How to Make Boron by Electrolysis

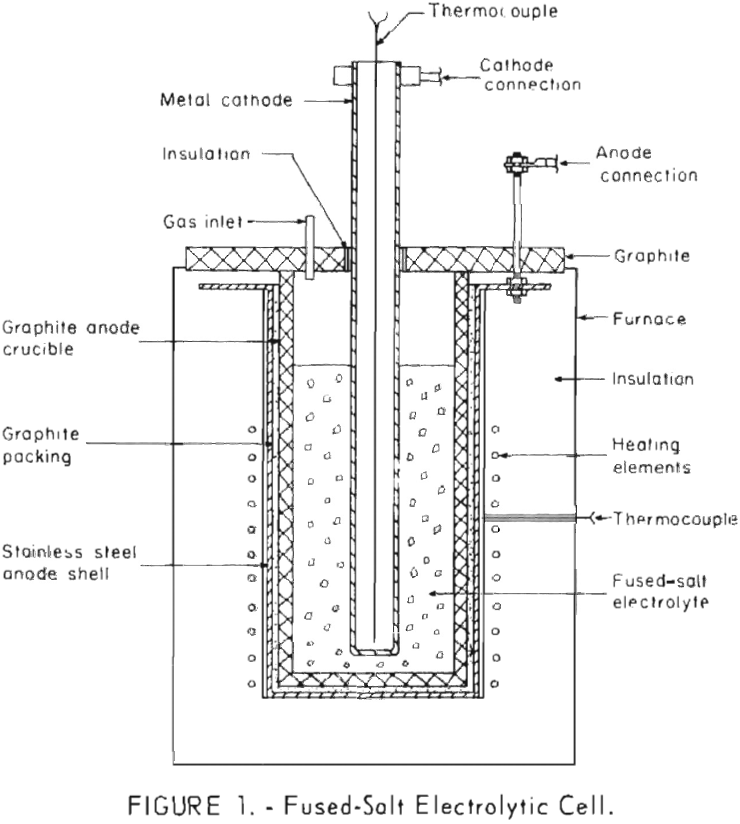

Because an economic method for preparing pure boron has not been developed, a program was started by the Bureau of Mines to evaluate existing techniques or to develop new methods for preparing the pure element. This report describes investigations directed toward the development of techniques for the preparation of pure boron by fused-salt electrolysis. Only […]

