Potash Flotation Process

Potash occurs in soft deposits generally associated with sodium chloride and varying amounts of clay slime, which because of its colloidal character, complicates the beneficiation process. Potash ores generally contain 20 to 40 percent KCL with the balance being NaCl and a small amount of clay slime, the latter usually in the order of 1 […]

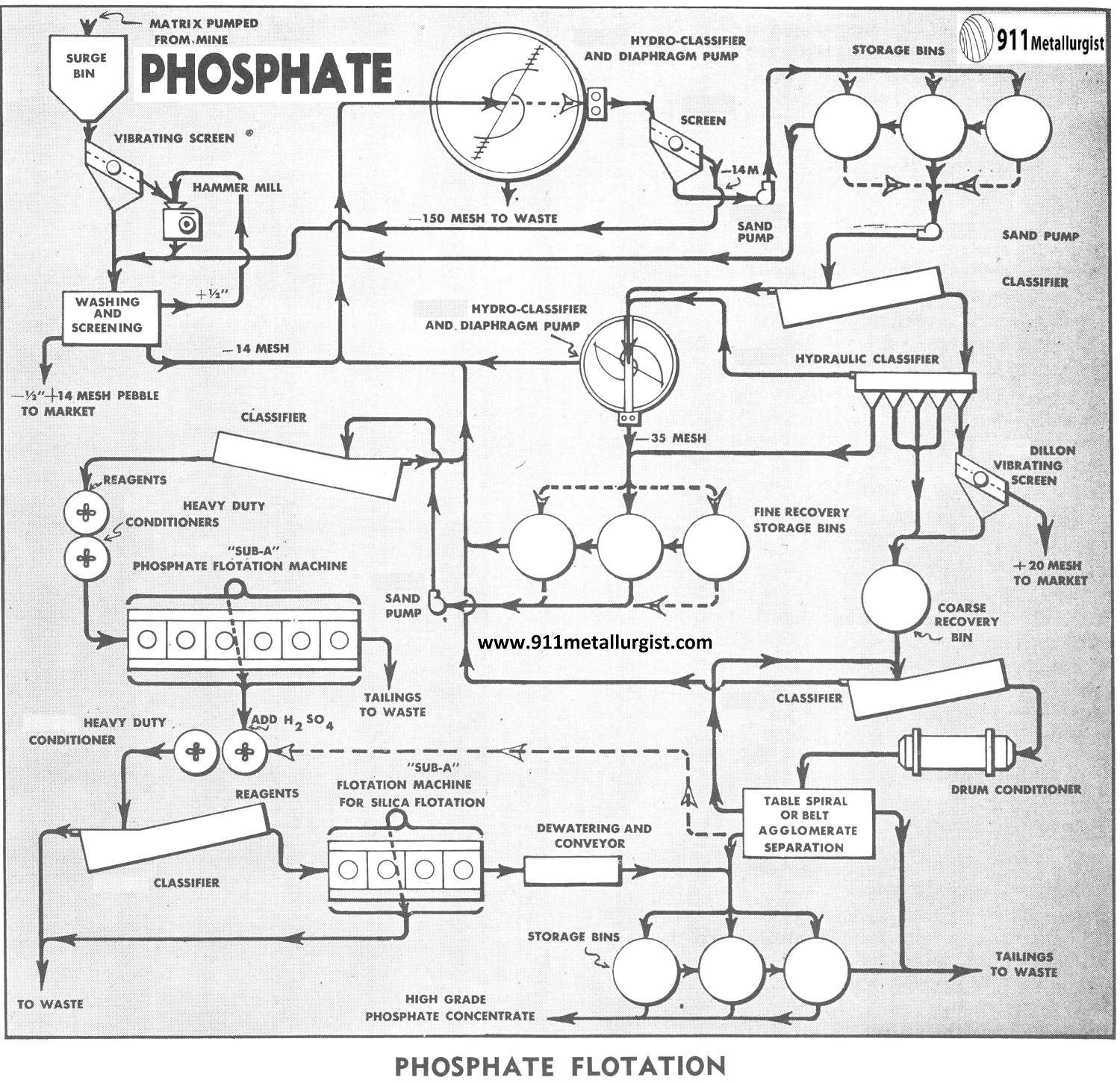

Phosphate Beneficiation Process

Large scale mining and processing of phosphate is essential for operating at a profit. In the Florida area, Phosphate Beneficiation by flotation unlocked the door to vast tonnages of ore which in the past could not be recovered by conventional washing methods which saved only the coarser pebble phosphate. Many of the areas now being […]

