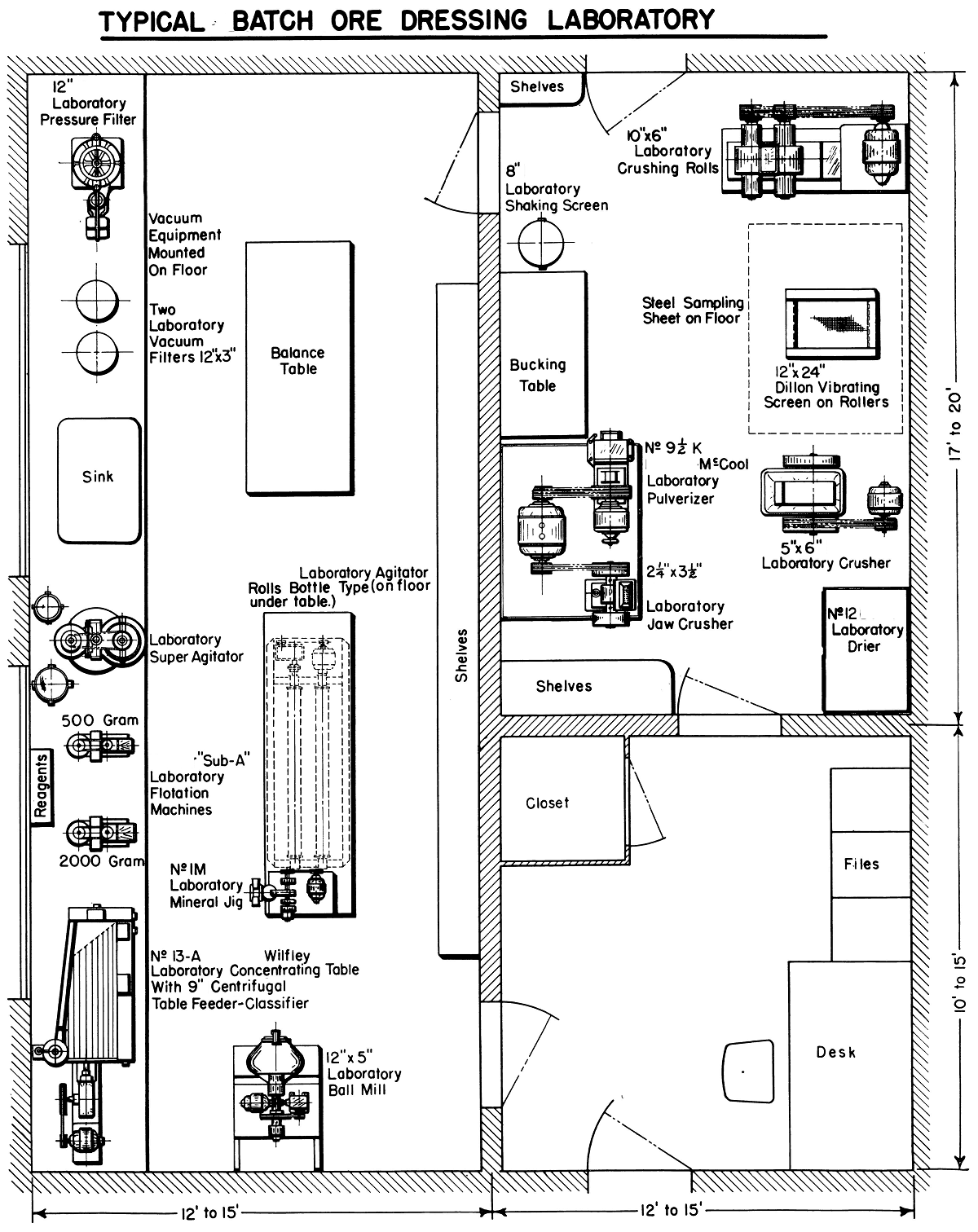

Metallurgical Laboratory Design

Size by Size Particle Size and Flotation Recovery

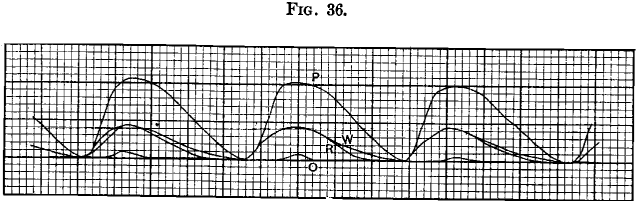

The unseen factors in flotation are those which affect the economic recovery and are not shown by the assays or analyses. The fact that equal tailings and equal grade of concentrates can be produced with widely varying physical properties of the products recovered and rejected is unrecognised in most cases. In the past, when studying […]