Smelting Taconite in Blast Furnace

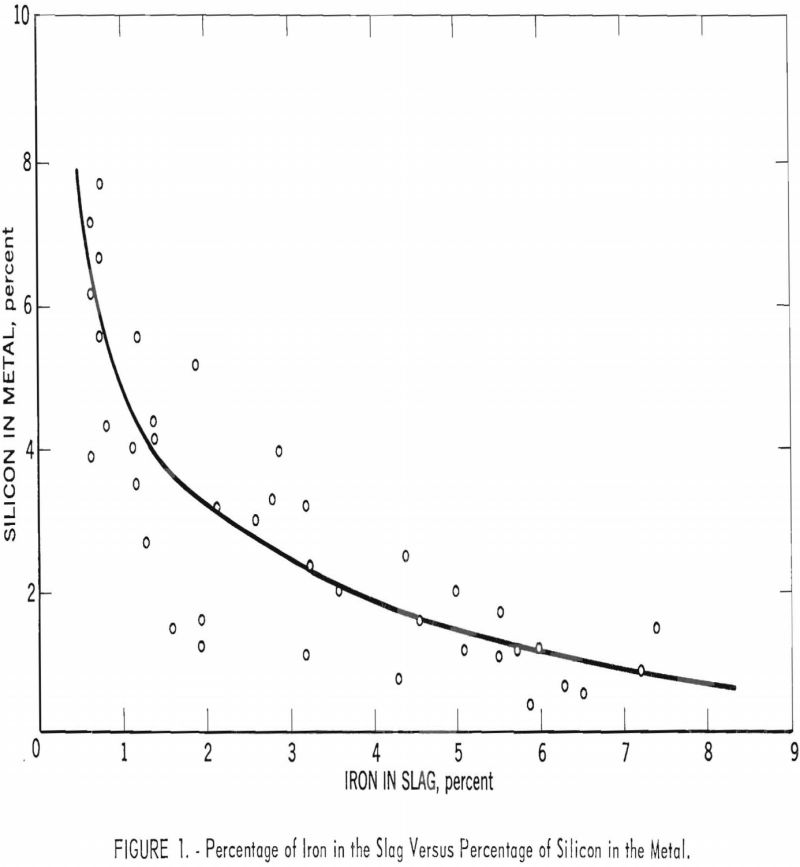

Crude Minnesota taconite was charged in the Bureau of Mines experimental blast furnace so that smelting characteristics of such highly siliceous raw materials could be studied and smelting costs compared with those of a standard Mesabi ore. The Bureau recognized that the highly siliceous nature of the crude ore and its relatively low metallic content […]

How Susceptible are Organic Compounds to Tritium Exchange Labeling

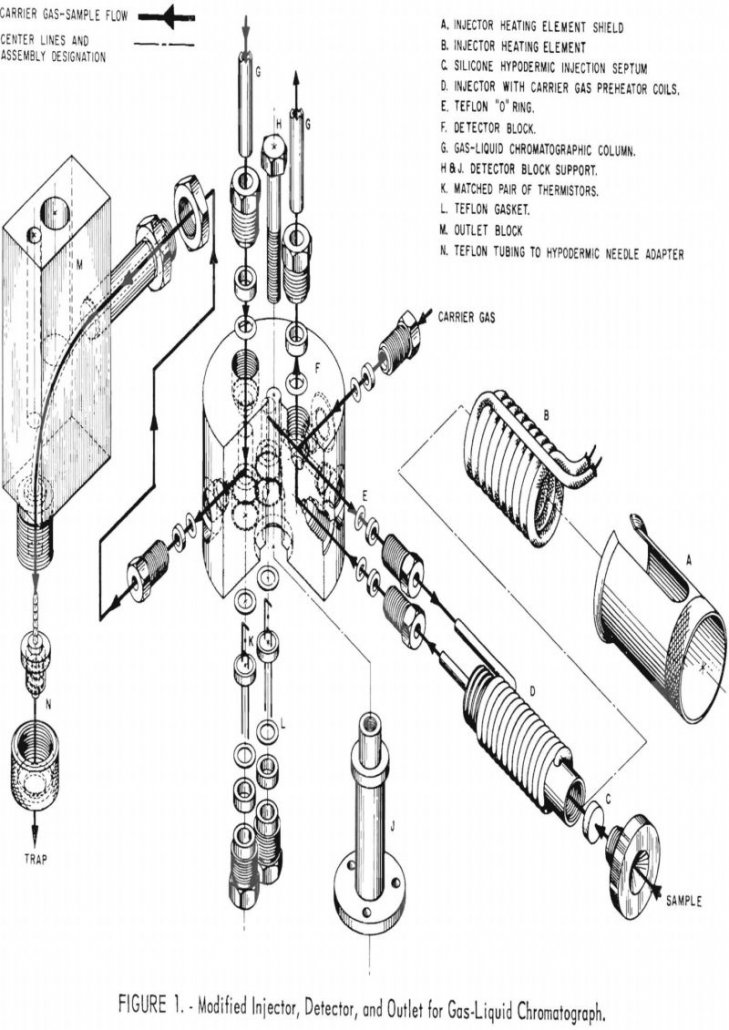

This report describes the preparation of tritium-labeled organic compounds to be used by the Federal Bureau of Mines in studying the role of certain gasoline constituents in gum-forming mechanisms. The gasoline constituents that have been investigated boil within a range of approximately 90 to 230° C. and can be classified as paraffins, naphthenes, olefins, diolefins, […]