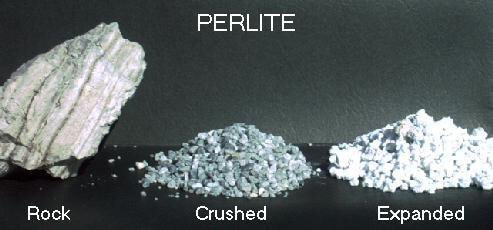

Perlite Beneficiation Process

Perlite, as required for the light weight aggregate industry, must be closely graded and the amount of minus 100 and minus 200 mesh perlite must be closely controlled. Perlite, being very brittle and friable, demands precautions throughout the flowsheet to eliminate excessive fines. Perlite Process Flowsheet The flowsheet illustrated is applicable for various tonnages from […]

Extraction Process of Pegmatite Minerals

Strategic Minerals, such as uraninite, garnet, monazite, zircon, cassiterite, columbite, magnetite, are often found closely associated with pegmatic orebodies. Concentration of these minerals is frequently complicated by hardness of the ore, presence of the clayey materials, and the fact that mineral sizes range from micron dimensions up, and have varying degrees of magnetic and electro […]

Nonmetallic Minerals Process Method

The following paper deals with the problems that have arisen in the application of the flotation process to the beneficiation of non-metallic ores by flotation. The most important of these ores are listed and the commercial specifications of the desired products are given. The problems caused by the complexity of many of the raw ore […]

Telsmith Cone Crusher Parts

Molybdenum Ore Processing by Flotation

This molybdenum flotation circuit, based on 250-500 tons per 24 hours is designed for low-grade molybdenum ore having high-grade streaks and with pyrite-quartz gangue. It is also basically sound for many other friable sulphide ores, such as antimony, silver and even some lead ores. The basic ideas stressed in this moly flotation flowsheet are the importance […]

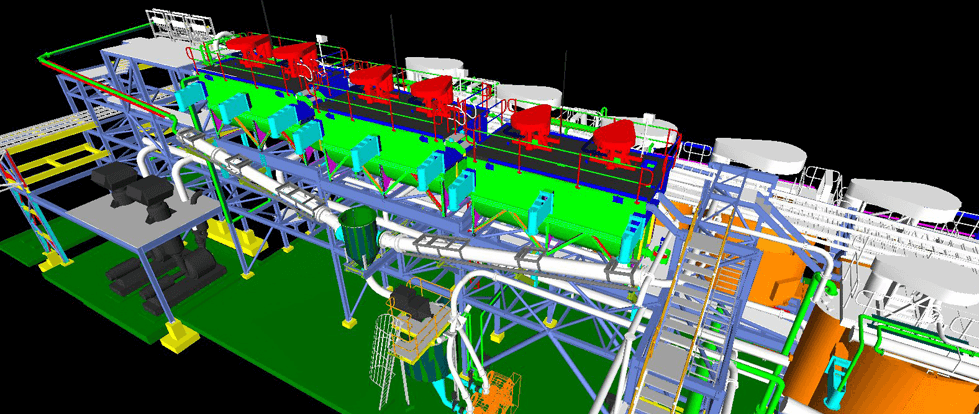

Design Flotation Plant

Design Study for 400-Ton per Day Flotation Plant The sulphur mill was designed for best adaptation to the mill site available. The design provided for simplicity of construction and final operation, and full usage of construction items available. Process FLOWSHEET The flowsheet was based on laboratory tests wherein troublesome factors were eliminated ahead of design and construction. The […]