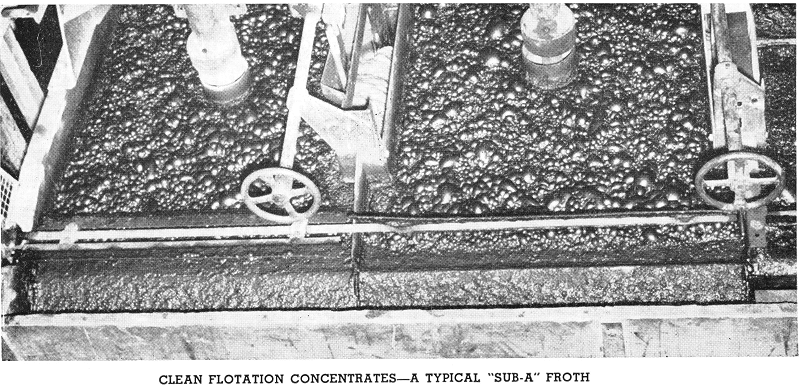

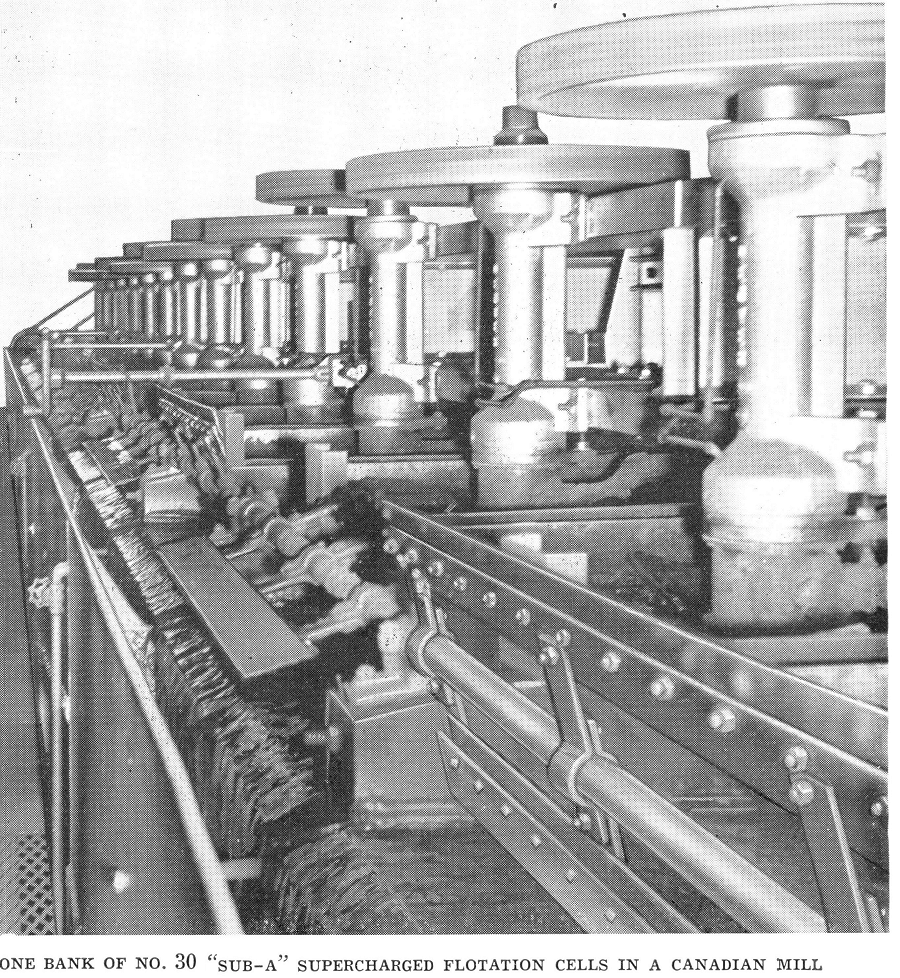

Froth Flotation Machines

There are certain variable factors which affect the Fundamental efficiency of a Flotation Machine. These factors, having different degrees of importance, are as follows: Type of Froth Flotation Machine Mesh analysis of the pulp Density of the pulp Reagents and pH Pulp temperature Conditioning Circulating load Contact period Aeration Of these factors influencing the flotation process, each […]