Spectrophotometry Determination of Copper in Tungsten Metal Powder

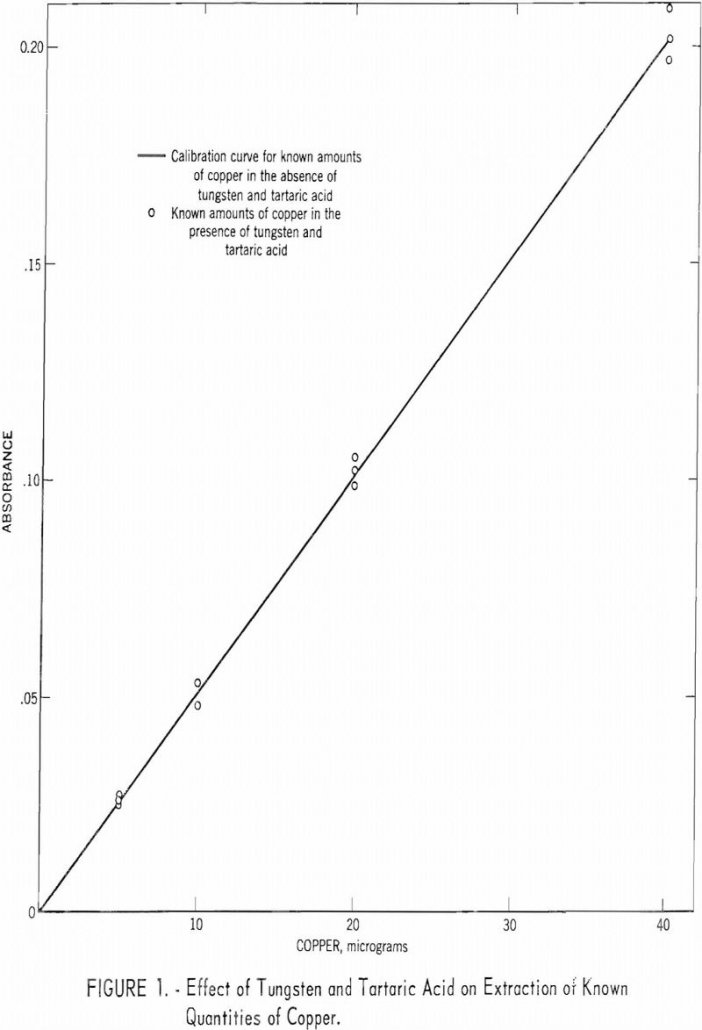

A spectrophotometry method for the determination of small amounts of copper in tungsten metal powder using the principle of solvent extraction has been developed. The metallic sample is dissolved in hydrogen peroxide, tartaric acid added, the pH adjusted, and the excess peroxide destroyed by boiling. Copper is reduced to the cuprous state, and the reagent […]