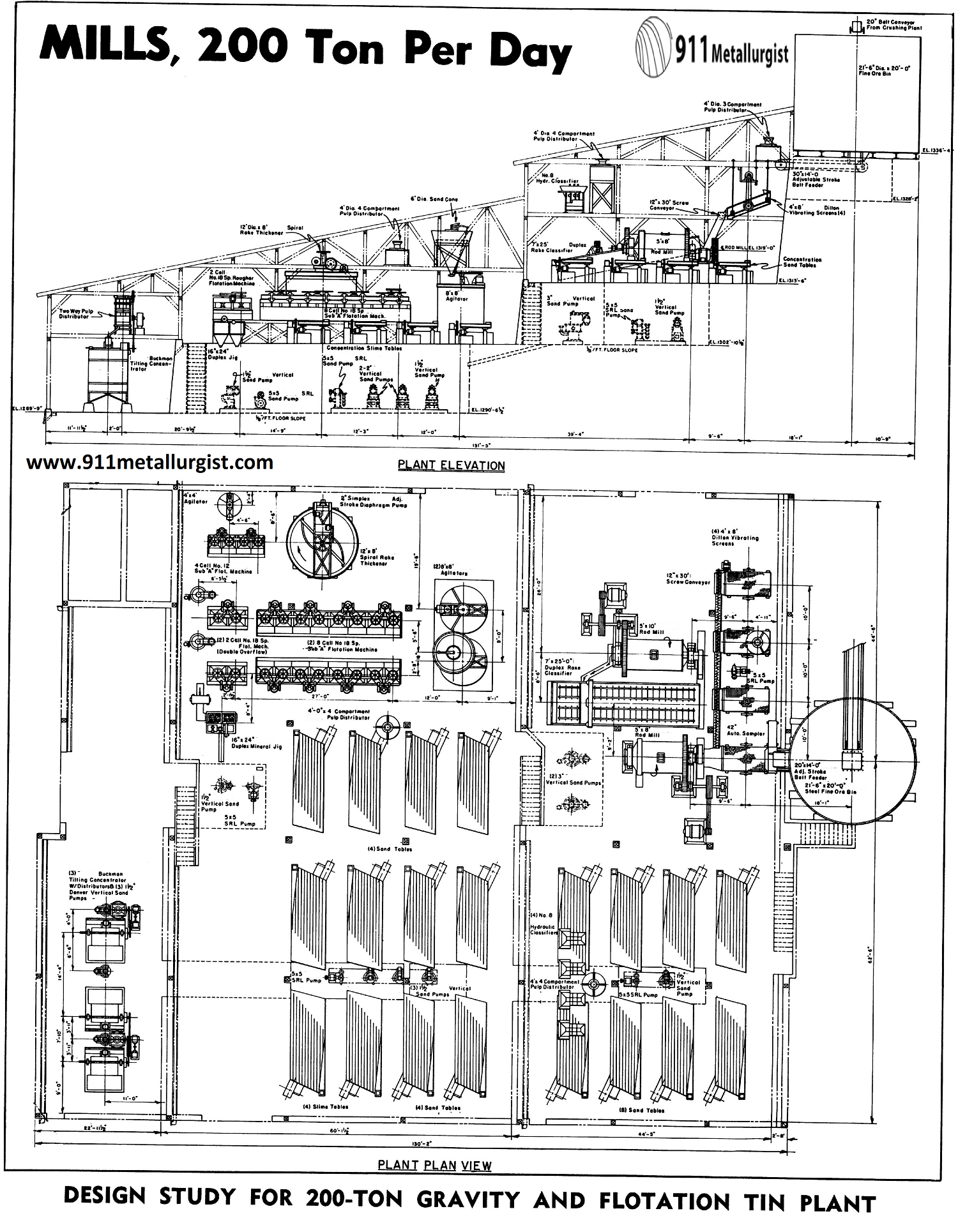

Tin Beneficiation Process

The scarcity of both skilled construction and operating labor in the region, caused the customer to under-score the terms “fool-proof” and “simplicity” in the instructions for the design of this 200 ton tin Beneficiation process plant. Flowsheet The tin process flowsheet was developed by laboratory tests which clearly indicated the method of treatment to give […]