Froth Flotation Principles

The Froth Flotation Machine is universally used for all types of flotation problems. This machine finds a wide acceptance due to its flexibility in construction, which allows the machine to be adjusted to handle pulps with divergent physical characteristics, as well as the common and intricate metallurgical problems which confront the present day operator. The Froth […]

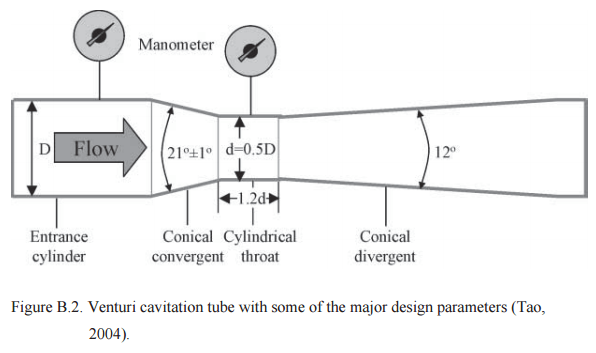

Venturi Cavitation Tube

Three types of convergent sections exist in classical Venturi tubes, i.e., machined, roughcast and rough-welded. Each type specifies a set of ranges for the entrance diameter (D), the diameter (Beta) ratio (β=d/D) and the Reynolds Number (ReD). The Venturi design in this study was specified to have a smooth (machined) internal surface in the convergent section, which is especially […]

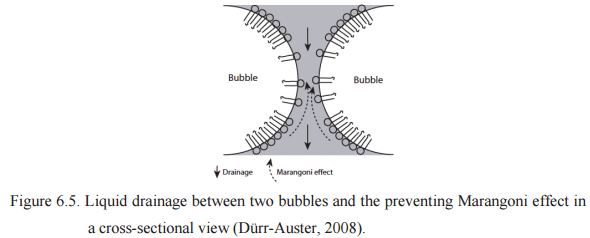

Marangoni Effect

Gibbs surface elasticity, which is commonly referred to as the Marangoni effect, is the surface tension gradient along the air-liquid interface that acts to preserve the film thickness and to prevent bubble coalescence as shown here.

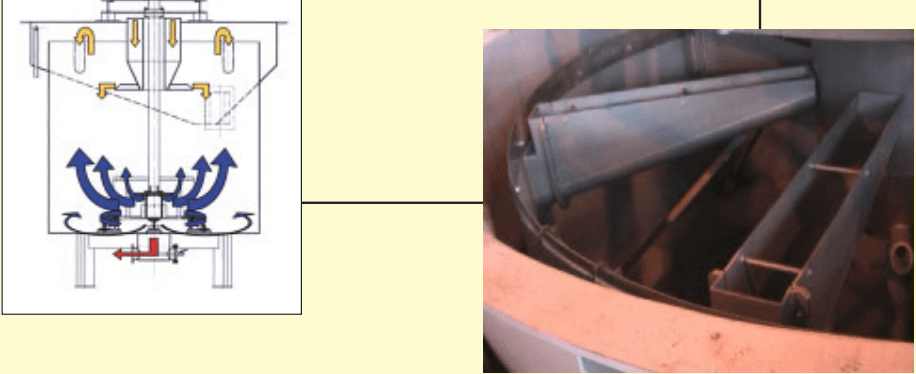

Internal Flotation Launders

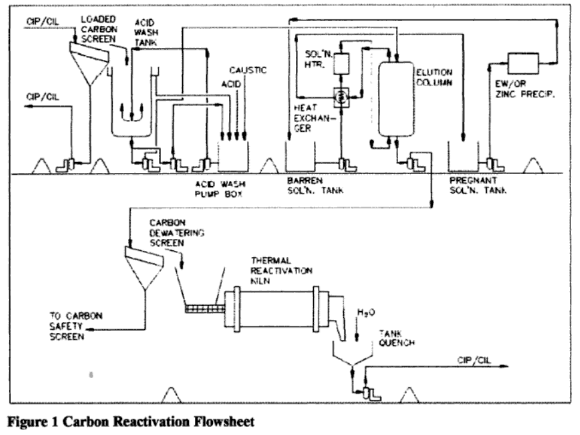

Washing Activated Carbon

In the process of washing activated carbon, a dilute hydrochloric acid solution (3%) is circulated/pumped into the elution column. The acid dissolves inorganic foulants such as calcium carbonate, magnesium and sodium salts, fine ore Minerals such as silica, and fine iron particles. The carbon acid wash cycle takes about 4.30 hours. Acid washing may also help […]

SAG Mill Reline

https://www.youtube.com/watch?v=9JEko22980I