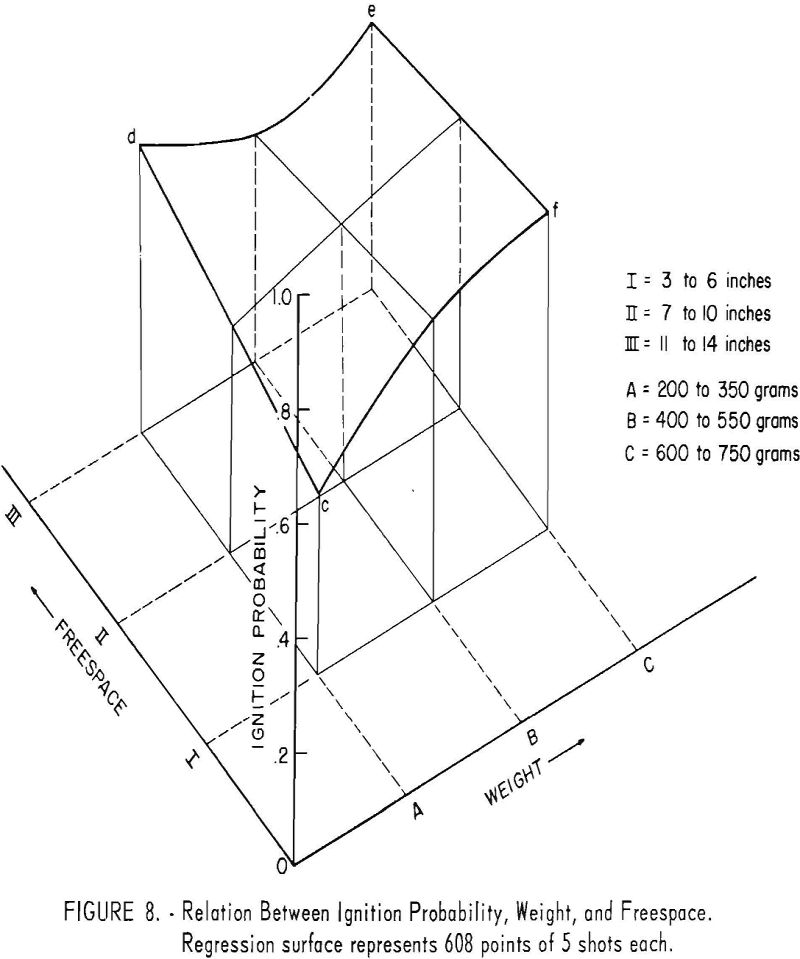

Variables Affecting the Probability of Ignition by Explosives

The principal official test performed by the Bureau of Mines to determine the permissibility of coal-mine explosives, commonly referred to as the gallery test, has been in use at the Bruceton station for many years. In this test the explosive under study is loaded into the borehole of a steel cannon and fired into a […]

