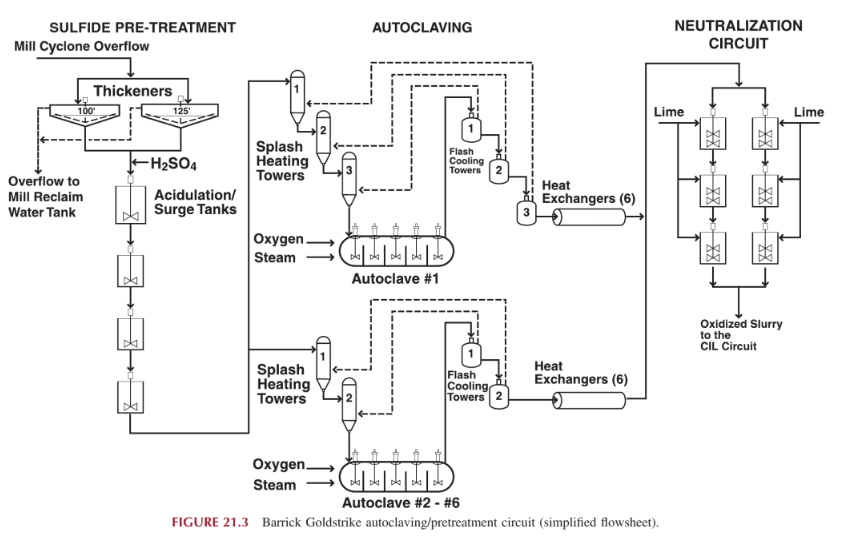

Autoclave Circuit & Gold

Slurry from the grinding circuit, at approximately 35% solids and 80—85% passing 135 mm is pumped to three thickeners. Thickener underflow, at approximately 54% w/w solids, is pumped to a train of four acidulation tanks. Sulfuric acid is added to the slurry to destroy sufficient carbonate prior to entering the autoclave circuit. Process air is […]

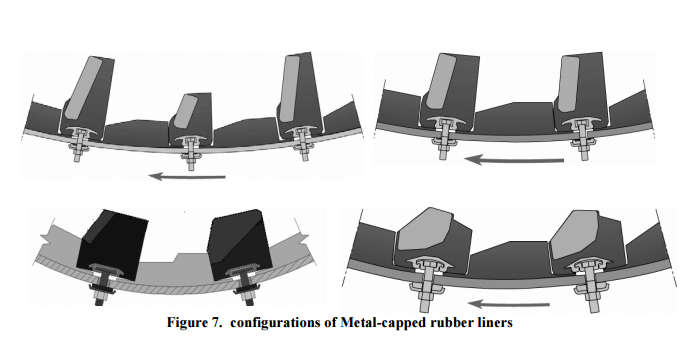

SAG Mill Liner Design

To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance. In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be considered. Each of these topics has had a considerable amount of research, […]

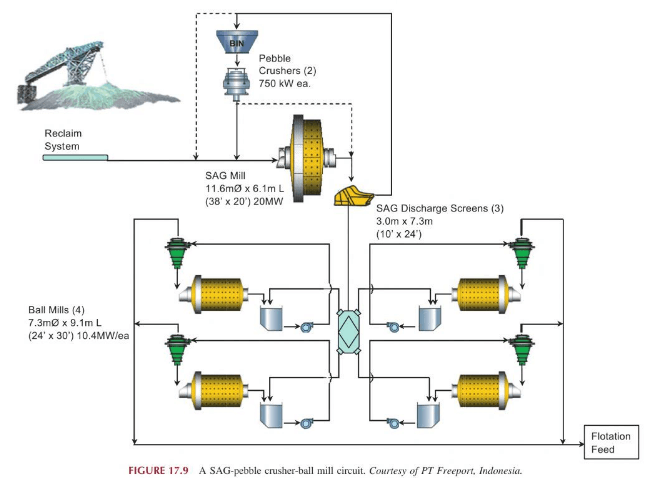

SAG Mill Grinding Circuit Design

AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations. SAG circuits are common in the industry based on: High single-line capacities (leading to capital efficiency) The ability to mill a broad range of ore types in various […]

High Clay Tailings Filtration

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

How to Improve Flotation Results

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

Froth Crowding to improve Carrying Capacity

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

How to Best do Maintenance on Flotation Cells

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

Flotation Circuit Recovery Optimization

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

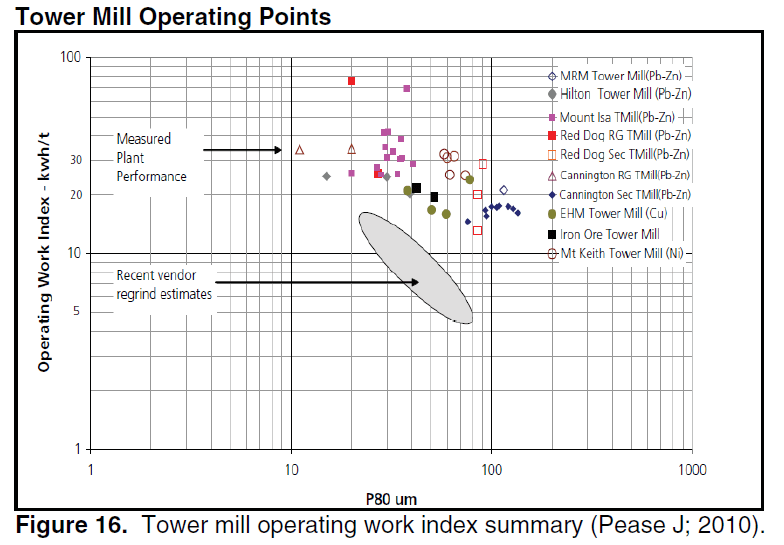

Tower Mill Operating Work Index

The principal method of grinding in a Tower mill is attrition (scrubbing of particles off material being ground), with the possibility of some shearing and compression breakage taking place due to the motion of the media charge created by the rotation of the helical screw enhancing the media pressure. The Tower mill is filled to […]

Sodium Thiosulphate Gold Leaching

The gold industry has been seeking alternative reagents for leaching gold from low-grade ores for the past 25 years. The cost and transport of cyanide, the poor recovery of gold from carbonaceous ores, the lack of selectivity of cyanide towards copper minerals and the cost of waste treatment are real factors which can make cyanide […]