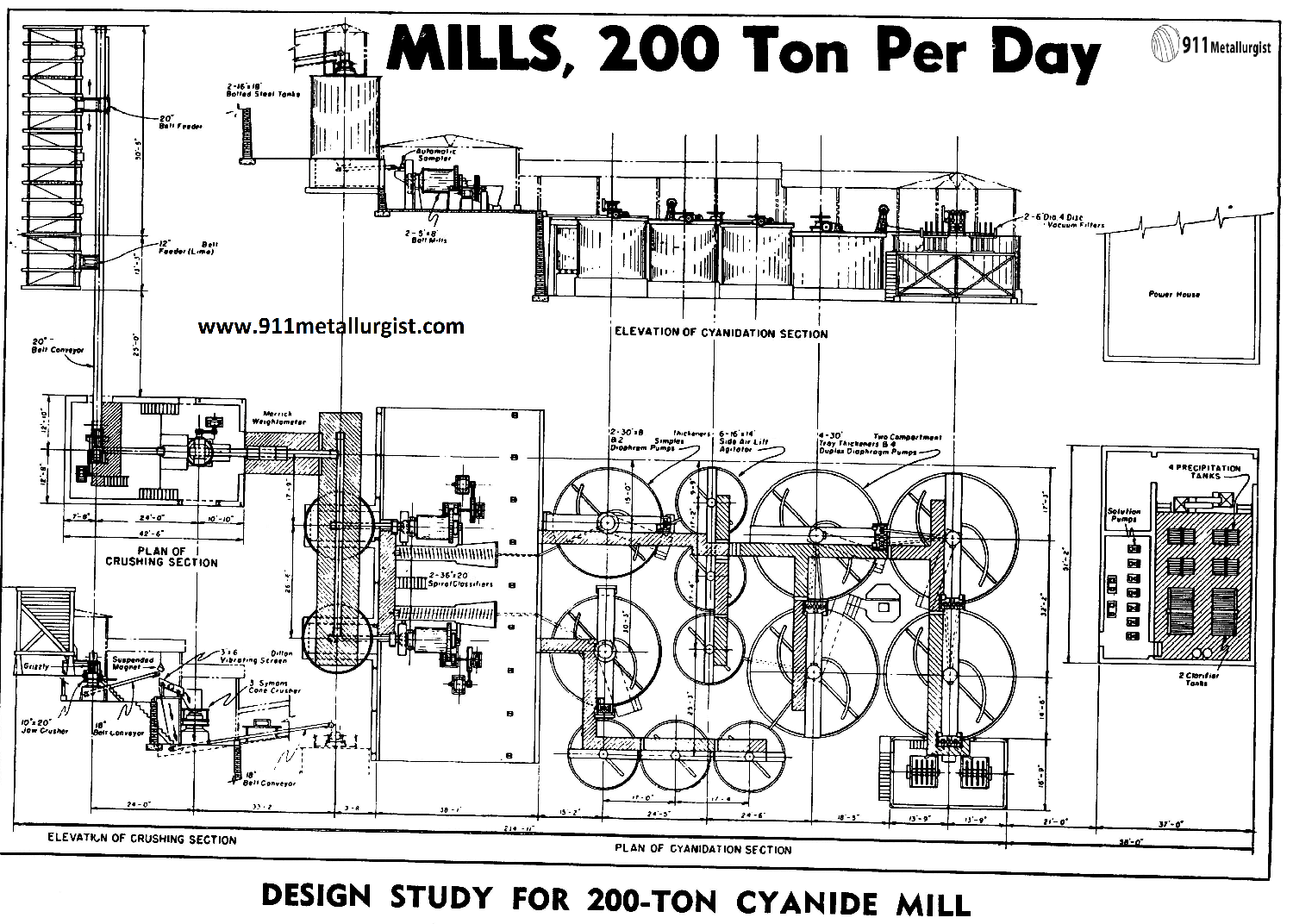

Small Gold Leaching Circuit Design

The gold cyanide leaching mill site is centrally located with respect to the mine, water supply and improved highway. This selection reduced both the length of the haulage road from mine to mill and main water supply line to a minimum. The location provided a sloping mill site, adequate tailings disposal area, housing space for […]