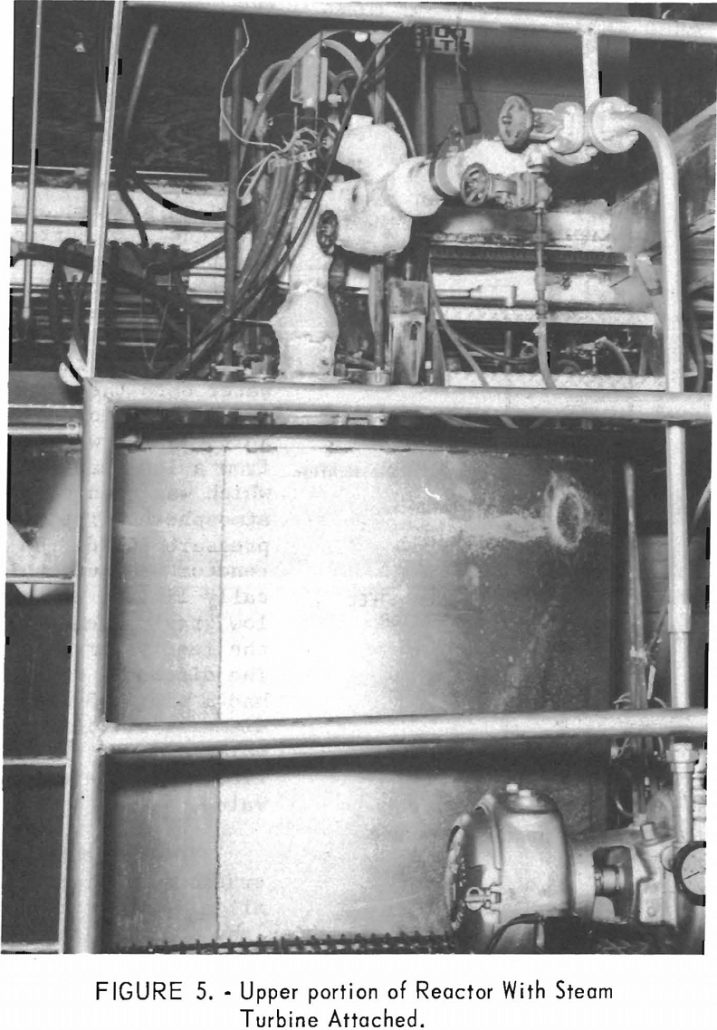

How to Recover Thermal Energy from Molten Salts

One objective of Project Gnome is to study the feasibility of a phase of the Plowshare program recovering thermal energy from an underground nuclear explosion. The test will be conducted in an underground salt deposit. It is anticipated that some of the energy thus released will be stored as thermal energy in molten salt. This […]

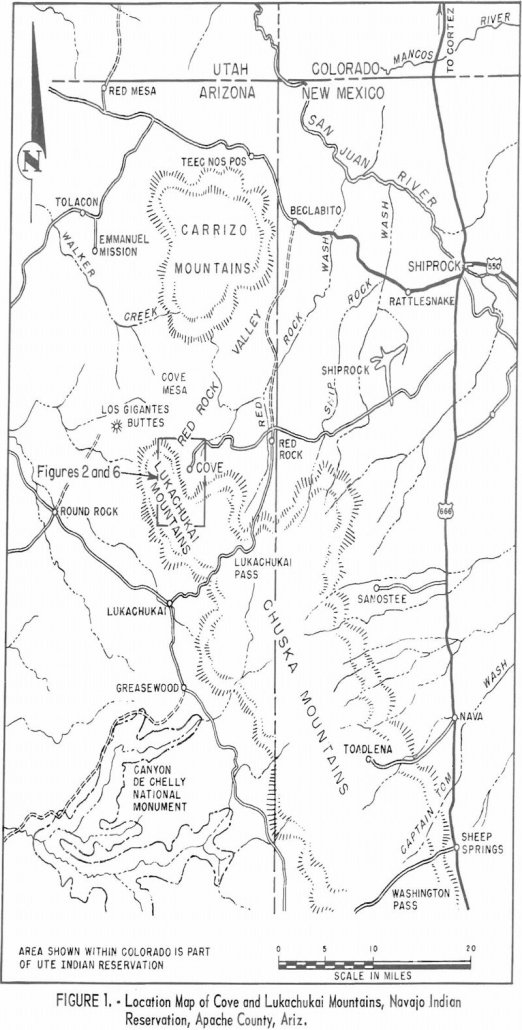

Uranium Mining

This report is one of a series published by the Federal Bureau of Mines to describe methods and costs of mining uranium on the Colorado Plateau. The Navajo Uranium Division of Kerr-McGee Oil Industries, Inc., mines uranium from several deposits of carnotite-type ores, which lie buried in the Lukachukai Mountains on the Navajo Indian Reservation, […]

Bacterial Copper Leaching

Among several suggested new processes for treating marginal ores in the United States, none is more intriguing than the possibility of extracting metals from low-grade materials by the action of microorganisms. One phase of a Federal Bureau of Mines investigation toward developing such a procedure was to isolate and identify specific chemosynthetic iron- and sulfur-oxidizing […]

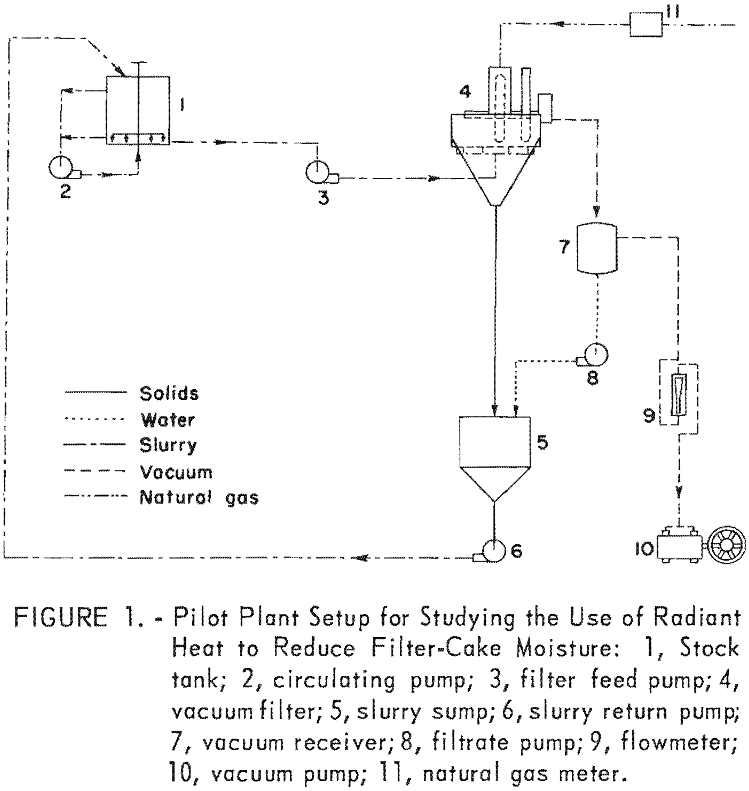

Dry Filter Cake using Radiant Heat – Reduce Moisture

This report stems from a study by the Bureau of Mines of the possibility of reducing coal filter-cake moisture by applying radiant heat directly to the filter cake while under vacuum during the drying phase of the filter cycle. One disk of a 4-foot-diameter vacuum filter was equipped with gas-fired radiant-heat generators and the effect […]

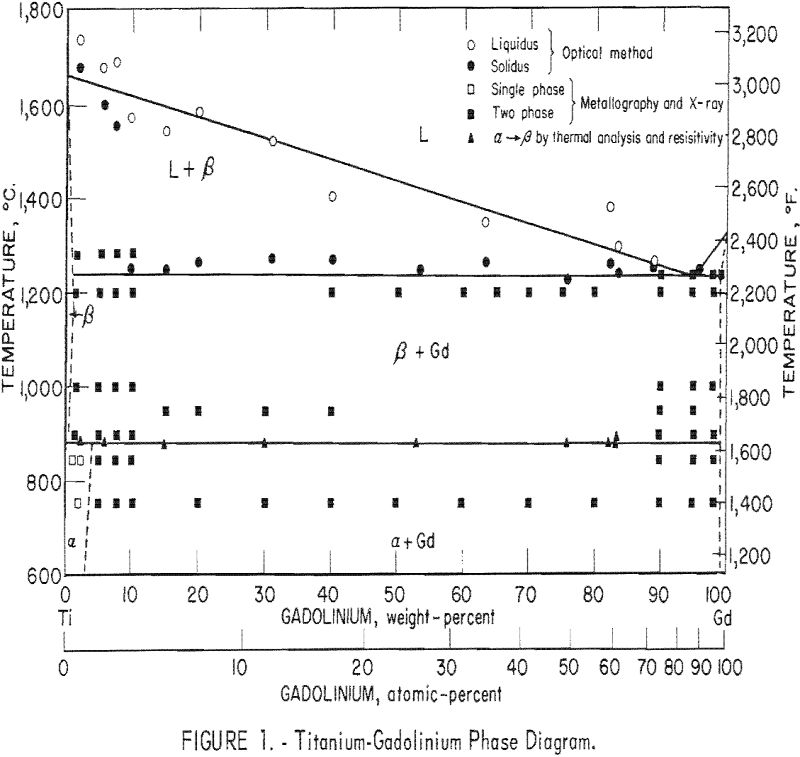

Titanium Gadolinium Phase Diagram

The results of this investigation indicate that the titanium-gadolinium phase diagram is composed of a single eutectic reaction and a peritectoid reaction at the alpha-beta transformation. The eutectic isotherm has been established at 1,240 ± 10° C. and extends from approximately 1 pct. gadolinium to beyond 99 pct. gadolinium at this temperature. The solid solubility […]